Ultraviolet radiation is used in everyday life and medical institutions to disinfect premises (rooms, hospital wards, etc.). In stationary conditions, industrial quartz lamps are used as a UV source. Such devices are not always available in everyday life, so situations arise when you need to decide what to replace the lamp with and how to make it yourself.

Quartz lamp for sterilization of a hospital room.

How to replace a UV lamp at home

It is impossible to make a quartz lamp at home, but it is quite possible to obtain a homemade source of disinfecting radiation using other methods. The lighting market is now confidently captured by LED lights. Various types of emitting elements of this class operate in the spectrum from soft ultraviolet to infrared. From LEDs you can assemble a UV lamp. But this method has a significant drawback - the low power of emitters of this type and their relatively high cost. Since disinfection of premises requires a source of sufficiently high intensity, such a method will be expensive.

UV LED.

There will also be little effect from visible light sources equipped with light filters - household LED flashlights or mobile phone flashes. At home, it is impossible to make a filter with good characteristics (high level of UV transmission in the required spectral band), and this class of flashlights belongs rather to the category of toys. In practice, they can only be used as currency detectors, etc.

A good source for obtaining a home ultraviolet source can be a DRL 250 gas-discharge lamp. A lamp of this power has an optimal radiation intensity for a medium-sized room. Based on the conditions, lamps of other sizes can be used. The parameters of gas-discharge lamps that are important for review are summarized in the table.

| Type | Power, W | Base type |

| DRL-125 | 125 | E27 |

| DRL-250 | 250 | E40 |

| DRL-400 | 400 | E40 |

| DRL-700 | 700 | E40 |

| DRL-1000 | 1000 | E40 |

Other standard lamp parameters, such as color rendering index, luminous flux, etc. in our case they do not matter.

DIY germicidal lamp for home

How to make an ultraviolet lamp with your own hands? To do this, you will need a mercury arc lamp (MAV) with a power of at least 125 watts. It must be wrapped in cloth, and then carefully split the flask with a hammer. In this case, you need to try to ensure that the inner tube is not damaged - it is because of it that everything is done. It is better to carry out these actions not in a closed room, because if the flask is damaged, mercury vapor is released.

Afterwards, you need to carefully remove the base with the glass tube from the fabric, put the rag with the fragments in a bag and hand it over to a specialized center. They cannot be disposed of with regular waste.

DIY UV lamp from DRL. Required part: glass tube

Now all that remains is to carefully pull out the glass tube - this will be a DIY UV lamp - and apply power. So we have gained experience in the question of how to make an ultraviolet lamp - there is nothing super complicated about it.

The main thing is that when quartzing a room, there should be no people or animals in it, and it is advisable to take even plants outside. After the procedure, the room is ventilated, and only after this can the flowers be returned to their places.

But you also need to know that an ultraviolet lamp does not destroy germs and bacteria found in furniture upholstery or under wallpaper. Disinfection with such a device is only superficial. Moreover, it does not matter at all whether the device is made at a factory or whether such an ultraviolet lamp is made with your own hands at home.

How to make a quartz lamp from DRL

Before making a bactericidal lamp from a gas-discharge DRL , you need to understand how the donor lamp is designed.

Gas discharge lamp DRL-250.

Externally, a mercury lamp differs little from a conventional incandescent lamp - the same standard threaded cartridge and glass bulb. The difference is striking - the balloon is opaque, and is coated on the inside with a white substance - a phosphor. Under the influence of ultraviolet radiation, this substance begins to glow. To initiate the glow, there is a UV light source inside the bulb. It is a tube made of quartz glass - it can withstand high temperatures. The flask is sealed hermetically, and the main and auxiliary electrodes are located in it. Inside there is liquid mercury, as well as a small amount of mercury vapor.

The device of a mercury gas discharge lamp.

At the moment of switching on, an initial discharge flashes between the main and ignition electrodes - due to the small distance between the elements. The initiating system begins to warm up. As the temperature rises, liquid mercury begins to transform into gaseous form, and when a certain concentration and pressure of metal vapor is reached, a discharge appears between the electrodes. The ignition time depends on the ambient temperature and can range from 8 to 15 minutes.

After warming up, the system begins to emit a glow, the spectrum of which covers the visible part of the spectrum in the blue-green region and the ultraviolet region. UV radiation causes the phosphor of the main bulb to glow red, and the visible color of the initiating block complements the glow of the large bulb to white light. The space between the inner flask and the ultraviolet radiation source is filled with an inert gas (nitrogen).

SEE how to make a stand for a quartz lamp.

To make ultraviolet from such a lamp, it is enough to remove the top flask. To do this, wrap the lamp in thick cloth and carefully break it. This must be done so that the indoor unit is not damaged. The inside of the glass is coated with powdered phosphor, so it is not recommended to carry out such an operation indoors. This should be done outside or in a well-ventilated workshop.

Important! The cylinder is under pressure, so measures must be taken to completely prevent the scattering of glass fragments.

Next, you need to remove the remains of the flask - and the homemade UV lamp is ready.

UV mercury lamp sources.

You can connect it to the network according to the usual scheme for such devices.

Standard DRL switching circuit.

Important! During the initial warm-up of the lamp, the current consumed by the DRL can reach a high value, so you cannot turn on the lamp in a household single-phase 220 V network without a choke! Before switching on, you must make sure that the ballast is designed for the rated power of the lamp.

Choke for connecting DRL to the network.

This method of obtaining a home source of disinfecting radiation has its disadvantages, the main one of which is low bactericidal efficiency. This is due to the non-optimal radiation spectrum for such a field of activity. But there are also advantages, including low cost and ease of manufacture.

Video: Step-by-step instructions for making a lamp.

How to make an ultraviolet germicidal lamp from a mercury gas discharge lamp

In this short article, the master will tell us how to make an ultraviolet bactericidal lamp with your own hands.

Ultraviolet germicidal irradiation is a disinfection method that uses short-wave ultraviolet light (ultraviolet C or UV-C) to kill or inactivate microorganisms by destroying nucleic acids and disrupting their DNA, rendering them unable to perform vital cellular functions. UVGI is used in a variety of applications such as food, air and water purification. Can be used to disinfect your home, face mask, etc.

To make such a lamp you need: 1. Wire 2. Multimeter. 3. Screwdriver. 4. Hammer. 5. Bottom of CD case. 6. Ballast for a mercury lamp. 7. Mercury-discharge lamp (ballastless - not suitable for this project). 8. Plug and ceramic lamp socket. First you need to disassemble the lamp. You need a middle part with a base. The flask needs to be removed. Work must be carried out outdoors. According to the expert’s advice, if a flask with mercury accidentally breaks during the process, then you need to fill the affected area with sulfur powder*. After a few minutes, collect the fragments and powder and dispose of them at a specialized facility. * This is what Wikipedia tells us about demercurization (removal of mercury) with sulfur.

Laboratory manuals indicate that it is completely useless to cover mercury with sulfur, since at room temperature and even when heated to 100°C, mercury and its vapors practically do not interact with crushed sulfur.

Mount according to the diagram. The cartridge secures to the top of the CD box stand.

Nuances in using mercury-quartz lamps

Maintenance of lighting installations with mercury-quartz lamps has some peculiarities, therefore, depending on the type of lamps, the following requirements must be taken into account.

The device of a mercury lamp.

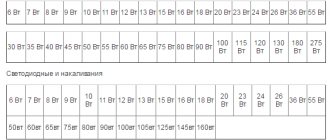

DRL type lamps are connected to the network using ballasts. Since the industry produces two- and four-electrode lamps, the type of ballast must correspond to the type of lamp. Lamps with a power of 80, 125, 400 and 700 W are produced only in a four-electrode design, and lamps with a power of 250 and 1,000 W are manufactured in two modifications. Therefore, this remark applies especially to the last two types of lamps.

As an exception, lamps of a four-electrode design can be switched on with ballasts for two-electrode lamps of the corresponding power, but in this case the spark gap must be removed from the ballasts. If the spark gap is not removed, the ballast will supply a high-voltage ignition pulse to the lamp, and the lamp will fail.

Switching circuit for a mercury-quartz lamp DRT.

External ambient temperature has a strong influence on the ignition voltage of lamps. If the lamp is used in enclosed spaces where the temperature does not drop below zero, then to ignite the lamp it is enough to apply a voltage of at least 200 V to it. Under these conditions, for four-electrode lamps, a conventional ballast in the form of a choke can be used. But this ballast will not ensure the ignition of such a lamp in outdoor lighting installations, where the air temperature can vary to 30 ° C and below, and a voltage of at least 300 V must be supplied to the lamp.

In this case, it is necessary to use another type of ballast, for example a transformer with high dissipation. This circumstance should be paid attention to, since the difficulty observed in winter with lighting the lamps can be explained by insufficient no-load voltage created by the ballast.

DRL lamps are designed for use in a vertical position, with the base up. However, if necessary, it can be used in any position. Operating the lamp in an inclined position may have some effect on lamp life. When operating lighting installations with DRL lamps, it is necessary to monitor the condition of the installation compensating for the low power factor.

Currently, it is customary to install compensating capacitors at group switchboards or at substations. This compensation system is called group compensation. It is also possible to compensate for low power factor by installing a capacitor at each luminaire. In this case, this system is called individual. If the electrical network is designed taking into account a compensating installation, then disconnecting it can lead to an increase in current almost doubling, which leads to overload of the network and transformers. The absence of a compensating installation requires an increase in the cross-section of network wires and the power of transformers.

When operating two-electrode DRL lamps, a very common drawback of ballasts is the absence of an ignition pulse, as a result of which the lamps do not light. It is necessary to check the reliability of contact between the current-carrying elements of the arrester and the panel on which it is installed, and try to replace the old arrester with a new one. If during such a replacement the lamp starts to light up, it means that the spark gap has failed. It should be borne in mind that the service life of the spark gap is significantly less than the service life of the lamp, so they must be replaced periodically.

If the ballast is not built into the luminaire, but is installed separately from it, then during all repairs and inspections, the reliability of the electrical contact in all connections and the grounding condition of the ballast housing and the luminaire must be checked.

Schematic diagram of a mercury lamp.

For PRK type lamps, the normal working position of the lamp in the device is horizontal. A deviation from this position of no more than 15° is allowed, since operating the lamp in a different position may overheat the cathodes and reduce the lamp burning time.

Lamps must be operated with ballasts supplied complete with the device designed to turn on this type of lamp. If the lamp is turned off, it cannot be re-ignited until it has completely cooled down. This requires a period of time of no more than 10 minutes.

When installing a new ballast or replacing a faulty one, you should make sure that it contains an interference-suppressing capacitor installed in parallel with the lamp, since otherwise the device may be a source of radio interference. If such a capacitor is not available, then in parallel with the lamp you need to connect a capacitor with a capacity of 0.05 μF for lamps of the PRK-4 type and 0.005-0.007 μF for all other types of lamps.

When replacing a burnt-out lamp with a new one, before installing it in the device, it is recommended to wipe it with cotton wool soaked in alcohol. During operation of the lamp, a large amount of heat is released, overheating it. Therefore, if the lamp is installed in a closed device that does not have ventilation, forced ventilation of the device must be provided.

When lit, PRK lamps emit intense radiation in the ultraviolet region of the spectrum and can have a harmful effect on people's eyes. In this regard, to protect your eyes when using such lamps, you must wear safety glasses. Under the influence of ultraviolet radiation, if the lamp is used carelessly, burns may occur on the skin, so the use of these lamps should be supervised by medical personnel, and in their absence, the necessary precautions should be taken.

Lamps of the DRSh type have a vertical working position. A slight deviation from the vertical is allowed, but not more than 10°. For lamps operating on direct current, the anode, the base, which has a large diameter with a “+” sign, must be located at the bottom and connected to the positive pole of the power source. In AC lamps, the ignition electrode should be located at the top. The lamp in the device is attached to the legs or to the bases of the current-carrying electrodes.

Connection diagram for a powerful UV lamp: L - DRT lamp; DB - throttle; K - button; C1 is a capacitor.

To ensure normal ignition of lamps, it is necessary to monitor the value of the supply voltage, which should be no lower than 115 V for 127 V lamps and no lower than 200-205 V for 220 V lamps. The lamp ignition process is influenced by the ambient temperature, which should not be below 15° C.

When the lamps are operating, forced cooling is not allowed, but when the lamps are installed in closed equipment, the dimensions of the equipment and its ventilation must be designed in such a way that the air temperature at a distance of 5-6 cm from the lamp bulb does not exceed 250 ° C. After turning off the lamp, it cannot be re-ignited until it has completely cooled down, which takes 5-6 minutes.

During operation of equipment with DRSh type lamps, it is necessary to carefully monitor the reliability of the contacts of all electrical connections, as well as the reliability of grounding of the equipment housing. Since the lamp can be a source of radio interference, you should check the presence of a capacitor connected in parallel with the lamp, and capacitors that block the power supply and are installed directly near the fittings with lamps.

The quartz glass from which the lamps are made quickly loses its transparency and crystallizes when its surface becomes dirty. Therefore, it is not recommended to handle the lamp with bare hands; you should wear cotton gloves. Before turning on the lamp, remove dust and traces of grease from its surface by touching its surface with your fingers, wiping it with cotton wool soaked in alcohol.

When the lamp is operating, a very high mercury vapor pressure develops in it, so the lamps are explosive. Personnel and equipment located near the lamp must be protected from fragments of the bulb in the event of its explosion. It should also be taken into account that the lamps emit a significant amount of invisible ultraviolet rays, and therefore measures must be taken to protect operating personnel from exposure to ultraviolet radiation. To protect the eyes, use special safety glasses.

How does UV kill viruses?

How does it all work? The fact is that the virus does not have a protective cell wall or membrane.

Therefore, short UV waves calmly penetrate into its interior and act directly on DNA and RNA, destroying them. But it is the doubling of the nucleic acid molecule that is responsible for the reproduction of the microorganism.

Even if UV rays do not kill the infection (low intensity or duration of irradiation), they still stop its reproduction. And if you cannot reproduce, then you no longer pose such a danger to other healthy cells.

But what is most important is that none of the viruses can adapt to such irradiation.

What does it mean? There are several types of disinfection of premises, including chemical.

So, during chemical treatment, there is some probability that certain types of viruses and microorganisms may subsequently change and develop resistance to certain solutions or their concentrations.

But there is no protection from UV. No matter how the infection changes, the direct impact of hard ultraviolet radiation on its nucleic acids will ultimately cause it to die.

They are afraid of such radiation, like vampires of the sun.

No matter how new and unstudied the virus is (Covid-19, SARS, etc.), it still has DNA, RNA, which means short-wave UV will penetrate its insides and destroy it from there.

According to studies, for irradiation efficiency to be 99%, a dose of about 1000 μWsec/cm2 is required.

This intensity will kill all viruses containing RNA, single-stranded DNA (coronavirus), and with a greater probability of 90% RNA, double-stranded DNA.