Difference in composition

First of all, you should know the production features of each material. The composition of an aerated concrete block includes quartz sand, cement, lime, water, and a little aluminum paste. For better strength, this mixture is processed with hot steam under high pressure.

The composition of expanded clay includes expanded clay and a mixture of cement. Next, the solution is thoroughly mixed and poured into molds, followed by compaction. After the mixture has hardened, the resulting blocks are removed from the molds and sent to dry for a month.

Production methods

Both gas silicate and expanded clay concrete are representatives of the group of cellular concrete, but the technical characteristics and composition of the materials differ significantly.

Gas silicate blocks are made from a mixture of sand, cement, lime, aluminum powder and gas-forming additives. During production mixing of the components, air bubbles appear, which subsequently form the porous structure of the material.

The composition of expanded clay concrete contains: sand, cement, expanded clay, water and air-entraining additives. Knowing the sequence and technological nuances, you can produce the material even at home. Unlike aerated blocks, expanded clay concrete does not require special equipment.

Manufacturers note that gas silicate and expanded clay concrete have different construction characteristics that should be taken into account before purchasing:

- strength. Expanded clay concrete has indicators of 50–150 kg/cm2, gas silicate is significantly inferior, the strength of the material is maximum 20 kg/cm2,

- moisture absorption. Expanded clay absorbs moisture 2 times less than gas silicate,

- volume weight. The indicators of gas silicate are 200–600 kg/m3, the weight of expanded clay concrete exceeds them several times, ranging from 700 to 1500 kg/m3,

- shrinkage. In contrast to the zero shrinkage of expanded clay concrete, gas silicate indicators are up to 1.5%,

- freezing and defrosting cycles. Expanded clay concrete - 50, gas silicate - 10,

- thermal conductivity. Gas silicate blocks have the best thermal conductivity characteristics; they are almost twice as good as expanded clay concrete.

Let's take a closer look at the advantages and disadvantages of each material.

Block properties

In terms of strength, expanded clay block is superior to aerated concrete. The density of the first is D800-D1200, while the density of aerated concrete block is D400-D600. The strength of expanded clay concrete blocks is 50-150 kg/cm2, and that of aerated concrete blocks is 35-65 kg/cm2.

Hollow expanded clay concrete blocks have a reduced load-bearing capacity. To improve this indicator, the voids should be laid perpendicular to the main supporting side.

High-quality and heavy expanded clay blocks are even used for the construction of multi-storey buildings (12 floors). But aerated concrete is used for the construction of three-story buildings, no higher.

But expanded clay concrete is not suitable for building a base or laying a foundation. It's all about a high humidity environment, to which they do not respond very well.

Comparative characteristics

When deciding whether it is better to use a gas block or expanded clay block to build a house, you need to consider several criteria. Thus, from the point of view of constructive use, a composite with expanded clay can be used on a construction site for screeding, monolithic structures and the formation of individual elements. The composition with aluminum powder is relevant only for the manufacture of blocks.

Blocks made of aerated concrete and expanded clay concrete Source twimg.com

Structure

Cellularity, which determines the low weight of materials and water absorption, is characteristic of both blocks, but is explained by different reasons. In the case of aerated concrete, this is the content of aluminum gas-forming agent. In expanded clay concrete, the porous structure is created by expanded clay. In total, the air content in each case is at least 70%.

Strength

When choosing whether expanded clay concrete or aerated concrete is better in terms of load-bearing capacity, preference should be given to a universal composite. Moreover, even hollow blocks with expanded clay in their composition have greater mechanical endurance than solid foam concrete products of similar density.

Block products made of aerated concrete are acceptable for the construction of houses up to 15 meters high on three floors. More durable analogues are suitable for the construction of buildings of 10-12 floors. But even this load-bearing capacity is not enough to lay the foundation and plinth. This is additionally explained by strong water absorption, which under constant load will lead to rapid destruction of structures.

Construction of walls from expanded clay concrete monolith Source ytimg.com

Thermal insulation

Which material keeps heat in the house better? The aerated concrete block has decent heat resistance due to its porous structure, inside which air circulates. Expanded clay in the block is known as a good insulating material for insulating attic floors, floors and voids between walls.

The higher the density of the material, the less thermal insulation it has and requires additional insulation.

Based on the above, aerated concrete can be laid in one row without the use of insulation. Expanded clay block retains heat inside by 1/3, which will require the use of extruded polystyrene foam and other thermal insulation materials.

Advantages and disadvantages of gas silicate

Speaking about gas silicate, we can confidently highlight the following advantages of this material:

- Low specific gravity.

- Unlike expanded clay concrete, this material does not require additional processing, due to which construction time is halved.

- High thermal insulation properties. Single-layer structures can be erected from GS without fear that they will be cold.

- Gas silicate can be laid using glue, which reduces the thickness of the seam (2 mm). Expanded clay concrete is laid only on a cement-sand mixture, and the minimum seam height is 10 mm.

- Easy to grind and cut.

- Has good vapor permeability.

- Smooth and even blocks with correct geometry.

Among the disadvantages of gas silicate, the following disadvantages are distinguished:

- Fragility. Due to its low strength, cracks form in the plaster quite quickly. Therefore, gas silicate is rarely used for the construction of load-bearing walls.

- High level of moisture absorption (100%).

- Low compressive strength.

- Low level of frost resistance.

- The inability to produce aerated concrete blocks at home, without specialized equipment.

- Flowability of walls. Without special fasteners, it is impossible to secure objects on a gas silicate wall. Of course, a nail will easily pierce the surface, but the hardware will not stick to it.

- Cannot be finished. It will be very difficult to apply decorative plaster or any other composition to a perfectly smooth surface.

Healthy! According to rumors, gas silicate is harmful to humans. Actually this is not true. During the processing of the material, its main component (lime) loses its negative properties.

Vapor permeability

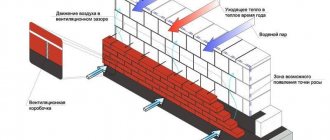

In terms of moisture resistance, these materials have significant differences. Aerated concrete absorbs up to 25% moisture, expanded clay concrete – up to 10%. However, due to the greater weight at the output, the moisture composition will be approximately the same. But the vapor permeability of expanded clay is significantly lower. True, many believe that breathable walls are more environmentally friendly and create a favorable microclimate. But in this case, you should be prepared for additional insulation.

Environmental friendliness

Sometimes you can hear that cellular concrete contains harmful aluminum. This means that such blocks cannot be safe in any way. In fact, the concentration of this substance is so low that it cannot threaten our health in any way.

When purchasing aerated concrete, it is very important to trust a reliable company. The fact is that low-quality cellular blocks partially contain slag and ash instead of sand. You can avoid this if you take your choice of seller seriously and also check quality certificates.

Price

Expanded clay concrete blocks are higher. However, if we take the cost of the box as a whole, then the final amount may be approximately the same. For example, to minimize uneven masonry, more mortar and plaster are used, but at the same time there are no additional costs for the purchase of special anchors. Shipping costs also matter. It will be cheaper to bring aerated blocks to the site, since the final weight of the material per cube will be less.

What is better - expanded clay block or aerated concrete? Each option has its pros and cons. Therefore, you should rely on the budget, number of floors, thermal insulation requirements and other factors.

supplies these materials directly from the manufacturer. We are pleased to offer affordable prices, consultations and assistance in calculations, delivery. Call now!

Expanded clay concrete or aerated concrete: which is better?

Building a house from expanded clay or aerated concrete has both a number of advantages and a number of disadvantages.

Advantages of expanded clay concrete:

- high strength,

- low price,

- high frost resistance,

- excellent sound insulation,

- moisture resistance,

- fire safety,

- environmental friendliness.

Expanded clay houses are not susceptible to mold or mildew. In addition, due to the strength of the material, cracks do not form in expanded clay walls. No additional wall reinforcement is needed. But expanded clay has a number of significant disadvantages:

- High thermal conductivity.

- External plastering and cladding are required.

- The work requires special tools.

- Expanded clay concrete is placed on a cement-sand mortar up to 10 mm thick. Because of this, large cold bridges are formed. This means you will need a lot of insulation, otherwise there will be high costs for heating the house.

Strengths of aerated concrete:

- Low thermal conductivity. Due to the presence of air in the pores, a house can be built even without insulation.

- Ease of laying. Aerated concrete blocks have even proportions, so they are easy to lay. Plus, the gas block is relatively light in weight.

- Thin seam with adhesive backing. The blocks are placed on a special glue, the thickness of which is 2-3 mm. Therefore, cold bridges practically do not form.

- Low cost of final construction. The price for a cube of aerated block is much lower than for a cube of brick.

- Ease of processing. You can cut blocks using available tools.

- Fire resistant.

- Absolutely environmentally friendly.

Disadvantages of aerated concrete:

- Fragility of the material. It is not recommended to build buildings higher than 2-3 floors from aerated concrete.

- Increased moisture permeability. The gas block must be protected from exposure to water.

- Facing a building using ventilated facades or ventilation gaps.

There is no clear answer as to which material is definitely better. Both types of composite blocks have their own advantages and disadvantages. First, decide which indicators are most important to you, and make a decision based on that. Do you want your house to be warm in winter and not overheat in summer? Then choose aerated concrete. Don't want to do reinforcement? Then you can use expanded clay.