Application and features of bored foundations

Bored foundations are indispensable in urban environments, where driving piles using the classical method of driving is prohibited due to vibrations transmitted to the ground. The use of bored piles is possible on any soil with the exception of rocky and coarse-clastic soils. The installation sequence is as follows:

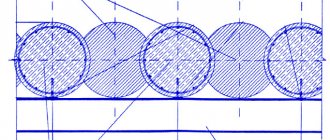

- drilling a well of designed diameter and depth;

- reinforcement;

- pouring concrete.

In some cases (for example, when drilling with a hollow auger), the sequence is reverse: first pouring, then immersing the reinforcement cage. The rods protrude above the concreting level: these ends are later used to tie the piles to the grillage.

On loose loose soils, drilling is accompanied by immersion of casing pipes - they form the walls of the well and serve as guides when constructing piles. As the well is filled with solution, the pipe is removed (not always).

Another way to strengthen the walls is washing with a clay solution: it removes the core from the well and strengthens the walls. The method is suitable for loose soils of average stability.

The load-bearing capacity of each element is determined based on the following indicators:

- pile diameter;

- immersion depth;

- soil characteristics;

- concrete grade;

- type of reinforcement and characteristics of reinforcement.

What kind of concrete is used in a bored pile?

Concrete grade for bored piles – SNIP

Revision 2.02.03-85 SNiP is the main document regulating the concreting of bored piles. GOST standards for concrete grades:

- 19804.2-79;

- 10060.0-95;

- 12730.0-78;

- 12730.4-78;

- 12730.5-84.

It is important!

Instructions for choosing the grade of concrete for bored piles can also be found in TR 100-99 (technical recommendations for bored foundations).

In accordance with the standards for various structures, concrete is selected as follows:

- M100-150 – preparatory work and installation of non-load-bearing structures;

- 200-250 – strip foundations, reinforced concrete belts, grillages;

- 300-350 – beams, trusses, floors, flights of stairs, bored piles.

Composition of concrete for bored piles:

- 25% crushed stone with a strength designed for a load of 50-60 megapascals;

- 25% sand;

- cement - 340 kilograms per cubic meter of mixture.

Depending on operating conditions, modifying additives may be added to the mixture.

Calculation of bored piles

Installation of bored piles in water-saturated soils

Strengthening the foundation with bored piles

What determines the grade of concrete

The composition of any concrete mixture includes:

- cement is the main binding component;

- sand – fine binder;

- crushed stone enhances the strength of the finished stone;

- water.

The grade is an indicator of the maximum load on the test sample, measured in kgf/cm2, that is, the ultimate strength of the structure without reserve. The brand is influenced by the proportions of the components used; to a greater extent, this value is determined by the quantity and brand of binder. In most cases, Portland cement is used for mixing, sometimes Portland slag cement.

In order to save expensive cement, when it is necessary to strengthen concrete, plasticizer additives are used:

- water repellents (for foundations serving in conditions of high soil moisture or in the presence of groundwater);

- hardening accelerators for rapid construction;

- Plasticizers to increase grade strength reduce cement consumption when producing concrete of the desired grade without loss of quality.

There are also additives that prolong the life of the solution, sealants and other additives, but they do not always affect the brand.

Along with the brand, builders use the concept of concrete class - this is an indicator with a safety margin. The meanings of brand and class are interconnected, so the markings for structures in projects are mainly given in pairs:

| Brand, M | Class, B | Load, kgf/cm2 |

| 75 | 5 | 65 |

| 100 | 7,5 | 98 |

| 150 | 10 | 131 |

| 200 | 15 | 196 |

| 250 | 20 | 262 |

| 300 | 22,5 | 294 |

| 350 | 25 | 327 |

| 400 | 30 | 393 |

Concrete consumption when installing bored piles

The volume of concrete for bored piles can be determined after the main technical characteristics of the piles have been calculated - load-bearing capacity, immersion depth, cross-section, pitch, quantity. Obviously, the higher the load from the structure, the smaller the step and the larger the other parameters. A bored foundation for a house made of aerated concrete will require less material than a foundation for a structure made of heavy concrete.

To determine the amount of concrete, you need to multiply the volume of one pile by their number. The volume of a pile is the volume of a cylinder, the height of which is equal to the immersion depth, and the diameter of the base is equal to the diameter of the pile/casing (if there is no widening). In accordance with building regulations, the consumption is 1.02 cubic meters per 1 cubic meter of structure.

Checking the continuity of concrete of bored piles

The actual load-bearing capacity of a concrete foundation corresponds to the design one only if the concrete is solid and there are no voids.

It is important!

Visual control of the continuity of the trunk is impossible. The test is carried out in two ways: with or without partial destruction of concrete.

In accordance with international standards, when using the first method, 20% of piles are subject to partial destruction, which is uneconomical.

Basic non-destructive testing technologies:

- surface testing (PET);

- cross-well monitoring (CHUM).

In the first case, shock pulses are sent to the pile, the ultrasonic sensor of the tester records the reflected waves, and the device interprets the information graphically. The advantages of this method are low costs and high speed.

In the second case, metal tubes of an ultrasonic transducer are embedded along the entire length, parallel to each other, into the shafts of the control piles during the concreting process. To control, the tubes are filled with water or (in winter) antifreeze. The liquid provides acoustic contact. The continuity of concrete in the space between the tubes is controlled. The measurement accuracy depends on the number and material of the tubes. This technology is more energy intensive, but provides a high level of defect detail.

Non-destructive testing technologies are economical, effective, practically do not depend on the depth of the pile (the permissible rod length is 100 meters), and also provide a high inspection speed (up to 100 pieces per day). Control can be carried out by one operator.

Completed projects that we are proud of

Moscow, bridge support

Photo report on the installation of piles by specialists of PSK Osnovaniye i Foundations LLC

More details

Tver, Pig breeding complex

Installation of drilled injection piles during the construction of a pig-breeding complex

More details

Zhukovsky, Moscow region

Photo report of the installation of sheet piling during the construction of a residential building

More details

Photo report of the installation of a pit fencing during the construction of a multi-storey building in Mytishchi

More details

Moscow, Bersenevskaya embankment

Photo report of the installation of secant piles during the construction of a concrete foreshaft in Moscow

More details

Moscow, Dmitrovskoe highway

Photo report of the installation of bored piles during the reconstruction of a traffic intersection

More details

View our other projects

Our Hyundai R330LC excavator with OMS OVR 80 S vibratory loader at the site

Vibration immersion of pipes PSK Osnovaniye i Foundations LLC

Work on removing pipes using a vibrating hammer by specialists from PSK Osnovaniya i Foundations LLC

Vibration immersion of pipes PSK Osnovaniye i Foundations LLC

Vibration immersion of pipes PSK Osnovaniye i Foundations LLC

Vibration immersion of pipes PSK Osnovaniye i Foundations LLC

What determines the choice of concrete grade for a strip foundation?

Strip foundations can be full or shallow. Structures such as garages, bathhouses, and prefabricated technical buildings are installed on a shallow foundation. A reinforced concrete frame is also installed in it, and a reinforcing belt is knitted.

The grade of concrete to be poured is selected based on:

- height of the house;

- number of floors;

- wall material;

- type of base;

- climatic features, soil moisture.

The purpose of the building is taken into account. An industrial building with equipment requires more foundation power than a residential building. Attention ! The calculation of the grade of concrete for pouring the foundation is included in the project.

What is a strip foundation

Structurally, a strip foundation is a reinforced concrete ring that accepts operational, static and other loads from load-bearing structures. A third of the costs in the construction estimate are allocated to the arrangement of the foundation. It represents a ribbon structure made of reinforced concrete, deepened below the freezing level.

Removable or permanent formwork may remain in the trench. A reinforcing belt is mounted in it. Longitudinal reinforcing bars with vertically installed pins in several tiers have to be knitted into one whole. An important step is that the reinforcement must be located in the thickness of the concrete mass after pouring.

What is the brand and class of concrete mortar

The grade of concrete is the ability of a sample to withstand the destructive force of compression and shock impulse. The sample is a standard cube poured into a laboratory flask. Concrete samples are stored for 28 days under standard conditions. Several samples are destroyed.

Strength is determined as the arithmetic mean of the results of all measurements, following the methodological instructions. The indicator is denoted by the letter M and measured in kg/cm2. The project specifies not a brand, but a class of concrete - denoted by the letter B, measured in MPa. The class is assigned based on the result of 95% of measurements. The class characteristics are accepted in the international system and most accurately reflect the compressive strength indicator.

The indicators brand, class and average strength are in accordance and are reflected in GOST 26633-2015.

Table

In addition to the class and brand of mortar, characteristics that affect the service life of the foundation should be taken into account.

Frost resistance (F) refers to how many defrosting cycles concrete can withstand without breaking. The workability of the mixture (P) means plasticity. P1 mixture is dense, you can apply it with a vibrator. P5 – the solution flows from the shovel. Water resistance (W) – the ability to absorb moisture. The higher the number (1-10), the lower the absorbency.

Classification of concrete by strength grades

In private and commercial residential and technical construction, the brand of building mixture is selected based on the ability of petrified concrete to withstand loads. The cost of concrete dough directly depends on the brand.

Composition and application of concrete M100

The construction mixture consists of quarry or river sand, gravel or crushed granite in volume fractions relative to cement as 1: 4.6: 7. The composition is used for the construction of monolithic walls of private buildings in the form of one-story country houses. Other uses:

- preparation of foundations for concrete work;

- repair of structural defects;

- installation of subfloors;

- street paths, for laying curbs and concreting pedestrian paths.

Application of construction mixture M150

The composition uses cement M400, quarry sand, crushed granite stone of fraction 20-40 in a volume ratio of 1:3.5:5.7. Sometimes crushed stone is replaced with broken bricks. Improved strength characteristics are achieved by using additives and additives.

In private construction, M150 is used at all stages - the material saves money.

Use:

- pouring the foundations of one-story wooden buildings;

- floor screed;

- creation of light-loaded floor slabs;

- home improvement.

Use of M200 concrete

The building mixture is intended for the formation of building blocks on reinforced concrete products, flights of stairs. In private low-rise construction, this is the main composition for pouring reinforced shallow foundations for domestic premises. The mixture can be used to make paving slabs and small structures.

For production, cement grades M400, M500, dry sifted coarse sand and medium or large crushed stone are used in volumetric parts of 1: 2.8: 4.8. Plasticizers up to 5 kg/m3 are used, water is no more than 20% of the total weight. There should be 300 kg of cement in a cube of solution.

Where is M250 building mixture used?

In terms of characteristics and methods of application, this building mixture corresponds to the M200 brand, but is more expensive. However, increased strength is required when pouring floor slabs and flights of stairs onto reinforced concrete products and underlays for airfield runways. The pool bowl, walkway, and supporting wall made of M250 are more durable.

The composition uses M400 cement, quarry or river clean sand and crushed stone from any mineral in a ratio of 1:2.2:3.9. Antifreeze additives and plasticizers are used.

Concrete grade M300

The most popular concrete in the construction of buildings and for pouring foundations is M300. However, the brand assumes variability in the batch. When using Portland cement M400, the volumetric ratio of components is required to be 1:1.9:2.8, and when using M500 the ratio is 1:2.4:4.3 of cement, sand and crushed stone. The sand should be coarse, clean, crushed stone is preferably granite, of a small fraction. The mixture contains plasticizers, antifreeze and water-repellent additives.

What are the advantages of M350 concrete?

Compared to lower grades, in M350 increased strength is achieved by using Portland cement M500 in an increased weight volume in relation to inert fillers. The use of additives allows you to reduce the amount of water in the batch and obtain P2-P4 plasticity. After the strength pressure, the material receives Zh8 and F200. These indicators ensure the reliability of structures in northern climatic zones.

Areas of application of M400

The M400 building mixture is intended for the construction of critical industrial, transport and hydraulic structures. Frost resistance of frozen sample F200-300. Surface water resistance W 6-12. Due to the additives, the mixture maintains the mobility of P4, allowing for dense installation.