How does charging work?

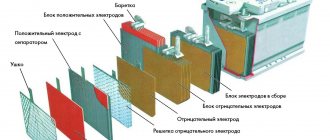

The operating principle is designed in such a way that by reducing the electrical voltage, temporary current is converted into direct current. For this circuit to work, you cannot do without a diode bridge and a step-down transformer. The charging voltage should be 5-10 percent higher than the declared characteristics of this parameter for the battery itself. The current must also be 10 percent greater than the battery capacity. Charging can also occur from a car battery, in which case the above points should not be taken into account.

Reasons for failure of chargers

Reasons why the device breaks down:

- Errors when charging the battery. The technical parameters for performing this task may not have been followed.

- Damage to conductors coming from the charger or disconnection of contact elements.

- One of the components of the charging equipment has broken. The problem may lie in the operation of the ammeter, fuse element or diode bridge.

- The problem is current leakage at a specific stage of its transmission.

The zxDTSzx channel presented detailed instructions for diagnosing battery chargers, and also talked about the main causes of device malfunctions.

Motorcycles and cars

Cars and motorcycles have occupied a significant niche in our lives; every family simply must have a vehicle. This type of charger is used for cars and motorcycles that are rarely used and therefore are not charged from the generator. The difference between such charges and others is their greater power, which produces a large current at the output.

The first step is to measure the output voltage of the charger. If the battery is fully operational and charged, then the voltage at the output should be in the range of 13.2-14.4 V. To measure the voltage, you need to switch the toggle switch on the multimeter to DCV mode. In this case, provided that charging when the battery is completely discharged will not produce a voltage at the terminal of 13.2 V, the use of this device is undesirable. You also need to check the charging housing if it is allowed by the design.

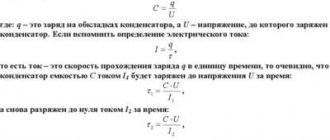

To check the strength of the charging current, you need to switch to the ammeter mode, which is connected in series to the circuit. You also need to take into account the control of the charger; if it is manual, then you need to set the current using a switch, and if automatic control is provided, you must take into account that the battery capacity should not be less than one tenth of the total volume.

Security measures

When eliminating battery charging breakdowns, you must take into account simple safety measures:

- Do not short-circuit the contact probes on the device. This may cause the device to short out and catch fire. The main board of the charger will fail and cannot be restored.

- When dismantling the battery, it is not allowed to short-circuit the positive and negative terminals connected to the battery. This will cause a short circuit in the on-board network, which will lead to catastrophic consequences. Damage to the electronic control unit and even failure of all electrical equipment may occur.

- If the car owner will restore the operation of the charger on his own, he must carefully select components. It is not allowed to use components that do not correspond to the elements installed on the board. This can lead not only to damage to the charger itself, but also to failure of the battery.

- When checking the charger after repair, the battery will need to be recharged. When performing this task, be sure to unscrew the plugs on the device’s banks if the battery is serviceable. Otherwise, the electrolyte solution may boil. In theory, the battery could explode.

User Alexey Techmaster spoke in detail about precautionary measures, as well as repairing charging equipment for the car’s battery.

Computer equipment and mobile phones

Checking these devices is quite simple and boils down to measuring the voltage at the terminals, which in no case should deviate from the voltage in the user manual or on the sticker on the case.

The multimeter must be set to DC voltage measurement mode if the auto-tuning feature is not supported. Due to the small size of such devices, it is very difficult to reach the contacts with probes; it will be convenient to use the simplest sewing needles. If this method does not help, then all that remains is to disassemble the charger housing and look for terminals with soldered ends of the electrical cord.

How to check battery amperage with a multimeter?

Despite the fact that for successful battery operation the main characteristics are voltage (charge) and capacity, a considerable number of drivers are interested in how to check the battery current with a multimeter or ammeter.

First of all, you need to remember that it is useless to measure the current strength directly on the battery. Moreover, it may cause a short circuit.

In order to check the battery amperes with a multimeter, you need to take readings directly from the electrical circuit. However, it is worth remembering that this characteristic will largely depend on the number and type of connected devices.

Household electrical appliances and power tools

Such devices can only be charged using more advanced devices. Such chargers usually have two power terminals and one control terminal. To transmit information about the performance and condition of the battery in the charger, a control output is required. This helps limit the charger current when it overheats or reaches its rated charge.

To check the voltage, it is enough to measure the voltage at the contact terminals. In fact, the check may be complete, but as you know, every rule has its exceptions. There are often cases when the charger is absolutely working, but for some reason the charging process does not occur or turns off without charging the battery.

In such cases, you must disconnect the battery and follow these steps. Disassemble the housing, since these devices are protected from external external influences and the ingress of various objects, and then solder the wires to the terminals. Since this is a very complex process, you need to use sharp objects to make grooves between the housing fasteners. After disassembling and connecting, you can use a multimeter to check the charge. When disconnected, the control contact is most likely damaged. If the nominal value jumps from nominal to zero, the cause may be weakening of the power contacts.

Checking charging using a multimeter

In recent decades, many devices have appeared that use rechargeable batteries or DC batteries to ensure autonomous operation. These are power tools, telephones, computers, and various household appliances. Each of them usually comes with a charger to keep the battery in working condition. Unfortunately, situations often arise in which the battery does not charge at all or discharges very quickly. One of the reasons for such phenomena may be a malfunction of the charger (charger).

How to measure voltage

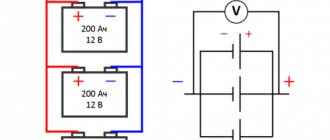

If it is necessary to check only the battery voltage, then the multimeter is switched to DC mode. If you need to check a source of electricity whose voltage does not exceed 20 volts, then in this sector the mode switch is set to the 20 V position. Then the black probe of the multimeter should be connected to the negative terminal, and the red one to the positive terminal of the battery, on the device display, at this moment, DC voltage will be shown.

Typically, a serviceable and fully charged car battery has a voltage of 12.7 V. If at this voltage the electrolyte density is normal, then the source of electricity can be used for its intended purpose.

The voltage of lithium-ion batteries of cell phones, as well as alkaline or gel batteries, which are used to start the engines of various motorcycles, diesel generators and other devices that require a certain charge of electricity to start operating, is measured in a similar way.

Video - checking the battery

A multimeter is a multifunctional device for measuring various parameters of electric current, so it can also be used to check the battery charge. To perform this work, you can use different types of multimeters. The cost of the product does not matter, the main thing is that the digital or analog measuring device is in good condition. How to check the battery with a multimeter will be discussed below.

Read also: LED lamp with photo relay for street lighting

Charger repair

So, a visual inspection did not allow us to find the cause of the breakdown, therefore, it is still impossible to do without repairs. At the initial stage, we will check the plug for damage and test the power cord through which power from the network is supplied to the device. There are situations when the cause of the breakdown lies precisely in the supply wire.

Using the simplest tester that is at hand, we will measure the voltage along the entire wire, starting from the plug and ending at the junction with the transformer winding. The criterion for a malfunction will be a complete absence of voltage or its intermittent values.

If the supply wire is normal, then the car battery charger will have to be repaired by replacing certain components of the internal operating circuit. And this already requires skills in handling electrical measuring instruments and knowledge of basic safety rules.

Malfunctions and methods for their elimination

It is necessary to search for the cause of a memory failure step by step, moving from one element to another, adhering to the diagram of their connection to each other.

Any part of the charger may be faulty. The standard equipment of the charging device includes:

- A fuse whose main function is to prevent failure of the main structural elements due to overload or short circuit. We start by checking it: a serviceable element will definitely show the presence of voltage parameters on both terminals, otherwise replacement is required.

- Transformer – converter of 220 V mains voltage into the operating voltage required for the operation of the device. We measure the voltage value at the output terminals of the transformer - if it is missing, it is necessary to replace this part.

- The galet switch is responsible for smoothly adjusting the voltage while charging the battery. It is diagnosed in several positions: if the voltage at the output is zero, it must be replaced. Moreover, the input voltage must be present.

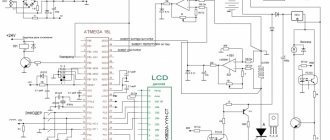

- At the last step, we diagnose the diode bridge, which converts alternating current into direct current, and the ammeter, which provides the ability to control the charging current. How to do this is described below.

It is in these components that you should look for the cause of the malfunction of the car battery charger, if previous actions did not lead to the desired result.

There may be several malfunctions, so all structural elements should be checked.

We carry out simple repairs of the charger with our own hands

We present to you recommendations on how to repair a car battery charger with your own hands:

- A malfunction of the supply wire plug is eliminated by replacing it: disconnect the non-working plug from the wire, take a usable element and connect it to the wire cores.

- The supply wire is not suitable for use: disconnect it from the plug and the transformer winding. We install a new one in place of the non-working one, carrying out installation by analogy with disassembly.

- Replacing a fuse requires care and attention. Carefully remove it from the body and install the worker in this place. If the fuse link has melted due to improper connection to the terminals, it is recommended to purchase a special wire block from an auto parts store and place a fuse in it.

- As for repairing or replacing more complex parts: transformer, biscuit switch, diode bridge and ammeter, this is an activity for professionals. This requires good knowledge in the field of electronics and physics, as well as experience in performing similar work.

Checking the diode bridge

A diode bridge is a complex structural element consisting of four diodes. First, the presence of input and output voltage is determined. If it is, then the cause of the malfunction is something else. If the measuring device shows a lack of output voltage, then the breakdown should be looked for in the bridge configuration.

To do this, each diode is tested individually to determine which one is not working and replace it. The criterion for a defect is the complete absence of voltage as a result of using various tester connection schemes or, conversely, its constant presence.

Monolithic diode bridges cannot be repaired; they are replaced completely assembled.

Checking the ammeter inside the charger

The last step in checking the functionality of a car battery charger is to test the ammeter. If, when diagnosing all the components included in the charging device, it was not possible to detect a malfunction, then with a high degree of probability we can say that the source of all troubles is the ammeter.

How to check its suitability for work? Everything is quite simple: we measure the voltage at its terminals and detect the absence of the latter. When we connect the terminals to each other, it immediately appears. This is an obvious sign that the ammeter is faulty and needs to be reset.

If all elements of the charger are checked and in good working order, but the battery still does not charge, then the cause of the malfunction must be looked for directly in the battery itself.