Method number 1 - improving natural lighting

The brighter and better the natural daylight, the lower the energy consumption in an industrial enterprise. It is necessary to create conditions that promote maximum penetration of sunlight into the room.

Recommendations:

- When choosing finishing materials for ceilings and walls, give preference to light options - they can reduce electricity consumption by 1 to 3% of the usual value;

- Avoid using curtains, curtains and other items covering windows, window openings and window sills;

- Make sure that the windows in production workshops are always clean - settling dust particles prevent the penetration of sunlight.

Method No. 2 - increasing the efficiency of artificial lighting

Using efficient artificial lighting devices in production workshops and industrial premises, it will be possible to save up to ½ of all energy costs regularly spent on lighting workplaces.

Recommendations:

- Make sure that fixtures, lamps, shades and other artificial lighting devices are always clean - constantly wipe off dust from them (the number of cleanings is determined by the specifics of production activities and usually ranges from 3 to 12 times a day );

- Use local (local) lighting - table lamps, floor lamps and lamps. By turning off or reducing the level of general lighting, it will be possible to reduce the cost of electricity consumption in an enterprise from 30 to 50% ;

- Select light zones in the production workshop by connecting general lighting in groups. This method provides electricity savings of 20 to 50% of the amount of energy spent on lighting an enterprise.

Method number 3 - control over energy consumption

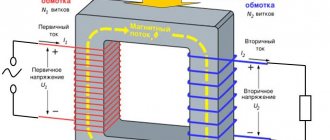

Use modern and innovative energy consumption metering systems. Special meters are presented in the assortment of not only foreign, but also Russian manufacturers - purchasing domestic products will allow you to save additional money.

Instructions for saving energy using modern technologies and developments:

- Supply electrical energy meters with a higher level of accuracy than those previously installed at the enterprise;

- Install automated commercial electricity metering (installation of ASKUE) to save resources;

- Continuously maintain careful technical records of the energy consumed – locally, as well as throughout the plant.

Method No. 4 - using energy-saving techniques

The introduction of energy-saving technologies is based on the installation of a special artificial lighting system and energy-efficient production equipment. The method under consideration involves one-time financial expenses.

Recommendations:

- Install lamps with high efficiency. Their use in industry allows saving from 20 to 80% of energy;

- Purchase ballasts that regulate the ignition order and stabilization of the discharge current of fluorescent lamps;

- Use lighting fixtures - they help reduce electricity costs by up to 15%;

- Give preference to energy-saving heating equipment for those workshops in which centralized water heating is not possible.

How to save on electricity here and now

The energy costs of most Russian enterprises are approximately one third of other costs. The reasons are trivial: the use of outdated, often physically worn out equipment that consumes large amounts of electricity, and the irrational use of resources. Consequently, the problem is formulated as follows: how to minimize the costs of maintaining an enterprise in working order and save a significant amount of money.

For the normal functioning of an enterprise, office, warehouse, the following are required: electricity supply, heat supply, water supply and sewerage. Let's look at them in order.

Reducing electricity costs is possible by implementing a number of measures, such as:

- replacing outdated models of electric generators with modern ones, whose energy intensity is significantly lower;

- transition to a system of energy-efficient lamps (for example, fluorescent lamps consume five times less electricity, LED lamps – eight times less);

- reducing the use of general lighting or even abandoning it will help reduce electricity consumption in the range of 20 to 50%;

- Zoning the work area (some things are illuminated brighter, for others dim light is enough) will also allow you to save a lot of money. Street lighting, for example, can be automated altogether: lights constantly running in the yard are useless, and they consume a lot of electricity. It makes sense to equip them with circuit breakers.

Assess how beneficial your cooperation with your current energy supplier is. Today, companies have a choice. Perhaps there will be someone who will offer the best tariff, conditions for making payments, the amount and procedure for repaying penalties.

Set up an effective control system. There are not enough counters to have a complete picture of unaccounted losses. Electricity leaks can only be internal, on the consumer side. But you should know about them in order to plan equipment replacement or repair.

Just keep the windows in your rooms always clean, to make better use of natural light, paint the walls in light colors. These simple manipulations also bring tangible benefits.

The lighting industry is evolving, and in addition to the long-popular LED and other energy-saving lamps, new solutions are emerging.

Schneider Electric specialists collected the opinions of entrepreneurs (including those involved in industry) regarding the practice of using a number of solutions in production to minimize energy costs:

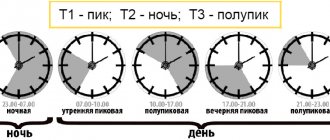

- A multi-tariff electric meter saves costs because at different times of the day, electricity consumption is calculated at different tariffs.

- Dimmers and time-delay switches regulate lighting intensity while maintaining light levels at eye-safe levels.

- Time-delay switches save up to 20% on electricity costs by disconnecting the appliance from the network for a specified period of time.

- Motion sensors allow you to save up to 45% of electricity (these, by the way, can be used when optimizing the street lighting mentioned above).

The use of dynamic diesel uninterruptible power supplies (DDIUPS) and the implementation of a free cooling system, tested at DATA centers, also significantly saved electricity consumption.

Method No. 5 - use of special equipment

By choosing energy-efficient machinery and equipment for an industrial enterprise, it is possible to save from 15 to 80% of the total amount of electricity. For example, it is recommended to use electric stoves equipped with induction heating functions, a controller control system, etc.

Optimize the performance of your production equipment by installing variable frequency wiring to control motors. The use of this method allows you to save up to 20% of the cost of electricity spent on operating electric motors.

Systematic replacement of all old equipment, including:

- personal computers,

- audio equipment,

- video equipment,

- power parts of the equipment.

Use innovative and cost-effective technology for replacement. One-time costs for its acquisition are quickly compensated by a significant reduction in energy consumption. For example, the efficiency of a lamp with 20 years of experience is 65% , and the efficiency of a new lamp is 95% . The total savings are from 25 to 80% .

Ways to save energy

Measures to save energy must be comprehensive. The effectiveness of the measures taken depends on the quality of your energy audit of the enterprise and scrupulous implementation of the instructions of energy auditors on the issues of saving electrical energy in production.

For our part, we suggest that you apply the following measures. They are divided into three categories for your convenience:

Simple ways

Energy saving in the enterprise by saving electricity

- painting the walls of the premises in light colors. This will increase the level of illumination in the room. Saving - 5-15% of electricity

- the use of windows with an increased glass unit area, with a rational location relative to the course of the Sun. Savings - up to 20%

- do not allow the incoming light from windows to be cut off or scattered by curtains or other objects. Savings - 1-5%

- It is very important to maintain the cleanliness of light sources: windows and lighting fixtures must be clean and transmit light well. Save from 3%

- replacing outdated and energy-consuming incandescent lamps in lighting fixtures with energy-saving lamps; the most economical are LED lamps. Savings in the segment of electricity consumption for lighting - from 50%

- control of lighting operating mode. Turn on the light source only when necessary, in the evening, and avoid using them after hours. Savings - from 5%

Advanced methods

- appointing an employee who will be responsible for the electricity consumption of your production equipment and computer equipment

- training company employees in the correct handling of equipment and computers. There is no need to constantly turn on and off your personal computer (it consumes no more than 400 W per hour). As a rule, modern computer equipment is equipped with a modern switching power supply, which consumes very little electricity in idle mode. Sleep mode is the best solution for a computer during a short-term absence of an employee. As for printers, scanners and other equipment, you just need to turn them off when you are not working with them

- systematic replacement of all old electrical equipment, audio-video equipment, power parts of equipment with modern and economical electrical equipment. The one-time high acquisition costs will soon be offset by the significant reduction in energy consumption and its increased operating efficiency compared to older models. A simple example: a lamp with twenty years of experience has an efficiency of 65%, and a modern new lamp has an efficiency of 95%. Savings - from 20 to 80%

- optimization of the heating system and turning off unintended electric heating devices that were additionally used to heat the room.

High-tech methods

Energy saving at the enterprise, high-tech methods

- installation of electricity meters with accuracy class 1.0

- for consumers with connected power equal to 150 kWh - installation of active and reactive energy compensation devices

- The installation of various sensors has proven high efficiency: presence, motion, time relay. Allows you to save 30% on energy costs by reducing the “idle” operation of lighting lamps

- reduction of power consumption by optimizing the operation of production equipment by installing variable frequency drives to control electric motors. This measure is also effective in setting operating parameters and regulating the operating mode of equipment, optimizing the work process. Efficiency - from 20% of electricity costs for operating electric motors

- installation of high-quality equipment soft start devices. Necessary to reduce the likelihood of overheating and breakdown of electric motors

Method No. 6 – working with personnel

One of the ways to save energy at an enterprise is to appoint an employee responsible for resource consumption. It will provide timely and, most importantly, careful control over the consumption of electricity in various workshops.

Note! If an industrial enterprise has more than 3-5 workshops, then it is recommended to appoint several responsible employees and distribute them among zones.

The duties of the employee responsible for the energy sector, appointed by order of the manager, will include:

- creating conditions for timely and high-quality maintenance, scheduled repairs and preventative testing of electrical equipment,

- carrying out calculations aimed at determining the volume of electricity consumed, as well as monitoring its consumption,

- personal development and introduction at the enterprise of technologies and measures, the purpose of which is the rational consumption of electricity.

Train production personnel to properly operate machinery and equipment. Introduce training at various levels (depending on the qualifications and professionalism of workers). Regularly inform employees about energy-saving technologies being introduced.

Implementation of measures to improve energy efficiency

After conducting a detailed Audit and justification for each activity, a phased implementation of the activities is carried out, taking into account the planned time frame, the planned effect and the necessary investments.

Organizational events

Most of the organizational measures, if properly worked out at the audit stage, can be implemented by enterprise specialists without the involvement of third parties. Some activities require the involvement of specialized organizations or additional financial expenses. All required investments must be taken into account at the audit stage.

Technical events

Technical activities in most cases require certain financial investments. The amount of investment is determined at the audit stage. Depending on the size of the investment, the net present value of the activities and the return on investment index, a decision is made on the source of investment. Depending on the source of investment, activities can be implemented based on the following principles:

— implementation of activities at the expense of the enterprise’s own funds; — implementation of activities using loan funds; — implementation of activities based on an energy service contract (energy performance contract); — implementation of activities based on a contract/supply agreement with elements of an energy service contract in terms of guaranteeing energy savings.

Local order to save electricity – is it worth introducing?

30% of energy losses in the Russian Federation are the result of citizens’ irrational and mismanagement of electricity consumption. In order to reduce this indicator and significantly reduce the company's current expenses for utility bills, it is advisable to adopt a local order to save electricity.

How is it formatted? There is no standard form established by current legislation. This means that the development of the order, its structure, content and procedure for implementation in production are determined independently by management with the participation of the employee appointed as the person responsible for energy management.

Note! The main thing is to familiarize all personnel involved in the enterprise with the order on energy saving, against signature.

comparison table

The main ways to save electricity at an enterprise were discussed above - their use will allow you to significantly reduce electricity costs without compromising the quality and efficiency of work.

Below are specific energy savings data (depending on the method chosen and applied):

| Way to save energy | Efficiency of implementation in production | Nuances of use |

| Increasing natural light levels | From 1 to 15% | The given indicator may differ depending on the specifics of production activities |

| Improving the quality of artificial lighting | Up to 50% | In addition to the above methods, it involves monitoring the serviceability of lighting fixtures |

| Careful control over resource consumption | To 10% | Installation of special meters + proper performance of duties by the person in charge |

| Energy saving technologies and their implementation | From 20 to 80% | Requires large financial costs, but is justified many times over in the long term |

| Briefing and awareness of involved personnel | To 10% | Staff should be informed regularly with the participation of an experienced instructor. |

| Operation of special equipment | From 25 to 80% | Do your financial capabilities not allow for a one-time replacement? Organize the gradual purchase of equipment |

Solving the problem of energy saving on an enterprise-wide scale is possible provided that all of the above methods of saving are applied simultaneously and properly. The more carefully you approach the task, the more costs you will be able to reduce.

Agree, it is much more profitable to direct funds to purchase equipment and additional equipment than to pay for utilities.

Video on the topic of the article: energy savings of up to 20% in production.

Simple ways

Simple methods include the usual saving of electricity in an enterprise. To do this you need:

- 1) Make sure that the walls in the premises of the plant/organization are light in color. If they are not, then they should be painted. This will provide higher illumination in the building and consequently contribute to a reduction in the use of lighting devices. This way you can reduce costs by 5 – 15%.

- 2) Installing large windows also contributes to better lighting and additional energy savings of up to 20%. It's good if the windows face the sunny side. In such rooms you can achieve maximum results.

- 3) Do not use curtains and blinds during the daytime. Will save you another 1 to 5%.

- 4) Regular washing of lighting fixtures will provide an additional savings of 3%.

- 5) Establish control over turning on and off lighting devices. If you make sure that the lights are turned off in time when they are no longer needed, this will help you save an additional 5%.

- 6) Use only modern LED lamps (and get rid of conventional fluorescent ones). This will make it possible to reduce energy consumption by 50%.

As you can see, you cannot achieve significant savings using such simple methods, but you will be able to reduce some costs.