For a long time now, no one has been paying attention to how the main kitchen unit works. Every now and then we hear purring, shuddering sounds, but none of us think that they directly indicate what type of compressor is installed in the refrigerator. Which compressor is best for a refrigerator is determined by the structural unit. Few people know what types of compressors for refrigerators there are: inverter and linear types. Most often, refrigerators are of the inverter type, although the linear version is considered traditional.

Those buyers who know what types of compressors there are for refrigerators are often interested in which one will work better, and with what equipment the refrigerator will last longer in operation.

Starting the Atlant refrigerator compressor “directly” without a relay with your own hands

First option

In motor compressors there are working, starting and common windings. The common one always stands separately (in old cylinders the vertex of the triangle is on the left, in old “pots” the vertex is at the bottom, in Atlanta, ACC, SECOP the vertex is at the top). We supply the first 220 volt wire to it. We feed the second wire 220 volts to the working winding. We make a short-term jumper using a toggle switch between the starting and working windings. The compressor started. look at the operating current, it should be the same as indicated on the relay of this compressor motor (0.9a; 1.1a; 1.2a; 1.3a; 1.4a; 1.5a). If the operating current is higher than 0.1A - 0.2A, then the compressor motor is faulty. The ammeter should have a frequent division value from 0 A to 2 A (we are interested in current from 0.5 A to 1.5 A). The general scale is up to 5-10 A (so that the ammeter does not burn out during startup). It is advisable to install a voltmeter. There are situations when, at low or high voltage, the compressor turns on and immediately turns off. That is, it would seem one of two things: either the relay or the compressor is faulty. But as it turned out, the cause was problematic voltage. But the main thing is the ammeter. Protection 10 A. helps with a short circuit, the starting current goes up to 6 A and your protection is enough. We collect all this in a convenient box. It is advisable to install an outlet - you will always use it as an extension cord. The result is a device that is used to check the compressor motor.

Second option

SIMPLE option. Take a wire with a plug, attach one end of the wire to the common winding, the other to the working winding, plug it into a socket, at the same time briefly bridge the starting and working windings with a screwdriver, the compressor has started, if there is an ammeter or clamp, measure the current, if not, judge by indirect signs . A working compressor will work and only warm up over time (30-40 minutes). The non-worker works (not always, of course), but gets very hot and quickly winds the electric meter, or the machine on the apartment meter immediately triggers. It is better not to use this option; strive for the first option.

Measuring winding resistance as part of the diagnostics of Atlant refrigerator compressor

First of all, you need to measure the resistance of the refrigerator compressor windings. Knowing the values of the starting and operating windings, you can easily determine the performance of the engine, and for a complete test, it is advisable to start it using a starting relay. The fact is that in the refrigerator motor, in addition to the electric motor, there is also a compressor, which quite often fails. This compressor has a piston that can get stuck, there is also a valve that can get stuck and as a result, the refrigerant pressure on the capillary tube disappears. Please watch the video in which I showed how to check the refrigerator motor with a tester. Just below, I have posted several tables that clearly indicate the resistance of the working and starting windings for the Atlant, Danfos, ACC engine. Knowing the resistance ratings that the manufacturer gave us, you can compare them with your own.

I think the video and table of resistances will greatly facilitate your work and save a small amount of money, because calling a specialist to your home costs something. There is also a nuance that was pointed out to me on my YouTube channel, we are talking about the starting and operating windings of the Danfos motor, the fact is that in the video I was mistaken, in the sense that I said that the starting winding always has more resistance, this Not certainly in that way. The Danfos engine has less starting resistance than working resistance, I apologize. Be careful, it’s better to find out exactly the ratings of the windings of your engine, and then draw conclusions. At the moment, everything is not stable and manufacturers are rushing from one extreme to another.

Video: how to check the refrigerator compressor

How to check and start a compressor from a refrigerator

Watch this video on YouTube

Atlant refrigerator compressor winding resistance

This table contains engines not only of Belarusian design, but also engines that are produced under the license of the Danfos brand. A little about weak points. The Atlant engine itself is of relatively good quality, but the valve is weak and reacts very poorly to low-quality freon, I mean R12a and R134a, in general, refueling must be done carefully, the valve often sticks. This manufacturer also managed to stick aluminum windings into some motors, which he doesn’t hide, motivating this by saying that thermal conductivity is better. I personally cannot judge the thermal conductivity, but they burn much faster than, for example, the same ones from Sekop.

Necessary tools for diagnosing the compressor of the Atlant refrigerator with your own hands

Before you check the refrigerator compressor, you need to prepare the tools and devices that you cannot do without. You will need a set of screwdrivers with different profiles; instead, you can take a screwdriver with attachments, and also:

- wrenches 8, 10 and 12 mm;

- pliers;

- side cutters;

- universal pressure gauge;

- tester (multimeter) or megohmmeter;

- conductor jumpers with alligator clips in the amount of 2-3 pieces;

- insulating tape;

- vinyl or rubber plugs.

You cannot do without personal protective equipment, which will be required when working with harmful substances.

Measuring insulation resistance with a megohmmeter

To check the condition of the insulation of the current-carrying conductors, you will need a special device called a megohmmeter. It allows you to measure voltage resistance from 200 to 1000 V.

Insulating materials have some electrical conductivity. As a result of exposure to high voltage, leakage current passes through them. Its value determines the insulation resistance. Based on the readings, the wear or suitability of the material is determined.

This work is performed in rare cases. Basically, copper wire is used for the stator winding of an electric motor, which is coated with a special insulating varnish. If it is broken, you will have to completely rewind the induction coil. The work can be done at home, but you will need special equipment and consumables. At the same time, you need to have knowledge and skills in this area.

Checking the compressor with a multimeter

A conventional multimeter is used to determine the suitability of an electrical circuit, or as most experts say, you can ring it.

First, dismantle the casing, remove the unit and remove the relay. The tester measures the resistance using contacts. If it is 20 ohms between the upper and lower left contacts, and about 15 ohms between the upper and lower right contacts, then the compressor is working.

Between left and right, the highest resistance value should be 30 ohms. The device may show other values, this depends on the engine and model of the refrigeration unit. However, they do not change by more than 5 ohms.

Then check the resistance between the feed-through wires and the casing. One end of the tester is connected to the copper part of one of the fittings, the other to the contacts. If the multimeter shows resistance, there is a problem with the motor. When a break appears on the display, it means the unit is in good condition.

Functionality check

For what reasons does the compressor stop working:

- Burnt out. This happens as a result of a sharp surge in voltage and increased load.

- The start protection relay is broken.

- Wiring faulty.

It happens that the device hums and works, but there is no cold in the chambers. The reason may be the release of freon gas. Then it is better to contact a specialist who will detect the leak and refill the system.

To find out whether the device is working or not, use a multimeter. Once you get to the motor, you need to make sure that the housing does not break through, otherwise it may cause an electric shock. This most often happens in old refrigerators. Attach the multimeter probes to the body and each contact in turn. If the display shows “∞”, then everything is in order. If numbers appear on the display, the winding is faulty.

To perform further diagnostics, you need to remove the casing and open access to the compressor. For this:

- Disconnect the wiring from the contacts.

- Cut through the motor tubes that connect it to other parts.

Important! Before you begin, find out what type of refrigerant your refrigerator uses. This gas may be explosive.

- Unscrew the casing mounting bolts and remove from the housing.

- Disconnect the relay by removing the screws.

- Now take a tester and measure the resistance between the contacts.

- Apply test leads to the right and left output terminals. Normally the resistance will be 30 ohms. The top right will show 15 ohms, and the top left will show 20 ohms.

Based on the motor model and the refrigerator itself, the values may differ ± 5 ohms.

- If the readings do not match, the device is faulty. If a break appears somewhere, the conventional or inverter motor must be replaced or repaired.

The compressor passed the test, but the equipment does not work? So, proceed to further tests, but not with a tester, but with a pressure gauge.

- You need to measure your blood pressure.

- Connect a hose with an outlet to the discharge fitting.

- Start the engine.

- Measure your blood pressure.

- The readings with a working device should be 6 atm and rising. In this case, you need to quickly turn off the pressure gauge, otherwise it will break.

- If the pressure does not reach 6 Atm, such an engine can be installed in medium-sized refrigerators. The readings reach 4-5 atm, which means the motor can be used in single-chamber refrigerators. A compressor with a pressure of less than 4 atm is inoperative.

The serviceability check has been passed, but there is no result. The unit still does not turn on. In this case, you can establish the operability of the motor by connecting directly, without a starting relay.

Important! Such work is life-threatening. Such diagnostics can be carried out either by a master or an experienced person.

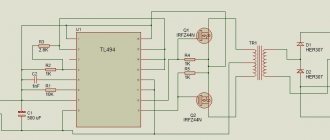

Connect the motor via a cord according to the diagram:

As a last resort, you can check whether the motor is working via a relay. Perhaps the current is not reaching the device.

- Before this, diagnostics were carried out without a relay, now connect it to the motor.

- Run.

- Arm yourself with a clamp tester.

- Use pliers to press the power cord that leads to the device.

- Look at the indicators: with a power of 140 W, the current should be 1.3 A. With a power of 120 V - 1.1–1.2 A.

Additionally, diagnose the start relay. Its contacts are also measured with a multimeter.

Now you know how to check the motor-compressor with your own hands. To be more convincing, watch the diagnostic video:

Features of diagnostics of the inverter compressor of the Atlant refrigerator

This type of compressor was invented not so long ago. The essential principle of its operation is that you can set the required temperature. The inverter compressor has a function that is responsible for adjusting the rotation speed. Thanks to the inversion principle, electricity is consumed more economically. Due to the fact that the compressor operates stably and smoothly with precisely specified output parameters, the temperature in the freezer and refrigerator compartment can be quickly and accurately adjusted.

Initially, the engine will accelerate to its highest speed, cooling the refrigerator chamber to the desired temperature. Then it works more slowly until operating conditions change.

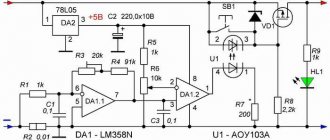

How to check if a refrigerator compressor is working or not? If it is not working, then you need to separately check the inverter, at the output of which 60 W and 220 W lamps are hung. They are connected in the form of a triangle. They should not burn without a generator. It is connected and the inverter starts, the lights light up in a circle. Then connect the compressor.

Objections

Experts raise their objections to the above statements. If the refrigerator is equipped with one compressor, then it always operates at maximum because it does not choose which chamber it needs to pump cold air into. This often happens when warm food is placed in the refrigerator compartment, but the freezer does not need additional cooling. In any case, the compressor begins to pump air according to thermal indicators. Therefore, when choosing a unit model and finding out which compressor is best for a refrigerator, the characteristics of the latter should always be taken into account. If the refrigerator is equipped with modern linear inverter motors, then the equipment will operate silently, despite the fact that there are two motors, and there will be no sudden surges or vibration.

Atlant refrigerator compressor design

At the back of the refrigerator, from the bottom, we usually see the compressor housing, it is usually painted black, inside of which it is hermetically sealed. He is in a state of weightlessness, in an oil bath. Compressors for most models of household refrigerators do not differ in design. Typically, their design is presented in the form of a piston electric motor with a starting winding powered by alternating electric current. Operating principle: the compressor constantly creates pressure, under the influence of which refrigerant vapor (freon) enters the condenser, where it is cooled and goes further in the form of liquid through copper tubes, cooling the inside of the refrigerator and taking away heat, after which it enters the evaporator, and back from it to the compressor. The process is cyclical. Naturally, if the engine does not turn on, the system will not function.

There are three terminals on the compressor housing. They are made in the form of pins and are located at the bottom of the compressor, forming a triangle. One of the contacts comes from the starting winding, the other from the working winding, and the third has one common terminal. Also, any compressor includes a relay - a device that starts the engine. It attaches to three pins and usually looks like a small box. In more modern refrigerators, which provide adjustment of the activation speed, the compressor is connected to another box made using more complex electrical circuits.

Causes of malfunction of an electrical device:

- burnt out compressor;

- damaged start relay;

- the cable to which the device is connected is faulty or damaged.

It would be logical to first check the cable itself, and then proceed to inspect the possible malfunction of the remaining parts of the device, if the cable is working properly.

Also, sometimes there are cases when the compressor turns on, hums, the light comes on, but it does not cool or cools, but very weakly. In this case, you need to pump refrigerant into the compressor, in our case it is freon, because it will most likely leak. In this case, you need to call a technician who will find the leak and pump in gas.

Briefly about the types of equipment

Based on the operating principle, this equipment can be divided into four types:

- Steam ejector, the coolant is usually water. Used in various industrial processes.

- Absorption, for work it uses not electrical, but thermal energy.

- Thermoelectric, based on Peltier elements, wide application remains questionable due to low efficiency (detailed information about these devices can be found on our website).

- Compressor.

It is the latter type of equipment that is widely used in household and industrial units.

Signs of failure of the Atlant refrigerator compressor

Symptoms of improper operation of the refrigerant circulation system in the refrigerator are, first of all, persistent temperature disturbances. The refrigeration unit operates cyclically, its start and stop depend on the temperature in the working chambers. A system of sensors and relays generates commands to turn the compressor on and off, but if the performance of the cooling unit is insufficient, there will be less than is necessary to turn off the relay.

The causes of the malfunction are sought sequentially - it is necessary to exclude the location of the possible problem from the chain. If the refrigerator compressor works without stopping, then the search area narrows noticeably, but this does not always mean that the breakdown occurred in this particular unit. Excessive cold, when the refrigerator freezes food, may indicate a malfunction in the temperature detection and control circuit of the unit.

It’s worth talking about a malfunction of the compressor itself if you notice characteristic signs of a breakdown:

- strong knocking, noise, vibration and grinding noise when starting and operating the unit;

- obvious overheating of the motor;

- the appearance of an oily puddle under the refrigerator;

- strong engine humming without signs of compressor operation.

These are a kind of signals indicating that there is a problem in the motor-compressor unit. But, since the unit consists of two devices, their malfunctions should be distinguished. This is the task of a specialist who understands how the refrigerator works, what circuits, compressor components and components interact when starting, operating and stopping the device.

Capillary tube

The capillary tube is an important part in any refrigerator. It performs the main task - transferring the refrigerant (freon) to the evaporator of the refrigeration unit. A capillary tube is a tube that creates a pressure difference between the evaporator and the condenser. Using a capillary, the required amount of freon is supplied to the evaporator.

Frequent malfunctions of the Atlant refrigerator compressor

Works nonstop

Careful and attentive attitude towards household appliances will allow you to quickly respond to incorrect operation of the units. Especially when the refrigerator defrosts or there is a power outage. If the compressor is running non-stop, the best solution would be to call an experienced technician.

The reasons for this problem include:

- Refrigerant leak, which leads to a decrease in freon in the freezer. Often this problem can be solved quickly and inexpensively.

- The compressor is constantly running - this is due to depressurization of the capillary tube and, as a result, blockage in the system.

- The sealing gum has dried out, it is impossible to achieve the set temperature inside, and as a result, the motor runs non-stop to maintain the optimal temperature and wears out.

If your refrigerator has an inverter compressor, then after reaching the set temperature it continues to operate at low speeds in energy saving mode. This operation of the unit is considered normal. This type of refrigerator includes Samsung models.

The compressor is running non-stop and needs urgent repairs. The compressor and other parts of the unit wear out and overheat very quickly, which leads to major, expensive breakdowns. The refrigerator compressor is hot - a reason to contact the service technicians.

It buzzes but won't start

Extraneous noise in the operation of a new refrigerator is often associated with the presence of transportation bolts. If you are dealing with new equipment from the Atlant or Beko brands, then you need to check the fastenings on the compressor.

If the engine hums but does not start, then timely contacting a specialist will help solve the problem quickly and efficiently:

- This happens when a pipe bursts.

- The thermostat is broken, technicians will replace the part at home.

Turns on and off immediately

Different models of refrigerators from Bosch, Sharp, Gorenje, Siemens differ in operating and downtime times. It also depends on the room temperature, the presence of heating devices near the device, and the set temperature regime. If the refrigerator compressor turns on and turns off after a few seconds, then the unit is faulty.

The refrigerator is operational when operating for 11 minutes and resting for 15 minutes, but 2 minutes of operation after 15 idle minutes is far from normal. When operating this way, the appliance does not reach the set temperature, which has a bad effect on food storage; repair of the refrigerator at home is necessary.

Main malfunctions of refrigerators in operating mode:

- The start-up relay, which protects the motor from overloads, is faulty. The refrigerator turns off and users hear a clicking sound. A part needs to be replaced.

- The electric motor has failed: the internal winding has broken; a specialist must be called.

- The compressor heats up due to the fact that the start relay winding breaks, and the refrigerator turns off. In this case, the part cannot be repaired. Replacement cost depends on the model.

Is it worth extracting copper from household appliances?

The question about the advisability of selling copper scrap can be answered unequivocally - yes, it is quite profitable and, moreover, saves natural resources. The second argument may seem insignificant, but if you think about it, all natural resources are exhaustible, and according to expert estimates, there are 5 billion tons of copper left in the bowels of the earth, which is quite a bit in comparison with other metals.

Is there copper in refrigerator parts?

In addition, copper is not contained in its pure form; ores have a large percentage of impurities and waste rock - from 70 to 95%. Currently, technologies make it possible to develop deposits containing 0.5% copper. When beneficiating such ore, a large amount of energy is expended; quarries and underground mines have a detrimental effect on the environment. This is why the metal recycling industry, including copper, is so developed.

If we consider the benefits of selling scrap metal in monetary terms, then for each kilogram of ferrous metal you can get about 6 rubles, in a standard old refrigerator about 60 - 80 kg. There are also two-chamber models weighing 100 kg, so you can earn up to 500 rubles, but if you disassemble the refrigerator and remove the copper from the compressor, you can still add 300 rubles to the price.

If the freezers are made of aluminum, then this is about another two kilograms or 200 rubles. In total, you can earn 1000 rubles if you put in minimal effort.

Repair or replacement of Atlant refrigerator compressor

Replacement of the compressor must be justified - this is a matter of competent diagnostics. You won’t be able to check the compressor with your own hands and replace it with full compliance with the technology, but you can damage the unit’s tubes, release all the refrigerant, or upset the balancing of the unit.

Due to overload, the internal winding of the motor will begin to heat up, which will not withstand this operating mode for a long time. If it is not stopped by the overheating emergency relay, the winding will burn out. It can be changed, although this is a labor-intensive operation.

The experience of service center specialists suggests that repairs involving the replacement of a compressor are more reliable than attempts to restore an old, already worn-out unit. But if its individual parts wear out, for example, rings, sealing gaskets, individual parts of the motor, repair is still possible. Let the technician figure out the reasons for the breakdown, and he will offer you ways to solve the problem.

Prevention of malfunctions of the Atlant refrigerator compressor

The components of a refrigerator compressor are divided into two groups - electrical (electromagnetic) and mechanical parts that interact during operation of the unit. A starting relay is responsible for the safe start of the system, smoothing out the currents when starting the motor. If the winding of the compressor starting relay has become unusable, then it does not work, does not direct current to the motor windings, and the refrigerator does not start. This breakdown can be prevented by competent operation, careful attention to the device, and timely calling a specialist for repairs.

If you notice a characteristic sign - the refrigerator compressor turns on and immediately turns off, then keep in mind that this will not go away on its own. The cause of the breakdown may be damage to the relay, wear of the bearings leading to jamming of the motor, or an emergency reset when the motor overheats. The most modern models of refrigerators can use an inverter motor control principle, in which a special unit changes the frequency of the current. These are very complex schemes in which the price of a compressor with a motor and an inverter is the highest among analogues. The cost of replacing such a unit is almost two-thirds of the price of the entire refrigerator.

Monitor the sounds and periods of operation of the unit - the linear connection diagram of the compressor motor with the start-protection relay is sensitive to voltage drops in the network, use a voltage stabilizer.

Current test

Next, just in case, check the current consumption. To do this, connect the relay and start the engine. It is advisable to use a relay that is known in advance to be operational. It is most convenient to use a multimeter with clamps. Clamp one power cord with pliers and take a look at the device readings. If the motor power is 140 W, then the current should be 1.3 A. If the power is less, then the current should be less.

So, if the refrigerator fan works, but the refrigerator does not freeze, then you need to check the motor-compressor. This way you will eliminate one of the causes of the malfunction. After this you can check the relay.

There are times when the relay is faulty and the compressor needs to be turned on. In this case, it starts by connecting to the network according to a special scheme. Two wires are connected to the central and working terminals - voltage will be supplied to them. Another third wire is connected to the working terminal. Then apply voltage and with one touch touch the third wire to the terminal of the starting winding. You need to be careful here, since the work is carried out with high voltage.

Continuing the topic: refrigerator power