SMD 5050 is a LED model that, despite its small dimensions, has high brightness levels. Due to this, they are actively used in the production of LED strips and automobile lamps. Based on SMD 5050, models such as 5630 and 5730 were designed. Their efficiency indicator is 80 Lumens per 1 Watt of absorbed power.

The power of 5050 SMD LEDs allows them to be used for the production of home lamps. But more often they are installed in “corn” light bulbs. From 30 to 100 elements are placed here, which provides a good luminous flux. The largest product produces the same amount of light as a 100 W incandescent lamp.

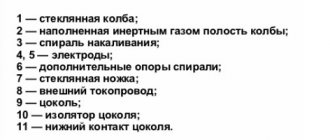

Description and characteristics of LED SMD 5050

Before purchasing SMD 5050 LEDs, you should carefully study the characteristics, since buyers are often sold Chinese counterfeits that do not meet the stated technical specifications.

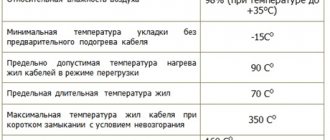

SMD 5050 Specifications Table

LEDs can operate without damage and with original light transmission characteristics for more than 3000 hours. When purchasing Chinese analogues, it is worth considering that almost all performance indicators will be about 3 times worse. But without experience, it is difficult to recognize fakes.

The following materials are used to create SMD 5050:

- indium;

- aluminum;

- gallium;

- phosphorus.

The composition also contains nitrogen compounds (as alloying additives). To make the case, the production uses plastic that is resistant to high temperatures. The diffuser is a lens filled with epoxy resin. Heat sinks are installed to cool the crystals. Each of the elements is equipped with three cathodes and the same number of anodes.

Main conclusions

SMD 5050 LEDs have high performance and technical parameters. They are used in most lighting devices; LED strips and other devices are made based on 5050 elements. The advantages of these components are:

- technical characteristics demonstrate high efficiency and increased capabilities;

- a set of parameters allows the use of SMD 5050 in medium and high power luminaires;

- the service life of these devices significantly exceeds the performance of all alternative light sources;

- The amount of electricity consumed allows SMD 5050 to be combined into chains of 3 elements, which reduces consumption and does not create excessive problems if one crystal fails.

Such qualities make SMD 5050 one of the most popular and sought-after LED devices. Share your thoughts about them in the comments.

Features of application

SMD 5050 are unique due to their original production scheme. They began to be produced a long time ago; this is one of the best options for mounting on tape. 3 separate and controllable crystals allow you to obtain different colors of light, as well as adjustment using the controller.

SMD 5050 is used as decorative lighting for:

- room decorations for the New Year;

- room decoration;

- creating light and music effects;

- advertising and attracting the attention of potential buyers.

The most popular colors of SMD 5050 tape

To obtain a bright white color, it is recommended to connect powerful SMD 5730 elements with the 5050 model.

How to choose

To make the right choice, you need to consider the following:

- presence of a QR code or barcode on the packaging;

- presence of characteristics;

- The kit must contain a passport and instructions for use;

- correct spelling of the name;

- the packaging must not be damaged.

LED SMD 5050 (original)

The seller should not refuse to return it if the diodes turn out to be non-working or do not suit the buyer. In addition, the product comes with a 1-year warranty if it is original.

How to connect correctly

Before purchasing SMD 5050 LEDs, you should figure out how to connect them correctly. First of all, the load characteristics of the diodes should be taken into account. You can connect to the network only if you have a resistor . It must be remembered that the resistance of the resistors should not be less than the nominal value. The quality of each element and its service life depend on this.

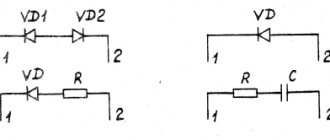

Connection diagram

To understand the connection diagram and be able to work according to it, you need to have the skills of an electrician. If a person is working with LEDs for the first time, the likelihood of connecting the elements correctly is very low.

LED connection diagram

If you have to do the connection yourself, you should study the instructions as best as possible and practice on other LEDs. The common current limiter-LED combination is used here. This circuit is suitable for all single-crystal designs, the only difference is in the ratings of the current-limiting element.

An exception is possible in the case of three crystals installed on an LED matrix. In the 5050 series, it has three cathodes and anodes. The connection is made for each of them separately.

SMD 5050 LED: technical specifications and connection

The most popular type of LED at the moment is the SMD LED 5050. These LEDs have filled the sales markets for a long time and have already become outdated, but they still remain a competitive type of lighting. This type of diode became popular after the SMD 3528 strip. It has a much greater luminous flux compared to its predecessor. As soon as this type of lamps came out, they began to actively use it in all areas of activity, since it is universal.

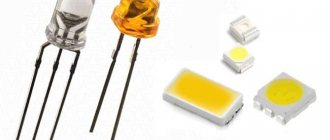

Appearance of SMD 5050

Looking at the modern market, we can conclude that SMD 5050 is used exclusively in tapes. It is not used for lighting lamps, because brighter and more powerful LEDs have appeared, such as 5630 and 5730.

But time passes, and progress also does not stand still. Today, filaments are widely used and introduced into sale. They heat up less, the crystal does not degrade as much, and accordingly, the service life increases.

Specifications

Initially, SMD 5050 LEDs were manufactured for use in various lighting devices. Their main advantages are high quality, and they also have stable characteristics. Virtually unaffected by vibration and temperature changes. Diode crystals are not afraid of moisture; only automatic installation is possible. It is most often used in general lighting, cars and decoration. SMD 5050 is made of three crystals of equal power. Both single-color and multi-color diodes are manufactured.

Description of the main characteristics of the LED:

| Characteristics of white diode 5050 | Values |

| Luminous flux, lm | 18 |

| Power dissipation, W | 70 mW |

| Working temperature | From –40 to +65 |

| Maximum current, mA | 60 |

| Direct voltage, V | 3,3 |

It is worth noting that colored diodes have the best characteristics.

Glow of colored tape

LED model features:

- Slight wear of the light flux (no more than 4%).

- The shell is made of heat-resistant material and can withstand temperatures up to 250 degrees.

- The most optimal operating temperature for a crystal is 105 degrees. At this temperature it will not lose its properties.

In fact, to select a diode, it is enough to know only four characteristics - maximum operating current, luminous flux, power and voltage. To take a deeper look at the characteristics of the SMD 5050, you need to look at the graphs and specifications.

You also need to know that the better the quality, the higher the price. You shouldn’t buy a cheap Chinese product, it’s better to buy a high-quality one right away. Comparing LEDs in this case is inappropriate, since SMD 5050 is many times better than its predecessors.

How to solder correctly?

For the best soldering results, you must adhere to the following rules:

- Soldering of the diode is carried out no more than once.

- Do not apply excessive force to the body.

- When working, only low-temperature paste is used.

- For high-quality soldering, the temperature should not exceed 300 degrees.

- You need to solder for no longer than 3 seconds.

RGB SMD LEDs 5050

The chips of these RGB diodes are not much different from each other. They are also used in almost identical things.

5050 RGB LED

These characteristics are taken from the original datasheet.

| RGB diode characteristics | Red | Blue; green |

| Power dissipation, W | 80 | 100 |

| Working temperature | From –40 to +95 | -40 to +90 |

| Voltage, V | 2,0 | 3,0 |

| Maximum operating current, mA | 30 | 30 |

Connecting LEDs

There is no difference in process between connecting a body diode and connecting an SMD 5050 LED. The most common “current limiter – LED” connection is used. This connection diagram is universal and is used for all multi-chip circuits. An exception is the LED 5050 SMD, which has three crystals on the matrix.

The three-crystal matrix in this series has three anodes and cathodes, and they are connected as independent elements. As for the SMD 5050 RGB models, they are connected using the datasheet, since they have different parameters.

Diode connection diagram (pinout)

When connecting, remember the following:

- Absolutely any model cannot be connected to the network without a resistor. If only one resistor is used, then it is permissible to connect one type of LED.

- The load characteristics of the diodes must match. The data is specified in the reference books.

- Under no circumstances should you use resistors whose resistance is less than the nominal value. This will significantly reduce the life of the diode.

Size

Any diode size is given in millimeters with an accuracy of 0.1 mm. During manufacturing, the size may change slightly.

To produce diodes, a transparent glass lens is used, and the housing is made of plastic that is resistant to high temperatures.

As a result, it can be noted that when brighter and more powerful LEDs appeared, they could not displace the SMD 5050 from the market. Recently, SMD 5050 has been used for the production of LED strips. Thanks to proven technology, excellent performance and impeccable quality, these LEDs are used in all types of lighting products. After what has been said above, you can easily say which LEDs are the best.

lampagid.ru

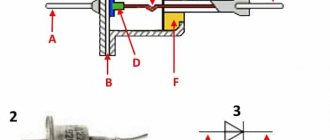

LED installation instructions

In production, group soldering is used for installation. Using a special mechanism, the LEDs are installed on a board that is coated with paste. The next stage is sending it to the oven. Here, under the influence of high temperature, the paste will disintegrate into 2 elements: flux and solder. After performing its functions, the flux will evaporate, and the solder will remain on the board tracks and contacts, ensuring a high-quality connection of the elements with the substrate.

To install LEDs yourself, use a soldering iron. The following rules should be taken into account here:

- the tip temperature should not exceed 300°;

- Before starting work, determine the polarity;

- contact time - no more than 9 seconds, otherwise the crystal may overheat, which will negatively affect the characteristics or cause burnout;

- at the time of soldering, the housing temperature should not exceed 260°.

The result of LEDs correctly installed on the strip using a soldering iron.

If you don’t have a soldering iron or the skills to work with it, you can use a special construction hair dryer . This technology is used in production using solder paste.

LED distance

Density is a technical parameter that will determine the number of elements installed per 1 meter of tape. There can be from 30 to 240 pieces. Density determines the characteristics of the luminous flux and the energy required for operation.

Example of LED density on a strip

To prevent degradation of the elements, a strip with a power of 120 or 240 diodes per 1 meter must be installed on an aluminum profile. If we are talking about purchasing tape on a reel, the manufacturer can indicate the total number of elements. For example, 300 LEDs per 5 meters. This means that the density is standard: 60 pieces per 1 meter.

Specifications

Before purchasing, study the parameters of the LED tape to know if it is suitable.

Main technical characteristics:

- Voltage. Most of them operate from a network with a direct current of 12 V. This value is constantly used in various fields: a car battery, feeding three LEDs through a resistor, a safer value for humans. 12 V tape is the most suitable option for creating lighting yourself at home. To connect, just use an adapter from a computer or a battery pack from a UPS. Less popular modifications are 24 V, 36 V. For addressable connection, a 5 V power supply is sufficient.

- Degree of protection from dirt and dust. This is an important parameter that is also taken into account when purchasing, since you need to know how the structure is protected from external sources during operation. More often, this degree corresponds to IP20, protecting the housing from exposure to solid objects, but does not prevent the ingress of water. Therefore, the design should be used inside a dry room. If direct exposure occurs and there is a high probability of contamination, it is recommended to use IP65 protection.

- Saturation (density) of LEDs. This characteristic indicates how many diodes are located over one meter. Possible values are 30, 60, 120, 240 pieces. The more of them are located on the smd 5050 LED, the more luminous flux and power is emitted. If the density is 120, 240 pieces, then the fastening is done on an aluminum profile, this will help avoid deformation of the strip. If the package or skein simply indicates a value of 300 pcs, then the manufacturer reports the total number of diodes on a strip of 5 meters.

- Light radiation. For the 5050 band, this value depends on the tone of the glow. For the human eye, the best perception is green. If the strip is turned on only in green mode, then a person perceives this glow as brighter than all others. The color temperature for 5050 cmd has the following values: warm flow - up to 4000 K (16 Lm), cold flow - up to 7500 K (20 Lm).

How to avoid connection errors

If there is no resistor, the LEDs must not be connected to a power source. If 1 resistor is used, only elements of the same type can be connected in series. When using a diode on three chips, each is connected through a separate resistor and connected to a similar diode in the next module.

We recommend watching the video: Errors when connecting LEDs.

It is prohibited to connect elements that differ in load characteristics. For example, connecting 5050 and 3528 LEDs together is not allowed. If a resistor with unsuitable characteristics is used, this will cause an increase in the load current to the LED, which will negatively affect its service life.