Design features

An industrial steam generator consists of a metal boiler. Its tightness is ensured by a plug. A heating device inside the device brings water to a boil, which then turns into steam. Its temperature reaches 160°C and higher. All functional equipment modules are located on the frame. They are represented by several components:

- The boiler of the steam generator is a reservoir in which water is located. Special sensors allow you to control the liquid level;

- electronic equipment - these are various devices, relays, switches and sensors, without which the device would not be able to function stably;

- pressure sensors - their task is to keep the pressure in the equipment itself under control.

Industrial steam generators differ in operating principles, as they have differences in composition. Thus, the main heating component in them can be a heating element, an electrode or an induction element.

Heating Features

The simplest heating method is heating using heating elements. They have different power. This solution is supported by resistance to dissolution in water and minimal risk of contamination. But scale will appear on the surface of the heating element itself, which over time will lead to a significant decrease in heat transfer and burnout.

Electrode heating of water involves passing a current through the water. Due to this, heat is released, which turns the water into water vapor. It is believed that this is not the safest method of heating. But there also remain problems with scale and burnout, and the cost of purchasing salt, which is used to increase electrical conductivity, also increases.

Induction steam generators are popular due to the fact that heating is carried out on the basis of high-frequency magnetic radiation and high currents. The advantage of this solution is the production of perfectly pure steam, but the equipment itself is not cheap. In any case, the use of equipment is the most economical solution. Reduced costs are achieved by low electricity consumption (2-3 times) to produce one kg of steam and rational use of devices.

Why do you need a steam generator?

The steam penetrates quickly and deeply into the fabric, smoothing out deep wrinkles. It can even cope with dense or folded matter in several layers. A steam generator can be found in a studio or dry cleaner, but it can also come in handy at home. You will be able to iron large amounts of laundry much faster.

Steam treatment is the fastest and safest method of disinfection, so in a family with a newborn child, a steam generator is indispensable. It will disinfect the fabric, ridding it of germs and viruses.

The steam generator is the optimal choice for large families, for families with small children, for seamstresses, as well as workers who comply with a dress code and are forced to change shirts and suits daily.

Advantages of industrial generators

This type is widely used in technological operations of various industries. The production of concrete and other building materials, the production and sterilization of food products, woodworking, petrochemicals, medicine - all these industries require treatment with steam. All models differ in technical characteristics, operating principle, and energy source.

It is advisable to buy an industrial electric steam generator for several reasons:

- high maneuverability - the equipment itself is compact in size, while all processes are automatic. If it suddenly turns off, the steam consumption immediately stops;

- operational safety – the devices have a high level of safety, despite the fact that they are capable of producing high-temperature steam under pressure;

- efficiency - steam generators have a high efficiency rate, operate automatically, and at the same time have the ability to be used under variable loads;

- efficiency - induction devices are considered the most economical, consuming 2-3 times less energy compared to equipment heated by a heating element or electrode. Gas and diesel steam generators are also expensive equipment to maintain, maintain and operate. Here, the economic effect of induction steam generators is slightly less than 1.4 times, but there are no problems with maintenance.

Industrial steam generators are safe and reliable equipment that can operate for about 20 years with proper maintenance. It only takes 5-10 minutes to get it up and running. This efficiency is achieved through a quick start system.

About the features of choice

The modern market offers a variety of equipment that is widely used in various industries. They all differ in functionality, basic characteristics, design and level of assembly. When choosing industrial steam generators, you should proceed from the following parameters:

- type of steam generator - electrode ones are easy to control and use, but consume a lot of energy. Autonomous models are good for use in different conditions, and heating elements devices can be used even in small industries;

- functionality - they directly affect how convenient and reliable the equipment will be in operation. In addition, induction steam generators have an anti-scale protection system, as well as systems that control the water level or temperature. All these parameters are aimed at making the use of the equipment more convenient and comfortable;

- productivity - it can be assessed by steam production indicators. Equipment performance is measured in kilograms of steam produced per hour. The steam pressure that is formed at the outlet of the boilers also matters.

Thanks to all these parameters, these devices are widely used in the processing of various products - food, agricultural. You cannot do without steam generators when processing and sterilizing goods such as tank trucks and secondary polymers.

More about prices

Features of electrical devices

For large-scale production, it is advisable to buy an industrial electric steam generator. Among its distinctive features are:

- compact dimensions, so the equipment takes up very little space;

- minimum maintenance costs;

- the possibility of installation without obtaining additional permits and coordination of the process with higher authorities;

- no need for special water preparation.

Electric steam generators produce volumetric saturated water steam, the temperature of which can vary between 130-160°C at a pressure above atmospheric. The power of the models can be adjusted, due to which the equipment is used in various fields. Among the technical characteristics of electric induction models are:

- steam capacity – from 50 to 1000 kg. steam/hour at pressure up to 6 kg/cm2

- adjustable power - 0-100% at operating steam pressure up to 6 kg/cm2.

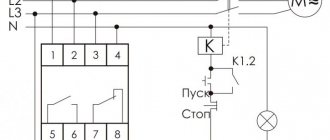

Electric steam generators do not operate on the basis of flammable materials, so there is no risk of fire or explosion. Each model is equipped with a digital unit that performs several functions:

- sets and maintains power at a given level;

- maintains specified pressure and temperature parameters;

- Ensures smooth performance management;

- protects equipment from power surges, automatically operates in normal mode in the presence of power surges.

A special microprocessor control unit with feedback is responsible for maintaining the temperature regime in a certain position. It works according to a built-in program with the possibility of remote access.

How is a steam generator different from an iron?

The iron has a built-in water tank, while the steam generator has a separate one. This is important because the iron becomes heavier with water. You have to constantly lift it, and this makes your hand tired. The steam generator does not have this problem: the water is in a separate container, and only steam enters the spray nozzle. The reservoir in irons is quite small, and during the ironing process you often have to add water.

The steaming power of different iron models varies from 25 to 75 g/min, and for steam generators it ranges from 50 to 125 g/min. It turns out that a cheap steam generator is comparable in performance to a good expensive iron. But a powerful steam generator is far superior to an iron in ironing efficiency: it will steam thick coats, double-layer curtains, and seasonal clothing that has been heavily wrinkled during long-term storage.

There is also a difference in size: the iron is more compact, making it easier for it to find a place in a small apartment. It will fit in a closet, on a windowsill, or on a hanging shelf. The steam generator is larger. And if you're looking for a travel option, consider only compact irons or small handheld steamers.

What is better: an iron or a steam generator? If your budget allows and you don’t mind the size, we recommend taking a steam generator with a dry ironing function: it will replace both devices.

How does an electric steam generator work?

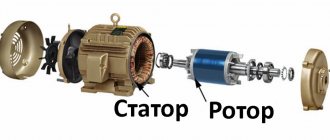

A control unit with a touch monitor is responsible for the operation of electrical devices. All the necessary parameters are displayed on it. All equipment is located on a frame made of rolled profiles. The main assembly components of the steam generator are attached to it. The boiler is responsible for steam production and is a welded structure. To protect against external factors, it is covered with a casing.

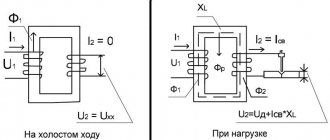

The operating principle is as follows: the required volume of water is supplied to the inductor, and this volume instantly boils due to the high temperature of the inductor. The resulting steam is fed to a separator, where excess moisture is removed (steam humidity is regulated) and supplied to the load. The amount of steam produced depends on the number of inductors. The choice of such equipment is supported by factors such as the absence of the need to obtain permits, no impact on the environment, and a modular design, thanks to which the power can be adjusted to the specific requirements of the user.

All models are fully automated, so no personnel are required. The equipment can be used in intermittent cycle mode. This allows you to significantly save on energy costs.

You can purchase high-quality and reliable steam equipment at. Its specialists are engaged in the supply, installation and commissioning of induction-type steam generators, and provide warranty and post-warranty service. If necessary, you can install additional modules to obtain the required equipment power.

How is a steam generator different from a steamer?

The steamer also produces steam, but not as hot. Its temperature does not exceed 100 °C. Because of this, the steam is more humid, and wet marks may remain on the fabric, which gradually disappear. The steam generator produces “dry steam” that leaves no residue. It also disinfects matter better due to its high temperature.

The steamer does a good job of removing hanging items. They are especially convenient for steaming curtains after washing - right on the curtain rod! Some steam generators have a special nozzle for vertical steaming.

As for steaming power, the steam generator is also ahead.

The steam generator is on par with the iron and steamer, and yet surpasses them. It is more powerful, which means it copes with more difficult tasks - dense matter and deep folds. It produces hotter steam, which means it kills more bacteria, molds and viruses. And it also saves your time!