Electric motor design and operating principle

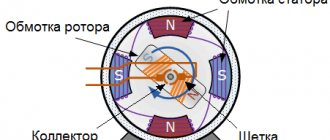

The operating principle of an electric motor is based on the interaction of a conductor with a current located in a magnetic field.

The magnetic field is created by the stator.

The main element of its design for a DC motor is a permanent magnet, for alternating current it is an excitation winding. The rotor (armature) has its own winding, to which voltage is supplied using a brush-commutator unit. The interaction of magnetic fields causes the rotor to rotate.

The collector consists of a set of contacts, which are copper plates located directly on the rotor. Micanite or mica cuffs act as insulators for each individual contact. Graphite brushes are sliding contacts pressed against the commutator.

Why do brushes spark in an electric motor?

Sparks, including on a working engine, appear due to mechanical action between the brushes and the commutator. The brush, moving along the commutator from one of its contacts to another, alternately forms and breaks a connection with each of them. Now remember what happens if you unplug any working electrical appliance from the socket - usually at such a moment a spark jumps between the plug and the socket. In the case of a brushed motor, this is the same phenomenon.

Read also: Which lamps are the most energy-saving

Therefore, a small spark even on a working electric motor is acceptable, since connections and ruptures constantly occur here.

Why do the brushes in the electric motor of a vacuum cleaner spark strongly?

The brushes in the vacuum cleaner motor are responsible for creating the so-called “sliding” contact. It converts mechanical impulse into electrical energy when the device operates. The elements move through the commutator, making and breaking connections with the contacts, and a small amount of sparking is considered completely normal. But if it is too strong, then the problem requires elimination, otherwise sooner or later the engine will begin to overheat, lose power and fail.

Sparking is considered abnormal if it is distinguished by a barely noticeable stripe in the commutator area.

There are several main reasons why the vacuum cleaner does not work well and the brushes spark:

- Wear. The part of the brush in contact with the commutator is made of carbon and with frequent use wears out and loses length and volume. Contact between parts deteriorates, and the engine sparks profusely.

- Pollution. During operation, the brushes, in constant contact with the commutator, form carbon and metal dust, which gradually accumulates on the internal parts. After this, when friction occurs, the engine begins to spark, and carbon deposits form, which only worsens the problem.

- Poor contact. Both old and new brushes may not fit tightly to the commutator; in both cases, the motor sparks.

- The angle of inclination is off. The brushes must be positioned strictly along one line passing through the axis of rotation of the commutator. If they are installed incorrectly, or are simply loose from constant vibration in an old vacuum cleaner, the motor will inevitably begin to spark.

- Short circuit between winding turns. This is the most difficult and unpleasant reason why the vacuum cleaner motor sparks and smells. Irregularities in operation are often accompanied by popping noises and a drop in speed. Repairing the brushes in this case is not enough. More often, you have to change the entire engine so that it stops sparking, or send it to a service center for rewinding.

If problems arise, sometimes they can only be eliminated with the help of specialists. But most problems can be corrected at home.

Causes of abnormal sparking of an electric motor

Intense flashes on brushes can occur for a number of reasons:

- the service life of the sliding contacts is exhausted (the springs or the brushes themselves are worn out);

- dustiness of the walls and contacts on the commutator and rotor;

- fault in the rotor or stator winding.

To determine a specific malfunction, it is necessary to diagnose the electric motor. This will help eliminate the cause.

Integrity of rotor and stator windings

More serious problems that cause strong sparking of an electric motor are interturn short circuits of the rotor or stator windings. It is difficult to fix such a breakdown on your own. Signs of a problem with the winding are:

- engine operation is accompanied by popping noises;

- sparks fly around;

- blackening is observed on the collector lamellas;

- The electric motor speed has dropped.

Advice! If, during a visual inspection, the damage to the winding cannot be found, then you can resort to electrical measurements using a multimeter.

It will not be difficult for experienced electricians to figure out how to carry out electrical measurements:

- on paired winding outputs to the collector plates;

- between the collector and the rotor (armature) housing;

- between the stator housing and the winding output;

- test the integrity of the stator winding.

Important! Resistance and voltage measurements will help identify a failed component of the electric motor. A vacuum cleaner with a faulty electric motor winding cannot be operated.

For home craftsmen without special equipment, rewinding a faulty electric motor element is very problematic. Therefore, it is necessary to contact a service workshop. When you contact a repair center, for example, with a Samsung vacuum cleaner, they may offer to replace its windings or purchase a new motor.

Ways to fix the problem

- If the angle of inclination is incorrect: it is necessary to carefully examine the surface of the nodes. Next, adjust the position using screws.

- If shorted: it is best to replace the motor. Or seek the help of specialists by contacting a repair center.

- If the brushes are worn out, then you need to find the brush holders, having first disassembled the engine, and replace the brushes yourself with new ones.

- If the contact is poor, you can let the vacuum cleaner run for more than 15 minutes at neutral speed.

- Sliding contacts must always be kept clean, but if contamination occurs, carbon deposits must be immediately removed using sandpaper or fine plaster and degreased.

Subscribe to our Social networks

Causes

Transient processes occur in the rotor windings due to intermittent mechanical contact of the brushes with the commutator plates, which causes the formation of small arcs.

Important : a fully serviceable engine does not exclude sparking during operation. There are other reasons that cause severe sparking and create the possibility of motor failure.

Brush wear

With prolonged use or poor-quality brush material, they no longer press tightly against the contacts of the commutator. Due to poor contact, the engine does not gain speed or does not start immediately. A worn brush can be easily identified visually.

Sometimes it is not possible to correct the situation by replacing only the worn part. The brush holder and spring should be replaced.

Short circuit in the armature winding

The consequence of such a defect is uneven sparking on the collector. It will be stronger on some plates than others. Due to the presence of an interturn short circuit, the current in certain sections of the rotor winding will be stronger than in others.

Rewinding the rotor or replacing it will eliminate the problem.

Fault in the stator winding

A defect similar to a short circuit in the rotor winding occurs in the stator winding. You can check the presence by measuring the resistance of parts of its windings. If there is a strong difference, it is necessary to rewind the winding or replace it.

Pollution

The product of brush wear is graphite dust, which is an additional source of increased sparking. Dust accumulates between the plates, which creates additional conditions for the formation of sparks. Preventive cleaning of the commutator with sandpaper and removing dirt between the plates will keep it clean.

Brushes not installed correctly

If the brushes are deviated from the norm towards the commutator surface, a significantly larger amount of graphite dust is generated during operation. Misaligned brushes must be corrected.

Poor contact between brushes and commutator

The electric motor spends part of its operating time in overheating mode. Under such conditions, carbon deposits form on the collector. Poor contact leads to increased brush sparking and even more carbon deposits.

You need to use fine-grain sandpaper to clean the surface of the commutator. To increase the stripping effect, use a screwdriver. Clamp the engine rotor into the chuck and remove carbon deposits with sandpaper at low speeds. Afterwards you need to finally polish it on a felt wheel.

Mechanical problems

Mechanical reasons are caused by non-compliance with the requirements of design and technological documentation. Most mechanical causes can be eliminated by turning the manifold on a lathe. Refer this repair operation to a qualified technician. Here are some types of faults that may indicate a breakdown:

- The surface of the collector is uneven;

- The shaft runout exceeds the value specified in the technical documentation;

- Individual collector plates protrude beyond a common level for all;

- Insulation protrusion (mica);

- The brushes in the brush holders move with jamming;

- On the contrary, the brushes are inserted into the brush holders with a large gap, which creates vibration during operation;

- The brush holders are installed far from the commutator;

- Uneven tension of the springs, resulting in a difference in the pressure applied to the brushes.

Videos that may help solve your case:

The heating element sparks in the washing machine

Now we know why a washing machine sparks - if the sparks are strong and appear only when the electric motor is running, then the problem is in the motor. But sometimes the reason lies in something completely different. For example, a worn heating element can easily spark in a washing machine - in some cases, sparks are visible even through the glass. If this really happens, you should immediately turn off the power to the washing machine without touching its body.

Next, we gain access to the heating element and check it with a multimeter (in diode testing mode, with sound indication), touching it with probes to the current-carrying contacts and to the housing - if the heating element “breaks through” onto the housing, the multimeter will beep and change readings. Instead of a multimeter, you can use dial gauges (in ohmmeter mode) - here it is easier to notice the slightest fluctuations in resistance. If the heating element fails, it must be unconditionally replaced - the heating elements are not repaired.

Sometimes the junction of the heating element with the wires can spark - in this case, you just need to clean the oxidized contacts.

Before checking the heating element, do not forget to drain the water from the tank by unscrewing the filter. Otherwise, you risk flooding your floor and even your neighbors.

Useful video

If the manipulations did not give the desired result and your vacuum cleaner is still faulty, then do not experiment and contact a specialist. The malfunction is more serious than you thought and should be dealt with by a professional. Further attempts to fix the problem yourself may lead to the vacuum cleaner being damaged, but this is due to your persistence and ignorance.

Source

What are they made from?

Brushes for grinders and other power tools are made from different materials, but the main ones are coal and graphite. This material has a low coefficient of friction and also has increased abrasion resistance. To improve contact, various impurities are added to the composition of graphite or carbon during the manufacture of brushes. Depending on the impurities used, the following types of brushes are distinguished:

- Coal

- Copper plated

- Carbon-graphite

- Graphite

- Copper-coal

- Copper-graphite

The composition of the main part affects not only the service life or wear, but also such a parameter as signs of sparking. The amount of brush sparking depends on the composition from which they are made. When purchasing them, you need to pay attention to the composition, and not purchase equipment of unknown origin and dubious quality.

Why do the brushes on a vacuum cleaner burn?

When operating a vacuum cleaner, it is necessary to periodically carry out a preventive inspection of the parts contained inside its body. You will need to turn on the electric motor. In this case, it is very important to pay attention to the intensity of the appearance of sparks in the area of its sliding contacts - brushes. A spark that is barely noticeable to the eye is normal for a properly functioning engine. But strong and frequent flashes indicate deviations in engine operation. And this is a reason to start looking for the reasons why the brushes in the vacuum cleaner spark, in order to prevent serious damage in the future.

Background

The electric angle grinder was invented in the first half of the last, twentieth century . Serial production began in 1954 by the German company FLEX-Elektrowerkzeuge. In our country, people over 40 remember what CMEA is. It was according to the plan of the Council for Mutual Economic Assistance in the 1970s in Bulgaria, then a country of people's democracy, in the city of Lovech that the production of angle grinders began under the Eltos brand . A significant part of the plant's products was supplied to the USSR.

The first Eltos, dubbed “grinders” by the Soviet people, had a sensational success in various industries and construction , and made it possible to mechanize and speed up many technological processes associated with the processing of sheet and profile metal. Due to the low number of revolutions, the straight grinders used before had only one function - grinding, and low mobility, since they were powered from a three-phase electrical network.

Modern grinders, which work wherever there is a 220 V outlet, owe their global distribution to German engineers who managed to turn a DC commutator electric machine into a small-sized, high-speed single-phase UKD, a universal commutator motor.

This difficult problem is solved by a brush-collector unit .

The engine brush is a modest part that performs important functions in extreme conditions.

Reasons why brushes spark

Very often you can notice how the brushes on an angle grinder sparkle. Signs of sparking are detected through the ventilation holes in the body of the power tool. Craftsmen are interested in why the brushes on an angle grinder spark, even after they have been directly replaced. There are many reasons for this, and to understand this, you need to have an understanding of the structure of a power tool. If you know how the angle grinder works inside, then understanding why the brushes spark strongly will not be difficult.

The reasons for strong sparking of brushes on grinders are the following factors:

- Faulty armature winding. If a violation of the insulation of the armature winding occurs, then this ultimately contributes to the development of an interturn short circuit, as well as a short circuit to the core. In addition, a winding break may occur, which will ultimately cause an increase in load. A characteristic sign of a faulty armature winding is a decrease in speed, an increase in noise and a drop in power

- The brushes do not press well to the commutator. A spring is responsible for pressing the main part, which, over time, loses its original springing properties.

- The rotor winding has broken off from the copper plate of the commutator - this phenomenon is extremely rare, however, if the power tool is overloaded, it may well occur

- The centering of the electric motor armature is disrupted, which ultimately contributes to strong sparking of the brush on the angle grinder

- The shape of the collector is broken. The collector, consisting of copper lamellas, has a cylindrical shape, which can be broken when the rotor is rewinding. At the slightest deformation of the commutator shape, sparking of the brushes will occur

- Violation of insulation between the collector lamellas. Each collector plate is insulated from each other, and if the micanite insulating layer is damaged, sparking occurs. The insulation between the plates may also be compromised due to the settling of the graphite layer in the grooves

- When the armature bearings are worn. If the bearings are faulty, then a beating of the rotating armature occurs, and as a result, signs of sparking appear

- Curvature of the rotor shaft. It is difficult to bend it, but if this happens, the engine begins to work under load. To prevent the tool from malfunctioning, it is recommended to replace the rotor

- If the ends of the armature windings are soldered incorrectly to the copper plates of the collector. Such errors are not allowed at the factory, but they can be made by the wrapper who rewinds the armature of the power tool.

- Inappropriate composition of graphite brushes. The parts in question are made from coal and graphite, adding different types of impurities. This is done for a reason, but in order to use brushes depending on the voltage and shaft rotation speed. Graphite can be soft or hard. The lower the supply voltage, the softer the grade of graphite selected. For high-voltage power tools, it is necessary to take hard brushes that do not contain copper.

- Deformation of the lamellas due to their heating. If the angle grinder experiences excessive loads, deformation of one or more lamellas of the collector may occur. The plates rise relative to the others, resulting in the contact being broken. This malfunction causes strong sparking of the brushes when operating the power tool.

- Poor contact at the brush connection point. If the terminal is loosely connected to the device, the result of this contact failure may manifest itself in the form of excessive sparking

- Presence of carbon deposits on copper plates - periodically or regularly it is recommended to clean the surface of copper lamellas from carbon deposits. Carbon deposits usually appear due to wear of the brushes, so if blackening is detected on the surface of the commutator, it should be wiped with alcohol

Often, after changing the brushes on an angle grinder, craftsmen observe the phenomenon of excessive sparking. Based on the factors described above, you can identify the cause and eliminate it before the tool fails. The elements in question are inexpensive, but due to their incorrect selection and use, the power tool may break. To find out what malfunction is causing strong sparking, you will need to disassemble the power tool and inspect it, as well as ring the rotor winding.

Why can brushes spark?

As soon as you notice a spark , immediately disconnect the vacuum cleaner from the power supply. Whatever the cause of the malfunction ultimately turns out to be, it leads to breakdown of the device and its elimination. It is important to react immediately and take all possible measures. At home and on your own, you can solve the problem if the reason is the following:

- Brush wear. If this is the reason, then the engine begins to operate with less power. Sometimes it may not start at all, or during operation it may sharply reduce its speed.

- Anchor failure. It is possible that the problem lies in the interturn short circuit of the armature winding. Pay attention to where the sparking is coming from. If it comes out with the same intensity from under both brushes, then you have guessed the cause of the breakdown. Another proof that you are right in this case will be the armature winding heating up during operation of the vacuum cleaner.

- The stater has failed. If the problem is related specifically to the operation of the stator, then sparks will be knocked out only from under one brush. The stator has two windings, which, when tested for resistance, should give the same result, equal to 4 ohms. If the resistance of the windings is different, then the reason lies here.

- The reason may be contamination of the collector contacts. In this case, you will see strong sparks from under both brushes. Carbon deposits will form on the contacts due to engine overheating. The engine speed drops and it begins to work intermittently.

- The collector has closed. Contacts are subject to wear and tear over time. As a result, fine graphite dust is formed.

Remember! It accumulates in the collector and at some point can accumulate in such quantities that it will cause the contacts to close.

Tilt angle

If the angle of inclination of the brushes relative to the stator is incorrect, sparking may also occur. The correct position is when both brushes are strictly on the same line passing through the axis of rotation of the commutator. Over time, due to constant vibration, the brush holder mount may become loose or even suffer mechanical damage. Carefully inspect the surfaces of the components. Parts that have cracks, chips or signs of corrosion must be replaced.

Each manufacturer introduces design features into its product line, and therefore different types of vacuum cleaners have different types of brush attachment. However, in general, all models have the same device, and the brush holder is usually screwed on with two screws and allows for adjustment.

Reasons for sparking vacuum cleaner brushes

Why do the brushes in a vacuum cleaner spark? Let's look at the main reasons in this article.

Wrong angle

Why do vacuum cleaner motor brushes spark? Incorrect tilt angle is perhaps the most common cause of the problem. The correct position is considered when two brushes pass the axis of self-rotation exactly on the same line.

Attention! If the equipment is used for a long time, they may become dislodged. Therefore, it is necessary to ensure that there is no distortion. Of course, all types of vacuum cleaners have different brush mountings, but, in general, all types have a common device - a holder. It is attached with two screws.

Closure

Do the vacuum cleaner motor brushes spark strongly? If you hear occasional pops; you notice that sparks are flying around the circle; If you observe blackening, then this is definitely an interturn short circuit. Alas, it is unlikely that a person without experience in this area will be able to cope with this problem. Therefore, it will be difficult to fix the breakdown yourself.

Wear of parts

Why do the brushes on a vacuum cleaner spark a lot? The most common and natural reason is wear of parts. Because of this, you will have to disassemble the entire vacuum cleaner.

With the help of brushes, contact between the electrodes occurs. And since they are an element of the electric motor, it is necessary to deal with it first.

This is very easy to do. After this, prompt replacement of parts is required.

Reference! When purchasing a vacuum cleaner, it is better to immediately take spare parts for the vacuum cleaner.

Poor contact

People most often encounter this when installing new brushes. They shouldn't be loose. You need to make sure that the spring is pressed tightly against the manifold. This can also occur due to the presence of dust, so you should clean the contacts well.

Dirt entry

Excessive tension causes more friction and dirt can form. Long-term use of carbon deposits promises rapid equipment breakdown.

The essence of the problem

Sparking brushes prevent the power tool from operating at full capacity. Since they are the connecting link in the electrical circuit, disruption of their operation leads to interruptions in the current supply. This negatively affects the motor winding and reduces its operating life.

Sometimes the fault may lie in the brushes themselves. They quickly burn out due to cracks, chips, scratches, and overheating. Replacing the old brush set will solve the problem. If the reason for the sparking is not the brushes, then the new ones burn the same way.

How to fix the problem?

Remove the old brushes and replace them with identical ones. New kits are available at most hardware stores or electrical outlets. When choosing a replacement, you should take into account the density of the graphite substance and the design features of a particular grinder. The composition and density of the brushes differ depending on the technical characteristics of the angle grinder. If these parameters do not match, the new brushes will also spark and burn.

Examine the collector for mechanical damage. If dust, dirt, or sand gets on it during operation, scratches, dents, and chips may form. Assess their extent, if any.

For minor damage, the collector lamellas can be sharpened using sandpaper or a lathe. The groove must be very careful, since any inaccuracies will lead to a greater deterioration in the performance of the brushes.