Composition and proportions of the mixture

Concrete grade M350 B25 is an elite type of heavy concrete with increased strength characteristics. It is used for the construction of buildings that regularly experience severe physical, mechanical, and atmospheric loads.

Important! Thanks to the precisely calibrated composition and the inclusion of high-quality components, the material also has high compressive and tensile strength.

Main components of M350 concrete:

- sand;

- crushed stone;

- cement.

The solution may contain screenings to partially replace the filler, antifreeze additives, modifiers and plasticizers.

For concrete M350, sand is selected from one of three fractions - medium, coarse, fine. Crushed stone or gravel can be of granite or calcareous origin (the introduction of both filler options is allowed).

Nevertheless, granite crushed stone with a density of about 2600 kg/m³ will further increase the strength of concrete, although it will negatively affect its price (it will be 7-10% higher). Granite has a density of 800 kg/m³, but it reduces the cost of production.

Crushed granite

Cement of grades M400 or M500 is introduced into the composition in an increased volume, due to which the material quickly sets. Plasticizers accelerate the hydration process and increase the resistance of concrete to moisture.

In addition to choosing the appropriate components, it is equally important to strictly observe their proportions:

- 1 part cement M400;

- 1.5 parts sand;

- 3.1 parts of crushed stone.

Important! For 1 part of M500 cement, take 1.9 parts of sand, 3.6 parts of crushed stone. To mix 1 cubic meter of concrete you will need 380 kg of M500 cement, 1370 kg of crushed stone or gravel, 720 kg of sand and 175 liters of water, as well as a plasticizer (according to the instructions).

Where is it used?

High-strength concrete is ideal for foundations and load-bearing supports. The material was appreciated as a good solution for high requirements. I used it myself when working with the foundation. But B25 concrete is poured during construction:

- frames;

- floors;

- load-bearing structures;

- piles;

- bridges;

- tunnels;

- runways at airfields.

Wherever strength is needed, B25 is suitable. Individual construction, industrial construction, various offices - it can be used everywhere.

Helpful information:

- Cement brand M500: how to choose and characteristics

- Using caustic soda to clean drains

- Concrete M250 (b20, b20, b20): application, composition and...

- Cement grades: application and interpretation

- Metal tile Monterrey: technical characteristics

- Polystyrene concrete - characteristics and scope of application

If you want to use B25 concrete and have no experience, I advise you to study GOSTs and SNiPs. They are written dryly and regimented, but they give a detailed idea of even the little things.

For example, why B25 (I answer - it can withstand pressure of 250 atmospheres without damaging the structure).

Or the documents will clarify some obscure things like vibration compaction. How many times have I watched the construction process, I have never seen technology used. At best, everything is done manually. Or in general, they’ll sketch it, accept/pressure and that’s it. But to obtain better results and higher strength, vibration compactors are simply necessary. Okay, I stirred a couple of buckets of the mixture, sealed it, knocked and it was done.

Concrete substitute and its advantages

But the scope of application of the B25 is an order of magnitude greater than simply patching a foundation. And the process of large-scale construction should be controlled so as not to suddenly be disappointed with the result after a couple of years. However, while studying the material, I found one alternative - purchasing prefabricated structures manufactured in a factory. Expensive, but quality and, as a rule, corresponds to the price.

Specifications

After final hardening, M350 concrete has the following characteristics:

- Mobility – P2-P4. The indicator can increase to P5 due to the addition of plasticizers, but they are not always needed. The higher the value, the more fluid the material becomes, which expands its scope of application.

- Frost resistance - up to F. Concrete will not lose its characteristics over 200 cycles of freezing and defrosting. Such high frost resistance allows the M350 to be used outdoors and in the harshest climates.

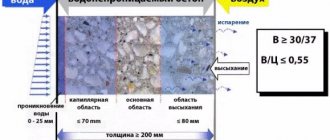

- Water resistance - W. There are almost no cavities or air bubbles inside the structure made of concrete grade M350, which enhances the protection of the material from moisture penetration. If the concrete is in the shape of a 15 cm cone, it will withstand a water pressure of 8 kg/cm².

- Compressive strength – 33 MPa. Also, to determine the technical characteristics of the material, its tensile strength during bending, equal to 3-3.6 MPa, is important.

- Specific gravity – 2320 kg/m². This figure allows the material to be classified as heavy concrete.

Advantages of M350

The material can withstand the highest loads, because its strength characteristics are considered optimal. The finished concrete mass is resistant to destruction and the influence of abrasive, compressive and tensile loads.

Other advantages of M350 concrete:

- High mobility of the solution. Concrete turns out to be very easy to lay.

- The presence of additives that increase frost resistance. These substances allow you to work with concrete all year round, and also use it regardless of the climate. The design is structurally integral and does not lose this property throughout its entire service life.

- Long maintenance-free service life. Buildings and structures made of M350 concrete are able to resist the action of natural factors - precipitation, wind, ultraviolet radiation. They are considered resistant to aggressive environments, so they last for many years.

- Sufficient density. The structures are reliable, durable, and can withstand impacts and other mechanical loads.

- Moisture resistance. The water resistance class of concrete M350 expands the possibilities of its use and provides a significant degree of protection against moisture penetration.

- Environmentally friendly. The material does not contain harmful impurities, it is safe for people and the environment.

Disadvantages of the M350

M350 concrete is considered strong, durable and belongs to the elite, but it still has its drawbacks:

- Fluidity. In some cases, this property may become not an advantage, but a disadvantage of the building material. If a plasticizer is added to the composition, the finished solution will not be suitable for all types of concreting work.

- Large amount of cement. Due to the increased rate of binder, concrete quickly thickens, hardens, and must be delivered to the construction site or poured into molds in an extremely short time.

- High price. The cost of a cubic meter of concrete mixture in this category is higher than that of lower-quality analogues. This inevitably increases overall construction costs.

Concrete M350 sets quickly

Scope of use

The range of applications for concrete mixtures is very wide.

READ Composition, strength class and other characteristics of concrete M400 It is used to implement the following tasks :

- erection of supports and other supporting structures;

- production of floor and ceiling slabs, pylons, beams;

- casting of airport road slabs and so on.

The good water resistance of this material allows the construction of various hydraulic structures, for example, swimming pool bowls.

If a concrete structure is not designed for operation with large and heavy loads, then during its construction it is permissible to use concrete of a class lower than B25. This will make it possible to reduce construction costs.

Strength classes

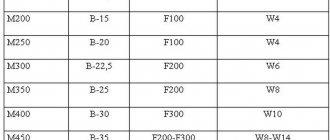

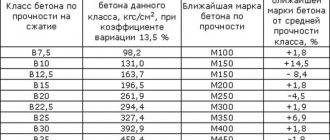

Concrete grade M350 corresponds to strength class B25. The brand designation indicates a rounded indicator of compressive strength in kgf/cm² when converted from MPa.

Important! The grade reflects the cubic strength of the concrete sample.

According to the standards, in 95 cases out of 100 this sample can withstand pressure of at least 25 MPa. In addition, M350 can be designated by the abbreviation BST (heavy concrete).

Areas of use

Concrete M350 is used in a variety of areas of construction and repair. It is considered one of the most popular compounds for commercial construction because it can withstand high loads.

The material is ideal for pouring monolithic foundations for large objects. It is rarely used to create foundations for ordinary low-rise buildings due to its high cost. The safety margin of such a house foundation will be too large and simply unclaimed.

Other areas of use of M350 concrete:

- Construction of reinforced concrete structures. Often, the material is poured directly into a hole drilled for support, with the walls pre-treated.

- Organization of floor slabs with many voids. Such products are light but durable; they do not require reinforcement, but their performance properties remain high.

- Creation of airfield and road slabs, including those used under the highest loads. To obtain such products, concrete is poured into molds and reinforced using special hydraulic equipment.

- Construction of columns and load-bearing floors. Finished products will withstand compression, pressure, and stretching without problems.

Concrete work at the airport

Important! M350 grade concrete is used to make swimming pool bowls, structures in areas where groundwater rises to great heights, tunnels, bridges, crane beams of buildings, septic tank and sewer wells, stairs and flights, and other critical structures.

Component quality

In order for the solution to meet the requirements of GOST, it is necessary to strictly monitor the quality of its components. Only fresh cement is used, which was produced no later than 6 months before the production of M350 concrete.

Cement must be properly stored under optimal conditions of humidity and temperature. To check the quality, take it in your hand, squeeze it well into a fist and evaluate the condition - the powder should be crumbly, loose, and not stick together.

If the composition contains lumps, its properties are no longer optimal: most likely, storage rules were not followed. The specific gravity of the final mixture greatly depends on the brand of cement, so low-grade binders are not suitable for production.

The sand must also be of high quality: dry, purified, without impurities (especially clay). If necessary, the sand is washed and sifted.

If any component of the solution has high humidity, the amount of water is reduced. As for the latter, clean drinking water without chemical additives is suitable for M350 concrete - this is exactly what is used in industrial conditions.

Important! Low quality water seriously degrades the properties of concrete.

Stages of concrete preparation

The required strength of a concrete mixture can only be achieved with a well-prepared solution. To do this, you need to use a concrete mixer, since it will be quite difficult to mix the mixture yourself, and in the end it will be almost impossible to get good quality.

READ Composition of expanded clay concrete, its proportions, properties and application

The preparation of the solution is as follows:

- the concrete mixer is loaded with dry materials (cement-sand mixture), which mix well;

- Then water is gradually added to the structure of the mixture and the solution is stirred until a homogeneous mass is formed. At this stage, it is possible to add plasticizers and other additives. For example, during the cold period it is permissible to use anti-frost options that reduce the freezing temperature of water;

- at the final stage, solid filler, previously moistened with water, is poured into the concrete mixer. The solution is thoroughly mixed to evenly distribute the crushed stone in the mass.

The strength of concrete directly depends on the quality of the ingredients . The sand should not contain any impurities, so before using it, it is sifted or washed. The water must also meet strict requirements. Using dirty liquid, for example, collected from a pond or river, there is a risk of reducing the quality of the concrete.

READ Types and installation of electrical reinforced concrete supports

Experts suggest using drinking water for this purpose. The presence of many companies specializing in the production of concrete mixtures allows you to get rid of the need to carry out this process yourself. But in this case, the costs of transport and the manufacturer’s markup increase.

Independent preparation of the solution and its installation

When creating a solution, it is important to strictly maintain the proportions of the components and follow the sequence of their connection. We are only talking about making up the ingredients yourself: when you buy a ready-made mixture, you just need to dilute it with water.

For work, it is mandatory to purchase a concrete mixer, since manual mixing does not make it possible to obtain a perfectly smooth, homogeneous mass. In addition, mixing crushed stone will cause unreasonably high labor costs.

Concrete mixer Kraton BEETONE 120

The course of action for the production of concrete grade M350 is as follows:

- Load sand and cement into a concrete mixer container and mix the components well.

- Pour in water without stopping stirring the mass (if modifiers and plasticizers are present in the composition, they are dissolved in the liquid in advance).

- Gravel or crushed stone is sprinkled with a little water, introduced into the general solution, and stirring is started again until a homogeneous mass is obtained.

Concrete of this brand, like other heavy concretes, sets very quickly. Filling is carried out within a maximum of two hours after preparation, otherwise the mixture will be spoiled.

If this is not possible, or if a concrete mixer is not available, it is recommended to order ready-mixed concrete M350 at the nearest plant. The quality of the composition will be higher, and the construction process will be reduced in time.

Before pouring the solution, carefully prepare the base - clean it of dust, debris, and dirt. Afterwards, formwork is installed from lumber (boards, bars, pieces of chipboard), or a ready-made structure is purchased or ordered.

In order for the formwork to be able to withstand the weight of the concrete monolith, it is reinforced in advance with lintels and spacers. If possible, make the formwork permanent - the polyurethane foam in its composition will serve as additional insulation.

Important! The screed or foundation must be reinforced with metal mesh or reinforcement.

After layer-by-layer pouring of M350 concrete, it is distributed as evenly as possible inside the mold and vibration is applied. Using a deep vibrator, you can get rid of cavities and voids in cement stone, improve its quality and ensure all the proper properties and technical characteristics.

It is equally important to provide optimal conditions for setting and complete drying of the composition. During the first 10 days, the surface of the monolith is irrigated with water and protected from precipitation and sunlight.

The structure reaches its final strength 28 days from the moment of pouring. At elevated air temperatures, this period may be slightly reduced and vice versa.

Composition of 350 concrete

This type of concrete is considered one of the most reliable. It can withstand heavy loads while fully maintaining its properties. The material easily copes with humidity, atmospheric pressure, mechanical stress and low temperature. To fully give concrete such parameters, it is necessary to use only high-quality raw materials.

The main characteristic of concrete is its resistance to frost. He carries them quite easily.

The M350 includes the following components:

- water;

- cement;

- crushed stone;

- sand;

- plasticizers;

- additives that improve specific properties of the material.

All concrete ingredients have their own characteristics in terms of strength, grain size, etc. For this type of solution, sand of any fraction can be used. It should be pre-cleaned by removing debris and dirt. The role of filler is performed by limestone or granite crushed stone.

For concrete, you need to use Portland cement of at least 400 grade. For 10 kilos of cement, you will need 15 kg of sand and 31 kg of crushed stone. If M500 cement is used to produce the mortar, then a little more sand and aggregate will be needed.

To prepare a cubic meter of solution you will need:

- 400 kg of cement M500;

- 725 kg of sand;

- 1 t of crushed stone or gravel;

- 175 liters of water.

If all proportions are strictly observed, then it will be possible to make reliable concrete with good parameters. If the ratios change in any way, then there is a risk of significant deterioration in properties.

Cost of concrete M350

The price of a cubic meter of M350 concrete depends on the region, manufacturer and additives included in the material. If in a given area raw materials are imported from afar, the cost of the finished product increases. On the contrary, for manufacturers who independently prepare or extract all the components, the price of concrete will be lower.

Important! The average cost of a cubic meter of M350 brand solution is 3600-4600 rubles.

Despite the high price, M350 concrete remains a popular material for the construction of critical structures that undergo high loads. It maintains its integrity for a long time, is not afraid of the influence of negative factors and can be considered one of the most durable and reliable compounds.

Production of concrete M350

When producing M350 cement, the manufacturer uses thorough mixing of all components to obtain a homogeneous, uniform mass. The main requirement of the manufacturer is the homogeneity of the mixture.

If the mixture is poorly mixed, this will lead to a decrease in the maximum permissible load coefficient, which will entail a decrease in the technical and operational properties of the building. In addition, it is very important to maintain the exact proportions of all components and meet all technology requirements.

In order to produce one cubic meter of M350 concrete, it is necessary to mix cement (400 kg), sand (752 kg in pure form), crushed stone (1000 kg) with 175 liters of water. The cost of concrete of this brand is set by the manufacturer independently; it depends on many factors that accompany production. The price is set based on current costs. The bulk of the amount goes to the components. The cost is calculated in a standard way. Of course, in order to make a profit, the manufacturer is forced to make a certain markup on the product. For this reason, each manufacturer has its own price and it can vary dramatically. Construction organizations purchase materials on their own, so they have the right to choose which manufacturer to cooperate with. The cost of the material will be significantly higher if the mixture includes additional additives (anti-frost, etc.).

READ ALSO: What exactly is the difference between concrete and cement?