Bricks are building materials that have increased strength and resistance to changing climatic conditions and temperature changes. An important technical indicator of artificial stone is its density, which affects thermal conductivity, wear resistance and weight category.

The density of a brick as a physical quantity reflects the ratio of the mass of the composition to the dimensions of the block with voids. The unit of measurement is kilogram per cubic meter (kg/m3). The parameter is considered the main one when selecting a brand of construction raw materials.

Density of ceramic brick

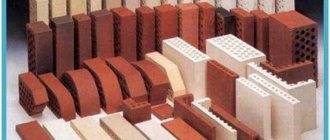

Ceramic brick blocks are made from clay, which is processed at high temperatures. Density indicators vary depending on the type of product - hollow or solid.

State standards prescribe the permissible density of the composition for a solid ceramic block from 1600 to 2000 kg/m3. The parameters for ceramic hollow bricks vary from 1100 to 1400 kg/m3 and are due to the large number of pores in the composition.

Ceramic blocks are suitable for the construction of stable structures - auxiliary or load-bearing. Solid bricks, due to the absence of a large number of voids, have increased strength and weight. Suitable for structures subject to constant loads.

Hollow ceramic bricks are used in the construction of residential buildings. For multi-apartment buildings, low density is important to retain heat in the premises. When determining the heat-saving qualities of a material, it is necessary to pay attention to the presence of special cracks. When constructing large objects, it is recommended to check each batch of bricks to confirm state standards.

Density of single brick

Single brick has a density of 1600 kg/m3. This type of brick, in turn, is divided into high-strength, ordinary and facing based on their characteristics, you also need to know where to use it, as well as the density of the glass (depending on the density, different applications). High-strength is used in the laying of load-bearing walls, ordinary for interior work, construction of partitions and walls, cladding for external cladding of buildings.

We recommend: How many bricks are in a cube: formulas and calculation table

Having considered all modern types of bricks, we can draw the following conclusions: when choosing this building material, it is necessary to be guided, first of all, by an understanding of what type of work the brick is being selected for, in order to correctly select its main characteristic - the density of the brick , as well as its type, which will guarantee durability and strength designs.

Density of sand-lime brick

According to the requirements of GOST 379-79, silicate blocks have strength grades M125-150. The material is made from lime, the mass of which can reach 90%. The volume of sand mixture is about 10%. The composition density indicator for silicate solid materials varies from 1800 to 1950 kg/m3. For hollow silicate sand blocks, the density standard must be no less than 1100 kg/m3 and no more than 1600 kg/m3.

The durability characteristics are influenced by the grain size of silicate crushed stone, the compression force and the production method. The pressure that is pumped onto the material during the technological process varies from 8 to 20 atmospheres. Therefore, the discrepancy in material density can be up to 30%.

The relatively low density of hollow sand-lime brick is due to the hollowness of the material, which reaches 33%. Due to this, the mass of the brick is reduced to 2.5 kg, and the thermal conductivity of the buildings being built is also reduced.

The characteristics of the material are optimal for the construction of partitions between rooms in apartments. The composition is not recommended due to its low density for the construction of load-bearing wall panels, stoves, because the blocks may become deformed and create an emergency situation.

When planning construction work, it is necessary to take into account that silicate raw materials quickly absorb moisture. Therefore, such building materials are not recommended for the construction of buildings in areas with prolonged precipitation, as well as in areas with high groundwater levels.

Density and specific heat capacity of brick

Brick is a popular building material in the construction of buildings and structures. Many people only distinguish between red and white brick, but its types are much more diverse. They differ both in appearance (shape, color, size) and in properties such as density and heat capacity.

Traditionally, a distinction is made between ceramic and sand-lime bricks, which have different manufacturing technologies. It is important to know that the density of the brick, its specific heat capacity and the thermal conductivity of each type of brick can vary significantly.

Ceramic brick is made from clay with various additives and fired. The specific heat capacity of ceramic brick is 700...900 J/(kg deg) . The average density of ceramic bricks is 1400 kg/m3. The advantages of this type are: smooth surface, frost and water resistance, as well as resistance to high temperatures. The density of ceramic brick is determined by its porosity and can range from 700 to 2100 kg/m3. The higher the porosity, the lower the density of the brick.

Sand-lime brick has the following varieties: solid, hollow and porous; it has several standard sizes: single, one-and-a-half and double. The average density of sand-lime brick is 1600 kg/m3. The advantages of sand-lime brick are excellent soundproofing. Even if you lay a thin layer of such material, the sound insulation properties will remain at the proper level. The specific heat capacity of sand-lime brick ranges from 750 to 850 J/(kg deg) .

The density values of various types of bricks and their specific (mass) heat capacity at various temperatures are presented in the table:

Table of density and specific heat capacity of bricks

| Type of brick | Temperature, °C | Density, kg/m3 | Heat capacity, J/(kg deg) |

| Trepelny | -20…20 | 700…1300 | 712 |

| Silicate | -20…20 | 1000…2200 | 754…837 |

| Adobe | -20…20 | — | 753 |

| Red | 0…100 | 1600…2070 | 840…879 |

| Yellow | -20…20 | 1817 | 728 |

| Building | 20 | 800…1500 | 800 |

| Facing | 20 | 1800 | 880 |

| Dinas | 100 | 1500…1900 | 842 |

| Dinas | 1000 | 1500…1900 | 1100 |

| Dinas | 1500 | 1500…1900 | 1243 |

| Carborundum | 20 | 1000…1300 | 700 |

| Carborundum | 100 | 1000…1300 | 841 |

| Carborundum | 1000 | 1000…1300 | 779 |

| Magnesite | 100 | 2700 | 930 |

| Magnesite | 1000 | 2700 | 1160 |

| Magnesite | 1500 | 2700 | 1239 |

| Chromite | 100 | 3050 | 712 |

| Chromite | 1000 | 3050 | 921 |

| Chamotte | 100 | 1850 | 833 |

| Chamotte | 1000 | 1850 | 1084 |

| Chamotte | 1500 | 1850 | 1251 |

It is necessary to note another popular type of brick – facing brick. He is not afraid of either moisture or cold. The specific heat capacity of the facing brick is 880 J/(kg deg) . The facing brick has shades from bright yellow to fiery red. This material can be used for finishing and facing work. The density of this type of brick is 1800 kg/m3.

It is worth noting a separate class of bricks - refractory bricks. This class includes dinas, carborundum, magnesite and fireclay bricks. Refractory bricks are quite heavy - the density of bricks of this class can reach 2700 kg/m3.

Carborundum brick has the lowest heat capacity at high temperatures - it is 779 J/(kg deg) at a temperature of 1000°C. Masonry made from such bricks warms up much faster than fireclay bricks, but retains heat less well.

Refractory bricks are used in the construction of furnaces with operating temperatures up to 1500°C. The specific heat capacity of refractory bricks depends significantly on temperature. For example, the specific heat capacity of fireclay bricks is 833 J/(kg deg) at 100°C and 1251 J/(kg deg) at 1500°C.

Sources:

- Franchuk A. U. Tables of thermal technical indicators of building materials, M.: Research Institute of Construction Physics, 1969 - 142 p.

- Tables of physical quantities. Directory. Ed. acad. I. K. Kikoina. M.: Atomizdat, 1976. - 1008 p. construction physics, 1969 - 142 p.

- Kazantsev E.I. Industrial furnaces. Reference manual for calculations and design.

- Mikheev M. A., Mikheeva I. M. Fundamentals of heat transfer.

Density of solid brick

The density characteristics of solid bricks are high. The blocks have indicators from 1600 to 1900 kg/cm3. The quality is affected by a small voidness - no higher than 8%, reduced thermal conductivity, which is 0.7 W/m°C. The material is wear-resistant, durable, but does not retain heat well and is heavy. Therefore, wall panels made from solid blocks are often additionally insulated.

Red solid bricks have the highest density. The indicator reaches 2100 kg/cm3. The raw materials are optimal for the construction of load-bearing wall panels, basement parts of buildings, supporting foundations and other structures with high loads.

The density of solid bricks is influenced by the characteristics of clay varieties, firing methods and temperature conditions. Full glazing is not performed on solid blocks, because high density will reduce vapor permeability. When exposed to excessive temperatures, the material shrinks greatly and is difficult to process. Therefore, experts recommend adjusting the method of cooling the blocks after the furnace. The bricks must be treated step by step with superheated steam, then left in the open air.

A high level of compressive strength and immunity to temperature changes, a high rate of moisture absorption give solid products wear resistance and frost resistance. The characteristics make it possible to use bricks for the construction of wall panels inside and outside the building, colonnades, supporting structures, load-bearing foundations, and basement floors.

Density of hollow bricks

The density of hollow bricks is reduced due to the presence of voids, the percentage of which varies from 13 to 50% of the internal volume. Porization ensures low weight of products, high thermal insulation and sound insulation characteristics.

Typical compaction values of a red hollow block vary from 1100 to 1450 kg/m3. The building material is suitable for the construction of partitions between rooms, lightweight panels, as well as for filling frame structures of houses. The density of the composition can be reduced to 1000 kg/cm3, while frost resistance will increase.

Clay brick

Traditional red brick is made by firing a prepared clay mixture in industrial kilns. Density depends on the variety:

- A solid clay brick is a block of baked clay with a regular rectangular shape. This material is very durable and conducts heat well, the density is 2000 kg/m3. Reliable solid brick is very expensive to produce, so it is used only for the construction of load-bearing structures.

- Hollow bricks are bars with holes inside, which reduce weight and cost, while its strength also decreases. The average density of ceramic bricks with voids does not exceed 1400 kg/m3. Thus, the material is suitable for creating partitions, lightweight walls and filling the frame of buildings. The advantages of hollow brick are its lightness, as well as a high level of heat and sound insulation.

Pros and cons of sand-lime brick

Density of facing brick

Facing (front) blocks have an even shape, a glossy surface, have average strength and reliable thermal insulation. The density characteristics of façade materials vary from 1300 to 1450 kg/cm3. The wear resistance of the composition is due to low porosity - from 6 to 14%. Bricks are made with slots and are used to decorate the external walls of buildings, design enclosing structures, park decorative forms, etc.

They also produce an additional subtype of building material - warm. The composition has a large number of pores compared to standard facing products. Density varies from 1100 to 1150 kg/m3.

Glazed facing blocks have a layer of glassy mass that is impenetrable to moisture. Repeated firing, which is required according to manufacturing technology after applying the glaze, does not affect the strength of the products. The compaction characteristics of the subspecies are typical - from 1300 to 1450 kg/m3. But the cost of the composition is higher than the standard one due to its high decorative qualities.

Types and characteristics

Traditionally, the classification of building blocks is based on their size and shape, the density of the ceramic brick and even the type of surface.

Let us consider the main parameters by which they are most often divided. 1. Density (emptiness).

The characteristics are largely determined by the internal structure. It is quite possible to judge them by knowing only the density of the blocks:

- The lowest void ratio (5%) is found in heavy-duty clinker, which is produced under brands from M400 to M1000. The minimum number of pores also provides it with increased frost resistance - from 50 to 100 cycles.

- The density of solid bricks ranges from 1600-1900 kg/m3. With a porosity of 8%, it is possible to obtain stones up to grade M300 with quite decent frost resistance values F15-50.

- Facing materials are much lighter and can have a fairly wide range of porosity values from 6 to 14%. Because of this, the strength characteristics suffer somewhat, which do not exceed M250.

- Density of a hollow product. The structure of the blocks itself may not differ from the row or even be close to durable clinker (6-8%), so the brand remains unchanged. But due to the presence of technological holes in the body, the weight is reduced and the thermal insulation abilities are improved.

In total, 6 classes of building blocks with density indicators from 0.8 to 2.4 t/m3 have been identified. This division greatly simplifies calculations when designing objects when it comes to loads and thermal protection of walls.

Other technical characteristics are approximately the same for all types of red brick:

- Water absorption is normally 8%, but this figure can vary within 6-14%.

- Air permeability – 0.14-0.17 mg/m·h·Pa.

- Shrinkage of blocks in masonry is from 0.03 to 0.1 mm/m height. These numbers are considered small, which is why brick buildings are less susceptible to cracking than others.

2. Thermal insulating properties.

If problems arise with this point, a decision is made to use hollow blocks in construction. They are distinguished from ordinary ones by the presence of through or blind slots, holes of round or rectangular cross-section. Due to the reduction in the amount of raw materials, their price is lower than for solid ceramic bricks, and the insulating characteristics of the stones are higher; this practically does not affect their strength.

The thermal conductivity of the blocks also allows us to classify them according to their efficiency, dividing them into 5 types. The best performance is for the lightest products with a specific gravity of 0.7-1 t/m3.

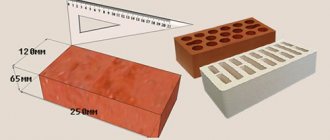

For this classification, a single solid GOST brick is taken as the basis. It has a good aspect ratio with an ideal multiple, allowing you to easily lay standard stones in any order. Even a centimeter tolerance on the seam is taken into account. The 1NF format is considered the standard (250x120x65 mm).

All other types come with a change in one of the linear parameters:

- 0.7NF - “euro” with a width of 85 mm.

- 1.4NF – one and a half (thickened to 88 mm).

- 2.1 NF – double has dimensions of 250x120x140 mm.

- 1.3 NF – modular. Here only the thickness remained standard, and the bed increased to 288x138 mm.

According to GOST 530-2012, the linear dimensions of bricks may have a slight deviation from the standard within 3-4 mm.