Stray current protection

The best way would be to ground all metal pipes and gas pipelines, as well as all electrical products located in the house or apartment.

The essence of the method is simple: stray current flows from a place with a high potential to a place with a lower one. The use, in this case, of grounding equalizes the potential difference, thereby eliminating the possibility of stray currents. There is one more subtlety in using water supply. Water (except distilled water) is an excellent conductor, and even replacing metal pipes with plastic ones does not always protect against stray currents. Where the mixer, even slightly, comes into contact with a conductive surface (which can be a wall), stray currents can also arise. Of course, in most cases this does not happen; in this article we are talking about places where stray currents have become an everyday thing. By the way, the water itself, due to friction against the walls of the pipes, can also generate electric static voltage (although this cannot be called stray current and is unlikely to lead to rapid breakdown of the mixer, but it can give an unpleasant electric shock when touching the mixer). As can be understood from the above, in order to protect yourself from stray currents, you need to not only ground all metal conductors, but also taps, mixers and other metal parts of pipelines, if part of the pipeline has been replaced with plastic pipes. As for stray currents from the TV and radio tower, simple grounding will not help. The fact is that we receive a high-frequency stray current from the television and radio tower, which can only be removed using a television antenna cable. Therefore, if this is your case, then instead of a regular grounding wire you will have to use an antenna. As for the more global protection of main water pipelines, they can use equipment that can detect a stray current and start a kind of countercurrent, that is, this equipment is capable of electrically creating at certain points in the pipeline the same potential as at the source of the stray current. According to the laws of physics, this will create a very large resistance for the stray current, and it will begin to look, as I already said, for the path with the least resistance. No one can say where it will emerge after such measures, but the task of protecting the main pipelines will be completed. In fact, it is possible to minimize the manifestation of stray currents, but to do this you need to determine where they appear and make more thorough insulation there.

Another way to protect pipelines and cables is to use dielectric insulation (for cables and pipes) or make plumbing routes using plastic pipes.

Appendix E. Determination of the dangerous influence of stray direct current

D.1 Samples for determining the dangerous influence of stray direct current are sections of underground structures.

D.2 Control means and auxiliary devices:

— a DC voltmeter with an internal resistance of at least 1 MΩ, recording or indicating, of any type;

— copper-sulfate reference electrode;

— electrode in the form of a steel rod in accordance with A.1.1 (Appendix A).

D.3 Carrying out measurements

D.3.1 Measurements are carried out at control and measuring points, wells, pits or from the surface of the earth at the minimum possible distance (in plan) from the pipeline. The positive terminal of the voltmeter is connected to the structure, the negative terminal to the reference electrode.

D.3.2 The duration and mode of measurements, as well as the step between measurement points along the route, are established according to the RD.

D.3.3 When making measurements in areas affected by stray currents, where the amplitude of oscillations of the measured potential difference exceeds 0.5 V, steel electrodes can be used instead of copper-sulfate reference electrodes.

D.3.4 The stationary potential of an underground structure is determined with the means of electrochemical protection turned off by continuously measuring and recording the potential difference between the structure and the copper-sulfate reference electrode for a sufficiently long time until a potential value that practically does not change over time is identified (within 0.04 V) . As a rule, this refers to a period of interruption in the movement of electrified transport, for example in cities at night, when there is no stray current. The stationary potential of a structure is taken to be the average potential value with a difference in measured values of no more than 0.04V.

E.4 Processing of measurement results

The difference ΔU, V, between the measured potential of the structure and the stationary potential is calculated using the formula

ΔU = Umeas - Ust , (D.1)

Umeas is the most negative or most positive instantaneous potential difference between the structure and the copper-sulfate reference electrode, V;

Ust is the stationary potential of the structure, V.

The assessment is carried out based on the largest range of fluctuations in the potential of the structure, measured relative to the copper-sulfate reference electrode (the absolute potential difference between the largest and smallest values). The presence of a positive potential difference exceeding 0.04V means the presence of a dangerous influence of stray currents.

D.5 Registration of measurement results

The measurement results (using an indicating device) of the instantaneous potential difference between the underground structure and the copper-sulfate reference electrode under the influence of stray direct current are recorded in the protocol in the form given in D.6.

E.6 Form of protocol for measuring pipeline potential when assessing the influence of stray direct currents

Protocol for measuring pipeline potential when assessing the influence of stray direct currents

Type of underground structure and measuring point______________________________

Measurement time: start _____________________, end_________________

Device type and number______________________________________________________________

Device verification date_________________________________________________________

Source

What are stray currents, their harm and methods of protection

Have you ever heard the expression “Stray currents”? No? So this is the directed movement of charged particles that occurs in a natural conductor. And in fact, this is a very dangerous and extremely undesirable phenomenon. In this article I will tell you how they appear and how they are fought. So, let's go.

yandex.ru

What are stray currents and how are they formed?

We all know that the condition for the formation of electric current is the presence of a potential difference between two points and the presence of a conductor specially designed for transmitting electricity.

So, stray currents are formed according to the same principle, only a natural conductor (earth) or a metal structure placed in this earth is used to transport energy.

With the principle of the appearance of these currents, everything seems to be simple, now let's find out what forms them.

Sources of stray currents

If we look at a modern metropolis, we will find there simply a huge number of electrified facilities, ranging from large supply substations with outgoing power lines, to electric trains and subways.

And all these energy objects are located on the ground or underground, which, of course, leads to their rather complex interaction through the ground and the formation of stray currents.

yandex.ru

The table above shows the main sources of stray currents; let’s look at an example to better understand the formation mechanism.

So, for the formation of points with different potentials, grounding loops in a system with a solidly grounded neutral are ideal.

In this case, the neutral wire PEN

on one side it is connected to

the charger

at the substation, and on the other to the grounding bus at the consumer.

yandex.ru

Damage to the insulation of cables laid in the ground also creates conditions for the formation of these currents. Well, they have formed and what next? But then the fun begins.

The influence of stray currents on metal

Tell me, what happens to a piece of metal if it is buried in the ground? That's right, under the influence of moisture and salts dissolved in it, the corrosion process starts.

And the current was formed and went to flow from one grounding to another, and if a metal object appears in its path, then the stray current will flow along it, since metal has much less resistance than soil.

yandex.ruA combination: dissolved salts, flowing electric current and metal (playing the role of electrodes) trigger the electrolytic process, and the rate of the electrochemical reaction, according to Faraday’s law, is directly dependent on the amount of current passing between the anode and cathode.

This means that the corrosion rate of, for example, a metal water pipe will be influenced by the electrical resistance of the soil and complex processes taking place in the anodic and cathodic zones.

What happens in the cathode-anode zone

So, our current through the ground has reached the metal pipe and found the “entry point” (free electrons flow into the conductor), this area is called the cathode and does not pose a threat to the metal structure.

But our current continues its path to the other pole of the potential difference and sooner or later leaves the metal back into the soil, and so the place where the stray current exits is called the anodic region and the escaping electrons “wash out” the metal atoms in this area, thereby significantly accelerating the corrosion process .

And a pipe, which according to all standards should last at least 20 years, can take on this appearance in a couple of years

yandex.ru

How to protect yourself from stray currents

As you already understand, stray currents are an extremely dangerous and undesirable phenomenon and there are two ways to protect against it:

1. Passive protection.

2. Active protection.

Passive protection

So, passive protection, for example, of a pipeline includes applying a special insulating material to the pipe, which isolates the metal from the aggressive environment. Various polymer compounds, epoxy resins, bitumen impregnation, etc. are usually used as insulation.

yandex.ru

But such insulation does not provide one hundred percent protection, and during installation and during operation the shell can be damaged, and thus the corrosion process will proceed very intensively in this place.

Active protection has proven to be much more effective

Method for determining the presence of stray currents in the ground

1. Essence of the method

The essence of the method is to measure the potential difference along the route of the designed structure between two points on the ground every 1000 m in two mutually perpendicular directions with the measuring electrodes separated by 100 m to detect stray currents.

Voltmeters with an internal resistance of at least 20 kOhm per 1 V scale with measurement limits: 0.5-0-0.5 V; 1.0-0-1.0 V; 5.0-0-5.0 V or other close to the specified limits. Copper sulfate reference electrodes.

(Changed edition, Amendment No. 1).

3. Taking measurements

The measuring electrodes are placed parallel to the future route of the structure, and then perpendicular to the axis of the route.

Voltmeter readings are taken every 5-10 s for 10-15 minutes at each point.

If the largest swing of the potential difference (the absolute potential difference between the largest and smallest values) exceeds 0.50 V, this indicates the presence of stray currents.

(Changed edition, Amendment No. 1).

APPENDIX 5 Recommended

Methods of protection

Stray currents are a phenomenon harmful to metals and dangerous to humans. There are two types of protection:

- passive;

- active.

The names speak for themselves, but only the combination of both types helps, if not eliminate, then at least greatly weaken the negative effects of BT.

Passive protection

The essence of this method is to apply special protective coatings to metal elements located in the ground. In particular, the surfaces of pipelines are covered with special insulating coatings:

- bitumen mastics;

- resins and polymer compounds;

- primers;

- insulating tapes.

Installation of structures protected in this way requires special care. Mechanical damage to the protective layer will turn into sites of active electrical corrosion

Active protection

In this option, the flow of BT is controlled, which itself is initially uncontrollable. For this purpose, cathodic polarization is used. Cathodic protection is arranged, in which the natural negative potential is replaced with an artificial one. Negative potential is applied to the protected structure.

Cathodic protection device diagramAttention! When constructing such protection, two methods are used: galvanic or using a current source (IT) of a constant direction. The first is on soils having a resistance of 50 Ohm/m or less

The second is when this value is exceeded.

The galvanic solution involves the use of an anode on which the entire BT is assembled. This “sacrificial anode” will be subject to corrosion, and not the structure itself. The material for such an anode is taken with an electronegativity higher than that of the metal of the object.

The use of IT makes it possible to apply opposite potentials directly to the structure and anode circuit. In this case, it is possible to adjust the magnitude of the potentials for different types of soil.

Application of IPT (direct current source) for protection

Water pipe protection

The construction of water pipelines for water supply of objects is carried out with the obligatory determination of the location of stray currents in water pipes. This is realized using potential difference measurements. To do this, two points on the ground surface with a perpendicular relative position are taken (selectively). To protect water pipelines, both methods are used: active and passive.

Protection of heated towel rails

Recently, water distribution in the apartment has been carried out using plastic pipes, but the heated towel rail is always made of stainless metal. In the case of using metal-plastic pipes, the aluminum located inside can be connected to the dryer and supply the BT to it. Even partial insertions into a water supply circuit made of insulating material can cause corrosion from the BT. To get rid of such currents and prevent corrosion, do the following:

- connect all metal elements in the apartment with each other through conductors: radiator, faucet, mixer, heated towel rail, etc.;

- then the resulting circuit is connected to grounding devices.

In this way, potential equalization is achieved.

Heated towel rail protection

Gas pipeline protection

Passive protection applied to gas pipes helps eliminate the influence of BT on gas pipelines. The insulation condition is checked periodically. However, such anti-corrosion armor is an addition to cathodic protection, which is widely used in the gas industry.

Disadvantages of cathodic protection systems

In addition to the main advantage - the presence of a protective potential, which allows you to reduce the corrosion rate of pipelines to a minimum, there are disadvantages. The disadvantages include the fact that if the calculations are performed incorrectly, overprotection is possible. In this case, an overestimated potential shift will only accelerate the destruction process. The installation itself becomes a source of BT.

Additional ways to reduce the effect of BT

These methods include the following activities:

- embankments under the rails should be made with materials that have low electrical conductivity;

- lay underground communications and external railway lines with maximum separation from each other;

- in energy supply systems, when designing, switch to TN-S grounding types.

The use of non-metallic pipelines and shut-off valves during new installations and major repairs eliminates the very fact of electrocorrosion.

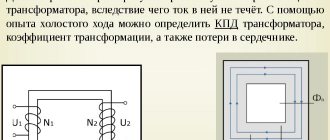

Methodology for determining the dangerous effects of alternating current

1. Essence of the method

The essence of the method is to determine the displacement of the average, the value of the potential difference between the pipeline and the copper sulfate reference electrode.

2. Requirements for samples

Samples for measurement are sections of steel pipelines on which AC voltage values between the pipeline and ground exceeding 0.3 V are recorded.

3. Equipment, materials

Voltmeter for measuring direct and alternating voltages with an input resistance of at least 10 MOhm (for example, type V7-41).

Capacitor with a capacity of 4 µF.

Portable saturated copper sulfate reference electrode (MES).

4. Preparation for measurements

4.1. The auxiliary electrode (EA) is cleaned with sandpaper (GOST 6456) with a grain size of 40 or less, degreased with acetone, and washed with distilled water.

VE and MES are installed in a special pit above the pipeline. The VE is installed in such a way that its working (non-insulated) surface faces the pipeline. First, solid inclusions larger than 3 mm in size must be removed from the part of the soil in contact with the VE. The soil above the VE is compacted with a force of 3-4 kg per area of the VE. In the presence of precipitation, measures are taken to prevent moisture from entering the soil.

4.2. To measure the magnitude of the potential shift, assemble the circuit shown in Fig. 6 with an open circuit between the HE and the pipeline.

5. Reduction of measurements

5.1. Measurements are performed in the following sequence:

10 minutes after installing the VE into the ground, its stationary potential relative to the MES is measured;

connect the VE to the pipeline and after 10 minutes take the first voltmeter reading. Further readings are taken every 5 s. Measurement duration is at least 10 minutes.

5.2. The average value of the SE potential displacement over the measurement period is calculated using the formula:

where is the sum of instantaneous values of the potential of the renewable energy source when connecting the renewable energy source to the pipeline, mV;

U with

— stationary potential of the SE, mV;

P

— total number of measurements.

Pipeline potential displacement measurement scheme

1

— steel pipeline;

2

- pit;

3

- voltmeter;

4

- capacitor;

5

- switch;

6

- copper sulfate reference electrode;

7

- auxiliary electrode

Mechanism of formation of stray currents

The algorithm for forming a BT can be considered using the example of an electrical circuit through which the engine of an electric locomotive operates.

An electrical substation, through a power line (power line), transmits current to a contact (phase) wire. The wire is suspended on electrical poles along the entire route. The electric locomotive's current collector removes it from the wire and supplies it to the engine, and from there to the wheels and rails (neutral wire). Further along the rails, the circuit is closed again to the substation's electrical network.

Important! The rails are not separated from the soil by a dielectric. This means that potential appears in the soil, the same as on them

Under normal conditions, this potential should be the same along its entire length.

Unfortunately, in practice this is not the case. The geometric breaks of a real railway are not ideal. The connection between metal and soil is not always the same. Therefore, the currents either spread across the ground or return to the rail. Where they collide with underground communications: pipelines, metal structures, cables, they pass through them (cathode zone). Coming out of the metal conductors (anode zone), they fall back into the ground. Then the stray currents through the ground return to the rail again and then enter the substation.

Formation of cathode and anodic zonesStray currents. Why is their size determined?

A one-time passage of current through metal structures does not cause much harm. Electrolytic corrosion is caused by constantly acting stray currents of certain parameters.

If the appearance of stray currents is caused by insulation failure in the power system or incorrect connection of electrical installations, then the most competent solution would be a detailed examination of the entire electrical circuit and elimination of the source of the leak. If stresses are detected in the soil near electric transport mains, it is necessary to take measures to protect metal structures (pipelines) from their influence (installation of drainage, insulation of metal with special protective coatings).

Source

Stray currents and methods of dealing with their interactions

Electric currents, the time and place of occurrence of which cannot yet be predicted in advance, are called stray currents. Unlike those electric currents that act stationary and whose influence on an object can be compensated using certain measures, stray currents appear unpredictably in an arbitrary place. The direction of these currents determines what process occurs in the object through which the current flows. If an object has a positive potential relative to another object or environment, upon contact with which electric currents arise, then corrosion (oxidation) occurs. If an object has a negative potential, then the parameters of the substance that is present in the liquid that is part of the medium through which the electric current flows are restored.

Since the chemical activity of elements in contact with a liquid medium representing an electrolyte is usually unknown, it is not possible to predict the time and place of the appearance of a stray current. As is generally accepted, the presence of a stray current leads to corrosion of an object that has a positive potential relative to the liquid medium through which the ion current flows. As the main measure to ensure the elimination of corrosion in long pipelines, so-called cathodic protection is used. To do this, a sufficiently high value of negative potential is supplied to the pipe, which guarantees a negative potential on the pipe for any parameter values that cause stray currents. In known technical solutions, a potential of approximately 6 kV is applied to the pipe.

It is believed that for any real values of the medium and electrolyte there is no positive current in the circuit, which can cause corrosion. There is so-called cathodic protection of the pipe from corrosion, which is quite effective, but has one drawback: the components that make up the pumped medium are deposited on its inner surface. These are various paraffins that significantly reduce the actually usable diameter of the pipe and increase the energy required to pump a unit of product. To restore the original internal diameter of the pipe, it is necessary to remove the formed paraffin deposits; for this purpose, mechanical cleaning methods are used, using special “brushes”.

The only effective measure to protect a pipe from corrosion by stray currents is to reduce to zero the currents that flow through the pipe in various sections. To do this, the pipeline is divided into sections to which voltages are applied, ensuring “zero” (or tending to zero) currents between the pipe and its environment. The “equalizing” current between sections will flow through the pipe and will not cause corrosion. Moreover, the zero current value between the pipe and the environment can be maintained automatically, using specially developed analog electronics. The output voltage of operational amplifiers will depend on the values of stray currents and the distance at which they are placed.

With a significant number of stray current sources, the number of sections between their compensation amplifiers will be significantly larger and the dynamic range of changes in their output voltages will be larger. Amplifiers must be covered by 100% negative feedback and have a small zero drift of their own. With the dynamic range of amplifiers, the output voltage of which can reach tens of volts, it is possible that corrosion from electric currents and deposition on the wall of the pumped product will be practically reduced to zero (when using amplifiers that are not very sensitive to common-mode signals). The equalizing current between sections will flow through the pipe and through the “ground” without causing corrosion of the pipe.

The level of stray currents depends on:

- from the electrochemical potential of objects between which electric current flows

— on the composition of the medium (electrolyte) between objects

- the distance along which the electric current flows

- from the presence of electromagnetic fields penetrating objects and electrolyte, which can create a release of radian energy (Tesla phenomenon).

The latter is especially dangerous if electromagnetic fields change quickly enough.

Definition of chemical corrosion.

Performed at M if the cables are damaged by corrosion and there is no information about the corrosion conditions of the route.

It is recommended to assess the corrosive activity of soils and natural waters using chemical analysis of the environment or the metal mass loss method.

The characteristics of the corrosive activity of soils relative to lead and aluminum are given in Table. 14 and 15. Corrosive activity of soils relative to steel is determined from table. eleven.

Table 14. Characteristics of soil corrosion activity relative to lead

| Soils | Indicators | Corrosivity | ||

| Amount of organic substances, % | Number of hydrogen ions (pH) | Amount of nitrogen substances,% | ||

| Sandy, sandy-clayey | No more than 1 | 6,5 — 7,5 | No more than 0.0001 | Low |

| Clayey, saline, calcareous, weak chernozem soils | 1 — 1,5 | 5 - 6.5 and 7.5 - 9 | 0,001-0,001 | Average |

| Silt-chernozem, peat; soils clogged with foreign substances (garbage, lime, slag) | More than 1.5 | Less than 5 and more than 9 | More than 0.001 | High |

Table 15. Characteristics of soil corrosion activity relative to aluminum

| Wednesday | Indicators of corrosive activity | Corrosivity | |||

| pH value | Amount of substances in soils, %; ion content in waters, mg/l | ||||

| WITH | SO | F 3+ | |||

| All soils, except those contaminated with foreign substances | 6.0 - 7.54.5 - 6.0 and 7.5 - 8.5 Less than 4.5 and more than 8.5 | Less than 0.0010.001 - 0.005More than 0.005 | Less than 0.0050.005 - 0.01 More than 0.01 | Less than 0.0020.002 - 0.01More than 0.01 | LowMediumHigh |

Possible protection options

To protect metal products from harmful effects, various methods are used, divided by the nature of their application into passive and active.

Passive option

Passive isolation

This option is the use of various insulating materials that form protection between the conductor and the metal. The following is used as insulation:

- epoxy resin mixtures;

- inclusion in polymers;

- bitumen coating.

But if we limit ourselves to only this option, then full protection will not work, since the insulating material is not a 100% barrier due to the presence of diffusion permeability. Therefore, isolation occurs in a partial way. In addition, in the process of moving pipes, such a layer can be damaged, resulting in significant scratches, cuts, through holes and other flaws.

Active protection

Indicates the use of an active method of localizing the source of influence through the use of cathodic polarization, where a negative charge displaces the natural one.

To implement such protection, you need to use one of two tools:

- Galvanic method - the effect of a galvanic couple, the destruction of the sacrificial anode is carried out, thereby ensuring protection of the metal structure. The method is active with soil resistance up to 50 Ohms per meter; if the resistance is lower, the method is not effective.

- DC source – ensures avoidance of dependence on the soil resistance force. Cathodic protection is used, the source of which is contained in the formed converter connected to the AC electrical circuit. Since the source is specially formed through its regulation, the required level of current protection can be set, depending on the prevailing circumstances.

Active insulation

This method can also have a negative impact:

- overprotection - exceeding the required potential, as a result of which the metal product is destroyed;

- incorrect calculation of protection - leading to accelerated corrosive destruction of nearby metal objects.

The given examples can be considered on the protection of such a product as a heated towel rail.

Corrosion processes on such products or other terminal plumbing products have never occurred, but this was a reality before the use of metal-plastic pipes, where there is contact with aluminum inside the wall. As a result, the formation of wandering elements occurs not only due to the use of plastic pipes in the immediate room, but also in others, since in an apartment building they can be used by a neighbor on another floor.

In this case, the use of much-needed grounding occurs in relation to any communication that is made of metal pipes, for example, a gas pipeline in the ground.

Types of Stainless Steel Corrosion

Owners of stainless steel dryers often complain that the device has become covered with rust. Gradually, more and more spots with a diameter of a couple of match heads appear on the surface of the heated towel rail. If you wipe the area of rust, a barely noticeable mark will remain, which over time covers an increasingly larger surface.

Being affected by corrosion, the water heated towel rail begins to leak. The root cause of the destructive process is stray currents. Metal structures that are constantly in contact with water are subject to two types of corrosion: electrochemical and galvanic.

Electrocorrosion occurs when metal through which electricity passes comes into contact with water. Due to high load, so-called metal breakdowns occur, which leads to the development of corrosion processes.

Galvanic corrosion occurs due to the interaction of dissimilar metals, one of which is characterized by higher chemical activity. In this case, the electrolyte is water along with the minerals and salts it contains. Hot water especially enhances electrical conductivity. In this case, the metal deteriorates much faster.

Causes and sources of occurrence

As we remember from the school physics course, for the formation of an electric current it is necessary that a potential difference arise between two sections of the circuit. The principle of the occurrence of stray currents is similar. Only the role of a conductor in this case is played by the earth.

On the territory of modern cities and towns there are many electrified facilities, ranging from power lines to rail transport, including equipment for traction substations. They are united by one factor - location on the ground. This leads to a rather specific interaction with the latter, manifested in the appearance of stray currents. Below is a table showing their potential sources and conditions for the formation of telecommunications with the soil.

Water supply protection

Passive and active methods are used to protect the water supply. Active consists of installing a device that generates a counter electrical signal. The passive method is to use an insulator. In addition, prevention and comprehensive pipeline protection are used as a method of protecting water pipes from stray electric current. Specialists coat the pipes with a polymer composition. As a result, metal corrosion does not occur.

Water supply protection

Passive option

The passive option is the main measure to rid any installation of stray electric current. It is called cathodic protection. Thanks to it, corrosion in long pipelines is eliminated. To perform cathodic protection, a high negative potential is applied to the pipeline. It guarantees the maintenance of a negative pipe potential, regardless of the parameter values caused by stray electric currents in pipeline systems. As a rule, a potential of 6 kilowatts is supplied.

Note! It is believed that in this case, regardless of the medium and electrolyte, there is no positive charge. This is how the pipeline is protected

This method is effective, but has one significant drawback: the elements that are in the medium are deposited on its inner surface. These are elements in the form of paraffins, which significantly reduce the diameter of the pipe and increase the energy required to pump the contents of the pipes. To restore the original internal pipe diameter and remove wax deposits, mechanical cleaning with a brush is usually used.

Passive option

Active protection

The only effective way to protect a pipeline from corrosion caused by stray energy is to reduce the current flowing in different areas to zero. To do this, the master divides the pipe into sections. He applies voltage to them. Thanks to this equalizing method, electricity does not cause corrosion. In this case, the resulting zero from the equation is supported automatically by analog electronics.

Device design

The device is manufactured in a metal case, sealed, designed to operate at ambient temperatures from -30 to +60 °C with a relative humidity of 100%. The weight of the device is no more than 300 g, overall dimensions are 190x83x35 mm. The front panel has an on/off button for the device, three terminals for connecting signal sources, a button for manually starting measurements, a sealed RS-232 connector, and a two-color LED to indicate the standby mode of operation of the device.

When you turn on the power button, the device self-tests and checks whether the measurement programs are included in it.

The button for manually starting measurements is blocked from being accidentally pressed when carrying the device. The device begins to take measurements if the “Manual start” button is kept on for at least 4-5 s.

The DAR software allows you to set an automatic or specified range for measuring voltage, stray currents, cathodic protection of pipelines for each channel, the interval between measurements, the number of measurement channels 1-2, the date the device was turned on and time.

This is interesting: Find out debt from bailiffs by last name

The connected device can wait a day, a week, or a month for the switch-on date. Viewing the results of measurements of stray pipeline currents can be in the form of graphs and tables. There is scaling along the “amplitude”, “time” axes, electronic magnifying glass, and printing. Accidental switching off of the device does not lead to loss of measured data and the set mode.