About flagstone

Flagstone is a collective name for natural minerals that, due to their structure, have the appearance of flat plates (slabs). Depending on the forming rock, granite, slate, sand and other types of stone are found. Manufacturers offer stone with a torn edge (wild) and processed, with a thickness of 2 to 15 cm and an average size of up to 50 cm (on the larger diagonal).

Flagstones are widespread in nature; they are mined by quarrying in a variety of regions: in Siberia, the Urals, the Pskov and Murmansk regions. Depending on the place of extraction, the stone has different shades: from gray, burgundy and beige, to ocher and green. A wide range of colors opens up a variety of possibilities for using flagstone. The thickness of the material determines how it can be used:

- Thickness 1-3 cm . Such slabs are ideal as a facing material, both for external walls (facades and plinths), and in interior design, including stoves and fireplaces. Application for the construction of paths is limited.

One of the varieties of flagstone is brown sandstone Source seattlehelpers.org

- Thickness 3-6 cm . The material is used in the construction of paths (paved and step-by-step), open terraces and parking areas.

- Thickness 6-14 cm . Construction of fences and installation of retaining walls on a sloping site.

Using flagstone as a road surface

A variety of materials are used to cover garden paths. This can be a simple backfill with small colored crushed stone or monolithic concrete, rubber or wooden coverings, paving slabs or paving stones, but nothing better than inexpensive and durable natural stone has yet been invented. And flagstone is just such a material - a beautiful, fairly durable and relatively inexpensive stone.

It is a slate slab material made from sandstone or limestone, divided into flat slabs of different sizes and configurations with a thickness ranging from 15 to 150 mm. Thin slabs are often used for exterior and interior wall decoration, but thicker ones are perfect for road surfaces.

The advantages of garden paths made of flagstone:

- beautiful appearance and wide range of colors;

- smooth and, at the same time, rough surface;

- excellent environmental performance;

- good strength, frost resistance, resistance to moisture and abrasion;

- long-term preservation of color shade;

- simple laying technology and mechanical processing if necessary.

All this makes this material one of the best among road surfaces.

Flagstone: 6 benefits of use

The numerous advantages of this natural stone have turned it into a sought-after material for country construction and the design of a personal plot. He is considered attractive for the following reasons:

- Durability . The stone can withstand significant loads and resists abrasion and winter and summer temperatures well.

- Aesthetic qualities . A variety of shades and textures allows flagstone to fit into any landscape and style.

- Environmental friendliness . Using the stone has no side effects.

- Attractive price . The material looks advantageous compared to other natural finishing stones (marble, granite).

- Easy to install . Flagstone paths are laid in a standard way, and they do not require border edging.

Natural stone is a godsend for any style Source pinterest.pt

- Performance characteristics . Flagstone is an ideal option - thanks to its rough surface, it does not slip during rain, and does not lose its decorative appeal over time.

Advantages and disadvantages of flagstone paths

- The use of this environmentally friendly natural building material has several advantages:

- a wide range of materials that differ in type of rock, color, texture and other indicators;

- absence of harmful components;

- good resistance to external factors and durability;

- the ability of most breeds to withstand the weight of transport;

- accessible process of laying and processing stones;

- ease of further maintenance.

- But flagstone coatings also have some disadvantages:

- higher price of material and cost of work;

- the need for preparatory work, such as, for example, removing the top layer of soil;

- use of additional equipment (transportation of heavy slabs, etc.);

- longer installation process (shrinkage of heavy slabs).

But, despite all the shortcomings, flagstone seems to be more advantageous compared to other materials. You can ensure comfort in your garden and save money by choosing a stone that is not too expensive. It is necessary to focus on compliance with technical requirements (strength and durability), as well as simpler installation technologies.

Did you know? Crystals of the mineral of the same name look like pomegranate seeds. The number of faces can reach 72. Paper, powder for polishing leather, and even mirror glass are made from this mineral.

Flagstone: selection criteria and possible defects

For owners of personal plots, flagstone is a good opportunity to organize an elegant and inexpensive road surface. It is more practical compared to concrete, which absorbs water more strongly and often begins to crumble after several cycles of freezing and thawing. When choosing flagstone, you should pay attention to the following characteristics:

- Thickness _ If the paths in your garden are laid dry (on a sand or gravel bed), then a material with a thickness of 4-6 cm will be required. If the base is a concrete screed, then the thickness is selected depending on the use: slabs from 3 cm are suitable for a driveway, for pedestrians - at least 2 cm.

The thickness is determined by the type of work Source www.stroyportal.ru

See also: Catalog of companies that specialize in landscape design of areas.

- Size and edge . For paving paths, it is optimal to choose slabs measuring 30-35 cm on each side; It’s more convenient to lay them out, and this coating looks more attractive. It is also worth refusing flagstones with uneven, jagged edges - it is almost impossible to join such parts beautifully. The size and quality of the edge can be ignored if you like natural landscapes (for example, English style).

- Color . He can provide important information and help with choices. It is known that stone of yellowish shades (beige, sand, ocher) is the most fragile and is poorly suited for laying paths; it is preferable to use it for cladding a facade or erecting a retaining wall. Flagstone stone for garden paths with a bright and rich color looks impressive, but, as a rule, has a looser, layered structure and is therefore less durable. The required density is distinguished by stones of soft, muted colors - gray, brown, with green and burgundy shades.

- Red flagstone . It is useful to know that this is gray flagstone, fired using a special technology. Its strength and other characteristics do not suffer.

Paths, platform and blind area made of flagstone Source domstroy45.ru

- Invoice . It is more pleasant to move on a flat, slightly rough surface. A material with a more pronounced relief is not so convenient; they try to use it for cladding the facade.

- Place of extraction . Its resource depends on the deposit of flagstone, which is characterized by such an important property as the coefficient of water absorption (more often called frost resistance). The more porous the structure of the stone, the more actively it absorbs water and the faster it begins to exfoliate.

Flagstone, like any natural material, may have some defects:

- Delamination . Violates the integrity of the slab; Over time, it will split into layers, and the fragment will have to be replaced. The good news is that delamination is easy to notice and the damaged slab can be rejected at the paving stage.

- Rust . This is the name for iron oxides that form on the surface of the slabs, a common defect, but not affecting the quality of the paving and the durability of the paths. Rusty deposits can be easily removed - the paths are moistened with water and cleaned with a brush after half an hour.

Style solution in brown and burgundy tones Source pyatigorsk.blizko.ru

Methods of paving flagstone

The main options for paving slabs: dry mix and glue.

Based on the type of base provided, they are divided into laying on a bed of sand, gravel or reinforced concrete.

For a garden path, a sand base is quite sufficient, because there are no great load requirements for it.

The stone for laying should be within 5-8 cm thickness; the larger the slab, the better.

A layer of crushed stone is added if the site has clay soil, so the path will receive an additional margin of safety.

On a gravel base, you don’t need too thick pieces of flagstone, 4-6 mm is enough.

Masonry joints can be filled with a sand-gravel mixture or soil with lawn grass seeds.

In the latter case, the distance between adjacent pieces of sandstone needs to be increased.

The method, which assumes a base of reinforced concrete, is suitable if flagstone is laid with your own hands in places with a large load on the surface. Sidewalks and driveways, basement around the building.

The material acts as a cladding glued to a solid base.

DIY brick grill

Video description

About natural stone paths in the following video:

Stone paths are made in three ways; they are united by one general rule: so that rainwater does not linger on the surface, the slope of the coating is set to approximately 3°. The choice of paving method depends on the type of soil, groundwater level and planned load. The technology for working on light soil (sandy or podzolic) will differ from the techniques used on heavy loamy soil (which is most of the Moscow region and large areas of neighboring regions).

Tool for the job

To make flagstone paths with your own hands, you will need the following construction and measuring tools:

- durable colored cord, pegs and a measuring tape at least 5 meters long for marking;

- building level at least 1 meter long;

- shovels and bayonet shovels;

- low wide container for mortars and mixtures;

- trowel and metal plastering rule;

- metal hammer and rubber mallet;

- steel or copper brush;

- vibratory ramming machine for compacting soil and bulk layers;

- concrete mixer if the total area of the paths is large and you do not want to mix the solution by hand.

If you don't have a full set of tools, you don't have to buy everything. You can simply rent it for the duration of the work.

Video description

About the construction of a garden path from flagstone in the following video:

Paving slabs on a gravel bed

Organizing a gravel bed is a reliable way for clayey and heaving-prone soils; the technology includes the following techniques:

- For installation, you can take material of a smaller thickness . It is allowed to use gray (more durable) flagstone up to 3 cm thick. The thickness of light varieties (sand, red, yellowish, white) should not be less than 4-5 cm.

- The depth of the trench exceeds the thickness of the flagstone by 20-30 cm.

- A two-layer cushion of sand (bottom) and gravel (crushed stone) is prepared Materials are used in equal quantities, the resulting pillow is carefully compacted with water.

- Laying a flagstone path on a layer of mortar is carried out in the usual way; the gaps between the slabs are also filled with mortar.

- It is recommended to separate every 70-80 cm of the canvas with expansion joints 2-5 cm thick. When the solution hardens, the expansion joints are filled with pre-selected material - earth (if grass cover is provided), sand or fine-grained gravel.

Path with gravel backfill Source helena-source.net

- The next day, the surface of the slabs is watered and cleaned with a brush to remove any remaining solution . If the path is made of light stone, it can be additionally coated with impregnation with water- and dust-proof properties.

Construction stages

The further step-by-step process for installing the tracks is as follows:

- Digging a trench.

- Installation of curbs (if necessary).

- Pouring the base.

- Laying slabs.

Digging a trench

After marking is completed, you need to remove the top layer of soil between the ropes. The depth of the trench may vary, but its average value is about 30 cm. To some extent, the depth is influenced by the properties of the soil. The stronger and harder the soil, the lower the indicator, and vice versa. For loose soils, the depth can be in the range of 0.5–0.6 m.

Important! If there is no concrete or cement base, then to prevent grass from growing between the slabs, the bottom of the pit can be covered with geotextiles.

This is necessary for installation:

- crushed stone drainage layer;

- sand pillows;

- cement or concrete base;

- flagstone directly.

Installing curbs and pouring the base

It is advisable to cover the bottom of the prepared trench with a drainage layer of crushed stone up to 10 cm. After compacting it thoroughly, sprinkle about 5 cm of sand on top and also compact it well. Such a layer will act to protect against flooding by melt and groundwater. Next, a cement-sand mixture, crushed stone is poured, or a concrete mixture is poured. To make the path last a long time and have a more decorative appearance, it can be fenced with borders.

Read how to build a garden path from decking boards.

Various materials can be used as fencing for pedestrian surfaces:

- You can make a permanent border out of brick . To do this, first they dig a ditch (you can prepare a common pit for both the curb and the path). After laying a layer of crushed stone and sand, lay the bricks on the cement mortar. To strengthen the structure, reinforcement can be placed under the bricks;

- a profile or metal corner serves as a border, remaining almost invisible;

- plastic borders, border tape or a special plastic profile are not capable of bearing a very large mechanical load, but do an excellent job of decorative function;

- concrete fencing is the most popular. To install them, a groove and backfill of crushed stone and sand are also required. Curbs are placed on cement mortar. You can purchase ready-made fences, pour them into the formwork yourself, or make them separately in molds and then lay them in trenches.

Laying flagstone on a prepared base, depending on the type

Flagstone can be mounted on various bases: sand cushion, concrete mixture, crushed stone and other options.

On a pillow of sand

The simplest and cheapest method for the foundation is to use sand. However, this method is practiced mainly for pedestrian sidewalks. It is unsuitable for heavy loads (driving cars, etc.). For such masonry, flagstone 5–8 cm thick and large in size is used.

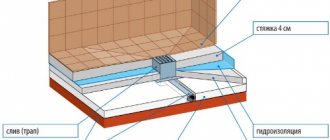

1 - compacted soil; 2 - geotextiles; 3 - gravel 10-15 cm; 4 - sand cushion 5-10 cm; 5 - natural stone 4-6 cm; 6 - border made of stone or concrete

The process of creating such a path consists of several stages:

- Dig a trench slightly deeper than the thickness of the tiles (about 10 cm).

- Fill the pit with a sand layer of several centimeters.

- For greater density, you need to moisten the sand (it is better to fill it in 2 passes, compacting it well).

- Lay flagstone with small intervals (they are needed for seams).

- Fill the gaps between the stones with sand (if you use soil, you can sow grass in it).

A sand base is not entirely practical, so it is recommended to use a dry sand-cement mixture, which after a certain time, under the influence of moisture, will acquire the state of a monolith.

Also learn how to make your own garden path from pallets.

On concrete

In flooded areas, as well as in embankments, a concrete base is most practical. A base made of other materials lasts for several years, after which the stones begin to sink into the soil, and the paths have to be redone. Concrete pouring is also capable of withstanding heavy loads and is used on any type of soil. The only drawback is the laboriousness of the process.

The technology for laying such a base is as follows:

- Dig a pit at least 40 cm deep.

- Strengthen the edges with formwork.

- Fill in a gravel or crushed stone layer at least 10 cm thick.

- Lay out the reinforcing mesh.

- Pour the concrete in a layer of 25–30 cm. Level it and leave until dry.

- To prevent cracking, the top should be watered periodically.

- After the concrete has completely dried, the formwork is removed.

- For laying tiles, you can use special mounting adhesive.

About the meaning of color and styling technique

When working with natural stone, aesthetic issues become of no small importance. In order for flagstone paths to please the eye with their natural beauty, simple rules for selecting combinations of colors and shapes of slabs are applied, which include the following provisions:

- Choosing a similar color . In this case, they try to match the stone to the color of the residential building; if it is wooden, then choose the appropriate flagstone - brown, ocher, brown; slabs with streaks and rings look especially beautiful.

Laying flagstone on paths

Beautiful and durable paths made of flagstone on a personal plot or summer cottage allow you to simultaneously solve several functional problems:

- they combine a residential building and outbuildings into a single complex with convenient and practical passages:

- contribute to the preservation of beautiful grass cover on lawns and gardens without the formation of paths;

- Thanks to this coating, you will no longer have to walk on damp ground in inclement weather or after rain.

improve the overall appearance of the site, influencing the design of the area;

Video description

About laying a backlit path in the following video:

- Contrast . Often the combination of two different colors looks much more impressive. The combination of a gray facade with paths made of reddish, cherry or opal-yellow stone looks advantageous; For yellow walls, gray or gray-green flagstone is suitable.

- A combination of stone of two shades . A primary color is selected that echoes the color of the house, and an additional color, in contrast, in a ratio of 4 to 1.

- Laying technique . To prevent the paths from looking sloppy, it is necessary to maintain the same thickness of the seams. To do this, you have to periodically remove excessively protruding edges on the slabs. Material consumption increases, and this must be taken into account when purchasing. Laying is carried out with alternating large and small stones, which allows you to get a path with a uniform pattern.

Large flagstone terrace Source pinterest.ch

Description of coverage

Flagstone is an exclusively natural coating, which will undoubtedly appeal to those who have a bad attitude towards any kind of fakes, from cement to laminate. Flagstone itself is calcareous or sandy shale. Basically, slabs with a thickness of one and a half to fifteen centimeters are used for construction.

Flagstones have been used in construction for quite a long time. People have had more than a hundred years to test this material's strength. In addition to its physical characteristics, flagstone can also please with its appearance: pleasant color, beautiful veins and a pleasant surface.

Flagstone slabs are an extremely environmentally friendly material, created only by nature. In addition, it is worth noting the increased strength and moisture resistance of this coating. When laying paths from flagstone, you don’t have to worry about it becoming lighter or changing its color over time. The flagstone does not fade and is not subject to abrasion. The surface of the stone is very pleasant to the touch and slightly rough, which guarantees a reduced likelihood of someone slipping on the path.

How to lay flagstone on a sand base

An invited team of professional builders will help in arranging the flagstone path in the garden. They will develop the design project and do all the work in a short period of time. This option is far from cheap. Therefore, doing all the work yourself, without anyone’s help, is profitable and also exciting. In addition, the process is not complicated, you just need to invite an assistant.

Laying flagstones

1. Drawing up a project.

Before starting all work, it is necessary to make a clear construction sketch, which largely affects the future success of the project.

The drawn plan must show schematically all the buildings, plantings, flower beds and other objects located on it. You can make photocopies in several copies so that other family members can display their ideas for the location of the paths. All opinions are analyzed, and the best option for everyone emerges.

When drawing up a preliminary design, it is necessary to take into account that the width of the path should accommodate two people (up to 1 m). When using materials of different colors, you need to indicate the transition locations in the drawing.

2. How to choose material for installation.

Once you have a plan, it is very easy to calculate all the coating parameters and determine how much material you will need to purchase. Then, when everything is calculated, you can go to the store.

• When choosing flagstone, you need to ask the seller where the material was extracted. It’s good if its deposit is located in the same climate zone. Then it will have frost resistance appropriate to the climatic conditions. • Pay attention to the color of the stone slabs. The greener the flagstone, the stronger it is. The light yellow stone is softer than all the others. The brightness and saturation of the slabs indicates their greater layering and softness. To determine the strength, you can crumble a little of the edges of the tile. • Each batch may contain tiles of different sizes. In this case, try to choose as equal as possible with a thickness of 1.5 cm or more. If a large load is planned on the pedestrian path (for example, a car), then its thickness should be at least 4 cm. • Smooth edges are not so important when choosing, since they are perfectly processed with a grinder.

• A sign of a quality stone is its moisture content. Flagstone stored in the sun for too long dries out and its strength properties are significantly reduced. To determine the moisture content, feel the flagstone of the second row. In addition to flagstone, for the construction of a path you also need cement, sand, medium-fraction crushed stone, and a curb.

What construction and measuring tools will be needed?

To build a path made of natural flagstone, stock up on:

• colored cord of increased strength; • pegs; • tape measure for marking (5 m); • building level (1 m); • shovels (scoop and bayonet); • container for preparing solutions; • trowel, plastering rule; • a metal hammer and a rubber mallet; • iron brush; • a machine for tamping and compacting the surface; • a concrete mixer (it will help with large areas of paths when you need to mix a lot of mortar).

If any of the tools are missing, they will always be rented.

DIY technology for making flagstone paths

1. According to the drawing, mark the lines of the tracks using a tape measure. Place the pegs at a distance of 5 m from each other. Stretch the colored cord (if it sags, reduce the distance between the pegs). 2. Preparation of the base consists of removing the top layer of soil (approximately 30 cm deep). The trench is dug slightly wider than the path itself. 3. Clean sand is not suitable as a base, since the load is created unevenly. The best option would be a concrete or cement-sand base. A layer of crushed stone (10 cm) is poured onto the bottom, compacted, sprinkled with sand 5 cm and compacted. The result is an excellent drainage layer to effectively drain ground and surface water. 4. Woven or non-woven geotextiles are laid on the drainage layer, capable of passing water down and preventing it from rising up. Another advantage is that it will prevent the germination of weeds. 5. The drainage is filled with a concrete mixture (7 - 8 cm) or covered with a dry cement-sand mixture (8 - 10 cm). Compact with a vibrating machine. 6. During the hardening of concrete, the slabs are laid out side by side and “adjusted” according to the pattern and shape. Moreover, it is not at all necessary that the edges of the drawing coincide. The beauty of a flagstone path lies in the chaotic arrangement of its components. 7. The slate flagstone is secured to the prepared base using an adhesive solution. To save glue, sand is added to it in a 1:1 ratio. It is better not to spare the glue solution so that it fills all the seams, and wash off the excess with a damp cloth to prevent it from drying out. 8. How horizontally and evenly the stone tile is laid and how much all its edges coincide with the neighboring ones is checked using a building level.

Laying the path

9. If desired, you can install beautiful borders. They are fixed to the drainage layer after preparing the support and laying the textiles. If the height of the curbs is not enough, then sand is poured into the edges of the trench. 10. The last step is to clean the surface. The level of the resulting paving surface and the level of the adjacent territory must be leveled.

Making paths from flagstone with your own hands is not difficult. It is only important to strictly follow the technology and purchase high-quality material for the work. Then you can hope for a successful result.

Video: building a garden path from flagstone

Source