Power supply for screwdriver

All modern screwdrivers are battery operated. To ensure that it always remains charged, a power supply is required. Chargers from different manufacturers can vary significantly. Firstly, the blocks are equipped with different elements, and secondly, their voltage can be 12, 14 or 18 volts.

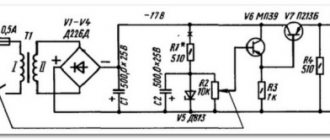

12 V chargers use transistors with a capacity of up to 4.4 pF, while the conductivity is at the level of 9 microns. To level the clock frequency indicators, capacitors are used. In chargers using this voltage, field-effect resistors are most often installed.

12V power supply circuit

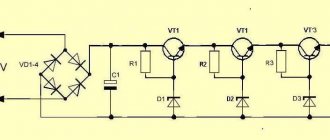

The 14 V blocks already use 5 transistors and pulse capacitors. A four-channel type current conversion microcircuit is used. The resistor capacitance does not exceed 6.3 pF.

14V charger circuit

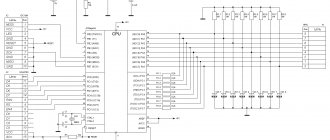

18 V chargers use only transition type transistors. A grid trigger is installed to normalize the maximum frequency. The current conductivity is in the region of 5.4 microns. There are 3 capacitors on the chip. A tetrode is located together with the diode bridge. Some models use chromatic resistors. Dipole transistors are sometimes used. 18V charger circuit

Network unit built into the battery

Work on modernizing the power supply must begin with the purchase of a ready-made unit with the appropriate dimensions and characteristics. The simplest solution is to go to the radio market and select a device that fits the parameters.

Then you need to carefully completely disconnect all parts from the body. Place the elements in the case from the screwdriver battery and secure them inside; if necessary, you need to lengthen the connections between the transformer and the control board. It is advisable to place these two main components with a gap to prevent overheating during operation under high load.

It wouldn’t hurt to attach a cooling radiator to the control chip. You can determine which parts will need cooling using a practical method. To do this, you need to work with a screwdriver for a while, then disconnect it from the network and touch the parts on the board. It will immediately become clear which element heats up more. We drill several holes in the block body for air intake.

If you have knowledge in the field of radio engineering and know how to work with a soldering iron, then you can make such a device yourself. Schematic diagrams of power supply devices can be found on many Internet sites. And, of course, you yourself can solve the problem of arranging the device according to your wishes.

DIY power supply for a screwdriver

The standard charger uses a three-channel chip. Depending on the voltage, a different number of transistors are placed on it, for example, 4 transistors are installed in a 12-volt charger. To reduce the negative effects of clock frequency, capacitors are installed in the blocks. They are of impulse or transient type. To minimize the consequences of electrical network overloads, thyristors are used in chargers.

Standard screwdriver charging circuit

This is important: in different models, not only different numbers of transistors are installed - they differ significantly in their capacity.

Power supply for a screwdriver from an energy-saving lamp In order to make a UPS from an energy-saving lamp, it is necessary to slightly change the electronic choke contained in each lamp by placing a jumper, and then connect it to a pulse transformer and rectifier. For low-power power supplies (from 3.7 V to 20 watts), you can do without a transformer. To do this, you simply need to add a few turns of semiconductor to the magnetic circuit of the inductor located in the lamp ballast, if there is room for this. The winding can be done directly over the factory one. To do this, it is better to use a wire with fluoroplastic insulation.

Power supply for screwdriver from charger

One of the cheapest ways to make a power bank is to use a regular smartphone charger. Every home now has two or more of them, and if you don’t have any extra, you can buy them for 50–100 rubles.

This is what the insides of a smartphone charger look like

The charging modification is carried out in the following sequence:

• Using a small diameter enamelled conductor, one turn of the winding must be added. After that, turn on the charger and connect the screwdriver to the battery. Using an oscilloscope, we measure the amplitude of the pulses and determine the voltage created by one turn of the additional winding. • Unsolder the USB connector, remove the test turn and wind the required number of turns until the required voltage is obtained. The new winding is soldered to the factory one in series. • We replace the standard capacitor and zener diode with new ones that correspond to the required voltage.

DIY switching power supply for a screwdriver

A suitable microcircuit is selected for the pulse unit, and assembly is carried out in the following sequence:

• Diode bridges and a thermistor are placed at the input. • Two capacitors are installed. • Drivers are used to synchronize the operation of the gates of field-effect transistors. • When installing transistors, the flanges are not short-circuited. They are attached to the radiator using insulating washers and gaskets. • Diodes are installed at the output.

Power supply for a screwdriver made from an electronic transformer

To adapt the transformer to the charger of your tool, it needs to be modified. To do this, you need to connect a capacitor at the output of the rectifier bridge. Capacitance is determined as follows - 1 µF per 1 W. The capacitor voltage must be at least 400 V. A thermistor must be installed in the gap of one network cable to limit the inrush current. A diode bridge is installed to rectify voltage with a frequency of 30 kHz. For normal operation of the device, a smooth start is required. Throttle L1 copes with this perfectly.

DIY screwdriver straightener

A rectifier is needed to convert AC to DC. It operates using semiconductor diodes, which act as converters. An oscilloscope is used to analyze the operation of the device. The main thing in the manufacture of a rectifier is the correct choice of diodes. For use in a power supply, elements with reverse current ratings of up to 10 amperes are suitable. The number of diodes is 4, and they should be installed as a bridge type. If the circuit is used on one semiconductor, the useful effect of the unit is halved.

This is important: it is prohibited to work with live electrical components. Before performing any manipulations, you need to make sure that the device is disconnected from the network.

Is it necessary to modify the screwdriver?

When the battery no longer holds a charge, the indispensable mechanical assistant turns into a useless tool. It is not profitable to buy another battery , because the cost of a battery can sometimes reach up to 50% of the price of a new tool. Therefore, every zealous owner begins to think about the issue of converting a screwdriver to power from the mains.

You can try to restore the battery characteristics, but this will be a temporary solution. Anyway, in the future the device will quickly discharge. Do-it-yourself conversion to power a screwdriver from a 220 V network is the best option for restoring the functionality of the equipment. What does this solution provide:

- the device can continue to function fully;

- there is no need to use batteries that require charging;

- The torque of the equipment does not depend on the state of charge of the battery.

The only disadvantage is the dependence on the length of the power cord and the availability of an electrical power source.

Transformer block for powering a screwdriver

Transformer power supplies are devices that contain a transformer that reduces the input voltage. In addition to it, such blocks contain a diode rectifier and a filter capacitor. The capacitor smoothes out the output voltage ripple. In fact, the transformer produces the same type of voltage as in a 220-volt network, or rather, sinusoidal. When operating from uninterrupted sources, its shape may be completely non-sinusoidal. The shape of the rectified voltage is not constant over time, so it is necessary to install an element that maintains a constant output voltage, which is done on a smoothing capacitor.

Advantages of transformer blocks:

• Simplicity and reliability. • The components are easy to find commercially. • No parts that create radio wave interference.

Power supply for screwdriver

In order to power a screwdriver with your own hands from a household electrical outlet, you will need a failed battery, a battery charger, stranded wire, electrical tape, solder, a soldering iron and acid. First of all, you need to solder an electrical wire with a plug to the contacts of the charger. Since the block uses brass terminals and the wire has copper strands, in order to solder them, you must use acid as a connector. The functioning of the entire device directly depends on the quality of this connection. At the second stage, work is carried out with a failed tool battery. The battery should be disassembled and the internal parts removed. During this operation, you need to use personal protective equipment, and it is recommended not to throw the internal filling into household waste, but to dispose of it in a place safe for people. At the final stage, it is necessary to solder the charger wires to the battery terminals, which are located in the inside of the case.

When making a homemade power supply for a screwdriver, you must carefully observe safety precautions when working with electricity. Before starting work, you need to carefully weigh the pros and cons (how much time it will take, what the cost of materials and spare parts will be), sometimes it will be easier and cheaper to take the charger to a specialized workshop or purchase a new unit.

How to make an 18V power supply instead of a battery

Power supplies for an 18V screwdriver are not easy to make with your own hands from improvised means and old electrical appliances. For example, the option for converting a 12V car battery into a computer power supply is not suitable. Professionals in radio engineering suggest assembling the unit yourself.

18 Volt power supply

Take into account the dimensions of the charger so that it can be mounted in the battery compartment of the screwdriver. Also, before remodeling, it is necessary to compare the input power parameters of the charger and power supply. If there is insufficient voltage, the screwdriver will not work with the required efficiency, and if there is too much voltage, overvoltage will occur and the elements of the electrical circuit will fail.

To place the power supply for an 18V cordless screwdriver instead of a battery in the case:

- Unscrew the battery cover.

- Clean the housing from all parts.

- Remove the printed circuit board from the screwdriver power supply.

- Install the board into the case in which the battery was located.

- Solder the output wires according to the contacts.

- Drill a hole for the input wires in the housing.

Assembled power supply

A dismountable mains transformer will do. The power of the part should not exceed 250 W, otherwise the design will not work. It is necessary to disassemble the transformer and wind up the secondary windings except the mains winding. Then the wire is wound onto 1 secondary winding and the required number of turns is obtained, producing the appropriate voltage and current.

Power transformer

You will also need a non-polarized paper capacitor. Approximate capacitance = 1 µF, and voltage not exceeding 400 Volts (optional). Any rectifier models that pass 10-20 Amperes of current are suitable as diodes. The minimum voltage on the return path must be at least 30 Volts.