Name and terminology in relation to optical sensors

As the name implies, these sensors use optics, which means light radiation of various ranges. That is, a sensor that responds to light. And, of course, some kind of signal indicates that light has been detected. In English terminology, optical sensors are often called PhotoCell Sensor , or Light Sensor , which means photosensor, or light sensor.

In our country, too, in addition to the common “ optical ” one, the same devices are called photosensors , or photoelectric sensors .

The simplest and most common version of such a sensor is a light sensor, which discretely reacts to the level of illumination and issues a signal to turn on the lighting at dusk (main application)

A great variety of photo sensors have been invented, and in my article I will try to popularize and classify this variety.

Operation of optical sensors

Activation. This is the keyword that should be used when describing the operation of any sensors. In our case, activation (or deactivation, but more on that later) occurs when the light entering the sensor input has sufficient intensity.

The operating logic is such that when light enters the sensor unimpeded, it will be activated. And when this light is interrupted by a barrier (a person, a workpiece, a machine part), the sensor is deactivated.

Attention! Don't be confused! Active does not mean at all that its contacts are closed and there is voltage at the output! The operation of the light detection circuit and the output switch may vary! It is possible that the light is interrupted, and this serves as a signal of activity. It all depends on the specific application.

Optical sensors (as well as inductive proximity sensors) are non-contact, that is, there is no mechanical contact with the observed object (activator). Unlike (for example) limit switches and pressure sensors.

In most cases, to increase noise immunity, light is used not from the usual spectrum, but from a laser light source (usually red). Such a source is easy to manufacture; the radiation is easily focused into a thin beam. And due to the fact that the radiation is in the visible part of the range, the position of the sensor is easy to adjust in space.

And here is one of the rare sensors with an ordinary incandescent light bulb, which I found during his lifetime. The emitter is a 6 V incandescent light bulb with a lens. The receiving element is a photodiode. Next is an amplifier and a Schmitt trigger on transistors.

Optical sensor with incandescent bulb and lens. A spot of light is visible below

This sensor is from a 1980 production line purchased with petrodollars from Switzerland.

Modern sensors respond only to “their” part of the spectrum, which allows them to operate accurately in conditions of interference and poor visibility.

Interference may be sunlight or artificial lighting, dust, smoke.

In case of poor care, ordinary dust and dirt can become a hindrance:

Dirty optical sensor, sensitivity adjustment knob on the side, emitting part looking down

On optical sensors, in most cases there is a “Dark On / Light On” switch. What does it mean? It inverts the logic of operation. With “Dark On,” the sensor is activated when no light reaches its input, that is, there is darkness at the input. When light hits, the sensor is deactivated, that is, its output returns to normal. In “Light On” mode, the sensor is activated when its input is illuminated.

There are models where there is a timer - the output signal appears some time after activation (triggering).

Since the sensor contains a threshold element, it needs to be triggered clearly. In this case, the property of hysteresis is used, which reduces bounce (frequent changes in the signal in the “unsteady” zone). To facilitate setup, manufacturers now install in the sensor housing not only an activation indicator, but also an indicator of a stable signal level. If it is lit, it indicates that detection is stable, with sufficient signal strength, and not at the edge of the sensitivity range.

Types of optical sensor

In modern conditions, optical sensors perform a fairly wide range of tasks in an industrial enterprise. To purchase the necessary equipment, you need to know in advance about all types of equipment and the conditions in which the device will be installed.

Depending on the principle of operation of the equipment, experts distinguish 3 types of devices:

- Barrier.

- Diffuse.

- Reflex.

Each type has its own characteristics, which you need to learn more about in order to choose the right option.

Barrier type optical sensor

The official name of this species is barrier. But this definition is rather strange, since in order to activate all the sensors, some barrier must pass through the beam.

The operating principle is based on a direct beam and two separate parts (receiver and emitter), which should be located as coaxially as possible opposite each other. This is the only way the beam will accurately hit the receiver. When an object appears between parts of the equipment, the sensor will signal this.

As soon as the beam comes into contact with the object, the switch is activated. A distinctive feature of the device is that it can operate at a distance of tens of meters between the receiver and transmitter. Experts assure that this type of equipment has good noise immunity, and therefore drops of liquid or dust will not interfere with the work.

Of course, the barrier device also has disadvantages:

- To connect equipment at a considerable distance from each other, you will have to perform a rather labor-intensive process with connecting the power wires.

- The installation process is greatly complicated, since a mandatory condition is complete alignment of the two parts of the barrier sensor.

- If a highly reflective object comes into the range of the device, this will cause false operation of the equipment.

- If the barrier has a transparent structure, then it will not weaken the beam, and therefore the sensor will not work. This must be taken into account during installation.

To eliminate the last two shortcomings, it is necessary to adjust the sensitivity control. Of course, to detect an object in the coverage area, it should not be smaller than the diameter of the beam.

Experts believe that the barrier type is the most reliable type of device. This is due to the possibility of using the device over long distances, as well as noise immunity. In other devices, the receiver and transmitter are located in the same housing, which does not allow them to be used over long distances.

A device with a separate transmitter and receiver allows you to install equipment at a distance of 10 meters from each other. In this case, the transmitter will stand in one place where power is supplied to it. It produces only the radiation function, and all other tasks are taken away from it. In this case, the equipment does not need to be configured.

The receiver is installed at a certain distance - this is where sensitivity adjustments are made, as well as other parameters are configured.

An important nuance: the receiver and emitter must be from the same set. The fact is that parts produced by different companies do not fit together and will not work.

It is the barrier type of device that is most common in security systems and is practically not used in enterprises, since there is no need for the distance that communication devices can support.

Diffuse view

The operating principle of the device is mirror image. In this case, the transmitter and receiver are placed in one housing. The emitter throws a stream of light onto a specific object, the beam falls on its surface and goes in different directions, depending on the characteristics of the optical system. The beam partially returns back to the receiver, thereby turning on the device.

The problem with a diffuse sensor is reflective objects that do not fall into the working area of the installation. To eliminate interference, it is necessary to use switches with background suppression.

The range is the shortest of all optical devices, it is only half a meter. This is compensated for by an important feature - if the equipment is configured correctly, it detects the appearance of an object in the work area. As you approach, the sensor will work as a threshold element.

Settings Features

To select the appropriate distance from which the sensor will begin to operate when an object approaches, you need to take a simple sheet of paper and check the activation conditions.

Adjustment options:

- Sheet size 10 by 10 cm - distance up to 40 cm.

- Size 20 by 20 cm - over 40 cm.

A similar operation is also carried out with a sheet of hot-rolled steel - the choice of method depends on the enterprise where the sensor is installed. For more precise settings, use a special table that shows the reflective properties of materials. Based on the data obtained, a correction factor is added.

Example: The sensor value is 100 mm, but it needs to be installed on a stainless steel object. In this situation, the correction factor will be 7.5. And the correct response distance will increase by 7.5 times - 750 mm.

Reflex type

The equipment turns on when the beam is reflected from the reflector - hence the name of the device. Afterwards, the beam passes to the receiver and the sensor is triggered. As soon as the object leaves the work area, the equipment will turn on again.

The maximum operating length of the device is 10 m. In theory, the equipment can operate at a greater distance, but stability is much more difficult to ensure - the sensor will stop working at the slightest displacement of the beam due to vibration or dust.

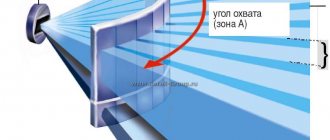

The equipment can be used for translucent objects. The receiver and transmitter are located in a single housing. The sensor is often used for installation on a conveyor belt so that the device works in a single system with other equipment - the product arrives at its intended place (the sensor signals this), and moves further (the reflector gives another signal).

Specific optical sensors

Three types of standard optical sensors were considered, but more specific options can also be found on sale, for example, a light grid. These are two plates located at a certain distance from each other.

There are photodiodes installed on one side and LEDs on the back plate. Using the overlap of this pair, it is possible, with a certain error, to calculate the geometric data of an object - width or height. The grid is connected to a controller, which transmits data to a central computer.

Light barrier

This is another type of specific sensor that is installed for the security of a specific facility in order to prevent people from entering the premises. The system is quite complicated to install, since in addition to the main parts it consists of two reflex sensors and a separate controller.

Laser system

An optical type sensor that allows not only to diagnose the appearance of objects in the coverage area, but also to measure the distance between them. The operating principle of the device is to measure the transit time through the beam. The same system is used in radar.

Fiber optic sensor

The principle of operation is that electronic circuits and optical elements are separated in space, and light is transmitted through optical fiber. Typically plastic fibers are used.

Such equipment is installed at facilities where the required area is very narrow or where there is a difficult working environment - increased risk of damage, constant humidity, strong vibration.

Analog type

These are optical output signal sensors. The operating principle is very similar to the laser type, since the desired indicators are measured depending on the intensity of the reflected signal.

Differences in the way light is transmitted

These are the main differences by which discrete optical sensors are classified. The difference is in the method of “delivery” of light to the input optical element of the sensor.

The most reliable -

With separate receiver and transmitter

Sales managers call such sensors barrier, or beam-intersecting. Although, I think this is incorrect - all discrete sensors work with the beam intersecting with some kind of barrier.

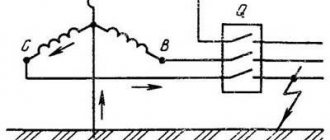

Optical transmitter-receiver type sensor with separate parts

This is the most reliable type of sensor in terms of range and noise immunity. In all other sensors, the transmitter and receiver of radiation are located in the same housing, but in this one they can be separated by tens of meters.

That is, the transmitter is installed in one place, and power is supplied to it. It emits without performing any other functions and without settings. And the receiver is installed at a distance, and sensitivity and other parameters and functions can be adjusted there.

The emitter and receiver must be from the same pair (set), although they can be purchased separately. Transmitters and receivers from different companies do not fit together (but this is not certain).

Such sensors are used in production where long distances need to be monitored. Also - in safety circuits, in security systems and where the air may be polluted (dust, gas).

There is also an option for domestic use - I saw barrier photosensors in an elevator:

Optical sensor in elevator

As long as some clothing or part of the body crosses the path of the sensor beam, no one will go anywhere.

With reflector (reflective)

These sensors combine a source (transmitter) and a radiation receiver in one housing.

Reflex optical sensor with retroreflector

The light is reflected from the reflector and comes back. Therefore, some manufacturers call such sensors retroreflective (reverse reflection).

Optical sensor with reflection from a reflector

By the way, the photo shows the Dark / Light On switch, sensitivity control, and stability and response indicators.

And here is a good photo, the optics of the transmitter and receiver are visible:

Reflex sensor on the optics side, mounted on a bracket

Such a sensor is necessarily a system. For example, a conveyor, and a sensor-reflector system controls the passage of a workpiece:

Reflex sensor on one side of the conveyor

A reflector may also be called a reflector, retroreflector or reflector:

Reflector for optical sensor on the other side of the conveyor

The maximum working distance at which stable operation is ensured is from 5 to 10 m for different models. Theoretically, more is possible, but in practice it is very difficult to ensure stable operation - the slightest shift of the beam due to vibration or weakening of the light due to dust, and that’s all.

The sensor is contaminated with dust, the maximum range in this case drops by about 30%

Reflex type sensors are most often used in production.

Diffuse

This type of sensor is reflective from the object.

Diffuse optical sensor with reflection from the object

It has the shortest range (up to half a meter), but it has an important property - when properly configured, it detects the appearance of objects in the coverage area. After all, you can’t put reflectors on every box or bottle!

The object can be on the axis of action of the sensor, at a distance. As you approach, the sensor, like a threshold element, is triggered.

In the simplest case, there is only one adjustment - sensitivity.

Cool sensors have several buttons or controls, and can be programmed and trained:

Diffuse sensor with training and many settings

Photoelectric sensors: purpose and device. Operating principle of photoelectric sensors

In industrial areas, specialized devices such as photoelectric sensors are actively used, which allow the most accurate detection of an incoming object without the need for physical contact. They are used when installing various equipment, and also come in different types and differ in their operating principles. You can select a suitable device based on its properties, as well as taking into account the situation in which such a sensor will be used.

Using various photo effects

During operation, photoelectric sensors use three possible photoelectric effects, which depend on how the properties of an object change in the presence of changes in light levels.

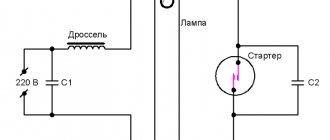

1. The effects are external when, under the influence of the received light energy, electrons fly out of the cathode of the lamp.

2. Internal effects differ in that the resistance of the semiconductor depends on the level of illumination.

3. The valve effect occurs when there is a driving force that depends on the lighting.

Types of devices

You can find photoelectric sensors of analog or discrete types.

1. For analogues, the output signal can vary in proportion to the available lighting level. Typically, such devices are used to create automatically controlled lighting elements.

2. Discrete devices change the value to the diametrically opposite indicator when a certain level of illumination is reached. They can perform all sorts of tasks on an existing production line and are widely used in industry.

An optical non-contact device regulates changes in the incoming light flux in the work area and can operate at a great distance, responding to changes in objects, their absence or presence. The design of this device has two parts that are responsible for proper functioning - a receiver and an emitter. They can be located either in one suitable housing or in different ones.

Device groups

Depending on the operating method used, photoelectric sensors are usually divided into four groups:

1. Working on the principle of beam intersection. In this case, the emitter and the receiver working in tandem with it have two separate housings, since this is required by the operating technology. Two devices are installed opposite each other, and when interacting, the emitter sends out a beam that is perceived by the receiver. If any object crosses this beam, the device immediately sends a corresponding signal.

2. Sensors with the principle of reflection from a reflector. Such devices are characterized by the fact that their emitter and receiver are located in the same housing. In addition to this unit, a special reflector is also used, which is installed opposite the device. During operation, the device sends a beam, it is reflected from the reflector and perceived by the receiver. A special polarizing filter allows you to configure the operation of the equipment so that the device perceives only the reflection from the reflector and nothing extra. Reflectors are different, so they are chosen based on the existing situation - distance and installation features. If during operation the beam stops reflecting and reaching the receiver, it means that some object has appeared on the line, and the device transmits a signal about this further.

3. Devices that reflect light from an object. For these units, the receiver and the accompanying emitter are also located in the same housing. In this case, the work is structured in such a way that a reflector is not needed, since its role is performed by various objects - the beam is reflected from them, hits the receiver, and the sensor sends the desired signal.

4. Fixed reflection sensors. In fact, this is an improved version of the previous version of the equipment. Devices work on the same principle, but they more sensitively capture and determine the state of an object. For example, using such sensors you can detect bulging packaging on the line or a package that is not completely filled.

Also, sensors can be divided not only according to their operating principle, but also according to their purpose. There are general purpose and specialized devices. The latter are designed to perform narrower tasks and solve specific issues. For example, they can recognize the presence of a label, a contrasting border, and other similar elements. All sensors perform the task of detecting any objects at a distance, and depending on the characteristics of the element, this distance can vary significantly.

Sensor characteristics

Typically, manufacturers accompany their devices with special technical data sheets, which accurately describe all the necessary characteristics that help to choose the right sensor. This is very convenient, since the buyer does not need to make any precise calculations to select a suitable device, but only need to correlate its parameters with the characteristics of the installation site and the specific situation in which the device will be used.

1. Practical detection ability is the main characteristic for such elements, since it means under what conditions the sensor will be able to perform its work, this indicator is also affected by the filling of the viewing angle, it can be complete or incomplete.

2. Range is another important parameter; it means at what distance the device can operate. Since it can be different for all sensors, there are options that work at a distance of several centimeters or devices designed for a range of meters.

3. The width of the sighting beam also plays an important role, since it directly affects the resolution of the sensor and what objects it can work with.

4. Reaction time is also important during operation; it takes into account at what speed the sensor will process objects, as well as its on and off time. It is necessary that the device has time to cover all incoming objects, keeping pace with their movement along the line.

5. Supply voltage is taken into account when choosing, since the introduction of sensors into the system should not have a serious impact on its performance, if the devices are too powerful, then they should be replaced with options that consume less energy so that they can work efficiently and perform their functions without disturbing general activity of the production line.

6. Also, when choosing, it is worth taking into account the pointing angles of the sensor, the features of its connection and installation, dimensions and weight, the level of security - all this also matters when the device operates.

When choosing a photo sensor, it is better to pay attention to well-known manufacturers who have already earned a certain reputation in the market. It is necessary that the device is as safe as possible and has an easy-to-use interface - this will make working with it comfortable and convenient. Also, the sensor housing must be well protected from dust and moisture - this will extend its service life. Its connection point must be standard so that there are no problems with installation.

https://www.techtrends.ru/techdept/techarticles/fotoelektricheskie_datchiki.php

Photoelectric sensors

A photoelectric sensor is a special sensor that is capable of responding to changes in illumination.

In special photoelectric sensors, 3 types of photoelectric effect can be used:

1. External photoelectric effect. It lies in the fact that under the influence of light energy, electrons will be emitted from the cathode of the electron tube. The magnitude of the emission current will depend on the illumination of the cathode.

2. Internal photoelectric effect. It will consist in the fact that the active resistance of the semiconductor depends on its illumination.

3. Valve photoelectric effect. The idea is that between the layers of the illuminated conductor and the unilluminated semiconductor, an electromotive force will arise, the magnitude of which will depend on the illumination.

It is important to know! Photocells that have an external photoelectric effect are a vacuum or gas-filled lamp with a cathode made of a photosensitive layer.

The anode and cathode of a special photocell are placed in a glass container from which the air will be pumped out. When the light flux hits the cathode, part of the radiant energy is transferred to electrons and electrons will fly out of the cathode. This phenomenon may be called photoelectron emission. To use it, an electric field will be created between the photocathode and the anode, which will direct electrons to the positively charged anode. When the action of light is stopped, then the current will gradually disappear. Industrial-type photocells will include:

· CG (Oxygen-cesium gas-filled).

· SCV (antimony-cesium vacuum).

The operation of each element will be determined by a number of characteristics. In this article we tried to consider only a few of them.

Differences in design

It's simple here. If we do not consider sensors of special design (for example, slot-type), then optical sensors can be of two types - in a rectangular and in a cylindrical housing.

I have given enough photos of the rectangular ones, but here are the cylindrical ones:

Optical sensors in a cylindrical housing with a reflector. Control of passage along the conveyor

Connection and types of output signal

This is where the main confusion lies. Sometimes it is difficult to understand what is a Normally Open (NO) and what is a Normally Closed (NC) sensor output. Those who have read my previous articles (links at the beginning) know perfectly well what this is. But in relation to optical sensors it is worth repeating.

Three events need to be linked:

- getting the light of the required intensity,

- turning on the activity indicator

- switching the output element (transistor or relay)

Confusion arises when activity (triggering) is understood as either the hit of light or the hit of an object. And what happens depends on the Dark / Light switch and the type of output - NO or NC.

In NC sensors, the indicator can light up when the contact is closed, or maybe when the sensor is active (These are different events!). Depends on the manufacturer.

I have an article on connecting sensors (link at the beginning), here’s another one. As a rule, the connection diagram is shown on the case:

Connection diagram on the sensor body. Switches, regulators, indicators and terminals - under a sealed translucent cover

In general, you need to carefully read the instructions and check everything in practice.

How to connect an optical sensor

Any optical sensor is connected to executive automation:

- programmers;

- control boards for various systems.

The connection diagram will have to be selected depending on the type of output signal that comes from the equipment.

General classification of optical sensor connection:

- for the dry type of contact group, closed or open are used;

- connection to the alarm system power supply;

- supplying power to relay sensors via a separate line.

Confusion arises because not all technicians understand the difference between a normally closed and open sensor output.

To understand the connection, you need to understand three events:

- correct light intensity;

- turning on an indicator indicating the activity of the device;

- switching a relay or transistor - output elements.

The Prior will not be able to be connected correctly if you confuse the activation and the light entering. And also, what processes are happening at this moment - the switch operates in a certain mode (Dark/Light), and the type of output is normally open or normally closed.

With a NC output, the indicator may light up when the contact closes, or when the sensor is active. We must not forget that these events are not the same. It all depends on the manufacturer.

Therefore, for correct connection, you need to carefully read the instructions and test the theory in practice.

Specific sensors

Light grid

These are two rulers located exactly opposite. One has LEDs, the other has photodiodes. Thus, by analyzing the overlap of light/photodiode pairs, it is possible to measure the geometric data of the object with some error. For example, the height or width of an object.

Light barrier - ruler for measuring the geometry of objects

The light grid is connected to a specialized controller, which provides data to the main controller.

Light barrier

It is used mainly for security, to keep people or irregularly shaped objects out of the controlled area.

For security, read my article on the blog. And also in the magazine Electrotechnical Market.

A couple of photos to make it clear what we're talking about:

Safety barrier – only what is needed passes through the conveyor, and only when needed!

Barrier in a sensor system

This is a rather complex system, which also includes at least 2 reflex sensors (4 in the photo) and its own controller.

Laser

These are optical sensors that have the ability to measure the distance to an object.

Laser optical sensor

Laser optical sensor with distance display

Laser optical sensor with distance measurement

The principle of operation is to measure the transit time of the beam. Like in radar.

Slot sensors

A separate type of sensors with a receiver and transmitter are slot sensors (fork-shaped). They are convenient because although the transmitter and receiver are separated, they are actually located in the same housing, the design of which has a slot.

Slit optical sensors. Two sensors, one ring with slots.

When an activator (object) gets into the gap between the emitter and the receiver, the sensor is triggered. Slot sensors are useful where the object whose movement is detected has a small, fixed thickness. This design is very similar to the operating principle of an incremental encoder.

Fiber optic, or fiber optic

I have come across such sensors in a diffuse design, and with a receiver + transmitter.

The idea is that the optical elements and electronic circuit are separated in space, and the light is transmitted through optical fiber (plastic fiber).

Fiber Optic Sensor Element

Do you see the red dot? This is the output of the fiber optic sensor.

At a distance of 4 meters there are the following blocks of fiber optic amplifiers (for three sensors):

Fiber Optic Amplifiers for Sensors

Such a system is installed where there is very cramped space (how to set it up?) and where electronics do not like to work - vibration, humidity, and a high risk of damage.

A few more photos of sensors with fiber optic cable:

Two transceivers with fiber optic wires to the electronic unit. Do you see any abrasions? These are traces from inductive sensors that constantly broke due to imperfect mechanics...

Electronic unit (fiber optic amplifier)

Optical part of the fiber optic sensor. Even taking a photo is problematic, let alone setting it up!

Electronic units – fiber optic amplifiers for fiber optic sensors in the photo above.

Expert of the LAN-ART company on optical transmitters - Berezkin E.N.

A specialist, an expert at the LAN-ART company on optical transmitters, Evgeniy Nikolaevich Berezkin, comments: “Today in every modern home there are optical receivers and transmitters operating via fiber optics. The optical transmitter of cable television networks (CTV) is used to generate an optical signal modulated by an electrical television signal with a group TV signal frequency range of 47 ... 862 MHz. Such transmitters use lasers, and photodiodes are used in receivers. The system uses optical radiation with a wavelength of 1100-1600 nm. “

Analog

These sensors are analog based on the type of output signal. The principle of operation can be similar to that of a laser, or the intensity of the reflected signal is simply measured.

Analog sensor

In this case, an analog signal corresponding to the distance to the surface of the unwinding coil is fed to the analog input of the controller (ADC). And the controller calculates the diameter of the coil.

An optical sensor that measures the distance to an object. The red dot on the right shows the measurement location. The sensor housing is protected from impacts by a fastening element

The same sensor is shown at the very beginning of the article. It also has a discrete output that can be programmed to trigger at a certain distance.

Optical flame sensor

This sensor stands apart - it perceives light from the flame of burning gas or other fuel. Used in industrial boiler rooms where increased safety is needed.

I remembered. My article is about modernizing a boiler room, where I installed soft starters instead of contactors.

Here is the model:

Flame sensor for boiler room with discrete output

Or this:

Flame sensor from gas combustion

The principle of operation is similar to that of a radio tube.

Hey, does anyone else remember that there were analog TVs with radio tubes?! An article about how I turned on an old tube TV.

Classification of photoelectric sensors

Standard photoelectric sensors use a directed light beam generated by a transmitter. Photosensors are capable of responding to opaque and translucent objects, as well as to water vapor, smoke, and aerosols. All photo sensors can be divided into 3 main types based on their operating principle:

• Photo sensors for beam intersection. They react to the blocking of the recorded light flux when the controlled objects move or when their size changes. As a rule, they have a transmitter and receiver made in separate housings. In such sensors, the light source and optical system form a narrow beam of light or a parallel, uniform light flux.

Overlapping the light beam of a discrete type photosensor causes the sensor output to trigger - the output is a discrete signal (as 0 or 1). In analog-type sensors, a uniform light flux illuminates the object. In this way, you can control the size of the object or the shutter blocking part of the light flux. Sensors in photoelectric micrometers, length, area, and deformation sensors operate on this principle.

• Photosensors of the diffuse type, in which the light flux hits the photocell after reflection from the controlled object, are usually made in one housing. The amount of reflected light hitting the photocell depends on the reflectivity of the object's surface (cleanliness of processing, the presence of a reflective surface and areas covered with paint). Such photosensors can also be used in surface cleanliness meters, photoelectric reflectometers, hygrometers, and so on.

Among the sensors working on this principle, there are those that are most sensitive to deviations in the level of light flux in comparison with the adjustment to the object. For example, it is possible to detect a swollen cap on a bottle, incomplete filling of vacuum packaging with products, and so on. For accuracy, sensors of this type can use a background suppression function.

• Reflex type photo sensors. Here, the light flux hits the photocell after reflection from a special reflective plate (reflector). Such sensors are designed in such a way that, thanks to a polarizing filter, they perceive reflection only from the reflector. This feature allows you to avoid false alarms when light is reflected from objects with a mirror surface, for example, from tin cans. There are reflectors that work on the principle of double reflection. The choice of a suitable reflector is determined by the required distance and mounting capabilities.

• There are also photo sensors for special purposes, but we will only mention them and will not include them under our classification.

If the sensors of the previous type have a receiver and a transmitter, as a rule, are located in the same housing, then in special-purpose photo sensors there is no transmitter, there is only a receiver. The luminous flux is created by the control (monitoring) object and contains information about the controlled parameter of the object. Similar photosensors are used in photoelectric temperature meters, radiant energy dosimeters, and devices for emission spectral analysis.

According to the international classification, this division most closely corresponds to the following markings in the designation of models:

- type T – beam intersection sensors (beam reception from a separately installed emitter);

- type R – reflex type sensors (reception of a beam reflected by a reflector (reflector));

- type D – diffusion type sensors (reception of a scattered beam reflected from an object).

Malfunctions and care of optical sensors

Just like the optics of SLR cameras, they need to be cleaned, carefully wiped and checked for mechanical integrity.

To clean optics, I use wipes soaked in water with the addition of a small amount of neutral detergent. For example, for dishes. Then I wipe it with a dry cloth. The main thing is that no abrasive gets in.

Another feature. In optical sensors, the emitting element is usually an LED. It has its own service life, and over time the intensity of its radiation decreases. Therefore, it is not surprising that once every few years it is necessary to adjust the sensitivity of the sensors, such is the problem...