During construction, the question arises of how to attach wooden sheathing to a brick wall, as well as timber and other wooden elements. For this, anchors, dowels, and cement mortar are used. The option for fixing wooden elements depends on what function they will perform and how much weight needs to be supported. The moment of installation is also important: during construction, the boards go into the walls, and then they are attached to it.

General recommendations

To choose the type of fastening, take into account what material the walls are made of, their thickness, and also what load they will withstand.

Using a drill, carefully drill a hole in the brick wall. While working, try not to expand it so that the brick does not crack. A dowel is inserted into the opening, which, when screwed, will curl into a knot and securely lock. This option is suitable for hollow brick. Next, a self-tapping screw will be screwed into the dowel. If the beam must withstand a large load, then it is better to use an anchor.

Methods of fastening to a brick wall

Soft method

This method is easy and quick to use, but unreliable - it is not suitable for heavy loads. But it is used for decoration and sheathing. This method can be used without the help of others, since it does not require construction skills. If you follow the instructions, the result will be satisfactory.

To perform fastening, you will need U-shaped metal brackets. They are fixed to the brick at a distance of 40 cm. At a level of half a meter from the floor, a 60 cm indent is made between them. The more fastenings, the more firmly the board holds. This will avoid deformation of the cladding. Under mechanical stress, the timber becomes loose and the structure is damaged. Therefore, be careful when working.

Hard method

This method is durable, reliable and will allow the structure to last for a long time. A hole is made in the brick into which a wooden plug soaked in glue is driven. A nail is driven through the beam into the cork. This method allows you to securely fasten the sheathing and prevent its deformation. It is designed for light load.

Other methods

Attaching timber to a brick wall is possible in other ways. To attach hanging furniture, the board is applied horizontally to the wall and secured using self-tapping screws, nails, and screws in the prepared openings. To ensure that the lockers can withstand the load, there are many attachment points. For partitions, the same rules are used, but they are fixed vertically. The timber should be secured with anchors for structures with heavy loads. This method is suitable for the door frame and roof canopies above the door.

The installation of timber for an extension occurs during the process of placing the end of the beam into the masonry. To do this, make a corresponding opening in the wall. But this is possible with a thick wall of one and a half bricks. If this is not the case, then the design will be end-to-end, which is unacceptable. In this case, you will need to use a support beam. It is attached to anchors, maintaining a distance of 30 cm. After which the beam is attached to the tree using metal corners and self-tapping screws.

Attaching a beam to a wall cannot be called the most difficult operation carried out during construction and repair work, but it requires care and strict adherence to all recommendations and existing rules.

Such manipulations are necessary when installing interior partitions, installing household appliances, or implementing design projects.

There are many ways to attach wooden beams to walls, and each manipulation must be performed using certain fasteners. Their choice depends on the quality of the foundation and the upcoming load.

How is timber attached to a brick wall?

During the construction of a house or its renovation, a situation often arises when it is necessary to attach a beam to a brick wall. In one case, it must carry a fairly serious load, in the other, it must serve only as a frame into which some kind of facing material is attached, for example, siding on the outside of the building or plasterboard on the inside. For those who know installation technology, attaching wooden beams to brickwork will not be a big problem.

When installing timber to a brick wall, you need to take into account the properties of the structure, parts, as well as the method of fastening.

Where is this type of connection used?

The scope of application of units where wooden beams are adjacent to a brick wall is extremely wide. Most often this type of connection is used for the following purposes:

- secure furniture, household appliances or interior elements;

- for installation of wooden partitions;

- to place doors in the opening;

- for internal or external insulation, where the sheathing of bars plays the role of a frame;

- to hang a canopy over the entrance to a house or in another place;

- for the construction of an extension to the building (vestibule or veranda).

Scheme of fastening the timber using the soft method using staples.

When it is necessary to fix interior items on the wall, a wooden beam is applied flat to the surface and fixed with fasteners. So it is able to carry a significant load. The greater the magnitude of this load, the more attachment points to the brickwork must be provided. The same rule applies when installing a partition, only the starting beam is installed vertically.

The door frame is constantly experiencing dynamic loads, so it is secured to the brick with a particularly reliable type of fastening elements: anchors. They are also used when installing various canopies that experience snow and wind loads.

When insulating brick walls externally or internally, a sheathing (frame) is assembled from the bars, which is the basis for installing the cladding: vinyl siding, drywall, plastic panels and other materials. In this situation, the tree experiences minimal mechanical stress, which is why it can be fastened with dowels for quick installation.

To build an extension, a reliable structure is required that can support the roof with all the ensuing consequences.

In this case, the wooden beams act as load-bearing beams and are adjacent to the brickwork at an angle of 90°. There are several ways to successfully rest them on a brick and securely fix them.

Flat installation on masonry

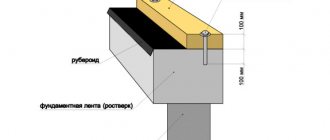

Scheme of attaching an anchor to a brick wall.

To install the beams on a brick wall with a full fit along the plane, you need to prepare the following tools and materials:

- electric drill;

- hammer-in dowels with plastic plugs;

- drills and drills with a diameter corresponding to the size of the dowels;

- hammer;

- measuring devices;

- pencil.

First of all, you need to make a marking, determining the position of the block on the wall, and outline it with a pencil. Then mark on the surface of the timber the places for drilling holes, which should be at a distance of 20-30 cm from each other. Further actions are performed according to the algorithm:

- Select a drill according to the diameter of the plastic insert for the dowel and drill holes in the block.

- Take a drill whose diameter is twice the original and make indentations so that the fastener heads go into the “sunk hole”.

- Attach the block to the designated location on the wall and apply markings to the brick through the prepared holes.

- Place a drill bit in a drill and drill blind holes in the brickwork. Place the timber, insert plastic plugs and nail it with dowels.

Some types of special fasteners.

The length of the dowels must be selected so that they plunge into the wall by at least 50 mm. If the load is significant, then the distance between the attachment points is made smaller (10-15 cm), and the recess into the wall is larger (80-100 mm).

Fastening to anchors is carried out in the same order, the difference is in a more careful selection of the diameter of the drill and careful drilling.

If the hole is too large, the shank of the fastener will rotate inside and it will not be possible to tighten the anchor.

Methods of performing work

In modern construction, high-quality fastening of wooden beams to walls built from various materials is often a necessity. Such work is performed for:

- strengthening structures;

- installation of new frames;

- construction of partitions;

- construction of light extensions;

- assembling designer furniture.

The timber is used to create lathing, a frame for cladding facade or interior walls, and securely fix furniture structures, household appliances or electronics. High-quality work makes it possible to create a structure that can withstand increased loads, decorate a room, or carry out a long-planned redevelopment.

Mounting options

To get the job done efficiently, use several fastening methods:

The simplest is considered to be soft, since to implement it you will need to attach special brackets made of metal and having a U-shape to the wall surface. The distance between them should not exceed 40 cm. The brackets themselves should be securely fastened, and a wooden beam can already be fixed to them.

Before choosing a fastening method, it is necessary to accurately calculate the upcoming load and clarify the features of the base.

The rigid fastening method requires the use of a variety of fasteners, which are chosen depending on what material the wall is made of. It can be:

- self-tapping bolts;

- dowel nails;

- anchor bolts;

- plastic or metal dowels.

The degree of complexity of the work depends on the quality of the walls, but all experts recommend fastening the wooden beams using a rigid method, as this will avoid further deformation of the assembled frame.

In most cases, it becomes necessary to attach the timber to a brick wall. It is important to know some of the features and nuances of the process in order to achieve the desired result.

In what cases is it necessary to fasten the timber to the wall?

Fastening timber to brickwork is a fairly common construction operation that may be required in the following cases:

- When fastening various structures and interior elements.

- When performing redevelopment.

- During the process of insulation or cladding of the facade, in this case it is necessary to fasten the wooden sheathing to the brick wall.

- For installation of canopies and canopies adjacent to the house.

Below we will consider in detail how the timber is installed.

Installation of wooden sheathing

Attaching the timber to the wall is done in different ways. In this case, the following parameters must be taken into account:

- wall material and decoration (aerated concrete, concrete, plastered, brick, plasterboard, etc.);

- beam section;

- the weight and scale of the structure that the beam must support.

These parameters determine which tools and fasteners need to be used to secure the beam to the wall. The following can be used as fastening elements:

- screws;

- nails;

- self-tapping screws;

- anchor bolts;

- metal and plastic dowels;

- U-shaped brackets;

- metal corner;

- wooden cotter pin.

Secure the timber to the concrete wall

Before attaching a beam to such a wall, it is worth assessing its dimensions, as well as the weight of the structure that it must support. If the beam is small and the structure is quite light, you can use technology using gypsum or alabaster mortar:

- a screw of the required diameter is tightly wrapped along its length with wire (it’s good if it’s copper);

- prepared holes in the wall must be filled with gypsum or alabaster mortar;

- quickly, without waiting for the solution to set, it is necessary to screw a screw wrapped in wire into the hole;

- after 10 minutes, when the solution has set but has not completely dried, carefully unscrew the screw;

- After the solution has dried, use this screw to secure the beam.

For more reliable fastening of powerful structures, this method is better suited:

- In the places of intended fastening it is necessary to drill holes (0.5-1 cm in diameter). To drill concrete walls, you need to use diamond-coated drills, carbide drills or pobedit drills.

Attention! To make quality holes, you need to cool the drill from time to time by immersing it in cold water for a few seconds.

- Pre-prepared wooden plugs of suitable diameter must be impregnated with glue. Do not use water-based glue, otherwise the cork will become deformed and swell.

- Drive the plugs into the drilled holes using a hammer.

- Wait until the glue is completely dry.

- The timber is attached to the wall using screws (they are screwed into the plugs).

To ensure that the fastening of the timber to the concrete wall is as strong and reliable as possible, it is better to use anchor bolts.

Fastening timber to a brick wall

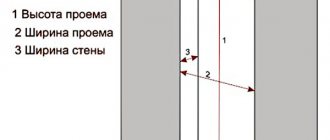

Attaching timber to a brick wall has some peculiarities. Before attaching the timber, you need to make holes in the wall in the places where the fasteners should be located. Holes in a brick wall must be made with a drill or drill bit with a Pobedit, carbide or diamond-coated tip. In this case, it is not recommended to use a hammer drill, since brick is a rather fragile building material. It is important to take into account the unevenness of the brickwork, therefore, before attaching the timber to the brick wall, it is worth taking measurements and making preliminary markings.

It is recommended to fasten structures that are light in weight using plastic or metal dowels. Before attaching the beam to a brick wall with dowels, it is worth assessing the weight of the structure. The heavier the timber, the correspondingly longer the fastenings will be. To ensure the strength of the fasteners, the dowels are coated with construction glue before installation.

The frequency of fastening placement directly depends on the cross-section of the beam: in the case of a cross-section from 2.5 to 4 cm, it is necessary to place fasteners at a distance of 0.6 m from each other, with a cross-section of 4-6 cm, the distance between fasteners is 0.7-0.8 m. To attach a beam to a brick wall in order to hold a weighty structure, it is better to use anchor bolts - this method is considered the most reliable.

Fastening a wooden beam to a wall made of aerated concrete blocks

Aerated concrete blocks are a fairly pliable and soft building material, which simplifies the process of fastening the structure, but at the same time requires special attention to performing load calculations. A load that is small in size and weight can be attached to bolts, self-tapping screws (wedge-shaped ones are better) or threaded screws located along the entire length. The installation technology itself is reminiscent of fixing timber to a brick wall.

If you need to attach something heavier to a wall made of aerated concrete, for example, wall cabinets, you will need more solid fastenings. In this case, metal, plastic or nylon (plastic) dowels will be required.

- Studs are attached to the reinforced belt on the aerated concrete wall at a certain frequency.

- A wooden beam is secured to the studs.

- The beam is fixed to the stud using a bolt and nut.

Installation procedure

The timber is fastened to the brick wall using a rigid method. To do this, the master will need:

- building level;

- drill;

- wedge-shaped anchors;

- screwdriver

You can use the dowels of the “quick installation” system; then a level, drill, dowels and a hammer are enough. First you need to make markings on the surface of the wall, checking the vertical and horizontal levels. Then you will need to mark on the beam itself the locations of the fasteners that will fasten the frame. The distance between them will be from 30 to 50 cm.

How to attach a wooden beam to a brick wall

Construction wood is used in brick, block and monolithic construction; this material is compatible with brick, concrete, plastic and metal, and has a number of advantages:

- Practicality - can be used as a main, auxiliary and finishing material;

- Easily processed - any construction part can be cut from the workpiece;

- Withstands heavy weight loads, used as interfloor ceilings and load-bearing supports;

- The material is environmentally friendly and durable, has noise and heat insulation properties.

However, there are a number of limitations that must be taken into account when using wood in construction. Thus, lumber is not laid in brickwork, nor plastered or poured with concrete.

This article provides examples of attaching timber to brick walls and other surfaces.

Material quantity determinations

Installation of sheathing under the lining begins with preparatory work.

At first glance, it may seem that preparing tools is not so important.

But that's not true. If you prepare all the tools and materials in advance, your work will go faster.

You will not waste valuable time searching for the right tool. Work will be smoother if everything you need is at hand.

Here is a list of what we need to stock up on:

- Beam or metal profile;

- Dowels or screws;

- Building level;

- Pencil;

- Roulette;

- Fishing line;

- Screwdriver or screwdriver;

- Axe;

- Saw;

- Solutions for treatment against rot, mildew and mold;

- Insect repellent compounds.

For these purposes, timber of 50×25 mm and 60×27 mm is used as standard. The material must be chosen of high quality.

Inspect the surface of the wood; there should be no chips, cracks, or knots.

The durability of the entire structure depends on the quality of the frame. Humidity is also an important point. The ideal option is considered to be no more than 12-16%, but is allowed within 18%. This factor determines whether the surface will be smooth.

The lathing, which will be attached to a concrete or brick wall, involves the use of dowels. For wooden ones, self-tapping screws are enough.

Lathing under the lining with your own hands is impossible without preliminary marking.

To do this, use a building level and a pencil. You need to decide on the direction of the lining in advance.

It can be placed vertically - this visually increases the height of the room, or horizontally - it expands the space.

As an option, you can use a mixed finish or diagonally. In any case, the bars must be perpendicular to the chosen direction.

The choice of lathing step width depends on your goals. Of course, the smaller it is, the stronger the structure, but the higher the price. Typically used from 40 to 60 cm.

If you will also insulate the room, take into account, first of all, the size of this material.

In this case, the pitch of the sheathing should be slightly smaller than the insulation so that it fits more tightly.

To make the frame even, we will use a fishing line and a plumb line. Using the building level, we will use the tools described above to create a visualization. We will install bars along these edges.

The fishing line will serve as a guide. Depending on the chosen direction, it is pulled either horizontally or vertically. The bars are fixed close to these guides. If necessary, add wedges or wood chips, or, conversely, grind down the surface of the wood.

You can use a laser level in place of the fishing line.

If there are window or door openings around the perimeter, it is mandatory to secure the bars around them.

When you secure the structure, do not forget to check the level.

Installation of the frame on the ceiling is carried out in the same way as on the walls. The only thing is that a beam of slightly larger diameter can be used. This is due to the difference in the thickness of the insulation used.

If you are going to sheathe semicircular or oval rooms, do not use solid timber. In this case, carefully monitor the proportions.

The lathing for the lining in the steam room is done according to special rules.

First you need to attach foil to the walls.

It traps steam. It also implies the use of larger rack bars.

In order to install slats of a smaller diameter, recesses are cut out in the larger ones, where they are laid. This method allows you to create greater rigidity, which is especially important in such conditions.

Due to the harsh conditions this frame will be exposed to, the wood may become warped. By using this design, the likelihood that the finish will float is practically eliminated.

How to make lathing for lining on the walls of log houses?

The complexity of the design lies in the significant differences in the walls. It is more difficult to level such a surface. What to do in this case?

The frame in this case is installed on the basis of beacons.

They involve the use of pads. It is important to maintain the level when installing them. If the surface has strong protrusions, they can be cut off with an ax or plane.

To summarize, let's focus on the important points. During installation, the choice of fastening depends on the surface. They are different for wood and brick. Do not forget to treat the surface with compounds against fungus, mold and rot.

— the fastening of the bars must be reliable;

— all front surfaces of the bars that interface with the sheathing sheets must be in the same plane;

The plane formed by the sheathing bars must be strictly vertical.

The era of wooden plugs, which were traditionally used to secure the blocks to the walls, is irrevocably a thing of the past. They have been replaced by polymer and metal dowels, which are available in a large variety on the construction market. A fragment of fastening a wooden sheathing using a universal dowel is shown in Fig. 31. The only difficulty that you may encounter during the installation process is the right

fork marking and drilling of sockets for dowels. Marking for dowels by measuring with a ruler is a futile task and in most cases leads to mistakes. The easiest way to do this work is with an electric drill. To do this, the block is applied to the wall in the position in which it should be after installation.