More than 200 completed projects in the Moscow region

We offer installation of a retaining wall made of bored piles in Moscow, the Moscow region and other regions of the Russian Federation.

We work with both individuals and companies. Everything is documented. We provide a 2-year guarantee on work.

View our completed projects

Advantages of retaining walls made of bored piles

The advantages of bored piles in the use of retaining walls include the following:

- Possibility of construction and reconstruction of the central part of cities, which is usually often built up.

- The possibility of constructing multi-storey buildings with the need to develop underground space.

- Ensuring the reliability and stability of the walls of excavated pits during the construction of foundation and overlapping structures.

- The technology for constructing retaining walls from bored piles makes it possible to completely eliminate uneven subsidence of the foundations of neighboring buildings and structures. This eliminates the occurrence of emergency situations.

- This technology is cost-effective and justified.

- Possibility of building buildings on any type of soil.

Photo gallery of completed objects using hole drills

Moscow, bridge support

Photo report on the installation of piles by specialists of PSK Osnovaniye i Foundations LLC

More details

Tver, Pig breeding complex

Installation of drilled injection piles during the construction of a pig-breeding complex

More details

Zhukovsky, Moscow region

Photo report of the installation of sheet piling during the construction of a residential building

More details

Photo report of the installation of a pit fencing during the construction of a multi-storey building in Mytishchi

More details

Moscow, Bersenevskaya embankment

Photo report of the installation of secant piles during the construction of a concrete foreshaft in Moscow

More details

Moscow, Dmitrovskoe highway

Photo report of the installation of bored piles during the reconstruction of a traffic intersection

More details

Installation of sheet piling pipe fencing in Moscow

Photo report of strengthening load-bearing structures and building foundation soils at the “Construction of the Krasnoselsko-Kalininskaya Line” project

More details

Strengthening load-bearing structures and foundation soils of a building in St. Petersburg

Photo report of strengthening load-bearing structures and building foundation soils in the area from Kazakovskaya station to Putilovskaya station

More details

Installation of bored piles with a diameter of 426 mm in Lobnya

Photo report of the installation of bored piles with a diameter of 426 mm at the object “Reconstruction of the warehouse building - First stage” in Lobnya

More details

View our other projects

We install retaining walls from bored piles in Moscow and the Moscow region

Buy Larsen sheet piling Turnkey bored foundation Bored piles using hollow auger technology (CFA method) Which is better: screw piles or bored piles?

Hills and slopes are a common occurrence even on flat terrain. If construction is carried out on such a site, an important point is to protect the site and structures on it from collapses and landslides.

One of them is a retaining wall made of bored piles on a site with a slope.

We install retaining walls in Moscow and the Moscow region.

Technology for constructing a bored retaining wall

The construction of buildings inside large cities, when buildings are located at short distances from each other, is always problematic. When digging a foundation pit, there is a high probability that the foundation structures of neighboring buildings, left without support from the ground, will begin to move apart. The way out of this situation is a bored retaining wall.

Essentially, a retaining wall is bored piles that are built in a row along the boundary of the pit of a new house.

Considering that this type of columnar foundation can be poured to a depth of 50 m, it becomes possible to construct retaining walls for deep pits, in which, for example, multi-level parking lots will subsequently be organized.

According to their operational characteristics, piles are powerful structures that can replace a thick layer of soil. But when choosing sizes, it is necessary to take into account several indicators, namely:

- type of soil at the construction site;

- ground water level;

- value of active soil pressure;

- its clutch:

- And so on.

A retaining wall made of bored piles is one or more rows of pile foundations that are poured into the ground at a certain distance, both in a row and between rows. The foundations can be arranged in a row or in a checkerboard pattern. In a retaining wall, all piles must have the same depth and diameter.

To determine the distance between the supports, which is called clearance, we must carry out the necessary calculations.

Features of a retaining wall made of bored piles

For such walls, secant piles, a type of bored pile, are more often used. Both are formed at the work site from the same materials, but the construction technology is different. In both cases, pre-drilled wells are filled with reinforced concrete. But the bored piles of the retaining walls are spaced from each other at the design distance, and the bored secant piles are located in a continuous palisade.

The installation order is as follows:

- The first stage wells are drilled, reinforced and concreted at a distance from each other. The distance is less than the diameter of one pile.

- After hardening, wells of the second stage are drilled, while the previous ones are partially drilled.

- The reinforcement cage is not placed in the second wells; they are immediately filled with concrete.

- Installation of the frame and formwork for the grillage. The ends of the reinforcing rods of the piles are connected to the grillage reinforcement.

Thus, secant piles are not just located continuously, but also partially overlap each other. The result is a monolithic wall.

Bored piles can be located either in a line or in an area. Brown secants - only in a line, although the line can have any configuration.

A bored retaining wall can be used for more than just slope strengthening. It is often installed before installing the foundation to enclose the pit in order to prevent the collapse of its walls.

The walls of underground structures – tunnels, parking lots, etc. – are formed in a similar way.

We will calculate and design a retaining wall of any complexity

The diameter of the piles should not be less than 40 cm. The specific indicator is calculated taking into account the soil pressure on bending, which takes into account the distance between the supports and the foundation of the neighboring house, plus the type of soil. Therefore, geological surveys are carried out at the construction site in advance, which will indicate the type of soil.

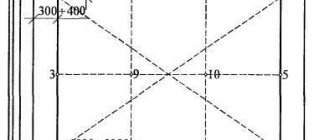

An important indicator is clearance. When calculating retaining walls made of bored piles, two of its values are taken into account:

- Between the rows. This value should not be more than three pile diameters. For example, if the diameter of the support is 0.5 m, then the distance between the rows should not be more than 1.5 m. If you increase the parameter, the pressure on the retaining wall of bored supports in the horizontal direction will create conditions for bending of the latter. This reduces the quality of the structure.

- Between piles in one row. A complex formula is used here, which contains several values: b=5.14 x lx C xd/E, where “I” is the height of the passage, “C” is the value of soil adhesion, “d” is the diameter of the piles, “E » – soil pressure (active).

The last formula is used in calculations if the soil at the construction site is hard and durable. If during the drilling process technology using water or clay solution is used, then the clearance should not be less than 0.7 m. If the construction of piles is carried out without fastening the walls or with the removal of casing pipes, then the distance between the supports should not be less than 0.4 m.

The design of the retaining wall necessarily includes a grillage, which will unite all the supports, making the structure more reliable and rigid. This is a conventional strip-type concrete structure, which is rigidly attached with bored piles. When constructing a single-row retaining wall from bored piles, hinged fastening of the grillage to the supports is allowed.

As for the size of the strip structure, it completely depends on the size of the piles. But there are certain standards that must be met when constructing a retaining wall.

- The minimum size of the overhang of the strip structure relative to the supports is 10 cm.

- Grillage height (minimum) – 20 cm.

- When constructing a wall in several rows, the height of the grillage structure is determined depending on the distance between the axes of the outer supports, here we mean the racks in the plane of action of horizontal loads. So this parameter should not be less than a quarter of this distance.

Bored piles with widening

Bored piles using the CFA method (hollow auger)

Load-bearing capacity of a bored pile

Concrete retaining wall

This construction of a monolithic structure is made using formwork from wooden elements or bored piles. And the best choice for quickly creating a reliable retaining wall is a factory-made reinforced concrete wall. The installation of such a slab is done using lifting equipment, and the slab itself can be cantilevered or buttressed.

For the installation of ready-made factory products, a foundation is simply not required in soil with a dense structure. A trench with a width slightly larger than the size of the base of the slab or console is sufficient.

Concrete retaining wall: design and implementation

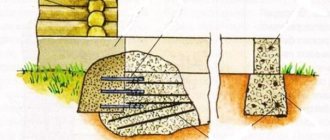

At the bottom of the trench, gravel and sand are placed in layers of 15-20 cm. The material can be compacted well with the help of good watering. Reinforced concrete slabs are placed exactly vertically, and they can be joined together by welding reinforcement embedded parts. A longitudinal drainage system is also installed and the entire space is filled with earth.

A retaining wall on stilts, made of reinforced concrete, can be placed on soft ground. In this case, the distance between the piles depends entirely on the length of the slab. The range of pile spacing is quite large, and they can be placed every 1.5, 2 or 3 meters. The diameter of the piles is usually 300-500 mm.

Retaining wall construction technology

The construction of a retaining wall made of bored piles is a standard construction of supports involving drilling the soil and pouring concrete mortar. The sequence of work carried out is as follows:

- A plan is made for the location of the piles along the boundaries of the pit with an exact indication of the drilling locations.

- Wells are drilled through one pile. Since the distance between the posts is not very large, it is impossible to drill two adjacent wells at once. The walls may collapse.

- The wells are washed and the bottom is filled with sand concrete.

- A reinforcing frame made of steel reinforcement is installed.

- The wells are filled with vibrating concrete.

- Intermediate wells are drilled, reinforced and filled with concrete mortar.

- A reinforcing frame for the grillage is installed on top of the supports, which is attached to the frame of the concrete shafts. Formwork is installed and concrete is poured.

Concrete is supplied to the well through a perforated steel pipe, which is gradually raised as the well is filled. In some cases, it is left inside as an additional reinforcing frame.

We make strong frames when reinforcing bored piles

This is an important component in the construction of a wall made of bored piles. The frame is made of a cylindrical shape from reinforcement with a diameter of at least 10 mm. The length of the structure must be equal to the length of the bored pile.

The gap between the transverse reinforcing bars is selected taking into account the diameter of the trunk.

- If the diameter is in the range of 400-450 mm, then the distance should be selected based on d/2, but not more than 200 mm.

- If the diameter is more than half a meter, then the distance should be d/3, but not more than 500 mm.

Gap between longitudinal reinforcing bars: 50-400 mm, taking into account the number of bars. It should not be less than 6 pieces.

About Additional structures when installing retaining walls

To drain groundwater and atmospheric precipitation behind the wall, we construct drainage gutters or drainage systems in the form of open ditches filled with gravel, crushed stone, or stone. The longitudinal slope from the wall is 0.04. In the wall itself, every 3 m we install tubes through which moisture will escape.

If the retaining wall is the boundary of the terrace of the pedestrian zone, then we install fencing structures along it. The minimum height of fences is 1 m.

According to the technology for constructing retaining walls, the outer parts of the piles must be lined. It can be monolithic or prefabricated concrete, stone or any decorative materials. The planes of the piles facing the ground are waterproofed. If there are no aggressive substances in the soil, then waterproofing can be carried out with hot bitumen, applied in two layers.

Our Hyundai R330LC excavator with OMS OVR 80 S vibratory loader at the site

Vibration immersion of pipes PSK Osnovaniye i Foundations LLC

Work on removing pipes using a vibrating hammer by specialists from PSK Osnovaniya i Foundations LLC

Vibration immersion of pipes PSK Osnovaniye i Foundations LLC

Vibration immersion of pipes PSK Osnovaniye i Foundations LLC

Vibration immersion of pipes PSK Osnovaniye i Foundations LLC