Reinforcing mesh

Today, welded mesh is one of the most popular types of metal products. Among these meshes, reinforcement meshes are the most common. The use of ready-to-install reinforcement mesh is an alternative to woven, expanded metal materials. Such meshes significantly facilitate, speed up and reduce the cost of the construction process. Full information about these materials is presented in this section. For more detailed information on certain aspects, it is recommended to visit other publications linked to in the article.

What it is

The reinforcing mesh is a lattice formed by spot welded smooth wires or corrugated metal rods (rods). The wires are placed perpendicular to each other, forming rectangular or square cells. The cell size can range from 50 to 500 mm.

Reinforcing mesh 200x200x12. Photo Novametal Trade

For production, steel reinforced wire made of low carbon steel is used. The wire may have a galvanized coating or may not have such a coating. The diameter of the rod also varies.

GOST, passport

The reinforcing mesh must meet the requirements set out in GOST 23279-2012 (85) “Welded reinforcing mesh for reinforced concrete structures and products. General technical conditions". Cross-shaped connections of rods (wire VR-1 according to GOST 6727-80 ) are carried out by resistance spot welding in accordance with the requirements of GOST 14098 .

When purchasing products from a manufacturer or supplier, you should choose companies whose employees are able to provide passports and quality certificates for the products. Documentation demonstrates that the products are manufactured in accordance with all standards.

In addition, the grids have certain design features :

- they must have rods of the same diameter in the same direction;

- the diameters of the working reinforcement are determined from the condition of the cross-sectional area required by the calculation of mechanical strength;

- the ratio of the smaller diameter of the rod to the larger one must be at least 0.25;

- the main pitch of the rods in one direction should be the same.

The standard strictly regulates the size of the additional step and releases.

Welded reinforcing mesh: types, characteristics

The production of welded reinforcing mesh is regulated by GOST 23279-2012. They are made by spot welding reinforcing wire or rods. Square or rectangular cells. In one direction, the rods have the same diameter, and the pitch of the rods is also the same. The operating fittings can be located in one direction (distribution in the second) or in both. Meshes with longitudinal reinforcing bars with a diameter of up to 5 mm inclusive are sold in rolls, and over 5 mm - in cards.

Such metal products are most often used for reinforcing reinforced concrete structures, masonry, road surfaces, and making fences.

The main advantages of these metal products:

- strength;

- rigidity;

- the ability to select a product with the desired rod diameter, shape and cell sizes.

Welded mesh products have little flexibility, so they are not used in areas with bending loads.

The range of metal reinforcing mesh includes light and heavy products:

- Lungs. Made from wire with a diameter of 3-10 mm. They may have transverse rods that span the entire width of the mesh fabric or offset ones.

- Heavy. They have rods with a diameter of 12 mm or more in one direction. Working reinforcement can be located in both directions or in one direction (transverse or longitudinal). The diameter of the distribution fittings is always less than the working one. The ratio of the smaller diameter to the larger diameter must be at least 0.25.

Table of types of reinforcing bars and wires for welded mesh

| Grid view | Working fittings | Distribution fittings |

| Heavy | A400 (A-III), A500C, A600C with a diameter of 10-40 mm | A400 (A-III), A500C, B500C, A600C with a diameter of 6-16 mm, A240 (A-I) with a diameter of 6-16 mm |

| Lightweight | Reinforcing steel class B500C with a diameter of 4-5 mm, reinforcing wire VR-1 with a diameter of 3-5 mm, rod reinforcement classes A400 (A-III), A500C, B500C, A240 (A-I) with a diameter of 6-156 mm | Reinforcing steel class B500C with a diameter of 4-5 mm and reinforcing wire class B-1 with a diameter of 3-5 mm |

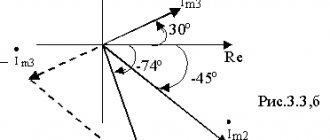

Markings, in drawings and specifications, examples

Symbols must be present on the packaging of all materials. They provide complete information about the products.

Grid markings are found in drawings, i.e. when designing buildings, roads and other structures. Designations are also present in the specification - a document that is a table defining the composition of a product.

Reinforcement mesh

But most often the packaging has markings. The decoding is located on tags , which are made of metal or plywood, and are attached to both sides of the roll or card.

The tags contain the following information::

- name or trademark of the enterprise that manufactured the product;

- type (symbol) of the product, which has the following form - xC x d / d1 x b x l, where: x - designation of the mesh type; C - designation of the name of the welded mesh (with the addition of the p-Ср index for rolled meshes); d, d1 - diameters of longitudinal and transverse bars indicating the class of reinforcing steel; b, l—grid width and length;

- number of nets in the package;

- package weight;

- date of manufacture and batch number.

The following is an example of marking a material with certain characteristics:

heavy mesh type 1 with longitudinal bars made of reinforcing steel class A500C with a diameter of 25 mm, with a pitch of 200 mm. and with transverse bars made of reinforcing steel class A500C with a diameter of 10 mm, with a pitch of 600 mm, a width of 2050 and a length of 6650 mm, with releases of longitudinal and transverse bars of 25 mm - 1С x 10А500С / 10А500С x 205 x 665.

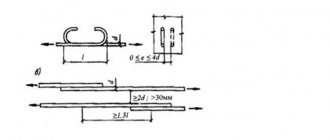

Characteristics and diagrams of heavy reinforcing mesh.

For heavy reinforcing mesh ( GOST 23279-85

) include

meshes

having rods with a diameter of

12 mm or more

(Fig. 1):

- with working fittings

in the longitudinal direction, the diameter of which is greater than the diameter of the distribution fittings; - heavy mesh with working reinforcement

in both directions; - heavy mesh with working reinforcement

in the transverse direction, the diameter of which is greater than the diameter of the distribution reinforcement.

The mesh dimensions must correspond to the dimensions in Fig. 1:

- mesh length - L

- mesh width - B

- diameter of longitudinal rods - d

- diameter of transverse rods - d1

- main pitch of longitudinal rods - S

- the main step of the transverse rods is S1

- free ends of longitudinal rods - a1

- free ends of cross bars a

.

As working reinforcement in heavy meshes,

hot-rolled reinforcing steel rods of class

A-III d=12mm...40mm

and thermomechanically strengthened reinforcing steel of class

At-IIIc d=12mm...18 mm

(Fig. 2).

During feasibility studies, the use of hot-rolled reinforcing steel bars of classes A-II

and

A-I d=12mm...32mm

.

As distribution reinforcement in heavy meshes

of type 1, reinforcing steel of class

A-III

and A

t-IIIc d=6 mm...16 mm

, in meshes of type 3 - reinforcing steel of class

A-II d=10 mm...16 mm

and class

A -I d=6 mm…16 mm

.

Ratio of smaller to larger rod diameter in heavy welded mesh

must be no less

0,25

.

The distance between the rods - the main step of the rods in one direction should be taken the same. In heavy nets

type 1 for transverse rods at the edge of the mesh, it is allowed to use an additional step of

100 mm, 200 mm and 300 mm

.

ATTENTION! Working fittings

on a rod length of 6 m should not have more than two butt joints, and on a rod length of 12 m - more than three butt joints.

Butt joints of rods

of one direction within the reinforcement step in the other direction are allowed through at least three bars.

NOTE: 1. Heavy meshes

type 1 with a width of

1500 mm...3050 mm

with longitudinal rods

d=36 mm...40 mm

and type 3 with a length of

3050 mm...6250 mm,

before the development of production of automated equipment, are manufactured using single-point machines and suspended welding tongs.

2. By agreement with the manufacturer, the use of heavy mesh

type 1 and

light flat mesh

with a length of up to

11500 mm

.

ATTENTION! In meshes with working reinforcement

All intersections of rods must be welded from smooth bar reinforcing steel of class

A-I

In meshes with working reinforcement

periodic profile (rod and wire), it is allowed to weld the intersections of the rods through one or two intersections in a checkerboard pattern, if there are no special instructions in the working drawings.

READ ALSO: Rod and wire reinforcement, characteristics, GOST reinforcement

In the reinforcing mesh

It is allowed to have no more than two unwelded intersections of rods in an area of

1 sq.m of mesh

from the number of intersections subject to welding.

Butt joints

of reinforcing steel rods

are performed by contact butt welding in accordance with

GOST 14098-85

.

Welding modes - according to SN 393-78

.

Areas of application: for floors, walls, foundations and more

Mesh reinforcement

Reinforcing mesh is used in the construction of buildings, road construction, in particular for reinforcing reinforced concrete structures: foundations, floors, concrete floors, as well as road surfaces.

Reinforcing mesh for foundations differs in the diameter of the wire used and the size of the cells. These indicators are very important, since together they play a major role in determining the load that a given mesh can withstand. From these indicators the possibility of using the product for certain purposes is calculated.

Therefore, when planning to purchase a reinforcing mesh and build a reliable foundation on its basis, you should pay attention to the following main parameters:

- reinforcement diameter;

- geometric cell size.

The mesh is supplied in cards and rolls. Therefore, when purchasing, it is economically feasible to clearly understand not only the footage, but also the geometry of the foundation.

It should be remembered: replacing or strengthening the laid mesh or poured foundation will be very problematic. Therefore, you should choose a product for the foundation very carefully.

Materials can also be used:

- during the construction of brick houses to increase the seismic resistance of buildings;

- for arrangement of temporary fencing of construction sites;

- for reinforcement during installation of roofing structures;

- in agriculture for the manufacture of frames for greenhouses and greenhouses, the construction of fences and cages.

Consumption per 1 m2, installation technology, what is required: clamps, stands and more

When strengthening the floor screed, the mesh is overlapped by 1-2 cells. Depending on the type of screed and type of floor, you may need:

- a substrate of expanded clay and sand for the subfloor;

- cleaning products and special compounds for treating old floors;

- hydro- or thermal insulation, consisting of insulation and film, when pouring a floating screed.

Fittings for beacons

In addition, you need :

- level;

- stands (clamps);

- lighthouses;

- damper tape;

- gun or welding equipment for fastening.

When reinforcing various types of foundations, mesh or frames made of reinforcement are used. The contractor will need to build wooden formwork and, in some cases, take care of waterproofing. And only then install the mesh and pour the concrete solution.

Depending on the tasks assigned, materials with certain technical characteristics are used: cell size and rod thickness. More specific information is provided in a separate article.

GOST 23279-20212

GOST 23279-2012 “Welded reinforcement mesh for reinforced concrete structures and products. General technical conditions" is the main interstate standard by which you can focus on standard geometric dimensions. According to this standard, welded mesh, depending on the diameters of the reinforcement used, is divided into heavy and light. In turn, according to geometric parameters and their relationships, meshes are divided into types. There are 5 of them in total.

In accordance with GOST 23279-20212, welded mesh is manufactured, depending on its type, with a width from 0.65 m to 3.8 m and a length from 0.85 to 9.0 m. The overall dimensions of width and length include the corresponding outlets.

It must be said that GOST 23279-2012 is a rather outdated standard. The history of its development goes back at least to the 70s of the last century. The application side of this standard is completely outdated. Therefore, taking into account new and continuously changing requirements for construction, the requirements for the geometric and power parameters of welded mesh are also changing.

It is also important to note that in connection with the cancellation of GOST 10922-2012 in 2021, the key sections of which regarding the main operational characteristics of welded mesh are referenced in GOST 23279-2012, today it is necessary to very carefully refer to this standard.

Advantages

The main advantages of using welded reinforcing mesh include the following:

- increasing the productivity of work performed by 12 times;

- reduction in personnel costs;

- no waste;

- possibility of manufacturing products of non-standard sizes;

- greater efficiency of the work process.

In addition, the materials themselves have a lot of advantages :

- strength;

- fire resistance;

- resistance to significant loads;

- ease of use.

Reinforcing and reinforcing - differences

Reinforcing mesh, which is a lattice made of wire or rods, is used to implement various projects. But the main purpose is reinforcement, which is why such materials are often called reinforcing.

But you should understand and remember that the category of reinforcing mesh includes several types of products that can be made of galvanized and non-galvanized metal, plastic, polypropylene, and fiberglass. To strengthen the floors and foundations, woven, expanded metal, and welded mesh can be used.

Reinforcement mesh as delivered.

Thus, reinforcing mesh is one of the types of welded materials. While the category of reinforcing materials includes several types of meshes that are used to solve corresponding problems.

Types of metal (steel) materials

The classification of grids is quite wide. The parameters for dividing materials into separate types are the reinforcement class, connection type, cell size, wire/reinforcing rod diameter, weight of 1 sq.m. Detailed characteristics of each type of material are presented below.

Fitting class: A500C, A3 and others

Marking of reinforcement classes is carried out as follows (one of the classes is taken as an example) - A3 (A400). The first designation was used in Soviet times, corresponds to the old GOST, now many experts prefer the second type of name.

Reinforcing mesh 150x150. Photo Novametal Trade

In the manufacture of meshes, reinforcing steel of different classes is used:

- A500C. Hot-rolled reinforcement is a round profile with two longitudinal ribs and several transverse projections, which are crescent-shaped and do not intersect with the ribs. The reinforcement has good strength and ductility characteristics. Marking “C” means good weldability. The production of A500S fittings is carried out from steel grades St3SP, St3PS and St3GPS. The fluidity index exceeds 500 MPa.

- B500. Cold-deformed reinforcement with a three-sided periodic (corrugated) profile, made of carbon steel. The mesh has strength and ductility, which the fabric does not lose under significant loads. The ribbed surface provides excellent adhesion to any materials.

- A240 - smooth round rods without any protrusions. In most cases, longitudinal ribs are applied to the axle, which improves adhesion to concrete. The fittings are produced from carbon steel 3PS/SP, less often from low-alloy steel.

- A300 is a round corrugated reinforcement with crescent-shaped protrusions, made from carbon structural steel ST5SP(PS) or low-alloy structural steel ST18G2S.

- A400 is a reinforcement that can have a smooth or corrugated surface. The smooth profile has no serrations or protrusions. The characteristics of a periodic profile include two ribs; there is also a corrugated surface of transverse protrusions, which are located on a helical line with three starts. The rods are made from low-carbon steels 35GS and 25G2S.

- A600C is a new modern hot-rolled reinforcement of a periodic profile with a tensile strength of 740 N/mm and increased resistance to corrosion due to the presence of molybdenum, niobium, and vanadium in the composition.

Type: 1C, 2C, 4C and others

Lightweight reinforcement mesh made of wire VR-1

There are five types of reinforcement mesh:

- 1C - heavy with working fittings in the longitudinal direction, the diameter of which is greater than the diameter of the distribution fittings. Grids are produced with square or rectangular cells. The diameter of the working rods ranges from 12 to 40 mm, the distribution rods – from 6 to 16 mm.

- 2C - heavy with working fittings in both directions. For production, steel reinforcement with a diameter of 12 mm is used.

- 3C - heavy with working fittings in the transverse direction, the diameter of which is greater than the diameter of the distribution fittings. For production, steel reinforcement with a diameter of 12 to 40 mm is used.

- 4C - lightweight with transverse rods across the entire width of the mesh. The diameter of the longitudinal and transverse rods ranges from 3 to 10 mm. They are made from VR-1 reinforcing wire with a diameter of 3 to 5 mm or reinforcement with a diameter of up to 10 mm (inclusive).

- 5C - lungs with displaced transverse rods. For production, reinforcing wire VR-1 with a diameter of 3-5 mm is used. or reinforcement - up to 10 mm.

The letter “C” in the designation indicates that the mesh is produced by welding. Often the letter is placed before the number - C1, C2, etc.

In addition, often the marking does not contain the letter “C”.

Packaging: rolls and cards

Meshes are made flat (in cards/sheets) or rolled .

Light meshes with longitudinal rods made of reinforcing wire with diameters from 3 to 5 mm are produced in rolls inclusive. Products are produced with square or rectangular cells.

Reinforcement mesh in cards

Reinforcement mesh maps can be square or rectangular, while in one direction, in accordance with GOST requirements, rods with the same diameter are always located. The dimensional accuracy of the reinforcing mesh produced in cards can be normal or increased.

Range, sizes, characteristics

Manufacturers offer a wide range of meshes with different cell sizes, wire/reinforcement rod diameters and weights. Reference data on the most popular grids 50x50, 100x100, 150x150 and 200x200 are presented in the table.

| No. | Grid type | Col. m. sq. in 1 t | Weight 1 sq. m. | No. | Grid type | Col. m. sq. in 1 t | Weight 1 sq.m. |

| 1 | 3VR1 50x50 | 452 | 2,21 | 8 | 5VR1 50x50 | 192 | 5,2 |

| 2 | 3VR1 100x100 | 1010 | 0,99 | 9 | 5VR1 100x100 | 357 | 2,8 |

| 3 | 3VR1 150x150 | 1399 | 0,72 | 10 | 5VR1 150x150 | 523 | 1,91 |

| 4 | 4VR1 50x50 | 276 | 3,62 | 11 | 5VR1 200x200 | 681 | 1,47 |

| 5 | 4VR1 100x100 | 494 | 2,02 | 12 | 6VR1 100x100 | 229 | 4,36 |

| 6 | 4VR1 150x150 | 806 | 1,24 | 13 | 6VR1 200x200 | 468 | 2,14 |

| 7 | 4VR1 200x200 | 1058 | 9,95 | – | – | – | – |

How to calculate weight, mass of 1 m2 of materials of different sizes; how to calculate using the formula

Material parameters: mass, width and length of cells are important when calculating their consumption when performing various works. The weight of the reinforcing mesh and all its standard sizes is determined by the formula and presented in tables.

When studying information, you should remember that the mass may vary. The indicator varies depending on the type of raw material: wire or reinforcing bar; type of wire and class of reinforcing steel; type of packaging: card or roll; package size. That is why the article presents two tables.

| Cell width*cell length*diameter of wire/rebar, mm. | Weight sq. m., kg. |

| 50*50*3 | 1.794 |

| 100*100*3 | 0.7 |

| 150*150*3 | 0.59 |

| 50*50*4 | 3.22 |

| 100*100*4 | 1.84 |

| 150*150*4 | 1.22 |

| 200*200*4 | 0.92 |

| 50*50*5 | 5.16 |

| 100*100*5 | 2.88 |

| 150*150*5 | 1.92 |

| 200*200*5 | 1.44 |

| 100*100*6 | 4.44 |

| 150*150*6 | 2.96 |

| 200*200*6 | 2.22 |

| 100*100*8 | 7.9 |

| 150*150*8 | 5.26 |

| 200*200*8 | 3.95 |

| 100*100*10 | 12.34 |

| 150*150*10 | 12.38 |

| 200*200*10 | 6.19 |

| 100*100*12 | 17.8 |

| 150*150*12 | 11.84 |

| 200*200*12 | 8,88 |

| 150*150*14 | 16,14 |

| 200*200*14 | 12,1 |

| 200*200*16 | 15,8 |

In addition, there is a special formula that allows you to calculate weight if you don’t have a table at hand.

First of all, you should calculate the mass of 1 m of the wire or rod used using the formula M = 3.14 (D2/4)*P, where:

- M – mass of 1 m, kg;

- D – nominal diameter of wire or rod, m;

- Ρ – steel density, in the averaged version it is taken equal to 7850 kg/cub.m.

To determine the mass of 1 sq.m. calculate the number of longitudinal and transverse rods and sum them up. The amount is multiplied by the mass of 1 m of rod.

Connection type

Reinforcing mesh is one of three types of welded materials . The reinforcement is connected using resistance welding technology. In addition, reinforcement is sometimes knitted, which makes it possible to obtain materials of the appropriate type.

Welded

Welded reinforcement mesh

Welded materials have precise and reliable connections; to increase corrosion resistance, one of the following types of zinc coating is used:

- galvanized, then welded (electrolytic zinc coating with a layer of about 10 g/m2);

- welded, then galvanized (electrolytic zinc coating with a layer of about 20 g/m2);

- hot-dip galvanized, then welded (hot zinc about 50 g/sq.m.);

- welded, then hot-dip galvanized (hot zinc about 130 g/sq.m).

The amount of zinc on the mesh is directly proportional to the service life of such a product.

Knitted

Knitting of reinforcement is performed in two cases:

- The contractor purchases reinforcement and independently produces a small number of meshes . For knitting you need wire cutters or a special gun. This method is used in cases where: it is necessary to use the remains of reinforcement;

- urgent work needs to be carried out, but there are no finished products;

- small volumes are required, the use of welding equipment is impractical;

- It is not possible to make the connection by welding.

GOST 23279-2012

GOST 23279-2012

5.3 Reinforcing steel of classes A400 (A-Ill), A500C, B500C and A600C with diameters of 6-16 mm is used as distribution reinforcement in heavy meshes of type 1. in type 3 meshes - reinforcing steel of classes A400(A-Sh), A500S.B500S and A600S with a diameter of 10-16 mm and A240(A-1) with a diameter of 6-16 mm.

5.4 Lightweight meshes should be made of reinforcing steel class B500C with a diameter of 4-5 mm. reinforcing wire of class BP-l with a diameter of 3-5 mm and rod reinforcing steel of classes A400 (A-Ill), A500C. B500C and A240 (A-I) with a diameter of 6-10 mm.

As distribution fittings, it is allowed to use reinforcing steel of class B500C with a diameter of 4-5 mm and reinforcing wire of class B-I with a diameter of 3-5 mm.

5.5 The grades of reinforcing steel for the production of meshes must correspond to the grades established by the design documentation (in accordance with the requirements of building codes and regulations for the design of concrete and reinforced concrete structures, depending on the operating conditions of the structures), specified in the order for the production of meshes.

5.6 Reinforcing steel must meet the requirements:

— rod reinforcing steel classes A400(A-Sh) and A240(A-1) - GOST 5781;

- rod reinforcing steel classes A500C and B500C - current regulatory documents1:

- rod reinforcing steel class A600C - current regulatory documents;

— reinforcing wire of classes Вр-l and В-I - GOST 6727.

5.7 Cross-shaped connections of rods in meshes should be carried out by resistance spot welding in accordance with GOST 14098.

Welding modes must comply with the requirements of current regulatory documents.

5.8 In meshes with working reinforcement made of smooth bar reinforcing steel of class A240 (A-I), all intersections of the rods must be welded.

In meshes with working reinforcement of a periodic profile (rod and wire), it is allowed to weld the intersections of the rods through one or two intersections in a checkerboard pattern, if there are no special instructions in the working drawings. The two outermost bars in the meshes must be welded at all intersections

In the reinforcing mesh, no more than two unwelded intersections of rods are allowed in an area of 1 m2 of mesh from among the intersections subject to welding.

5.9 The breaking force or temporary tensile strength of the rods at the welding points during the tensile test (weakened at the intersections and joints) must not be lower than that required by GOST 10922,

5.10 Requirements for the shear strength of welded joints of rods - in accordance with GOST 10922.

If the welded joints of bars made of reinforcing steel of periodic profile, located in two or one direction, are not subject to equal strength requirements in accordance with GOST 10922, then the rejection load during shear testing should be at least 30% of the tensile strength of the reinforcing wire or the lesser tensile strength of the reinforcing steel diameter

5.11 Cross-shaped connections of the net rods should not be destroyed by impact when the nets are freely dropped from a height of 1 m.

5.12 Butt joints of reinforcing steel bars should be made by contact butt welding in accordance with GOST 14098.

Welding modes are in accordance with current regulatory documents.

Working reinforcement on a rod length of 6 m should not have more than two, and on a rod length of 12 m - more than three butt joints.

Butt connections of rods in one direction within the reinforcement pitch in another direction are allowed through at least three rods.

5.13 The values of relative settlement in cross-shaped joints of rods (in fractions of the smaller diameter of the rods being welded) should be for reinforcing steel classes A240 (A-I). A400 (A-III), B500C, A500C and A600C from 0.2 to 0.5.

5.14 The values of actual deviations of the geometric parameters of the meshes should not exceed the limits specified in GOST 10922.

5.15 Longitudinal and transverse rods in meshes must be straight.

The values of actual deviations from the straightness of the rods should not exceed 6 mm over a rod length of 1 m.

1

In the Russian Federation, GOST R 52544 applies to reinforcing steel of classes A500C and B500C.

Manufacturing, machines and other equipment

The machine tool industry offers a large number of models of machines for the production of reinforcing mesh. The entire variety of machines is divided into two groups:

- manual equipment for small-scale production;

- automatic for mass production of products.

Manual equipment is designed to organize economical production of welded mesh. The machine is distinguished by its simple design and cost, which is several times lower compared to multi-contact automatic welding machines. Using a manual mesh welding line allows you to quickly and efficiently organize the production of this type of product. The unique features of manual lines include the ability to produce non-standard reinforcing mesh (for example, with rods of different diameters).

Manual welding line UTS-102

A striking representative of this type of equipment is the manual welding line UTS-102.

The line for the production of reinforcing mesh from measuring rods works with pre-straightened and cut-to-size rods, which are automatically fed from hopper trays to the welding zone. The transverse bars are fed from the hopper, and the longitudinal bars are loaded into the automatic feeding position to the welding portal manually.

Reinforced mesh production machine

The automatic line for the production of welded mesh WPA works with longitudinal wire when unwinding from coils. Straightened and cut to size transverse rods are fed from hopper trays automatically into the welding zone.

This line operates with a combined feed of longitudinal wire from coils and measuring rod.

Welding portal , which is the main part of the line, is often equipped with a cross-bar feed module and additional modules to increase productivity:

- feeding longitudinal bars;

- pneumatic guillotine;

- packager.

This class of machines includes:

- semi-automatic multi-point mesh welding machine (LTS-1000K1);

- automatic multi-point mesh welding machine (MTM-2000K1-1).