What is PGS

The abbreviation ASG hides a mixture of sand and gravel. Its preparation is regulated by state standard 23735-2014, adopted at the end of 2014. The standards do not apply only to placer, which is used as concrete aggregate.

The scope of application extends to construction work of the following objects:

- installation of temporary road flooring, repair or preparation for asphalt paving;

- leveling compacted base for the foundation;

- compacting embankment for drainage, pit, trench;

Self-embankment without adding cement and water Source poled.rf

- solid concrete filler, the proportions of crushed stone, sand and cement in which determine the casting of certain building structures;

- decorative design of a public area or the courtyard of a private house.

The bulk mixture is represented by minerals of different fractions. Based on this, the following components are distinguished (in mm):

- sand – up to 0.16, from 0.16 to 5;

- gravel – from 5 to 70;

- boulders – from 70 to 150.

There is also a classification based on the percentage of coarse elements:

- Natural materials cannot be further processed after extraction. The amount of gravel is limited to 20%. It is mined in mountains, ravines, lakes, rivers and seas. The first option is relevant for the formation of a dry embankment.

- Enriched after extraction is subject to sorting. The event is aimed at removing sand, adding gravel up to a limit of 90%, eliminating boulders, dust and clay. Additionally, there are 5 groups regarding gravel content (in%): up to 35, 50, 65, 75.

Enriched mixture of minerals Source stroyshans.ru

The choice of ASG is based on the following:

- fraction of constituent minerals;

- percentage of sand, gravel and boulders;

- grain size limit;

- presence of dust, clay particles or lumps;

- bulk density;

- radionuclide activity;

- filtration coefficient.

By density of the embankment we mean the ratio of weight to volume of the mixture without forced compaction. Information regarding filtering is provided at the customer's request. The content of dusty particles for a natural mixture is limited to 5%, clay lumps - 1%. For enriched PGS, 3 and 0.5%, respectively.

How to prepare concrete from ASG

ASG concrete is used in many areas of construction. It is applicable in road construction, drainage construction, and embankments for road surfaces. The option under consideration is often chosen by builders when constructing suburban buildings. Their choice is determined by the composition of such concrete, suitable for constructing a solid foundation for the planned building. But in order to properly prepare such a material, you need to understand what raw materials it is made from and in what ratio the components must be mixed.

Composition of ASG

Sand and gravel mixture is a natural material. It is mined in quarries, or from the bottom of rivers and seas. Based on the content of ASG components, two types are distinguished:

- Natural origin - the amount of gravel containing 10-20%, sand 80-90%;

- Enriched by artificial method - gravel 15-75%, sand 25-85%.

Certain types of ASG belonging to the first group are suitable for the production of concrete, but enriched mixtures are superior to them. In the manufacturing sector, they have a reputation as a filler that is close to ideal, due to the absence of foreign components in the form of dust and clay particles.

Which mixture is suitable for preparing concrete?

If we take as a basis the percentage of gravel particles in the composition, then there are five groups of enriched ASG. The most suitable in construction is the fifth group (contains no more than 25-35% sand). The best option is when the mixture includes stones of different sizes - large, medium and small. Then a high level of strength during the hardening period is achieved, good indicators of the concrete mixture’s thickening, and cement consumption is saved. Determining the specific type of ASG used depends on the project and type of structure:

- Simple concrete work - gravel size maximum 80 mm;

- Production of reinforced concrete structures (not factory type) - gravel with a particle diameter of no more than 30 mm;

- Making foundations - 30-45% sand with a size of 5 mm and 55-70% gravel with a diameter of 5-70 mm.

Concrete composition

In the process of mixing concrete you will need:

- Warm water;

- OPGS;

- Portland cement;

- Shovel;

- Concrete mixer/mixing container.

Which cement to choose

In the production of concrete, which is based on ASG, it is necessary to use Portland cement of grades no lower than M300, with an additive content of no more than 20%. It is possible to use grades M500 or M600. Brand M400 is not suitable in this case due to its rapid setting properties. Its use is not recommended.

Component proportions

The ratio of dry Portland cement and OPGS for preparing concrete mass:

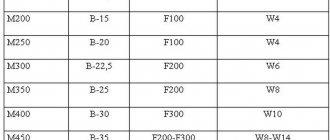

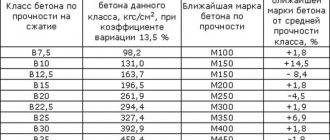

| Concrete grade | Cement/OPGS in liters | |

| Portland cement M400 | Portland cement M500 | |

| M100 | 1:10,2 | 1:12,4 |

| M150 | 1:8,2 | 1:9,8 |

| M200 | 1:6,7 | 1:8,1 |

| M250 | 1:5,3 | 1:6,3 |

| M300 | 1:4,9 | 1:5,9 |

| M400 | 1:3,5 | 1:4,2 |

| M500 | 1:3,2 | 1:3,7 |

Classification of concrete grades according to the purpose of the building foundation:

- Foundations of light outbuildings not higher than one floor - M150;

- Slab foundations in the form of strips for houses no higher than one floor - M200;

- Foundations made of monolith or slabs - M250;

- Monolithic foundations for houses with a height of 2 or more floors - M300;

- Heavy-duty foundations with short setting times - M400.

Preparation of concrete from ASG

Mixing using a concrete mixer: The concrete mixer is started empty and runs for a short time without loading. Next, a portion of the total volume of water is poured into buckets and the entire volume of the ASG is filled. The resulting mass is swirled in a concrete mixer for several minutes. At the next stage, change the position of the mixer and fill in the entire required volume of cement. As mixing progresses, add more water until a homogeneous mass is obtained. Pour the entire available volume of cement and sand-gravel mixture onto a flat surface or a previously prepared container, mix them until smooth. Make a conventional slide out of the mass, dig a hole in the middle, pour water into it and mix thoroughly. The listed options are suitable for people who already have experience working with similar components. If you have no experience, use ready-made mixtures. It is enough to dilute them with water to obtain the desired concrete. After preparation, the finished mixture is placed in formwork and compacted. Compaction is not recommended to be done with a shovel. For the correct result, use a tamper. The time for concrete to gain strength is 28 days. With proper care and proper temperature control, concrete gains 65-70% of its strength characteristics within 5-7 days.

Concrete has found application in various fields of construction. Its main components are: sand, water, cement and gravel. To obtain a high-quality mixture, they must be used in a certain ratio. A serious deviation from the norm will lead to the formation of a low-quality solution that cannot be used for the construction of foundations or other building elements.

ASG concrete is used in many areas of construction. It is applicable in road construction, drainage construction, and embankments for road surfaces. The option under consideration is often chosen by builders when constructing suburban buildings. Their choice is determined by the composition of such concrete, suitable for constructing a solid foundation for the planned building. But in order to properly prepare such a material, you need to understand what raw materials it is made from and in what ratio the components must be mixed.

Selecting a proportion

Technical characteristics and what proportions of cement and sand and crushed stone for concrete are observed determine the quality indicators of the cast structure. Based on this, experts recommend choosing a product from a trusted manufacturer, which accompanies the order with certificates.

For the construction of buildings, it is better to purchase enriched ASG extracted from reservoirs.

The process of extracting river sand and gravel Source time56.ru

There are practically no unnecessary impurities in such mixtures. They can reduce the adhesion of mixture components with cement and additives in the solution, deteriorate the strength characteristics and quality indicators of concrete as a whole. If it is intended to use the material in dry form, then products from the mining industry can be used.

Composition of concrete for the foundation

There are no strict regulations regarding the content of ASG in a cube of fundamental design. However, developers rely on the classic ratio of cement and ASG for concrete:

- 1 part binder (M400-500);

- 8 parts of filler of the fifth group;

- 0.5-1 part water.

The amount of solvent depends on the moisture content of the sand-gravel mixture. As a result, a working composition will be obtained that is close to the standardized concrete M150, which is prepared in the factory. It can be used for the construction of supporting structures for low-rise buildings and outbuildings. And so for casting rough screed, walls, decorative paving stones.

Casting a concrete foundation with ASG Source r24minjust.ru

See also: Catalog of companies that specialize in laying foundations, as well as the production of stoves and fireplaces

Composition of various grades of concrete

ASG concrete is used not only for the construction of foundations. These can be load-bearing walls, piles and columns, road surfaces for pedestrians, vehicles and aircraft, individual structural elements of the building (ceilings, beams, arches). For each object it is important to use a different cement mortar.

Thus, the ratio of sand with gravel and cement in popular grades of concrete is presented in the tables.

Water is added within 0.5-1 parts relative to cement.

| Brand | Proportions for 10 kg of M400 cement (binder component * sand * gravel) | Proportions for 10 kg of cement M500 (binder component * sand * gravel) | |

| 100 | 10*46*70 | 10*58*81 | |

| 200 | 10*28*48 | 10*35*56 | |

| 250 | 10*21*39 | 10*26*45 | |

| 300 | 10*19*37 | 10*24*43 | |

| 400 | 10*12*27 | 10*16*32 | |

| 450 | 10*11*25 | 10*14*29 | |

Proportions of ASG and cement for concrete

The quality of the cement-sand mixture with crushed stone directly depends on the components. At the same time, their ratio, as well as quality, is important. There are construction formulas that are accepted as axioms. They have been developed experimentally and have proven their effectiveness in practice.

This universal formula gives the following proportions:

- OPGS – 4 hours;

- cement – 1 hour;

- sealer – 0.4 tsp.

A binder is a construction term that refers to a liquid used to dilute dry ingredients to give them elasticity. More often, water is used as a sealer.

To measure ingredients correctly, we recommend that you choose the same unit of measurement. For example, count everything in kilograms or liters.

For ease of calculations, the builders compiled the indicators into a table. In it we can see the consumption of cement, cement or crushed stone to obtain a solution of a certain brand.

For example, let's see what we need to mix the M400 brand solution:

- Select the intersection of the corresponding row with the columns. We find that per kilogram of Portland cement M400 you need to take 3.9 kg of ASG.

- The next column shows the consumption of sand and gravel mixture per 10 liters of Portland cement.

- Next we see that from 10 liters of cement powder and the required amount of ASG, 31 liters of concrete will be obtained.

For the purposes of “home” preparation of building mixtures, the universal unit of measure is a bucket. Anything will do: plastic, metal, enameled, colored. The main thing is that it is 10 liters.

Let's learn how to calculate in buckets. At the same time, we will find out how many components are required to mix 1 cube of concrete.

The equation for calculating the amount of cement looks like this: 1000 * 10:31 = 323 liters or 32.2 buckets, and we calculate the ASG using the following formula: 1000 * 35:31 = 1129 liters or 112.9 buckets.

We take all the numbers from the line which brand we want to prepare. In the example, we calculated the dry ingredients for the M400 brand.

If you find it difficult to navigate the tabular figures, you can use an online construction calculator to calculate the amount of materials needed.

Water is calculated individually in each situation. The sand in the mixture can be dry or wet, and the stones can have different porosities. Together, these characteristics affect the final grout consumption.

What is the best thing to do so as not to make a mistake with the volume of water? Just don't add all the liquid at once when mixing. First, it is better to pour 2/3 of the expected volume, and then pour it in parts until the desired consistency of the solution is achieved. So, experimentally, you will determine the optimal consumption of the sealer.

The table we reviewed contains the volumes of starting materials for different grades of concrete. To determine which brand is best, look at where other types are used:

- M150 - for the blind area of small buildings, one-story houses.

- M200 - when pouring bases in the form of strips or slabs.

- M250 – for dense monolithic slabs.

- M300 – for the construction of a monolithic foundation.

- M400 – in the production of ultra-strong concrete structures.

Cement mortar: find out how to mix it correctly

As you can see, it is not at all necessary to prepare a super-strong composition if you need to build a country house or fill a platform for a car.

Making your own concrete

It is not difficult to prepare the solution yourself. To do this, you need to decide on the ratio of cement and sand with gravel for concrete and purchase the necessary materials. It is important to ensure access to drinking or industrial water without impurities.

You will also need the following tools:

- shovel for pouring dry materials or mixing them;

- the bucket is used as a measuring tool and container for water;

- sealed trough or electric stirrer.

Preparation of mortar in a concrete mixer Source klimatlab.com

Recommendations from the experts

It’s easier to get acquainted with the proportions using ready-made tables. There are also online calculators. Without access to the Internet, you can determine the ratio of enriched ASG and cement using an ordinary bucket. The container is filled with a mixture of sand and gravel. Next, the voids are filled with water. The amount of liquid will correspond to the required volume of cement.

For the construction of structures that are subsequently subjected to heavy loads, a reinforcing frame is required. Some novice craftsmen believe that increasing the cement component will have a beneficial effect on the result. However, the recipe is not aimed at saving binder, but at the optimal amount to obtain a high-quality result.

Cracked concrete due to a recipe violation Source rusvoin.ru

How much ASG is needed for 1 cubic meter of concrete?

Let's continue the calculations. From the ratio of the amount of ingredients in the “buckets”, we derive the ASG values in liters and kilograms. This will allow us to find out how much OPGS is needed per 1 cubic meter of concrete.

- Let's calculate how many liters 1 serving takes in total. Let's convert the previously obtained values of the mixture components into liters, and then add them up. 10 (cement) + 63 (gravel) + 5 (grout) = 78 l.

- Let's find out how many servings fit in a cubic meter: 1000 m3:78 l = 12.82.

- Let's calculate the volume of sand and gravel mixture in liters per 1 cubic meter: 63*12.82=807.66.

- Let's convert liters to kg. To do this, multiply the specific density by the volume. 1650*0.80766 = 1332.63 kg.

Anchors for concrete

As a result of calculations, we found out that the consumption of PGS per 1 m3 of concrete will be 807.66 liters (1332.63 kg).

Briefly about the main thing

A mineral mixture mined from reservoirs is used as a filler for concrete.

For loaded structures, an enriched mixture of sand and gravel of group 4-5 is used.

You can find out about the proportions of inorganic components in cement mortar from ready-made tables, use a calculator on the Internet or the traditional method.

The amount of water in concrete should not exceed 20% of the total mass. You can focus on 0.5-1 part, similar to the binder.

Exaggerating the dose of cement leads to a decrease in the quality characteristics of the finished structure.

Ratings 0