X

Penetrating waterproofing for concrete is a mixture that makes the concrete surface waterproof. In other words, if you treat the bathroom floor with this composition, you can sleep peacefully. Your small local flood will not disturb the neighbors below. This is not a fiction, but a real effect from treating concrete with high-tech compounds.

Everyone is accustomed to thinking that waterproofing is the outer covering of the foundation with some kind of rolled waterproof material. But probably many simply do not know about such a new word in construction technologies as penetrating waterproofing. We will help you understand the principle of operation of this product, and also consider the technology of use.

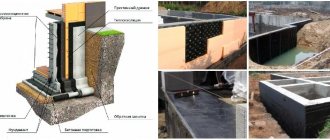

It happens that when building a garage or a country house, we cannot provide for all the nuances. And so, in the new basement, where you wanted to store wine and beautiful jars of preserves on the shelves, a pool was formed in the spring. Optimists can rejoice at unplanned innovation. But the realists already realized that an important point had been missed. Need protection from groundwater. What to do? Digging up the foundation?

Helpful information:

- Waterproofing the blind area around the house: types and stages

- Brand of concrete for the foundation

- Vibrator for concrete

- Concrete grades and their use in construction

- Anchors for concrete

- Fiber fiber for concrete: a marketing scam or not

No need to dig anything. Just for such cases, a unique waterproofing composition for concrete has been created.

Penetrating waterproofing: what is it?

The name itself suggests that the substance must penetrate somewhere to protect against water. And it penetrates into those pores and microcracks that form inside the layer of cement-sand mixture during its shrinkage.

Some may doubt the effectiveness of such coverage. It is difficult to imagine what is not visible to the eye. But to dispel doubts, let's give a simple example. For almost half a century, deep penetration waterproofing impregnation has been successfully used when drilling oil wells to protect concrete structures from water and aggressive chemicals. By the way, drilling one oil well costs more than a hundred million rubles.

Let's look at the work of the waterproofing composition under a microscope. How can this solution, which looks like liquid cement, penetrate deep into a concrete wall or floor to a depth of 10 to 90 cm?

Firstly, simple laws of physics apply here. Under the influence of osmotic pressure, active substances are “drawn” into the thickness of concrete (the same laws apply when water is absorbed into a dishwashing sponge).

And secondly, chemical processes take place here. The substances of the mixture react with the calcium components of cement, where they form crystals. These crystals fill all pores, microcracks and do not allow water to pass through. Moreover, when the structure gets wet from the outside, the crystals grow and penetrate deeper.

The stronger the surface moisture, the more intense will be the penetration of the active components of waterproofing into the thickness of the concrete.

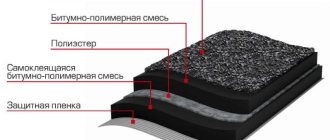

Waterproofing coating is available in the form of ready-made solutions or dry mixtures. It includes:

- high quality cement;

- sand;

- polymer additives;

- chemically active substances.

Although this product is not cheap, I would like to justify its cost and add a few more bonuses. This is what distinguishes penetrating impregnations from the usual roll coating:

- Penetrating coating makes concrete 10% stronger.

- The number of cycles of temperature changes that a concrete base can withstand increases to 100.

- Despite being waterproof, the structures remain breathable (steam and air pass through the pores without hindrance). This helps prevent mold growth.

- The product reliably protects the internal metal frame of reinforced concrete from corrosion.

- The coating can be used externally during the construction phase or internally during renovation work.

- The service life of the composition is equal to the life of concrete. And since the composition increases the strength and durability of the base, the service life of the waterproofing increases accordingly.

What is penetrating waterproofing

This is a waterproofing that penetrates deep into the concrete through a chemical reaction with the base. Penetration goes inside the existing pores and voids, thereby forming a waterproof barrier in it. Deep penetration inside is what distinguishes penetrating compounds from standard waterproofing materials, such as coating, roll and membrane, since they all protect only the surface without penetrating deep into the element. Upon penetration, penetrating compounds form a kind of integral whole with concrete and, unlike standard insulation, can be destroyed or damaged only when the concrete itself is destroyed.

Penetrating insulation materials help solve problems associated with:

- Waterproofing of porous bases - Consists of protecting concrete and other structures with porous surfaces from excess moisture and exposure to water. Without proper protection, they are at risk of damage, mold growth and other problems. A high-quality penetrating product will repel both water and various chemical elements, salts and oils, while allowing the concrete to breathe.

- Protecting porous substances from deterioration – Excessive porosity in cement and other substances can lead to deterioration over time. Penetrating sealant protects the structure being treated by significantly reducing the amount of chemical elements and water penetrating and affecting it.

Penetrating materials consist mainly of special cements, quartz sand and additives such as sodium silicate and lithium silicate, siliconate or silane-siloxane. These special additives distinguish some penetrating products from others.

In what cases is waterproofing for concrete used?

To answer this question, let's look at the problem from the inside. Despite all its “reinforced concrete” properties, concrete quickly becomes brittle when exposed to moisture, aggressive liquids, mold and mildew. The internal metal frame rusts and collapses. Obviously, in order to preserve the building for many years, it is necessary to prevent the access of water inside.

So we got the answer. Wherever there are problems with high humidity in the room or where airtightness is required, waterproofing impregnation can be used. It protects the foundations of houses well from moisture. Allows you to keep basements dry. It is used to seal wells, swimming pools, and bathroom floors.

Types and types of waterproofing

To understand the benefits of penetrating compounds, let’s take a short excursion into the world of construction technologies. Let's remember the main types of waterproofing.

Table. Methods of waterproofing.

| Methodology | a brief description of |

| Coating waterproofing | The main types are hot bitumen mastic, polymer resins, bitumen-rubber mastics. Materials are applied to well prepared and cleaned surfaces. Protect walls, floors, and ceilings from water penetration. The compounds crack and lose elasticity due to temperature changes and vibrations. Usually after 3-4 years the coating requires replacement. |

| Adding additives | According to the principle of action, chemical additives that are used when mixing concrete are similar to penetrating waterproofing. They fill the pores in the concrete as it dries. The resulting waterproofing concrete is used for screeds and filling voids between slabs. |

| Pasted insulation | It is carried out by gluing roll materials. They are applied in 3-4 layers. Used for external water protection of foundations, walls, roofs. Polymer materials can be laid on top of old coatings. They are resistant to aggressive liquids, do not rot, but can be easily damaged by mechanical stress. |

| Spray type | You can call this coating liquid rubber. The polymer-bitumen emulsion is applied with a special spraying tool. The liquid composition will get into all hard-to-reach places and fill all pores. The coating can only be used for outdoor work. The sprayed film needs protection from mechanical damage. |

Let us not diminish the merits of these methods of protection. Each composition can be optimal for a specific case. When choosing a suitable material, you need to consider all the pros and cons.

The principle of operation of penetrating waterproofing on concrete

Concrete is porous, meaning it contains small holes that can allow moisture to pass through. Over time, moisture can cause problems such as leaks, efflorescence, mold and cracks in the concrete. Concrete penetrating materials are designed to protect it from water and moisture by forming a chemical barrier of a waterproof compound.

Porous concrete

The surfaces of reinforced concrete structures can be effectively protected by applying special coatings. Penetrating coatings have the ability to penetrate, making them useful for not only primary waterproofing, but also for renovation work.

Produced in the form of a dry mixture with penetrating properties, products based on mineral binders are used for waterproofing concrete bases with developed capillary porosity (reinforced concrete, brickwork, etc.).

The operating principle of penetrating waterproofing products is as follows:

During application, concrete penetrating polymers (made from silane or siloxane polymers) penetrate into the voids and capillary pores of the concrete and react with the alkalis it contains to form hydrophobic compounds in the pore structure.

Chemically active substances penetrate into the pores and capillary paths of concrete, where they react with free lime and sediment on the surface of the pores. The pores (or microcracks) are filled, reducing permeability and helping to make the substance waterproof.

If the structure comes into contact with water molecules, the reaction resumes and the compaction process moves deeper into the concrete. The same process underlies the “self-healing” of microcracks. When applied, the coating creates a film inside, filling voids and capillaries. Within 10-30 days the material will begin to crystallize, keeping voids and capillaries filled with crystals that adhere to the concrete, trapping water and high humidity.

Scheme of operation of penetrating waterproofing:

Scheme of operation of penetrating waterproofing

Important: Penetrating materials only work in areas where there are small pores, microcracks and capillary channels. Penetrating coatings will not work in areas where there are large voids, cracks or voids at the rebar interface.

Scope of application, pros and cons

“Everything is relative,” said Einstein. Same with waterproofing. There can't be pros without cons. Let's move on to theory and break down all the advantages and disadvantages of liquid waterproofing with deep penetration function.

So, the pros:

- no need to dig up the foundation for processing;

- the solution can be applied with a simple brush like paint;

- the composition modifies concrete: makes it water-repellent, increases strength, frost resistance;

- after treatment, concrete retains its breathable properties;

- no need to dry the surface before applying impregnation;

- the product is safe for humans;

Disadvantages (or rather difficulties) that accompany construction work on applying a penetrating mixture:

- If the wall being treated is no longer new, you need to very carefully clean the surface to free clogged pores. You will need to completely remove the existing coating (plaster and paint).

- For the composition to work, the base must be thoroughly moistened. The solution is applied only on wet concrete. Without this, active additives will not penetrate deep into the pores.

- Large cracks, as well as seams, need to be glued with special paste-like compounds.

- The activity time of the chemical components of the mixture is limited. It is 30 minutes after preparation.

- Work must not be carried out at sub-zero temperatures.

- The drying process also requires compliance with certain conditions. The treated surface is covered with film and periodically moistened for another 2 weeks.

- The coating is not used for brick, cellular concrete, or stone surfaces.

Someone will say: “Good luck guys! I’ll go get some roofing felt.” But what if you imagine that such concrete will last at least 100 years, and your great-great-grandchildren will swim in the pool you built? Or maybe after thousands of years during excavations they will find your ideal wine cellar and admire the talent of the builder? Well, no, thanks! What kind of roofing material!

Let us give examples of industrial applications of penetrating compounds to dispel your last doubts. Here's where penetrating waterproofing is used:

- designs of subway structures, tunnels, bridges, thermal power plants, overpasses;

- berths, piers;

- water treatment and hydraulic structures;

- sewerage systems, including settling tanks, ponds, aeration tanks;

- containers for drinking and technical water supply;

- foundations, walls, floors, ceilings of buildings and structures;

- dams, tunnels, mines.

Review of popular brands: my rating

And now about the main thing. How not to buy simple cement instead of a unique powder. Unfortunately, the construction market is saturated with fakes. Therefore, experienced craftsmen strongly do not recommend buying expensive materials in dubious places at a suspicious discount. Give preference to chain stores that cooperate with large manufacturers. They will be able to show product quality certificates, as well as documentation containing information about the manufacturer.

Penetron

The brand has been known in the construction market for half a century. Penetrating waterproofing Penetron has the following characteristics:

- It is used to insulate swimming pools, garages, bathrooms, foundations, and basements.

- The cost of the dry mixture is about 330 rubles. for 1 kg.*

- Product consumption is 1 kg per 1 sq. m (when applied in 2 layers).

- The solution is prepared immediately before application. The proportion consists of 1 part water and 2 parts dry powder. When mixing, you need to pour the powder into the water, and not vice versa.

- The temperature of the treated surface should not be lower than +5 degrees Celsius.

* Prices are valid for the month of May 2021.

Penecrete and Penebar as an addition to Penetron

Penetron's companions allow you to create ideal waterproofing. Penecrit is a dry mixture. It is diluted with water to form plasticine, and the seams, cracks and crevices are coated with it.

Before applying any penetrating composition, the surfaces of the seams must be carefully prepared. First, they need to be trenched to a depth of 45 mm and a width of 25 mm. Then thoroughly remove dust with a brush and moisten to create adhesion.

Penebar is sold in rolls. This is a solid black sticky cord. It consists of composite materials that expand in volume upon contact with water. This ability is used to fill seams more densely.

Briefly, the installation technology looks like this:

- the seams are thoroughly cleaned of dirt and cement;

- A composite cord is laid into the resulting grooves. The paper layer is first removed from the surface. The ends of the strips are cut obliquely and joined end-to-end. To prevent the tourniquets from moving, they are secured with staples or pegs;

- after abundant wetting, the tourniquet turns into a waterproof gel and increases in volume by 3 times. The composition tightly fills all cracks and crevices.

Penebar can be laid on damp material. But it is necessary to exclude use on surfaces with standing water and at temperatures below +5 degrees Celsius.

Lakhta

One of the best products in the rating of penetrating waterproof insulation among Russian manufacturers. In terms of quality, Lakhta is compared to Pentron.

Waterproofing is a one-component mixture of cement, quartz sand and special additives. Thanks to chemical processes, the solution merges with concrete into a single whole. The penetration depth is more than 10 cm. Dry powder consumption is 1.2 kg per 1 sq.m. This is the maximum consumption when applied in 2 layers on a rough surface. When used on a smooth surface, consumption is reduced to 0.8 kg per 1 sq.m.

The cost of a bag weighing 25 kg is approximately 5150 rubles. (or 207 rubles per kg)*. The material is also sold in packages of 5 and 10 kg.

The impregnation agent is used in industrial and individual construction. It is used to treat swimming pools, garages, balconies, basements, and drinking water tanks.

Structures treated with Lakhta waterproofing become resistant to alkalis, petroleum products, and other aggressive reagents.

The composition cannot be used for the following materials:

- super-dense concrete;

- plasters of various types (lime, gypsum, cement);

- highly porous and block structures.

Differences in penetrating waterproofing

Different manufacturers use slightly different manufacturing techniques. This is reflected in the very purpose of this material, as well as in the scope of application.

One of the popular brands, Osmosil, offers ready-made (liquid) products in several standard variations. Sold in buckets, just open the package and you can start working.

There are such cords. Insulation requires certain conditions, including the recommendation not to use this material on surfaces to which vibrating equipment will be applied. For these purposes, the company has similar insulation, but with the addition of latex.

The penetrating paint is applied to the walls with a regular brush, but in the photo it looks like a worker is applying putty. The permissible temperature for using the material, according to the manufacturer, ranges from -30 to 80 degrees. But application is permissible only at temperatures from +5 degrees to 35.

After application, work in the area of insulation should stop for a couple of days, but the period depends on the type of material, details on the bucket with insulation. The penetration depth is about 50 cm.

There is also a domestic one that produces similar materials. But, unlike the previous one, they are produced in dry form. It can be used both for external and internal work. Used everywhere.

The only limitation is the use in concrete structures made in a special way, when there are no capillaries on the surface. The penetration depth is about 100 cm.

Calmatron

Calmatron has a wide range of applications. This is due to its real effectiveness and deep penetration into structures.

Calmatron has the following characteristics:

- The service life of the coating is from 20 to 50 years. It depends on the aggressiveness of the environment.

- Penetrates to a depth of 15 cm.

- Consumption – 1.6 kg of dry mixture per 1 sq.m.

- Increases the strength of concrete surface by 30%.

- It can be added when preparing a cement-sand mixture or coated with finished structures.

- Contains safe additives that allow the product to be used in drinking water containers.

- Reduces the level of penetration of radionuclides by 5 times.

- Resistant to petroleum products, diesel fuel and mineral oils.

Finishing work on walls, floors and ceilings treated with penetrating waterproofing can begin only 1 month after impregnation.

The Calmatron line contains self-expanding strands for seams and elastic polymers for insulating surfaces prone to deformation.

Crystallisol

Kristallizol can be called a leader among domestic manufacturers. The Russian brand of the GidroStroyKomplekt plant has proven itself:

- quality products;

- a wide range of items;

- positive customer reviews.

Kristallizol has all the characteristics of high-quality waterproofing. The affordable price makes it popular among buyers.

Crystallisol was used in the treatment of such objects as the Moscow metro, the gateways of Volgograd, the Faceted Chamber of the Kremlin, and the Triumphal Arch on Kutuzovsky.

In everyday life, Crystallizol products are used in garages, bathrooms, wells, swimming pools, house foundations, and basements.

Penetrating waterproofing for concrete

Despite the fact that the method of application of this type of waterproofing is similar to the previous one, it is classified as a separate type. If the principle of action of coating materials is to create an outer thin layer of protection from bitumen or polymers, then the basis of penetrating waterproofing for concrete is a deeper effect.

As the name of the method implies, the composition begins to “absorb” into microcracks and pores of concrete, as well as into the junctions of different parts of the structure, penetrating to a depth of 15-20 centimeters. Having come into contact with moisture, the composition crystallizes and forms a water-repellent layer - very durable and insoluble in water. At the same time, it not only performs a moisture-proofing function, but also generally strengthens the structure of concrete. It is important to remember that this method only works with concrete surfaces.

Liquid waterproofing for concrete

Liquid waterproofing is a ready-made composition for treating concrete. Compared to dry mixtures, ready-made impregnations have some advantages. Let's highlight the main ones:

- When applied, a monolithic rubber-like film is created that adheres to every millimeter of the rough surface.

- Liquid rubber can be used on uneven surfaces.

- Application using special sprayers allows you to treat large areas in a short time.

The combined use of penetrating impregnation and liquid rubber makes concrete invulnerable to water.

There are 2 types of liquid coating. Let's see how they differ.

| Name | Characteristic |

| Liquid rubber |

|

| Liquid glass |

|

The nuances of using liquid waterproofing for concrete

Liquid rubber is used in cases where other materials are ineffective or when it is necessary to provide protection against moisture in hard-to-reach places. It is also used in cases where the surface is prone to cracking.

The average cost of 1 kg of domestically produced solution is 150 rubles/kg.* At the same time, the consumption is 2.6 kg per 1 sq. m. with an application layer of 2 mm. For an area of 10 sq.m. you will need to spend 3900 rubles.

An important point is that this liquid is difficult to apply correctly if you do not have experience. In this case, you will need the help of professionals with tools. The application layer in 1 approach should be no more than 2 mm.

Other nuances of using liquid polymer solutions:

- the surface needs careful preparation;

- You cannot add additional water and cement to the mixture;

- use is not allowed at temperatures below +5;

- Do not apply to icy surfaces.

And finally. The applied layer of liquid glass or rubber is very easy to damage. Therefore, such a coating itself needs protection, but from mechanical influences.

* Prices are valid for the month of May 2021.

Liquid waterproofing for concrete: characteristics

In addition to dry mixtures, there are other ways to protect concrete structures from the harmful effects of moisture. One of them is the use of liquid waterproofing. Today you can find liquid materials of this type of various compositions, but the most common are the following:

In addition to dry mixtures for waterproofing, there are also liquid compositions

- liquid rubber;

- liquid glass.

These materials have both advantages and disadvantages. Before purchasing one of them, it is recommended to study the features of their use. Liquid products are much easier to work with, especially when compared with bitumen mastics, membrane films and roll products.

You can buy liquid waterproofing for concrete at the construction market, in a store or on the Internet. The cost of such compositions is approximately 2 times higher when compared with dry mixtures. Liquid substances that make concrete waterproof are also convenient because they can be applied to an uneven surface.

The nuances of using liquid waterproofing for concrete

The process of applying the protective composition itself is quite simple. It does not involve heating the mixture, as is the case with bitumen mastic. It is also worth noting that the quality of waterproofing of this type is very high. Among other advantages of the liquid mixture, one can highlight the fact that it does not cause any harm to human health, since it does not emit active chemical compounds.

Liquid waterproofing for concrete must be applied with a brush or roller

Liquid water insulation is resistant to high temperatures, so in the summer there is no need to worry that it will start to melt. This material is an excellent alternative to rolled and other insulators.

Liquid glass for concrete waterproofing is applied using the following tools: brush, construction roller. The viscosity of the composition resembles the thickness of PVA glue. This mixture is applied in a thin layer, which after drying requires additional protection. This is due to the fact that the finished layer has poor resistance to mechanical stress.

This type of penetrating insulation achieves excellent results. Impregnations based on dry mixtures increase water resistance, and liquid compositions make the concrete structure virtually invulnerable to water. But this method also has some disadvantages. For example, making a layer of the required thickness with your own hands is quite difficult. Therefore, it is better to use the services of a professional.

Characteristics of coating waterproofing for concrete

Many inexperienced craftsmen may get confused, mistaking coating waterproofing for penetrating impregnation. This is normal, because these compositions are similar in appearance. But here are their differences:

- The penetrating agent enters through the pores deep into the structure, and the coating protects only the surface from water. It penetrates inside only to a distance that is sufficient for a strong grip.

- Penetrating waterproofing is applied in 2 layers, and coating compounds have a thin coating.

Here are the important properties of polymer waterproofing:

- enhanced adhesion to the porous structure of the material;

- water-repellent properties;

- elasticity, which is created by adding polymer components.

The coating material is chosen for each specific situation. It is important to read the instructions before purchasing. It should say on which side the product can be applied. The composition must be resistant to water pressure. If you choose the wrong one, it will simply peel off and fall off. Accordingly, it’s money down the drain.

Coating waterproofing

The basis of coating waterproofing for concrete is the hermetically sealed application of bitumen mastic to the entire surface of the foundation. This mastic is available either as a ready-to-use solution or as a mixture of two components, which must be mixed in the required proportions before use. In this case, it is important to take into account the so-called “survivability” of the material - that is, the time during which it retains the necessary viscosity for normal application.

Most often, such waterproofing is applied in several layers, each subsequent layer on top of the hardened previous one. At the moment, the most common option for protecting concrete from moisture is coating waterproofing.

Features of waterproofing paint for concrete

We have already looked at different waterproofing materials. Now you can consider yourself an expert in the field of concrete waterproofing. But to complete the picture, one more type should be added. This is a special water-repellent paint.

The main advantage of the paint is that it can be applied with a brush without the help of professional equipment.

For information: paint can be one-component or two-component. One-component enamels are already ready for use. Their hardening occurs under the influence of moisture from the air. And two-component mastics are supplied in 2 packages. Their contents must be pre-mixed. The setting of the protective layer occurs due to a chemical reaction.

Enamel is often applied to the inside of swimming pools or water storage tanks. It doesn't look like cement at all. The paint has pleasant colors and a smooth surface. Acrylic mastics lend themselves well to tinting.

This coating can be applied to the facades of houses. The paint easily smooths out small cracks and fills construction joints. It can withstand both negative and positive water pressure.