Battery connection options

Battery connection diagrams

Serial, parallel and series-parallel connection of batteries

The article is devoted to possible options for connecting batteries and the characteristics that result.

Any battery has the following main characteristics:

- Rated voltage (V - Volt)

- Capacity (Ah – Ampere*hour)

- Maximum amount of stored energy = Nominal voltage multiplied by Capacity (kWh - kilowatt-hour)

There are three possible options for connecting batteries to each other - in series, parallel or series-parallel. Depending on the connection scheme of the batteries in the Battery Bank, the Nominal Voltage or System Capacity may change, while the maximum amount of stored energy of all batteries will remain unchanged.

So, let's consider each of the possible options for connecting batteries into a Battery Bank:

1) Series connection of batteries

With this connection, the negative terminal of the first battery is connected to the positive of the second, the negative of the second to the positive of the third, and so on.

In the case of such a connection, the system capacity remains unchanged, but the system voltage is the sum of all batteries connected in series.

We have 4 batteries with a capacity of 200Ah and a nominal voltage of 12V. By connecting them in series, we get a nominal voltage of 12V*4=48V and a capacity of 200Ah. In this case, the maximum amount of stored energy is determined as the sum of the maximum energy reserve of all batteries - 200Ah*12V*4=9600Wh*h=9.6kWh, or, which is the same, as the maximum energy reserve of the entire battery bank - 200Ah*48V= 9600W*h=9.6kW*h.

This switching circuit is used to raise the system voltage.

2) Parallel connection of batteries

With this connection, the positive terminals of the batteries are alternately connected to each other. The negative terminals are also connected alternately to each other.

In the case of such a connection, the system voltage remains unchanged, while the capacity of the Battery Bank is the sum of all batteries connected in parallel.

We have the same 4 batteries with a capacity of 200Ah and a nominal voltage of 12V. By connecting them in parallel, we get a nominal voltage of 12V, and the capacity will be 4*200Ah=800Ah. In this case, the maximum amount of stored energy is determined as the sum of the maximum energy reserve of all batteries - 200Ah*12V*4=9600Wh*h=9.6kWh, or, which is the same, as the maximum energy reserve of the entire battery bank - 800Ah*12V= 9600W*h=9.6kW*h.

This switching circuit is used to increase the capacity (charge current) of the system.

3) Series-parallel connection of batteries

This connection is the most popular when assembling Battery Banks for various purposes.

With this connection, chains of series-connected batteries are connected in parallel.

For example:

Let's look again at our 4 batteries with a capacity of 200Ah and a nominal voltage of 12V. By connecting 2 batteries in series and then combining them in parallel, we get a nominal voltage of 12V*2=24V and a capacity of 200Ah*2=400Ah. In this case, the maximum amount of stored energy is determined as the sum of the maximum energy reserve of all batteries - 200Ah*12V*4=9600Wh*h=9.6kWh, or, which is the same, as the maximum energy reserve of the entire battery bank - 400Ah*24V= 9600W*h=9.6kW*h.

Note: Please note that the maximum amount of stored energy does not depend on the battery connection diagram!

Various battery connection schemes are needed to optimize the operation of a set of equipment used together with batteries. By choosing different connection schemes, we set the required currents and voltages for the entire system.

You can read about which connection scheme to choose for your own solar power plant, as well as how to calculate the required capacity of the Battery Bank in the article:

Calculator for selecting a solar-powered lighting and traffic light kit

Meanings of terms related to Alternative energy

Battery connection options

Battery connection diagrams Serial, parallel and series-parallel connection of batteries The article is devoted to possible options for.

Features of parallel battery connection

How to connect two batteries in parallel: the plus of each element is connected to the plus of the next one, and the minus to the minus.

Formulas (U – voltage, I – current, C – capacity, E – electrical energy):

Scheme

Battery parallel connection diagram

System capacity

Connecting batteries in parallel allows you to increase the system capacity without increasing the voltage. For example, when connecting three identical batteries in parallel from the diagram above, the battery voltage will be 12 V, and the capacity will increase to 600 Ah (200 Ah * 3).

What is it used for?

Most often, parallel connection of batteries is used in emergency or uninterruptible power supplies. Parallel connection of batteries allows increasing power, therefore it is also used in heavy special equipment and in the engines of heavy-duty vehicles. This type of connection is also common in the fleet: it provides operation of emergency communications and life support systems, lighting and auxiliary diesel engines.

Features of charging in parallel connection

How to find out the battery capacity

When this process begins, it is preferable to transmit a fairly large charging current. After all, the surface of the battery will be restored first, and then its lower layers. At the same time, it is desirable to reduce the current, since the intensity of the electrochemical reaction decreases, as a result of which, due to the large amount of energy, the electrolyte may “boil” (its decomposition will occur).

If we consider one of the most popular types of batteries - lead-acid, then if this requirement is violated, it is unlikely to immediately fail. But its service life will obviously be significantly reduced.

In general, if we talk about charging power supplies, then it is worth focusing on the fact that it is advisable to use factory devices. If you exploit something else, then certain aspects may not be taken into account (or incorrectly taken into account), which will result in problems in the future

Methods for connecting a second battery

Reasons for VAZ 2110 battery discharge

If we talk about installation recommendations, there are several general rules:

- The device is located outside the cabin, as it emits harmful fumes.

- Select a battery with the same capacity as the main one.

- The generator is replaced with a more powerful one or another one is installed so that the charges of both batteries are restored quickly and the generator does not fail, since the second battery requires additional power.

- For connection, choose short cables, then the batteries will work more efficiently.

Which battery and cable to choose

A power source is selected that can withstand a large number of discharge/charge cycles, since it is expected to operate in this mode, for example, gel batteries. But they also have a number of disadvantages, for example, recharging from the on-board network.

Please note that it is possible, but not recommended, to place an acid battery and an AGM battery together, since the AGM battery will take charge from the acid battery, thereby discharging it. Acid batteries take a long time to discharge and take a long time to charge

AGM has a higher starting current, charges faster and discharges faster.

Calcium devices are absolutely not suitable for the role of additional ones, since they are sensitive to complete discharge; antimony ones behave better, but the best option is combined batteries.

Parallel connection

To connect two batteries in a car, connect the positive and negative terminals of the battery according to the diagram. A fuse is placed on the positive wire coming from the standard battery, then this wire is led through the cabin to the battery in the trunk and a second fuse is placed on it. This is done so that if the wire is damaged, a fire does not occur in the cabin. Fuses are selected according to the wire cross-section. Thus, jumpers connect plus to plus, minus to minus (it is not advisable to throw a minus on the body, since it gives noticeable resistance). A fuse is also installed on the wire to the generator and to the amplifier.

Disadvantages of this method:

- All consumers are connected to the main battery.

- The electric charge comes from the additional power source through the standard one when the latter is discharged, and this takes some time.

- The additional battery feeds the main one until their charges are equalized, so the battery with the smallest capacity and the lowest residual voltage becomes fully charged at best. A good battery does not charge.

This mode of operation adversely affects the service life of both batteries, so it is preferable to consider another connection option.

With diode isolator

The next method, which allows you to connect 2 batteries to a car, involves connecting the battery to the on-board network through a diode separator. The device conducts current from the generator to the additional battery, isolates the second battery from the on-board network and the standard battery, preventing the flow of current between them. You can connect not only a second, but also a third, and even a fourth device to it. They will charge simultaneously and evenly.

Diode separator for battery

The price of diode insulators is determined at several thousand rubles. For example, a Chinese-made insulator for 3 batteries costs 6,000 rubles.

Powerful consumers are connected to an additional power source, and the charge of the main device is not consumed. However, this scheme for connecting two batteries in a car has a drawback: if the devices are powerful, the battery quickly loses charge, since the powerful consumer in this case still “hangs” on one power source.

To the common circuit

The problem is solved if you purchase a second battery for the car, and connect it through an isolation device (URA200, 300, 600) - a relay that allows you to manually connect and disconnect an additional battery using the “start” button or automatically. The device is installed in the gap of the positive wire, from which the additional battery is charged. The manufacturer indicates that there is no need to replace the generator in this case.

The on-board network consumes energy from both power sources at once, and switches between them when the charge in one of the batteries drops, and charges according to the principle of insufficiency, that is, first of all, the charge from the generator goes to the most discharged batteries. Some devices can be connected to indicators that show how much charge is left in which battery.

Simultaneous independent charging of several batteries

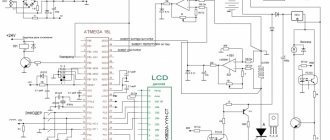

I welcome homemade lovers to visit Samodelkin. I would like to present a circuit for charging several batteries at the same time. Which battery does not matter, adjust to your needs... The circuit diagram uses a capacitor reset to automatically charge several batteries at the same time. 3 stages of a multi-position charger circuit using a capacitor reset: 1. operational amplifier comparator detector stage 2. On/off interval generator based on IC 555 3. capacitor reset circuit stage The purpose of the operational amplifier is to maintain a continuous charge of the battery, and accordingly turn off / restore. The charging process is carried out through a capacitor reset system. Let's look at the stages in detail: Scheme of operation of the Operational Amplifier for battery charging. The first stage can be seen below:

parts list: op amp: LM324 potentiometers: 10K zener diode 6V/0.5 watt R5 = 10K diodes = 6A4 or equivalent. The circuit under consideration is for connecting 4 batteries at the same time, and therefore we use 4 op-amps. Op-amps A1-A4 are driven by four core op-amp IC LM324, each configured as separate compartments to detect the attached corresponding battery based on charge levels. As can be seen in the diagram, the non-inverting inputs of each of the op amps are configured with corresponding positive battery signals to provide the required battery voltage. The advantages of each battery are associated with the capacitor reset output, which will be discussed in the next part of the article. The inverting pins ( - ) of the op-amp are connected through a single common zener diode. Potentiometers are connected to the (+) battery and are designed to adjust the disconnection of a charged battery, according to the voltage of the zener diode. The presets are set so that when the appropriate battery voltage reaches full charge, the proportional value at the (+) pin of the op-amp will exceed the reference level (-) of the contact zener diode. The above situation immediately turns the op amp output from its initial 0 voltage to a high logic level equal to the supply voltage level. This maximum output of the op amp triggers IC 555 so that IC 555 produces on/off intervals for each attached capacitor reset circuit... IC 555 to generate periodic on/off. The following diagram shows a stage based on IC 555 to periodically generate on/off followed by resetting the capacitor.

parts list IC = IC 555 R2 = 22K R1, C2 = calculated to get the desired charge reset cycle speed As shown in the above circuit, pin#4, which is the reset pin of IC 555, is connected to the output of the corresponding op-amp stage. Each of the op amps will have their own individual IC 555 stages along with a capacitor reset circuit stage. When the battery is in the process of charging and the output of the op amp is held at zero, IC 555 remains disabled, however, the moment the corresponding connected battery is fully charged and the corresponding output of the op amp becomes positive, the IC 555 connected to that battery is activated, resulting in to the fact that its output pin #3 generates periodic on/off cycles. Pin #3 of IC 555 is installed with its own individual capacitor reset circuit, which is responsible for the on-off cycles from the IC 555 stage and begins the process of resetting the capacitor to the connected battery. To understand how the reset capacitor behaves in response to the on/off cycles of the IC 555, see the following section of the article: Reset Capacitor Operation Circuit: As requested, the battery must be charged through the reset capacitor circuit, as follows:

• While IC 555 remains in the OFF state, BC547 receives bias through its 1K base resistor, which in turn holds the TIP36 transistor in the ON position.

• This situation allows the collector capacitor to reach its maximum value. In this position the capacitor is charged and awaits discharge. • The moment IC 555 is activated and begins the turn-off cycle, the turn-off cycle periods turn off the BC547/TIP36 pair and turn on the TIP36, which instantly closes and dumps the charge from the capacitor into the corresponding battery. • The next turn-on cycle from IC 555 returns the situation to the previous conditions and charges the 20,000 uF capacitor, and once again, with the next subsequent turn-off cycle, the capacitor is allowed to dump its charge through the corresponding TIP36 transistor. • This occurs continuously until the corresponding battery is charged. All op amps for each connected battery operate in a similar manner to regulate the state of the connected battery. Good luck! Source

Is this option suitable for power supplies of different capacities?

Is the battery being recharged when the engine is idling?

Connecting different batteries in parallel does not pose any danger if we consider the problem from a voltage point of view. Nothing bad can happen to the battery terminals. The discharge or charge of power supplies will occur synchronously due to the nature of the connection. But if we touch on the topic of currents, then it’s a little more complicated. So, it is necessary to ensure that it does not exceed a certain value, which is indicated directly by the manufacturer.

The most common are 100 A and 130 A. The reason for this limitation is that the terminals themselves will not be able to transmit such current (although theoretically the battery itself can do this). But this is the very top, which can only be a matter of seconds. Let's look at a more realistic use case.

Great Wall Safe KOMBEZ4KH4.RU Logbook Installing a second battery

Many have encountered the problem of not having enough current in the vehicle’s on-board network when using a winch, a chandelier, or who knows what. And immediately there is a desire to install a more powerful battery, or better yet two, but not every generator can cope with a battery or two amps for 150-200 in a compartment, this situation can be corrected by a second generator, fortunately there are a large number of them produced and they come in both left-hand drive and right-hand drive, and with some electronic modifications and modifications we can get two generators and two batteries. This is all good, but there are a few “BUTs”. Sometimes it’s difficult to find a place on the engine for the second gene, and the presence of some electronic modifications is not good, unnecessary electronics are evil!

And here it is a miracle of technology: URA-200 (device for decoupling 2 batteries)

This device is designed to automatically connect/disconnect an additional battery to the vehicle's on-board network. It is used on cars, as well as on sea vessels with an on-board voltage of 12V.

URA provides autonomous battery operation, which allows you to use one of them to power additional devices, such as a car radio, refrigerator, lighting, winch, etc. This eliminates the discharge of the main battery, which is necessary for reliable engine starting.

URA 200 is a power relay with a built-in microcontroller, which avoids voltage drops, as in the previously released URA 60 and URA 120, and does not require additional installation of a regulator with increased voltage.

The second battery is connected and disconnected automatically when the main battery reaches and maintains voltages of ≥13.2V and ≤12.8V for 6s, respectively.

To force the device to turn on, a “start” terminal is provided. Forced activation of URA 200 is used when connecting additional high-power devices (winches, additional lighting) or when starting the engine in the cold season.

Its price tag is around 1800 rubles, analogues cost about 4500-5000 rubles.

Self-installation is quite possible and not a hassle, and now you are the owner of 2 batteries of 100A each!

UAZ Patriot › Logbook › Electricity. Dual battery. Charging the battery

Among travel cars, a very popular solution is to install two rechargeable batteries (AB) on the car.

In this case, auxiliary consumers that are used in the parking lot are connected to the second, additional battery: inverters, refrigerators, lighting, laptops, TVs, etc. In this case, the main battery is disconnected from the on-board network during parking and is used only for the starter. While driving, the batteries are connected in parallel or through various decoupling devices. While driving, the additional battery must be charged from the vehicle's generator. I want to share my experience, from which it follows that this solution is not optimal. The whole point is that the car's generator will not be able to charge a severely discharged battery to full capacity. After the first serious discharge, the battery will always be half empty, no matter how long it is connected to the generator. I assume that using the battery in a mode of constant significant undercharging and subsequent operation in modes close to complete discharge will lead to its rapid degradation. I understand that the majority can write that they use such a scheme and everything works for them. Perhaps, but I would like to know in this case, by what means is the battery capacity measured and what is it compared with? Personally, I measured the number of kilometers traveled on an electric boat motor, and took charging at home from a 220V network as a starting point. Of course, these are not laboratory tests: waves and wind create a significant change in conditions, but most often the routes were cyclical and if part of the route is against the wind, then the second part is downwind. I have used several different batteries with the outboard motor. And a special traction motor, designed for electric motors, and ordinary starter motors.

The essence of my personal experience comes down to the fact that a car alternator cannot fully charge a severely discharged battery. It recharges it, but only a little, at best to half the capacity (hereinafter we mean the effective capacity of the battery*). To charge a discharged battery in the field, we tried connecting it both in parallel and instead of the main battery of the car, we tried charging both at idle and while driving with it all day long. By the way, cars also changed. The result was the same: if the battery was heavily discharged, then after charging it from the car, the next mileage was reduced by at least half, compared to when the battery was charged at home using a charger from a 220V network.

Besides everything else, it seems to me that charging from a car generator is not at all useful for severely discharged batteries. When connected for charging, the battery in the first part is charged with very strong currents, about 25-30 amperes - and this is unlikely to prolong their life!

Now about what I use. For charging at home, I got a Ctek multi-stage charger. Its maximum charge current is only 5A. And over time, I noticed that after some cycles of using it, the mileage increased even compared to the old charger, which had a maximum charge current of 15A. Usually I set the charging current to about 8A, which was 10% of the battery capacity, as stated in the instructions for the charger. I don’t know if it’s due to the low charge current or the multi-stage nature, but most likely it’s both. For charging from a car while traveling, we purchased a Berkut charger (SmartPower SP-Car), designed to charge the battery from a car cigarette lighter. The result of this circuit is up to 80% of the range from charging with Sitecom: not much better than a generator with a three-mode relay regulator. But here everything happens automatically and there is no need to monitor the charging current, and the main thing is that there are no prohibitive charging currents, the maximum is 7A (according to the passport). Of course, it is only suitable for charging the battery during the day, i.e. when the car is in motion all the time, you won’t be rattling the engine all day in the camp. But we must pay tribute, even in this case, at idle, it must charge the battery to its maximum, because the output voltage does not depend on the supply voltage.

Source

How to properly connect two batteries

To successfully carry out this operation, you should follow the following tips:

- It is necessary that both the first and second batteries are in perfect condition. As you know, rechargeable batteries, after a certain number of charge and discharge cycles, begin to deteriorate, become unusable, and, as a result, discharge faster. If you connect an old battery to a new battery, the old battery will “absorb” energy from the new one, and eventually both batteries will be discharged. This, in turn, will not allow the power unit to start.

- A switch should be used for the second battery. This device will use the energy of the first battery, but will allow you to retain the charge of the second charging capacity. This will also allow you to always remain confident that you can calmly “sit down and leave.”

- In order to avoid damaging the vehicle's electrical wiring, it is worth using a more powerful generator, or installing another one.

- The batteries should be approximately the same power, but if the batteries are of different power, this can lead to failure of the batteries.

- It is necessary to use short cords to connect the batteries, then the operation of these batteries will be most efficient.

So, by trying to follow these recommendations, you can make your leisure time in nature, fishing, hiking or hunting truly colorful and unforgettable.

However, you need to decide on how to connect the two batteries to each other.

The first method: serial connection: a jumper is placed over the terminals: its own jumper for the “negative”, its own jumper for the “positive”, then the remaining two “opposite” terminals of the two batteries are connected to each other, and the “positive” and “negative” wires are connected to the rest of the vehicle's electrical system.

Second method: parallel connection: with this type of connection of two batteries, the jumper is placed as follows: the “negative” and “positive” terminals of the batteries are connected, then wires are removed from the paired batteries, which are connected to the rest of the vehicle’s electrical system.

After the batteries have been connected to each other, you should install either a switch or a switch between them.

This step will allow you to use the energy resource of only one battery. For example, when the engine is turned off, the car lights or audio system will work.

If the vehicle's engine is turned on, the energy required to operate electrical appliances in the car is generated by a special generator. But, the truth is, fuel in a vehicle is wasted much more, and this, in turn, leads to incredible fuel costs.

Conclusion

Summarizing the above, it is worth saying that installing a peripheral battery in a car will be the best solution. Now you don’t have to worry about sudden battery discharge and subsequent problems getting a spark for ignition.

But the second battery will only be effective if it has been installed and connected to the first in accordance with generally accepted recommendations and standards. Incorrectly connected batteries will become a real headache for the car enthusiast. When choosing a battery, you need to focus not only on the size, capacity and brand, but also clearly understand the purpose of the battery and its scope of application. For example, there are starter and traction batteries designed for different purposes.

Write comments, additions to the article, maybe I missed something. Take a look at the site map, I will be glad if you find anything else useful on my site.

3 comments on the post “Connection diagram for two batteries”

There cannot be a parallel connection of batteries!!

The battery itself consists of six batteries connected in SERIES,

placed in the housing. Therefore, what you call a parallel connection,

physically it is a MIXED, series/parallel connection!

moron... the battery is a bank of batteries connected in series... the banks can be connected in parallel

By connecting two batteries in parallel, the current in AH does not increase; if you take two batteries of one hundred AH each and connect them in parallel, the same amount of 100 AH will remain, but in series it will increase by one revolution, as well as the voltage itself. You can also make the UPS independent of an external power source.

About battery voltage and capacity

Let’s briefly examine the common opinion - “when two batteries (batteries) are connected in series, their capacity does not change, it remains the same as that of one battery, so the battery life with such a connection will be shorter.”

But what about the law of conservation of energy? Yes, when batteries are connected in series, the capacity is formally calculated as that of one battery, and the voltage doubles (or triples, quadruples, etc., depending on the number of batteries connected in series). When connecting the battery in parallel, the capacity doubles (triples, etc.), but the voltage remains the same.

Battery connection options

There is no contradiction here. When people talk about a battery (usually a car battery), they say its capacity, but do not specify the voltage. It’s just that everyone is used to the fact that batteries have a voltage of 12V, and it is understood that mentioning this is stupid. But in general, a capacitance without indicating voltage has no physical meaning. There are batteries of very different capacities and for different voltages - 2V, 6V, 12V, and, rarely, 24V. In addition, any identical batteries can be connected in series, parallel, or series-parallel at the same time.

But you just need to indicate its voltage after the size of the capacitance, and everything falls into place. After all, the energy intensity in any case, no matter how we connect the batteries, will remain the same.

So, if, for example, two 200Ah 12V batteries (for example, a Delta GEL 12-200 battery) are connected in series, you will get an energy capacity of 200Ah 24V. And if these same two batteries are connected in parallel, you get 400Ah 12V. Let's check: 200Ah * 24V = 480Ah * V = 400Ah * 12V

But for current calculations (usually, the nominal charge current is considered to be a current of 0.1C, where C is a value equal to the battery capacity), C is taken exactly according to the number on the left, i.e. in our example, with a series connection C = 200, and with a parallel connection C = 400. It is easy to see that the power of the charger in both cases will be the same.

For the first case, the charging current will be 0.1*200 = 20A, but at a voltage of 24V. Those. charging power, P = 20A 24V = 480W

For the second case, the charging current will be 0.1*400 = 40A, but at a voltage of 12V. Those. charging power, P = 40A 12V = 480W

If we consider single batteries, then, for example, one 600Ah 2V battery (see section FAAM Rechargeable Batteries) in terms of energy capacity corresponds to one 100Ah 12V battery (for example, DELTA GEL 12-100 Battery).

To get a large battery, for example, 24V, from these batteries (600Ah 2V), you need to connect 12 pieces of such batteries in series using jumpers (Jumper for 250 mm batteries). The total final capacity will be 600Ah 24V. This energy intensity, when compared with 12-volt 200Ah batteries (and these are used in trucks), corresponds to 6 pieces (three chains of batteries connected in parallel, where each chain consists of two batteries connected in series):

(600Ah*2V)*12 = 600Ah*24V = (200Ah*24V) + (200Ah 24V) + (200Ah 24V)

Please note that all the figures specifically show that if the minus of the inverter is connected to the conditionally first battery, then the plus is connected to the last. It should be connected this way to compensate for the resistance of even the thick copper wires connecting the batteries. Otherwise, due to their resistance, at enormous currents, the battery “far away” from the inverter terminals will be neither “rechargeable” nor “rechargeable”.

So, the capacity (read “energy capacity”) of a battery (a combined group of batteries) is the amount of electricity (i.e. power equal to the current multiplied by VOLTAGE) that the battery delivers when discharged to the lowest permissible voltage.

To ensure a long battery life, it should not be discharged more than 80%. For a 12-volt battery, this corresponds to a voltage at its terminals of approximately 11.5V. But here it is important with what current relative to the battery capacity we discharge it.

The greater the discharge current, the lower the voltage to which the battery can discharge. This is because when a relatively small battery capacity is quickly discharged with high currents, the electrolyte does not have time to mix, and the discharged layer accumulates around the plates. The battery voltage drops and the load is removed. However, after several tens of minutes, the electrolyte is mixed and the capacity (and, accordingly, the battery voltage) increases.

If you discharge with a small current relative to the capacity, then you can drain all the energy, which is bad for the longevity of the battery. You should always leave at least 20% of the capacity. More on this below.

Note that during charging, the charger gradually increases the voltage on the battery, and then, after removing the charge, the voltage decreases, returning to a calm state (for example, on a 12-volt battery, depending on the type of battery, it usually increases to 14 ,1 – 14.5 V, and after removing the charge, even without load, within half an hour it returns to 12.5 – 12.8 V).

Source

When is a second battery required?

Those who use electric winches will definitely need a second battery, since this device requires a lot of energy and quickly discharges the battery. However, it may also be useful for those who use other electrical equipment in the car:

- laptop;

- DVD;

- microwave;

- anti-theft system;

- coffee maker;

- heater;

- powerful stereo system and subwoofer.

Installing a second battery in the car provides the advantage for which it is installed: you do not have to carry a second power source with you just in case, connect it if necessary and periodically charge it from the charger so that it is always in working order.

It is not difficult to calculate whether a second battery is needed, for example, for music in a car. To do this, you need to take into account that the power of an average battery with a capacity of 60-65 Ah is approximately 4 kW. If the sum of the powers of all consumers is more than 2 kW, then you need to take care of installing a second battery. To find out what power a consumer has, just look at the passport or study the sticker on its back cover; you can often find the necessary information there too.

Parallel connected batteries

Parallel connected 12-volt batteries are charged with a 12-volt charger.

When connecting batteries in parallel, the capacity increases, but the voltage does not change. The batteries in the battery should be of the same type and age, and the cables connecting them should be short and thick to reduce voltage drop.

Several 12-volt batteries connected in parallel are charged with a 12-volt charger. The battery charging time will be longer than for a separate battery.

How to properly remove and connect the battery in a car

The interaction of components in a car provides the driver and his passengers with comfort and safety. But if something goes wrong, the car needs professional help.

The battery in a car is of great importance, allowing the car to drive on the road at night, illuminating the road ahead. In addition to lighting and signaling to other road users, the battery performs other functions - for example, starting the engine. Of course, such a demand for the electrical element in question leads to the need to replace the battery. And although it is not necessary to go to a service station to replace it, it is worth following a clear sequence of steps.

Technical limitations

If you look at the technical characteristics of the permitted current value, you usually won’t see large numbers here. Thus, it is usually not allowed to connect together batteries whose capacity varies from 5 to 25 times (as a rule). Moreover, this aspect must be carefully studied, since even a short circuit is possible. The risk of its occurrence is in the range of 15-70 capacities of the smallest battery (depending on the brand and technical implementation). Roughly speaking, the less time they operate, the higher the current value you can work with. So, if the difference between them is 5 times, this means that they will be able to function all the time (theoretically). But if we are working with a 20-fold difference, then it is desirable that the count be in seconds. Many power supply manufacturers specify current thresholds for their products. For example, 2.6 A.

How to connect batteries to parallel charging?

The batteries are connected quite simply:

The power supply (plus and minus) is connected to the charger, as well as the balancing cable, which consists of 7 wires, this is so that 6S batteries can be charged.

It is not enough to simply connect the batteries. There are rules here, more about them below.

Rule 1. You cannot charge batteries together with different numbers of sections, large voltage differences and different types. Also, you cannot allow a large spread of capacities: you can charge 500-1500mAh, 1300 and 2200mAh batteries together, but 500 and 8000mAh batteries cannot be charged together!

That is, if you want to charge batteries in parallel, then for example, you can only connect: 4S Lipo 1300mAh and they are all discharged to approximately 3.85-4 volts.

In addition, only the following types of batteries can be charged in parallel:

- LIPO;

- LIFE;

- LI-ION.

Why stick to small voltage difference?

This is due to the fact that the batteries, when connected alternately, will try to equalize each other’s voltage. An example is communicating vessels with water. The most “full” battery will begin to supply current to the less “full” battery until they become the same in voltage.

Rule 2. This leads to one more thing: first you need to connect the power wires of all batteries, wait a few minutes (see the table of dependencies below) and then connect the balancing wires.

How long do you need to wait for the battery voltage to equalize?

The table is, of course, approximate, but reflects the full essence of the issue:

For example, if one battery is discharged by 50% (from the maximum voltage mark to the minimum), and the second is discharged by 20%, then you will need to wait about 15 minutes, since 50-20 = 30%.

What happens if you connect a charged battery and a discharged one? The answer is simple - since too much current will flow from charged to discharged, the tracks on the parallel charging board will melt, because they are not designed for such high currents.

Why connect batteries into a battery

In any electrical systems or devices there are ohmic losses: part of the electrical energy is converted into heat without producing useful work. The higher the voltage of the electrical system, the lower (with the same power) the current, the lower the ohmic losses and the lower the price of the system. Those. It is beneficial to have high voltage electrical systems. Moreover, the greater the power of the system, the greater the gain of the high-voltage system compared to the low-voltage one. Therefore, small UPS (several hundred VA) usually have one 12-volt battery (this is cheaper), a UPS with a voltage of several kVA uses a battery with a voltage of tens of volts, and in powerful UPS with a voltage of tens of kilowatts, the battery voltage can exceed 500 V .

Therefore, the purpose of using batteries with series connection of batteries is to reduce losses and increase efficiency.

Sometimes the capacity of one battery is not enough, and you need to increase the capacity. Sometimes it is more convenient not to replace a battery with a larger capacity, but to place another one of the same battery in parallel, so that the total battery capacity of the battery doubles.

For example, to increase the operating time of a high-quality Eaton Powerware 9130 UPS from a battery, one or more of the same batteries are connected in parallel to the existing battery.

Series connected batteries

For batteries connected in series, the voltage increases, but the capacity remains the same.

Two 12-volt batteries connected in series are charged with a 24-volt charger

When connected in series, the batteries must be of the same type and age. The capacity and manufacturer must also be the same. If one of the batteries has been used before, then most likely its capacity is already less than nominal and during charging it will be charged first. But the charger may not “notice” this and will try to fully charge the remaining ones. The temperature and pressure in the old battery case will increase. Gas will begin to be released, and the active material of the plates will begin to deteriorate.

Under load, the wear of the old battery will increase. After the weak cells have used up their charge, the good ones will continue to produce current. The voltage across the discharged cells will drop to zero, and then their polarity will reverse (this most often happens in large batteries). An uncontrollable increase in pressure and temperature will follow and a catastrophe will occur.

It is recommended to replace the entire battery of batteries connected in series. If you change only one, the state of charge of all batteries should remain the same. The small difference will be eliminated by the charger during the absorption phase. If the differences are large, the more highly charged battery will be recharged, and the undercharged battery will begin to sulfate.

Two 12-volt batteries connected in series are charged with a 24-volt charger. Three - 36-volt.

We calculate the necessary indicators

So, we need to provide a significant amount of current using parallel connected batteries. How do we know what we need? To do this, you can use a special formula, which will now be given:

And now the decoding of the formula:

T is the current that will be obtained. It is necessary that it coincides with the desired result.

RTEEP – discharge current per unit of battery. That is, how much one battery can provide.

KEPOT - the number of batteries of the same type.

In amateur radio practice, it can be difficult to obtain the required values. The same formula will make achieving your goal easier.

What is extremely undesirable to do

Adhere to certain security measures to protect yourself from possible troubles and financial waste. Do not perform actions that could damage the battery housing. Do not tilt or overturn the battery. Also, do not damage the filler plugs or necks.

Do not add acid or store a discharged battery, especially at sub-zero temperatures. By damaging the contacts, you risk incurring additional costs by damaging the equipment. Be careful when working to remove and connect the battery in your vehicle.

How to properly remove the battery

Before disconnecting the battery, you will need to take precautions. It is worth knowing that the battery in a car contains an amount of energy that can cause fatal injury to a person! Moreover, the battery contains corrosive substances inside that can produce flammable gas.

If you want to understand the question of how to properly remove the battery from a car, prepare the necessary tools and materials. For work you will need: a wrench extension, a set of attachments, safety glasses and gloves, an old toothbrush, a tray, clamps, water and baking soda. Before starting work, turn off the ignition and wear safety glasses and gloves to protect your eyes and hands.

Next, follow the established sequence:

- First you will need to find the negative terminal on the battery, which often stands out due to its black coating. Often the negative terminal is indicated by a “-” sign. Accordingly, the positive terminal is indicated by the symbol “+”

- Determine which attachment you will need. Size matters if you need to unscrew the nut from the negative terminal. First the negative terminal is disconnected

- Take the nozzle and place it on the nut located next to the negative terminal. Estimate the size of the socket for loosening the nut. The attachment fits onto the wrench, which may require a wrench extension.

- Turn the key counterclockwise. Disconnect the negative wire so that it does not touch the terminal

- Similar actions are performed with the nut on the positive terminal. After disconnecting the positive wire from the terminal, do not allow its bare end to come into contact with the metal surfaces of the car.

- After turning off the power to the battery, disconnect the fastener, and then lift the battery from the compartment. Make sure you get outside help first, as the battery weighs up to 20 kilograms

- Clean the compartment with a toothbrush and baking soda, then let the area dry

After completing the above steps, you can begin installing a new unit and then connecting the battery.

Why is a second battery needed?

There are many areas of application for a second battery:

- Ensuring the operation of additional electrical appliances necessary for a comfortable pastime in nature (for example, such as a refrigerator, lighting fixtures, musical equipment).

- A vehicle equipped with an electric winch must in any case be equipped with a peripheral battery.

- Executive class vehicles are, by default, equipped with a video player, TV, coffee maker, microwave and other electrical appliances that provide increased comfort when traveling.

- Security video surveillance systems, anti-theft systems, all kinds of radio alarms, as well as devices designed for active vehicle protection, must also be equipped with their own separate battery.