Concept

The design features of the anchor make it possible to effectively use fasteners in the process of installing objects of impressive size and weight to the surface of a material of varying density and strength.

The products are actively used in the construction industry, including for repair work.

Hardware is presented in a wide range. They differ in design, material of manufacture and purpose. Along with universal options, anchors are produced that solve highly specialized problems.

The main thing is to choose the right anchor bolt for a specific situation. The base material to which the fastening will be made, the dimensions and weight of the object that needs to be securely fixed to the wall are taken into account.

The principle of operation of fasteners is simple. The anchor element is inserted into a previously created hole corresponding to the cross section of the spacer sleeve. The nut is tightened. The cone tip opens. The sleeve increases in diameter, fixing the anchor bolt in the seat.

Important! A variety of hardware are produced that are allowed to be used in special conditions - aggressive chemical environments, in rooms with high humidity.

What are anchor bolts for masonry

A brick anchor is a universal fastener that is equally successfully used both in the field of capital construction and when performing simple repair and improvement work on buildings and premises for various purposes. With the help of such fasteners, which are a bolt of a special design, objects and elements of even significant weight can be securely fixed on the surface of a brick wall. Such anchor bolts, in particular, can be used to secure furniture and interior items, lamps and chandeliers, suspended ceilings, wall-mounted facades and much more.

The design features of this type of bolt and the principle by which it operates are contained in its name: anchor in German means “anchor”. The element that ensures reliable adhesion of such fasteners to the inner walls of a pre-drilled hole in the brick is a special sleeve. Placed in a hole in the wall, when the head of the anchor bolt is twisted, it begins to increase in diameter, pushing out the inner walls of the hole and coming into reliable engagement with them.

In order to make the adhesion of the anchor bolt sleeve to the walls of the hole in the brick even more reliable, a special notch is applied to the side parts of its outer surface.

Difference from dowels

To ensure expansion of the wall, a self-tapping screw is inserted into the dowel. The functioning mechanism of both elements is based on the expansion of the wall material. The dowel fastening system is simpler: a self-tapping screw is screwed into them or a large nail is driven in. With anchors things are more complicated. Their fastening system consists of two parts. At the moment of screwing into the spacer, its “petals” open in the cavity of the wall. This ensures reliable adhesion.

In terms of purpose, both types of fasteners do not differ. They are used to secure heavy objects. The only difference is that the anchors can withstand heavy loads: from 100 kg. A through fastening system on a load-bearing wall is implemented.

Device

The design of the anchor bolt for hollow bricks consists of two elements. One is spacer, the other is non-expansion, locking. The second is twisted or driven into the first, which is in turn placed in a pre-drilled hole of a suitable diameter. In this case, the petals open and cling to the channel walls. This creates a strong connection.

Installation Features

The process of installing an anchor in a hollow brick is simple, but involves several nuances. Knowing them will reduce the likelihood of errors and poor quality of work. They are as follows:

- Drilling is performed with a drill turned on in non-impact mode. Using a hammer drill may cause the structure or circumference of the hole to crack.

- When choosing the size of an anchor for hollow bricks, take into account the thickness of the plaster and other finishing material (if any).

- Installation is carried out in compliance with strict horizontality. Deviation from a given plane will lead to subsequent weakening of the structure.

- The sleeve (glass) of the anchor goes completely deep into the hole until expansion begins.

- The expansion of mechanical hardware is carried out with effort and accuracy. An extra turn of the rod can cause the element to rotate. As a result, it will have to be dismantled and the process repeated again, but in a different place.

- Installation in a hole with a screwed anchor is only possible by installing a chemical type anchor or installing a metal element of a larger diameter.

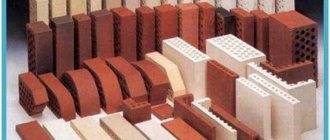

Varieties

Anchors differ not only in size. There are design features of technical parameters. Anchor products for brick walls are divided according to their intended use. A specific type of hardware is used for certain installation work.

Important! To ensure reliable fixation of an object in a brick wall, it is recommended to take a responsible approach to the choice of anchor products.

Driven type

Allows you to secure critically heavy weights. Made from high-strength material or carbon steel. It is treated with a specialized anti-corrosion coating, which ensures an increase in service life. The product is manufactured in one piece, which increases the reliability of the fasteners. A popular type of hardware is the collet anchor.

Drivers

The anchor is driven into the brick with a hammer. Its working part becomes wedged. This way the element is securely fixed in the wall. Then the bolt or stud is screwed in.

Wedge type

The scope of application is identical to the hammer type analogue. The method of installation in a stressed and unstressed concrete plane is allowed. Refers to reliable fastening elements. Capable of withstanding high loads. Used in dry rooms.

Made from various types of steel. Differs in specific execution. On one side there is a stud with a metric thread, onto which a nut is screwed. On the other hand, there is a spacer system in the form of a coupling with an internal shank.

Wedge

MSA type

Brass products, the outer side of which is characterized by the presence of a special sleeve with a large notch. The design allows you to increase the density of fixation of fasteners in the wall cavity. The permissible intra-sleeve cross-section is in the range of 8-10 mm.

Chemical principle

External design: cylindrical tube. Inside there are two ingredients - organic and inorganic. Reacting with each other, they harden and provide the required degree of strength.

Chemical

Important! Chemical-type fastening structures are in high demand because their use is allowed in places with high humidity, in porous substrates. Even in such extreme conditions, they are able to hold the elements together.

The name hardware was given in view of the chemical principle of operation - a chemical reaction. Has no smell. It is an environmentally friendly product. Does not harm the environment and the human body.

The negative aspects of using the product include the high price and different setting times of the composition. The latter depends on the variety of adhesive mixtures.

With ring

The peculiarity of the product - the presence of a ring - ensures its scope of application. It is convenient to install suspended structures on wall and ceiling surfaces. In construction it is used for securing scaffolding. Allowed to be used for bricks with a dense internal structure - only solid ones. In porous and hollow materials, fasteners lose their effectiveness.

With ring

Double-spacer

Additionally, a spacer sleeve is provided that opens simultaneously in two places. The first spacer element does not come into contact with the solid masonry surface. The reliability of fixing the product in the wall increases. The sample shows good results in the tensile test, therefore it is used in difficult operating conditions.

Double-spacer

Main types of fasteners for brick walls

Anchors specifically designed for installation in brick building structures differ not only in their size, but also in their design and technical characteristics. Accordingly, the scope of application of such fasteners also differs, each variety of which is designed to solve specific installation problems. That is why, in order to ensure high reliability of fastening objects that are fixed on a brick surface, you should approach the choice of anchor bolts very responsibly.

Specialists working in the field of modern construction and renovation are often faced with the need to perform installation work on masonry structures. This problem is solved using several types of anchor bolts:

- driving;

- wedge type;

- MSA type;

- double-spacer;

- fasteners, the upper part of which is equipped with a ring instead of a standard hex head;

- working on the principle of chemical fastening.

Each of the above types of fasteners used to perform installation work on brick walls deserves to be discussed in more detail.

Drive-in type anchor fasteners

Such anchor bolts are the simplest type of fasteners of this type. Drive-in anchors are used for fastening to building structures made of solid brick. The principle of operation of such an anchor bolt is that after installation in a previously prepared and thoroughly cleaned hole in the wall, a spacer element is activated in it, which ensures reliable fixation of the fastener. After the driving part of the bolt is securely fixed in the brick, the threaded element is screwed into it.

Parameters and installation of a drive-in anchor (click to enlarge)

Wedge type anchor

The design of such an anchor bolt, as is clear from its name, has a special element that is wedged during installation. Expanding in the holes made in the brickwork, the wedge element reliably fixes the fasteners to the building structure. Most often, fasteners of this type are equipped with screws that have a recessed type head.

Characteristics of wedge type anchor bolts

MSA Type Anchor Fasteners

A special feature of this type of anchor bolts is the presence of a brass sleeve in their design. On the side of such a sleeve there are longitudinal slots that divide it into separate petals that expand during installation of the fastening element. To ensure significant expansion of the spacer sleeve during the process of screwing a threaded element into it, the internal hole in it is made in the shape of a cone rather than a cylinder.

Dimensions and parameters of MSA anchors (click to enlarge)

Chemical anchor bolts

These anchor bolts, fixed in a pre-prepared hole using a special adhesive composition, are the most reliable type of fastener for walls made of hollow bricks and porous materials. The adhesive composition used for chemical fasteners fills the internal cavities in the hollow and porous material, thereby securely fixing the bolt in the hole.

Chemical anchor in the wall

The rules for installing such fasteners are quite simple and are as follows: a hole is drilled in the brickwork or in a structure made of porous material, which must be thoroughly cleaned. A capsule with glue is placed in the hole (or the adhesive composition is pumped into it from a special tube), and then a bolt is inserted.

Naturally, for the adhesive composition used for installing chemical anchors to completely harden, a certain time is required, which depends both on the composition of the adhesive and on the ambient temperature. Manufacturers producing such anchors for bricks must indicate in their recommendations the period required for the adhesive to completely harden.

The injection mass of the chemical anchor can be located inside the capsule or in a separate tube

Ring Anchor Fasteners

The ring, which is present in the design of such anchor bolts instead of a standard hexagonal head, is intended for more convenient installation of various objects: lamps and chandeliers, cable routes, communication elements for various purposes, etc. Manufacturers of such fasteners produce them with rings of different sizes so that consumers can choose bolt depending on the weight and dimensions of the objects fixed with it. A variation of such an anchor bolt is a fastener with a hook instead of a ring, which allows you to remove a fixed object from it if the need arises.

Characteristics of anchor bolts with rings (click to enlarge)

Double spacer anchor products

Anchor bolts of this type, in the design of which there is a spacer sleeve that expands during installation not in one, but in two places at once, allow reliable fastening, including in hollow bricks. The high reliability of using such products is explained by the fact that at least one of its spacer elements will be located not on the hollow part of the brickwork, but on the solid part of its internal structure.

Parameters of double-spacer anchors (click to enlarge)

The above review lists only the most popular types of anchor products used for fastening in brick. In fact, modern industry also produces other anchors that can be used for bricks and form reliable connections with such building materials. Such fasteners differ not only in their design features and technical characteristics, but also in cost, which must be taken into account when choosing them.

Fastening rules

Expert recommendations:

- Holes for anchors are made exclusively into the body of the brick. It is strictly prohibited to make them into inter-masonry butt joints. Such fasteners are not capable of holding a heavy object. On the other hand, damage to part of the seam joint negatively affects the load-bearing capacity of the wall, weakening it.

- Installation of fasteners is carried out in strict perpendicularity to the plane of the brick. Even minimal deviation is not allowed. The technological process is disrupted. The fixation becomes unreliable.

- When calculating the depth of the hole to be made for the fastening element, it is imperative to take into account the thickness of the finishing layer. The surface can be puttied or plastered. Fixation of hardware should be carried out exclusively in the plane of the wall, and not in the plane of the facing or decorative material. Incorrect calculation of the depth of the fastener will cause it to fall out.

- After drilling, the hole is cleaned of dust and dirt, particles of brickwork, and plaster. Use a special construction brush, vacuum cleaner or other available means.

Following the recommendations of specialists will allow you to create a high-quality fastening and guarantee its reliability.

Types of dowels for brick walls

Dowels are used to attach furniture, paintings or other objects to brick walls, as they can withstand heavy loads. In order for the fastener to be securely held in the base, it is necessary to select the correct type and size depending on the grade of brick or concrete. If the dowel is not used for its intended purpose, it may not withstand the load and fall out of the hole.

Types of dowels and their features

1. Externally, the dowel looks like a cork and has a cylindrical shape with a cavity. When the screw is screwed in, its body expands and rests against the walls of the hole. The most common are nylon and polyethylene expansion dowels. To prevent a screw or nail from falling inside, the fastener is equipped with a special collar equal to the diameter of the screw head.

2. For walls made of porous or hollow bricks, anchor fasteners are used. As soon as such a dowel begins to be screwed into the brickwork, its end expands or twists into a knot. The resulting “nut” inside the voids securely holds any object.

3. Nail dowels are used for fastening slats under cladding with finishing material; they are small in size. They come with a nail. Install them together through a hole in the rail and wall. Then they hammer it in with a hammer.

4. Special umbrella dowels are used to attach thermal insulation. An umbrella is inserted into the hole in the wall and through the insulation, and then a nail (plastic or metal) is driven in. For large loads, for example, up to several tons, metal dowels for concrete and brick are used.

5. Metal fasteners are best suited for suspended ceilings. In the event of a fire, the plastic ones will melt and the ceiling will collapse.

- reliable fastening that can withstand heavy loads;

- easy to use;

- Can be used both indoors and outdoors.

Due to the presence of spikes and whiskers on them, they do not turn while screwing in the screw.

Nuances and recommendations

Before drilling, you need to find out what the wall is made of. To do this, install a Victory drill bit into the drill and turn it on in shockless mode. Slowly make a test hole. In this case, the drill should only be held perpendicular to the wall. The degree of softness of the material is determined by the effort expended. If at times the drill passes easily, with gaps, it means that the walls are built of hollow bricks.

The material can also be determined by dust from the hole:

- concrete – light gray, white, feels like flour;

- silicate – white, like sand;

- foam concrete - soft, coarse-grained, also like flour;

- brick – red.

When choosing dowels, you need to take into account the load they will have to withstand. For example, for exercise machines it is recommended to use fasteners with a depth of at least 85 mm. The dowels should be the same size as the hole.

Installation Guide

The mortar between bricks can crumble due to mechanical stress, so you need to work with brick walls carefully. For drilling, you should use a drill, not a hammer drill. Because the brick is destroyed by impacts. This not only spoils the appearance of the wall, but also makes subsequent use of the damaged area for installing a dowel difficult. Making a hole even and the right size in a brick wall that is crumbling is extremely difficult. Hollow building material should never be drilled using the impact method, as this will cause it to crack.

- In the place where it is planned to drill a hole, a mark is applied (pencil or pen).

- A recess is made with a knife or nail. This will make it much easier to start drilling a straight hole.

- When choosing the diameter of the drill, it should be taken into account that the dowel should go in with little effort. If the diameter of the fastener is 9 mm, then the hole should have the same diameter. If the brick dowel moves, it may fall out under the weight of the load. The depth of the hole should be equal to the length of the dowel. It is also necessary to check that the screw matches the length of the dowel and is not too short or too long.

- The drill is installed perpendicular to the recess, and they slowly begin to drill in a non-impact mode. As soon as the depth becomes 1 cm, increase the speed and drill further to the desired size.

- If the drill does not have a stop-limiter, then in order not to make the hole too deep, a mark is placed on the drill. To do this, apply a dowel to it and apply a mark or tape at the same level as it.

- After a hole has been drilled in a brick wall, it is thoroughly cleaned of dust and pieces of brick. A vacuum cleaner is great for this purpose. Simultaneously with the technique, you can clean with a pencil, moving it in and out.

- A dowel is inserted into the hole and carefully hammered in with a hammer, not too hard, so as not to damage it, otherwise it will have to be replaced. If you plan to hang the cabinet on special hinges, then first screw in the screw, but not all the way, leaving a gap of about 2 mm. After which furniture is hung on it. In other cases, for example, when attaching sheathing slats, it is twisted (hammered) to the end.

Recesses are made in concrete using a hammer drill. In this case, the cross-section of the drill must match the size of the dowel. Unlike brick, the hole in concrete is made 5 mm longer than the fastener. After which it is cleaned of dust and crumbs, and only then the fasteners are clogged.

If you don’t have enough dowels, you can always make them yourself. To do this, a round peg of the required length and diameter is cut from a wooden block. It is desirable that it has a cone shape, as this makes the fastening more reliable. Standard dowel sizes: diameter – 5, 6, 8, 10 and 12 mm, length – from 25 to 160 mm.

This modern device will help you quickly “hammer” dowels, or rather, it uses special dowel-nails with a moving washer. There is no need to make holes to work with it. Thanks to the strong piston, the construction gun fires the fastener with great force. It is excellent for both solid bricks and concrete. The driving depth can be adjusted. At the end of the dowel there is a washer, which moves towards the head during driving. As a result, the landing is even more reliable. A construction gun is used to secure metal and wooden objects to concrete or brick.

Before choosing fasteners, you should accurately determine the load that it will experience, as well as the material from which the wall or ceiling is made. To keep it as firmly as possible in the brick wall, you can use dry tile adhesive. The solution is pushed into the recess, after which the fastening element is inserted. After a day (depending on the speed of drying of the glue), you can screw in the screw.

Installation features

In the practice of modern construction, anchors are in demand. They provide a reliable way to install equipment and fix massive objects and structures on the walls and ceilings of a building. It is important to choose the right hardware for the job.

Fastenings for solid bricks will not provide the necessary adhesion to hollow material. Therefore, it is important to first determine the base raw materials from which the enclosing structure was erected.

Sequence of work:

- The plane is marked. The work is done with the utmost care. Hollow ceramic bricks are fragile. If you make two holes with a small interval between them, the material will most likely be deformed.

- The hole in the brick is made with a specialized drill. The cross-section of the anchor element and the depth of its placement are taken into account. The perpendicularity of the hole produced is a guarantee of high-quality work.

- After creating the hole, it is cleaned of dust and debris. Depth accuracy is checked.

- When inserting the anchor, make sure that the gap between it and the wall is minimal. If it turns out that the product is loose, it is better to take larger hardware. It should be selected according to the diameter of the resulting hole.

Important! Installing a hammer-type product is the same painstaking process as installing a spacer analogue. If you apply excessive force when hammering, not only the fastener itself will be damaged, but also the wall.

How to properly install an anchor in brickwork

Anchor products used for fastening various objects on brick structures are designed in such a way that their installation does not cause any difficulties. It is performed in the following sequence.

- A hole is drilled in the structure to be fastened. Its diameter must correspond to the diameter of the anchor product.

- After thoroughly cleaning the hole, an anchor bolt is driven, inserted or screwed into the brick.

- When tightening the bolt head, it is necessary to achieve maximum expansion of the spacer sleeve, which will be evidenced by reliable fixation of the fastener in the brickwork.

Anchor installation principle

When choosing a place to drill a hole, you should pay attention to the fact that it does not fall on the gap between the bricks filled with cement mortar. This hole must be made only in the body of the brick itself.

It is also necessary to pay attention to the condition of the material from which the building structure is made, because cracks in it can significantly weaken the joint being formed.

In modern construction, fastening elements such as anchors can, without exaggeration, be called irreplaceable. These hardware provide the connection of building structures during installation, serve to install equipment, and are also used to securely fasten massive objects to walls and ceilings. Brick is one of the most common building materials today, so the need to use an anchor with a brick wall arises during construction or renovation very often.

Fixation to the roof base

The product is used to ensure reliable fastening of the rafter system. The Mauerlat, presented in the form of a beam, allows you to evenly distribute the load on the walls of a permanent structure. The procedure for fixing roofing material is carried out using several methods. Each of them involves the use of special fasteners. Ankera is no exception. Moreover, the resulting fastening is characterized by increased reliability, strength and durability.

To the roof

The main disadvantage of the technique is the high cost of hardware. But, if you compare the durability and the absence of the need for repairs for several years, the investment pays off. It is justified to use a mechanical fastening method. The option is popular.

Step-by-step instructions for performing the work:

- Waterproofing is first carried out along the perimeter of the walls of the capital structure. This can be roofing felt or other material that protects against moisture and contact between the wall material and the rafter system.

- Subsequently, the Mauerlat is arranged and holes are made in the right places. It is recommended to make the markings immediately on the wooden plank, making it easier for yourself to work in the future.

- The beam is mounted on the anchor. Providing improved strength parameters is achieved by subsequent screwing onto bolts with washers.

Types of anchors for working with brickwork

Today there are many types of these fasteners. They have different purposes, therefore the design of different anchors is different. For example, there are so-called frame anchors, which are used only for attaching windows and door frames to the wall. There are foundation anchors. With their help, metal columns are installed, for example.

Anchors of different sizes are also designed to perform different tasks.

Chemical anchor for hollow bricks and ordinary bricks.

The future strength of the structure we create will depend on the correct choice of the fastening system.

Let's look at anchor systems used for brickwork.

The driven anchor consists of a spacer (sleeve), a bolt and a nut. The spacer part is hammered into the prepared hole. The bolt is screwed into the spacer together with the nut, then the nut is removed. This type of mounting fastener is used for subsequent screwing of hinges or corners using a nut. You can hang shelves, cornices, etc. on them.

There are such types of drive-in anchors as hook bolt, angle bolt, and ring bolt. Their purpose is different from that of conventional bolted anchor fasteners. For example, heavy kitchen cabinets or bathroom water heaters are usually hung on a bolt angle. The ring can be used to hang, for example, wickets or gates in a brick fence.

Scheme for screwing a dowel into a brick wall.

Wedge fasteners are used more often for through fastenings. The wedge firmly holds the attached element on the wall surface.

The so-called MSA. This fastener is made of brass. Like all fastening anchor systems, it has a notch on the outer surface of the sleeve for better adhesion to the inner surface of the hole in the wall material. The maximum internal section of the sleeve is 8 mm. It is intended for fastening not very heavy products and materials to a brick wall.

Visor

The hole for fixing the visor above the entrance is made with a drill. Steel or wooden brackets holding the structure are subsequently secured with anchors.

Important! Construction stores sell special drills for fragile building materials that do not destroy its structure.

Drilling is done carefully and carefully. First, markings are made for the desired height of the visor. There is no need to drill into seam joints. The canopy may collapse.

Anchor products have improved properties compared to other hardware. Provides an increased degree of fixation of heavy objects. This is subject to the purchase of products in specialized construction stores with quality certificates for the existing product. It is important not to skimp on fastening. Such a mistake can be costly.

Features of lightweight brick walls

Walls are hollow for two reasons:

- First : when slotted brick is used for masonry.

- Second : when the walls of a building are lightened by constructing cavities-wells inside the masonry, which are then filled with heat-insulating material. When making well masonry, both hollow and solid bricks can be used, so a variety of anchors may be needed in the work.

Well cavities in brick walls

Well-type masonry consists of two parallel walls connected to each other by transverse diaphragms - which is what we see in the photo above. It is they who perform the role of anchors in this case. Thanks to them, vertical wells are formed, which, in order to increase the thermal properties of the enclosing structure, are filled with either foam insulation or loose insulation.

As an option, concrete-anchor masonry can be performed. What is she?

In principle, this is a type of well masonry, only here cellular or ash concrete is used as insulation. Since it hardens and forms a strong monolith, the means to achieve maximum structural rigidity here is anchor brick.

Anchoring lightweight masonry with bricks

This intriguing name hides the most ordinary bricks, which are laid into a row of spoons with pokes. This is done so that the protruding edges form teeth in the internal cavity of the wall.

During the hardening process of the concrete poured into the wells, the anchor bricks will be firmly fixed in it. In the above picture, even without words, you can clearly see how in this case the anchoring of the brickwork is carried out.