Dismantling the foundation. Methods and mechanisms

Our company has at its disposal many types of special tools and equipment, with the help of which work on dismantling the old foundation of a house or cottage is carried out in a matter of days

- It is often possible to dismantle an old brick foundation using high-power manual jackhammers and without the need to involve heavy special equipment. In this case, the cost of dismantling the foundation will be significantly lower.

- We can demolish a strip concrete foundation using an excavator. The destruction of the foundation is carried out with a bucket, and the reinforced base is cut with a grinder. In special cases, the use of a hydraulic hammer is required - a special attachment on the excavator boom.

- It is impossible to remove a foundation made of concrete piles, and even with a concrete tape around the perimeter, without using a “hydraulic hammer”. In the same way, a buried foundation is dismantled. We load all the broken concrete into dump trucks and remove construction waste from the site. At the request of the customer, the hole formed after dismantling the foundation is filled with leveling soil, and the surface is leveled. Filling the area with soil is an additional service and is calculated separately.

Methods for dismantling strip foundations

The strip foundation can be dismantled in several different ways. A number of professional tools are used for this work - it can be a hydraulic hammer or a jackhammer. It all depends on the strength of the foundation.

Parsing methods:

- Dismantling with a hydraulic hammer - this tool is an attachment to the excavator boom. It works on a similar principle to a jackhammer. It is used for grinding bricks and concrete. After this procedure, concrete fragments are loaded into the back of a dump truck and removed from the territory;

- Dismantling with an excavator bucket - this method for dismantling a strip foundation is rarely used;

- Dismantling with jackhammers - this method is used if it is impossible to use equipment (access to the site is difficult, limited space around the foundation). Using jackhammers, the foundation is crushed into small fragments. Such work requires time and the use of physical force, so it is more expensive than using heavy equipment.

Dismantling a strip foundation can take from one to three days, depending on the complexity. In addition to the listed tools, hydraulic shears (the most modern method), diamond cutters, sledgehammers and crowbars can be used.

A strip foundation is much easier to dismantle than other types of similar structures. The thickness of the product in rare cases exceeds 50 cm. The work may become more complicated if the structure contains reinforcement or channels.

How much does it cost to dismantle a strip foundation?

Dismantling a strip foundation is a labor-intensive job that requires high competence and experience from the workers performing this task. Many activities will require special equipment.

Prices

Type of work performed Cost, rub

| Foundation demolition no more than 6x6 meters | from 35,000 rub. |

| Dismantling the foundation no more than 8x8 meters | from 45,000 rub. |

| Removing the foundation no more than 10x10 meters | from 55,000 rub. |

| Demolition of foundations larger than 10x10 meters | Calculated individually |

| Garbage removal with a 10 cubic meter dump truck. | From 8000 rub. per flight |

| Garbage removal with a 20 cubic meter dump truck. | From 14,000 rub. per flight |

A preliminary calculation of the cost of dismantling is carried out according to the data provided by the client. After the engineer visits the site, the final price is determined. It includes the complexity of the work, the area of the foundation, its strength, and the use of special equipment. The price may be influenced by the distance of the object from the city, the complexity of the entrance, the presence of other houses nearby (building density), the method and the chosen method.

Breaking, not building, or dismantling the old foundation

When construction is carried out on an empty site that has not been subject to pre-development, no additional difficulties arise.

Things are different if there is an old building that needs to be demolished.

Dismantling walls is usually quite simple, but dismantling the foundation can be difficult.

Most often, amateur builders know how to dismantle only the formwork after pouring the foundation, and not how to dismantle it completely.

This work is labor-intensive and, so as not to waste extra effort and time, it is better to do it in a certain sequence.

Therefore, to properly dismantle the old foundation, it is necessary to draw up a technological map.

In the case where the use of special equipment or blasting is not required to break the old foundation, dismantling is done manually.

First of all, to simplify the process as much as possible, you need to acquire the necessary tools.

It is not very convenient to buy more on the go, as this will lead to unnecessary time spent on trips to hardware stores and, as a result, will slow down the process of dismantling the foundation.

Not every type of base can be disassembled manually. As a rule, they dismantle the strip foundation on their own. To do this you need to have on hand:

- • jackhammer,

- • scrap;

- • hammer drill;

- • sledgehammer;

- • diamond cutter.

We suggest you familiarize yourself with the Foundation on clay, what kind of foundation to build on clay - Stroyfora

If possible, it is very convenient to rent a hydraulic hammer, which can easily deal with even high-grade concrete.

Typically, such a tool is provided by construction companies or large stores that have a department that deals with rentals.

If you need to minimize the cost of work, you can do without a hydraulic hammer.

When it is necessary to dismantle a monolithic concrete foundation, using a tool is not the best solution, since due to the special strength of the structure it will quickly become unusable. In such a situation, the most reasonable solution, of course, if there are no buildings nearby, would be to carry out blasting operations. To do this, they attract craftsmen who have the appropriate licenses.

Dismantling methods

Before proceeding directly to dismantling the foundation of the house, it is necessary to choose the optimal method in a particular case. The number of them is quite large, and each one is worth considering.

The most popular and, moreover, the most difficult in a physical sense is manual demolition.

The cost of such foundation dismantling is noticeably lower than with other methods.

True, the hydraulic equipment used in this case requires a lot of electricity to operate, which should be taken into account when drawing up estimates.

When choosing this method, you need to pay attention to the fact that it is more suitable for a strip base. It is good to use manual disassembly when dismantling a brick foundation, when it is also desirable to preserve as much building material as possible.

Exploding the old foundation is the most effective way to dismantle the foundation, but its price is very high. In this case, the time required to complete the work becomes minimal.

However, explosive materials can only be used if there are no buildings nearby that could be damaged during the explosion. All necessary calculations are made by professionals.

Good results are also obtained by a method such as a hydrocline, in which water is supplied under very high pressure into pre-drilled shafts in the foundation. As a result, the structure develops cracks and splits.

Ultrasound is also used for dismantling. To do this, ultrasound waves are sent into pre-made cavities, under the influence of which the unnecessary structure is destroyed.

The prices for such foundation dismantling are high, since in this case expensive special equipment is used.

In addition to all of the above, there is a method in which special compounds are used.

They, after being introduced into the base through specially made holes, provoke its significant destruction after forty-eight to fifty hours.

This method is usually called non-explosive.

The technology for this method of dismantling the foundation is not very simple, so carrying out the work yourself would be a mistake.

In the case where it is necessary to dismantle the pile foundation, any of the above methods are used. If the piles are screw, after removing the grillage they are unscrewed.

Pile foundation

Dismantling a pile foundation

The pile foundation is dismantled as a last resort, for example, when laying new underground communications. Piles help strengthen soils with weak bearing capacity and there is usually no need for their dismantling.

Use a grinder to cut off the top of the pile foundation and you’re done.

How is a country house dismantled and garbage removed?

Next, the dismantling of the dacha on the summer cottage occurs logically:

- The roof is being dismantled.

- Then we disassemble the walls, door and window openings.

- We saw and disassemble the floors.

- Finally, we dismantle the stove.

- We load all construction waste into a container and transport it to the landfill. Or, at the customer’s request, we store it in the garden for further use.

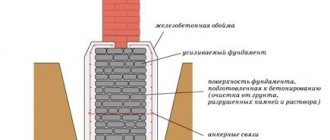

Reinforced concrete foundation

The old concrete base is considered the most difficult to work with. Even a foundation that has stood for decades is very difficult to break. This is due to the structure of the concrete itself, consisting of a mixture of cement, sand and natural stones of the middle fraction - crushed stone, and the presence of steel reinforcing rods with a diameter of 10-12 mm in the frozen mass.

There are several main types of monolithic foundations. In construction you can find strip concrete foundations of one or another depth and slab foundations. The technology for dismantling them is the same.

Reinforced concrete foundation: scheme and implementation

Before breaking a concrete foundation, it is necessary to study all possible methods of dismantling it. They are divided into mechanical, manual power and physical, using the laws of physics. Some of them are more expensive, but allow you to remove the old foundation in a matter of hours, others do not require finance, but their implementation will take from several days to several weeks.

Mechanical methods for dismantling concrete

In order to make it possible to break a concrete structure, the following types of mechanical assistants are used:

- Excavator with a set of hydraulic attachments (scissors, drill, jackhammer, hydraulic hammer). With one machine, you can remove the soil around the foundation, break the foundation into pieces, load them into trucks and fill the resulting trenches with soil.

- A hydraulic wedge is specialized equipment used to break rocks and break concrete foundations. The device uses the ability of a liquid to transmit pressure applied to it in all directions evenly.

- An ultrasonic emitter allows you to break concrete foundations by exposing them to high-frequency sound waves reaching 100 MHz.

- Diamond cutting with disk or cable cutters allows not only to break the foundation into separate parts, but to obtain them of the correct geometric shape for further use in construction.

Manual dismantling of a concrete base

If you don’t want to spend your own money on work that you can do yourself, we’ll tell you how to break a concrete foundation on your own. For work, prepare:

- shovel;

- construction chisel (differs from a metalworking chisel by a much larger length);

- sledgehammer;

- perforator;

- grinder;

- wheelbarrow

We begin the work by digging in the concrete base so that it can be easily accessed along the entire perimeter. We remove the soil and put it in a dump nearby, since it will later be useful for backfilling the trench.

Carefully inspect the surface of the foundation for cracks. It is more convenient to start work from them. If you have a hammer drill, you can drill many holes arranged in rows in the transverse direction. After this, installing a pointed bit to make it easier to break the concrete, we break off the foundation in pieces.

It will not be possible to break steel reinforcement with a hammer drill. For this purpose, we cut the previously released rods with a grinder, observing safety precautions. Be patient, as it will not be possible to quickly remove the old foundation from the site manually. Small pieces of concrete base can subsequently be used as rubble stone when making a new foundation, installing a fence, etc.

How to break an old foundation with your own hands

Home >> Foundations >> Destroy the foundation and destroy the concrete

It would probably be more correct to address this article to everyone who is planning to build something, but oh well, I’m more used to it this way, because I think everyone has built something at least once in their life, but as a rule, before building something, you need to remove or break something, well, one in a word, free up the site for new construction.

The story will be short, we will talk about how to destroy a concrete foundation or any monolithic concrete structure that has already served its purpose and is interfering with your future plans due to its location.

About 15 years ago, I was invited to advise on how to remove an old and quite powerful foundation from under equipment on the territory of a working oil refinery, and close to the equipment working around the clock. You understand that it was impossible to explode; there was no technology as powerful as it is now. And the foundation was simply wonderfully good, it was even a pity to break it, although it was built in the 30s of the last century, when chiseling, sparks flew out, the peaks for jackhammers became dull within 10 minutes. This is how they could build at that time.

I asked for a couple of days to think about it and began to rummage through my database and imagine I found a way out of the situation. Back then, not everyone was comfortable with computers; I had just begun to master them myself, so I kept everything in paper form.

Of course you will say that now there are plenty of opportunities to destroy the foundation. In general, you will be right, there really are hydraulic hammers, diamond cutting and other equipment, and there are companies that provide these services, but firstly, this cannot be applied everywhere (for various reasons, remoteness, no access to equipment, etc.) , secondly, all this is very expensive. In general, read on. What are the options.

I found in my library that the chemical NRS-1 is produced in the Moscow region. They still produce this product called SIGB, here is their website https://www.sigb.ru/sigb.php. I will briefly describe what it is.

NRS-1 (non-explosive destructive agent of the first modification) and it is intended for the destruction of mainly concrete and reinforced concrete monoliths, but can also be used for other durable structures. This product is a powder, non-flammable and non-explosive. When mixed with water, a working mixture is formed, which, when poured into the cavity (borehole), significantly increases in volume, creating pressure on the walls. A stress is created in the massif that exceeds its ultimate tensile strength and the massif collapses with the formation of cracks. I will not go far and deep into the theory.

This is the technology I used to destroy the foundation of an operating oil refinery.

The most difficult thing was drilling the holes, the administration allocated 5 workers with powerful hammer drills, in a week they drilled the holes (the optimal diameter is approximately 30 mm), the diagram of the holes is shown in the figure, during this time they brought NRS-1 powder and I started work.

I prepared the working mixture as follows. Water is poured into a clean container (for example, a bucket), after which the powder is gradually poured into it with continuous stirring at the rate of 270 ml of water per 1000 g of powder. The mixing time of the mass should not exceed 8-10 minutes.

The holes were filled with working mixture to the mouth. I must say that the use of NRS is effective at temperatures from +2 to +30 degrees Celsius. The higher the wall temperature, the colder the water should be.

A day later we got the result as in the picture, half the plant came running to look at the “consequences” of our work. True, where the reinforcement was, it was necessary to cut it with a special tool. I must say that this “pleasure” is not cheap, I don’t remember how much it cost then, but now 1 kg of such powder costs about 120 rubles/kg. The whole process to destroy the foundation took us 1.5 tons, but the company is rich, and they had no other choice. You can view this technology in more detail on the website I indicated above.

Also watch a video on this topic

Of course, I understand that it is not always advisable to use such an expensive technology, but let it be in your database, just in case it might come in handy. Special equipment for performing similar work can always be found on the Internet, there are no problems, but all this is very expensive today.

But what to do if, as they say, the budget is limited or if access to equipment is impossible. Here are some tips from my experience.

1 I did this several times, when I didn’t have a hammer drill and a jackhammer at hand, you need to take a blowtorch and heat it in the place where you need to break the foundation, and then pour water on it. An excellent way, concrete or stone begins to crack on its own and all you have to do is finish it off.

2 We use the “weak” side of concrete, low bending and tensile strength. We drill a hole or several, no more than 200 mm from the edge of the foundation, insert a jackhammer PIC into the hole (as in the picture), it is better to weld a rod to the peak to make it easier to hold and work with a sledgehammer, this is even better than a jackhammer. Instead of a pike, you can order a new pike from a turner, from ordinary metal, from a rod with a diameter of 30.0 mm, just make the pointed (conical part) longer, approximately 150.0 mm, then the impact force will be less and the concrete will be destroyed better. I think you understand me. 3 You can use a scarpel, as in the picture, and work with a sledgehammer, breaking off pieces of concrete piece by piece, but in this case holes are still needed.

4 There is another old ancestral method (by the way, it was used in ancient Egypt), you need to drill holes (preferably with a diameter of 30.0 mm) along the chip line, insert, or rather drive in wooden plugs (the plugs should fit very tightly into the holes) from dry wood (the wood should be taken from a hard type and preferably from the core of the tree, you can also use birch) and soak them in water (when wet, the wood increases in volume by about 15%) when a crack appears, you can use the methods described above. This method is especially good if the concrete monolith already has large holes; when the wood is impregnated with water, it develops colossal forces and tears any concrete, including any natural materials including granite.

It is better to impregnate wooden corks in this way. Place an ordinary plastic disposable cup of water on top of the driven cork, having first pierced a hole in the bottom with a needle or small nail (this is so that the water gradually saturates the wooden cork with water). In about 10 hours you will see that your foundation will be covered with cracks.

Approximately like this. All the methods described above are applicable to any other materials, including those of natural origin. Well, that’s probably all, although they say “breaking is not building,” but sometimes breaking is not easy. If you have any other options, write, I will be very interested and I will certainly add them to this post.

Dear colleagues, on my website there is a lot of interesting information besides concrete, so I recommend that you look at other materials about some unique, in their own way, technologies for the production of building materials:

2 Expanded vermiculite and perlite - today, these are new opportunities for production and business.

3 Sulfur concrete and sulfur asphalt are unique technologies and equipment for their production.

4 Cellular concrete - which is better? We choose the best option. The best and inexpensive option for technology and equipment for the production of building blocks from non-autoclaved aerated concrete

5 Polystyrene concrete non-combustible blocks for construction using the method without formwork construction.

Well, on this optimistic note, let me end, click on this link and look at other interesting materials on my site.

Dismantling secrets: how to remove the old foundation

Often, when purchasing a plot of land or inheriting it, you end up with a dilapidated house that can no longer be used. And if breaking the upper part of the structure does not present any special difficulties, then in order to remove the old foundation of the structure, you will have to suffer quite a bit. Not everyone knows how to remove the old foundation. Today we will talk about this.

The abundance of different types of foundations for a house or outbuilding does not imply the use of one universal method of dismantling. Let's look at the main types of foundations and how to destroy them using mechanical devices or on your own.

The simplest option for both installation and dismantling is a brick columnar foundation, which consists of several separate supports partially buried in the soil and protruding above it. It is made by laying it on a cement-sand mortar. Sometimes reinforcement is placed in the seam for strengthening.

Columnar brick foundation: diagram and implementation

In order to be able to break such a foundation, it is enough to have a construction chisel and a hammer or sledgehammer, since removing the foundation of such a structure is not difficult. The main task is to break the masonry joint. To do this, just place the chisel on the seam and hit the striking part several times. This way you can gradually break each old column.

Difficulties may arise when working with the underground part. To facilitate the process, you will need a simple bayonet shovel, which is used to dig around the perimeter of each foundation to the very foundation. After this, you can continue working. After removing all the supports, all that remains is to level the site as it was and you can use it at your own discretion.

The next type of foundation that should be discussed in detail is a foundation on piles. The latter are cylindrical supports that are screwed or driven into the ground. Sometimes, to strengthen the pile caps, they are connected by a common bond made of wood, metal or concrete - a grillage.

They begin to break such a foundation by dismantling the top trim. The wooden and steel grillage is attached to the piles using bolts or welding. In order to conveniently remove such connections, you will need a grinder with a metal disc. It is used to cut off bolt heads or welding seams. How to break up a concrete grillage will be described in more detail below in the section on how to remove the old strip foundation.

Pile foundation with grillage: diagram and implementation

If a problem arises, how to break a foundation on piles, carefully read this paragraph. Steel screw piles are buried into the ground by screwing them in manually or using specialized construction equipment. It is also not difficult to remove them from the soil. It is enough to drill a through hole in the pipe of the old support, insert a piece of pipe of suitable diameter about two meters long into it and unscrew it, rotating counterclockwise.

The situation is more complicated with the process of removing driven piles, since it was only possible to remove the foundation from the site on such supports using special equipment - a truck crane or an excavator. Renting such equipment with a driver will cost a certain amount. You cannot cope with such a difficult task on your own.

The old concrete base is considered the most difficult to work with. Even a foundation that has stood for decades is very difficult to break. This is due to the structure of the concrete itself, consisting of a mixture of cement, sand and natural stones of the middle fraction - crushed stone, and the presence of steel reinforcing rods with a diameter of 10-12 mm in the frozen mass.

There are several main types of monolithic foundations. In construction you can find strip concrete foundations of one or another depth and slab foundations. The technology for dismantling them is the same.

Reinforced concrete foundation: scheme and implementation

Before breaking a concrete foundation, it is necessary to study all possible methods of dismantling it. They are divided into mechanical, manual power and physical, using the laws of physics. Some of them are more expensive, but allow you to remove the old foundation in a matter of hours, others do not require finance, but their implementation will take from several days to several weeks.

In order to make it possible to break a concrete structure, the following types of mechanical assistants are used:

- Excavator with a set of hydraulic attachments (scissors, drill, jackhammer, hydraulic hammer). With one machine, you can remove the soil around the foundation, break the foundation into pieces, load them into trucks and fill the resulting trenches with soil.

- A hydraulic wedge is specialized equipment used to break rocks and break concrete foundations. The device uses the ability of a liquid to transmit pressure applied to it in all directions evenly.

- An ultrasonic emitter allows you to break concrete foundations by exposing them to high-frequency sound waves reaching 100 MHz.

- Diamond cutting with disk or cable cutters allows not only to break the foundation into separate parts, but to obtain them of the correct geometric shape for further use in construction.

If you don’t want to spend your own money on work that you can do yourself, we’ll tell you how to break a concrete foundation on your own. For work, prepare:

- shovel;

- construction chisel (differs from a metalworking chisel by a much larger length);

- sledgehammer;

- perforator;

- grinder;

- wheelbarrow

We begin the work by digging in the concrete base so that it can be easily accessed along the entire perimeter. We remove the soil and put it in a dump nearby, since it will later be useful for backfilling the trench.

Carefully inspect the surface of the foundation for cracks. It is more convenient to start work from them. If you have a hammer drill, you can drill many holes arranged in rows in the transverse direction. After this, installing a pointed bit to make it easier to break the concrete, we break off the foundation in pieces.

It will not be possible to break steel reinforcement with a hammer drill. For this purpose, we cut the previously released rods with a grinder, observing safety precautions. Be patient, as it will not be possible to quickly remove the old foundation from the site manually. Small pieces of concrete base can subsequently be used as rubble stone when making a new foundation, installing a fence, etc.

In addition to the listed forceful methods of influence, there are several methods that were used in ancient times and appeared relatively recently. The first uses the pressure force of wood when it swells. The method is not quick, the first results will be noticeable after 10-12 hours. It is better to use it together with subsequent power, since it will not be possible to completely remove the old foundation in this way.

To carry it out, wooden cylinders are driven into pre-drilled holes in the concrete. You can use cuttings of birch cuttings for shovels or carpenter's dowels. A plastic cup with a hole in the bottom is attached to each of them and water is poured into it. The principle of operation is based on the gradual swelling of wood and its expansion of layers of concrete. In Ancient Egypt, megaliths for the pyramids were broken using this method.

The second method appeared in the 80s of the last century. It consists of using an expansion of certain chemical compositions. On sale you can find non-explosive expanding materials of the brands NRV-80, NRS 10, which are fine powders.

To prepare the working solution, the substances are diluted in water in a certain proportion and poured into pre-drilled holes in rows. After some time, the concrete can be easily broken into pieces. This method is convenient from the point of view of preserving the peace of neighbors, since it is very rare to break an old foundation without noise.

Safety precautions during dismantling

Before starting to demolish a structure, you need to fence off the demolition area and prevent strangers, especially children, from being near it.

The work is carried out from 9 am to 10 pm, and it is worth remembering that in some regions it is prohibited to make noise on weekends (Saturday, Sunday).

People who will do the dismantling must wear the following protective clothing:

- protective overalls or suit made of thick fabric;

- closed shoes;

- a headdress in the form of a helmet (when it comes to demolishing a high brick or concrete fence);

- work gloves;

- safety glasses or mask (if you need to work with a welding machine);

- respirator (needed in rare cases when dismantling brick sections).

Each stage of work is carried out with increased care to avoid causing injury to yourself or others.

It is worth doing everything carefully, especially if you need to keep the material from the old fence intact.

Features of dismantling different types of foundations

The technology for dismantling the foundation depends on its material and depth of location. Much also depends on whether heavy equipment can access the site.

The columnar (or pile) foundation is usually dismantled along with the country house. If we are talking about houses built several decades ago, the foundation must be removed. After all, over time it begins to deform and lose strength. You can leave the foundation if you have to dismantle a new building that has survived a fire. In such situations, the foundation usually retains its properties and can be used for re-construction.

Columnar foundations are most often dismantled manually using a sledgehammer and a hammer drill. The exception is when the foundation of the house is additionally reinforced with concrete, or is located deep underground. In such situations, you have to use a wheeled tractor with a hydraulic hammer. If it is impossible to approach the foundation, a manual concrete breaker with a compressor is used.

So the foundation is gradually dismantled using sledgehammers

Strip foundations - concrete and brick - are not dismantled manually; this is too difficult and time-consuming work. Therefore, to dismantle them, a wheeled excavator with a hydraulic hammer and a bucket is used. This technique allows you to crush the foundation into a small fraction and then dig it out of the resulting trench. Garbage is removed by flatbed dump trucks.

The excavator allows you to simultaneously destroy the foundation and quickly load garbage

Monolithic reinforced foundations (with reinforcement inside) or consisting of concrete slabs, if their area is small, can be destroyed using a wheeled tractor with a hydraulic hammer. For large volumes of work, more productive heavy tracked equipment is used.

Manual labor is used to dismantle any foundation. It is necessary for separating reinforcement from concrete, sorting and cleaning construction waste.

Additional description of some dismantling methods

To make it easier, foundation dismantling is usually carried out using large, heavy construction equipment. This method allows you to complete the work in the shortest possible time and does not involve physical exertion. If there is no equipment, you can use the manual method, which is ideal for dismantling the pile foundation.

Hydraulic equipment can help with the work, but its operation is accompanied by the consumption of a large amount of electricity. The use of this technique will not cause harm to other buildings. Using a hydraulic hammer, you can break any reinforced concrete structure.

Dismantling the old foundation can be done using the most modern technology, which involves the use of hydraulic shears. Their working surface has a diamond coating. If desired, the instrument can be rented by contacting specialists from stores with the appropriate products. This approach is convenient if the work is one-time. When several permanent buildings or commercial structures are to be dismantled, the optimal solution would be to purchase special equipment.

Selecting a dismantling method

Dismantling various foundations begins with choosing the appropriate technology. There are several of them, and in order not to make a mistake, you need to pay attention to the following parameters:

- Type of foundation, depth of its occurrence.

- The presence or absence of reinforcement.

- Condition, type of soil.

- Features of groundwater.

- The level of wear of the base material - concrete, brick or other. Its type also matters.

- Design features that could have been made specifically for it.

If you consider all these points in detail, there will be no problems with choosing the right dismantling method. In most cases, they agree to either the manual or mechanical method, but sometimes even they, with all their advantages, are not suitable. Read more about each method below.

Recommendations for working with strip foundations

Dismantling a strip foundation is easier. This is due to the fact that the thickness of the base in rare cases exceeds 50 cm. For disassembly it is recommended to use:

- diamond cutter;

- perforator;

- sledgehammer;

- scrap;

- jackhammer.

Additionally, the use of special equipment for strip foundations will only be necessary if the structure was built using thick reinforcement, the diameter of which exceeds 30 mm. This also applies to cases where there are channels inside the structure.