Application area

Having moved to a new apartment, everyone wants to divide the available space into zones. Many people use the option of installing a frame and then covering it with sheets of plasterboard or other material, but there is also a time-tested technology in which partitions are made from edge-mounted bricks.

Individual construction involves the use of this method of installing walls in bathrooms, showers, storage rooms and utility rooms.

It is possible to install brick stone on an edge and in a multi-layer wall when constructing external or internal layers.

Every two to three rows laid out on edge, reinforcement is performed with the load-bearing wall using an installed anchor.

This technology is widely used for cladding walls, stoves and fireplaces.

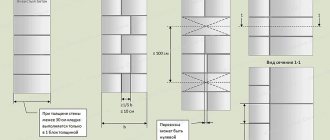

Quarter brick brickwork. Arrangement of brick partitions

Brick is characterized by strength, moisture resistance, fire resistance and durability, and its different types allow the construction of walls of different types of structures.

Brickwork used in modern construction can have different thicknesses, from 0.5 to 2.5 bricks. For the construction of small partitions that do not experience load-bearing loads, and the internal walls of stoves and fireplaces, masonry with a thickness of a quarter of a brick is often used. When using a single brick of standard size 65x120x250 mm, the construction of 1 meter of wall with this type of masonry requires 31 bricks, while the wall thickness is 65 mm. The given parameters indicate that this type of masonry is economical, and the erected structures occupy a small amount of usable space.

In addition, the use of quarter brick masonry is common when cladding panel or frame houses, fireplaces and stoves, when constructing multi-layer walls and constructing internal and external walls.

The construction of such thin structures is quite complex because it requires not only the careful installation of each individual brick, but also constant instrumental monitoring.

In addition, it is also possible to reinstall the bricks if the partition is not vertical enough. The complexity of this type of work comes from maintaining a certain thinness of the seam and a possible deviation in the verticality of the structure of no more than 1 cm over the entire height. The work of tying the partition, made using the quarter- or half-brick method, to the load-bearing structures of the building: floor, walls, ceiling, is also quite labor-intensive.

All of the above operations significantly increase the cost of constructing thin brick partitions, so many owners of suburban areas, when starting to build houses, prefer to do it themselves.

General rules

Before you begin the practical implementation of your plan, you must obtain the appropriate permit for construction work. This is explained by the dubious capabilities of such walls in terms of perceiving load effects. You should carefully consider your decision and document it in order to protect your neighbors and relatives.

Having started construction work, for the construction of the first row they use only whole brick stones that do not have chips or cracks.

Brick laying is carried out along the waterproofing layer; for its implementation, only one permitted technique is used - “tying”, when the top stone overlaps with its center the vertical seam located in the previous row.

During the work process, constant monitoring of the vertical evenness of the wall is carried out - the maximum deviation from the base level should not exceed one centimeter.

Maintain a certain sequence and strictly follow the masonry rules: brick installation is carried out exclusively on the edge, anchors with a diameter of eight millimeters are used for reinforcement, the mortar mixture is applied carefully, the row is laid along the mooring.

To increase the strength of the wall being built, a small amount of lime is added to the masonry mixture to improve its ductility.

Remember that edge masonry is used for the construction of walls whose height and length parameters do not exceed three and five meters, respectively. In other cases, laying bricks on edge is not allowed.

Where is edge laying used?

Professional builders do not use the correct name for the method - quarter brick masonry. Instead they say edge-on masonry, and a wall raised in this way is called a “quarter-brick wall.” For reference: the bed is the long side of the brick, the spoon is the long narrow side of the brick, the poke is the short narrow side of the product.

Wherever edge-on bricklaying is used, in partitions or external walls, it significantly saves building materials, time, and labor costs. The disadvantage that clearly manifests itself with this method of masonry is visible in the construction of internal partitions. It is necessary to carefully control the verticality of the masonry; horizontal deviation can also be easily missed due to the fact that the wall is built quickly, since it is laid with the high side vertically, and the brick is relatively small in size. In such conditions, missing a level and plumb check of two or three bricks for the evenness of the masonry means a possible deviation. Therefore, most often, quarter brick masonry is used where it is easier, namely:

- When constructing internal interior partitions, when remodeling or adding premises to a private house. Masonry in one row and in a quarter of a brick requires periodic reinforcement of the wall - after 3-4 rows between the brick rows, reinforcement is laid, which at the ends of the partition is attached with anchors to the load-bearing walls. And also, if the partition is installed on a finished floor, then the floor under it must be removed, and after raising the wall, fill the base with concrete mortar to the level of the existing floor.

- When constructing partitions for decorative purposes, low and short. For example, to protect the space under the bathroom, as a railing in a private house, etc.

- In load-bearing walls, if calculations require maintaining the exact thickness of the wall, and laying half a brick or brick is impossible. Such powerful structures are also built using reinforcement through 3-4 rows, but not only along the long side, but also across, where the levels of the bricks coincide.

- When decorating the walls of a house with facing bricks. In addition to reinforcement along the rows, transverse reinforcement is used, in which the pins are placed on one side into the quarter wall, and on the other side they are driven into the finished load-bearing wall of the house.

Laying on edge requires constant monitoring of levels. The possible error should not exceed 10 mm in the height of the wall, counting from the bottom of the wall or partition. This minimum deviation angle can be easily leveled with a layer of plaster.

Calculation of material quantity

Before determining the need for brick material for each square meter of planned masonry, you should clarify the permitted thickness of the mortar joint. As a rule, the average value for the horizontal and vertical options is 1.2 and 1 cm, respectively.

The permitted deviations allow an experienced specialist to comply with the approved standards and ideally lay out the masonry of interior partitions. In addition, the material is used rationally and waste is minimized.

All that remains is to find out the dimensions of the material planned for purchase, add to them the parameters of the seams and determine the need for stones for one square meter.

What is needed to build a brick wall on edge

Mooring cords, orders, beacons, trowel, level, mallet - specialists stock up on everything they need before erecting decorative walls or for facing bricks on edge. Under any options and circumstances, you can’t go anywhere without high-quality cement mortar. You certainly shouldn’t skimp on it - it should be of a brand no less than M-400. In addition, for a stronger and more reliable adhesion, it is necessary to fill the seams well.

What should the solution be so that the cladding of buildings and the design of interior spaces (stoves, fireplaces) are not only aesthetically pleasing, but also durable? So, you will need high-quality high-grade cement, the purest river sand, hydrated lime, and a super plasticizer. The kneading must be carried out carefully by experienced craftsmen, because a fairly thin seam will have to be made when laying a quarter-brick wall. If the mixture is hard and tight, it will not be possible to do the work accurately; if the consistency is too “liquid”, it will also be difficult to achieve sufficient strength. All bulk components are mixed using a mixer, sand, cement and lime are added in a ratio of 9:2:1. Water makes up 1% of the resulting mass. All components are mixed little by little and brought to a homogeneous consistency.

If the cement mortar contains a high-quality plasticizer, the amount of water in it is significantly reduced. Thanks to this, excellent quality of the mixture for brickwork is achieved. The solution is not mixed in large quantities; its quality is no longer the same after 3 hours. It should be taken into account that for 1 sq.m. You will need about 5 liters of ready-made high-quality solution.

Mix the solution

In order for a wall built from bricks installed on an edge to be sufficiently reliable, it is necessary to choose the correct consistency of the masonry mortar. To prepare it you will need the following materials:

- cement M400;

- washed river sand that does not contain debris;

- plasticizers;

- lime.

Considering the fact that the masonry joint of the wall under construction must be thin, the mortar mixture is prepared especially carefully. If it turns out to be rigid, then the distribution of mass over the brick surface will be complicated. But a liquid mixture will not work either - it will flow down the surface of the wall.

To prepare the correct solution, you need to add one measured share of cement material and lime to five parts of sand and mix everything thoroughly.

A plasticizer additive is diluted in water; the volume of liquid should be one percent of the cement mass. The prepared suspension is added in small portions and stirred until a homogeneous consistency is obtained.

The plasticizer contained in the mortar mass reduces the volume of water, which has a positive effect on the quality of the masonry material.

It is allowed to purchase a ready-made dry composition, to which you only need to add water. The solution is prepared in small batches in order to have time to produce them within two hours.

Practice has proven that up to five liters of masonry mixture are needed to lay one square meter of brickwork on an edge.

Laying bricks on edge snip. Laying bricks on edge during house construction

Today, it is quite popular to build houses from ceramic blocks, gas and foam concrete, and frame technologies are in demand. But bricks can also be different, solid, hollow, silicate, ceramic, and all of them are still successfully used for the construction of residential buildings, outbuildings, etc.

There is a difference between the usual laying “on the bed” and on the edge. Which is used in special cases. When is it necessary to pay attention to the last option? Is it possible to lay a brick on its edge and when is this option acceptable? The answers will be given by InnovaStroy specialists.

When might it be necessary to lay bricks on edge?

This approach allows you to save a lot on material when building partitions or, for example, a brick fence. The wall turns out to be just as strong, about 6.5 centimeters thick, but much fewer blocks will be used during construction (up to 25% of the material).

But there are pitfalls here too. If installation is done incorrectly, or lack of specific knowledge and experience, the situation can only worsen: the construction work itself will take a long time, and the strength characteristics of the building may deteriorate significantly. Therefore, it is worth turning to the professionals in your field, InnovaStroy, to weigh the pros and cons of such savings.

Of course, laying bricks on edge allows you to save a lot on material and labor. But there are situations when this method of building a house is allowed:

- If you plan to redevelop the premises both in the house and in the apartment. In such cases, it is necessary to provide additional reinforcement of the brick partition on the edge, for which reinforced rods are used, as well as a method of fastening to the load-bearing wall with anchors. Such devices are used somewhere after 2 rows of brickwork, and this should be done before the screed (a special fixation for the base of the wall) is poured.

- When it is planned to cladding the external walls of a house, installing a fireplace or stove.

- If it is necessary to build so-called “scenery” in bathrooms, showers or kitchens. These should be low edge-on brick partitions.

- If you plan to build multi-layer walls (about 2-3 layers), you cannot do without tying them with reinforcement.

Only specialists can decide whether it is possible to lay a brick on its edge. Otherwise, not only unforeseen expenses are possible, but also exposure to enormous risks, because the building may be unstable, fragile, and short-lived.

Therefore, before ordering the construction of a cottage and determining the main materials for construction, it is better to resort to the opinion of professionals, listen to their recommendations and make an important decision.

- Initially, before deciding on this type of installation, it is necessary to obtain permission from certain authorities. This is due to the fact that the load-bearing capacity of such walls will be very doubtful if the approach is incorrect. Therefore, it is worth not only carefully weighing your decision, but also obtaining documentary evidence that the technology is suitable and will not affect the safety of household members.

- When laying bricks on edge begins, it is important to build the first row from whole blocks; they should not have the slightest damage or chips.

- The masonry must proceed strictly according to waterproofing, only the “tied” method is acceptable (the ratio of the top brick and the vertical seam between the lower elements).

- When working, it is necessary to clearly control the vertical evenness of the wall - deviation relative to the base is allowed no more than 1 cm.

- It is important to adhere to a certain sequence, following the rules: laying should be done clearly on the edge, installation of anchor fasteners with a cross-section of up to 8 mm connecting the load-bearing wall and the first row of masonry, careful application of the mortar, placement of the rest side by side according to the same principles and according to the mooring cord.

- To increase the strength characteristics of the wall, you can add a little lime to the masonry mortar. The quality of work and the plasticity of the mixture will be much better.

- It is important to consider that it is unacceptable to build quarter-brick walls more than 3 m high and 5 m long.

Brick preparation

Everyone knows that brick stone has an average density and has a moisture absorption level of fourteen percent. This means that, when laid dry, the stones will begin to absorb water from the mortar mass, worsening the quality of setting.

To avoid this, it is necessary to moisten the bricks by soaking them before work for a couple of hours, giving them about thirty to forty minutes after the water procedure to get rid of excess water on the surface.

List of materials

It is best to lay the brick according to a template. Because laying on edge is not an easy task even for professionals.

When constructing ¼ brick brick partitions, the following materials are used:

- cement grade 400;

- sand;

- superplasticizer;

- hydrated lime;

- single red clay brick;

- wooden mortgages 65*120*120 mm in the case of openings;

- reinforcing bars 4...6 mm or rolled wire.

Masonry technology

If you are working with brick material for the first time, the levelness of the masonry can be achieved in a simple way: on the end sections of the future wall, install a pair of even bars vertically, and strengthen the board between them. Using this rule, you can build a wall. The board will replace the marking cord; aligning the bricks with it will be easier. Before the construction of the wall begins, the installation of anchors is marked, and holes are drilled in the load-bearing walls for them.

A strip of roofing felt material is laid under the base of the masonry, acting as a waterproofing layer. Based on the ceiling, floor and walls, you can draw the outline of the future partition.

The first row of masonry is laid out on the mortar mixture, the vertical joints must be filled. The brick stone is laid out in a bandage - a new row begins with an offset of half an element to overlap the vertical seam located next to it below. The stones that complete the row are, if necessary, cut with a grinder or beaten with a pick.

Brick laying is carried out using the “press” method. A layer of masonry mixture is applied with a trowel, the bonded part of the previously laid stone is additionally covered with it, a new brick is brought in, pressed and leveled in place.

Work technology

The first row of such brickwork is laid out only in whole blocks. In addition, when constructing an internal brick partition, prior permission from the architectural service of the city or district is required. For partitions or light building materials (plasterboard, wood) such a permit is not required. But even a brick curtain wall inside a house or apartment cannot withstand the same load as a wall with two or more bricks, so such partitions must be loaded carefully.

How to lay a quarter brick wall:

- Before starting masonry, the base for the first row is covered with a layer of waterproofing. This can be roofing felt or several layers of thick plastic film.

- The first, lowest row of a wall or partition is laid out only on spoons.

- Along the edges of the partition, anchors with a diameter of up to 8 mm and a length of at least 700 mm are driven into the load-bearing wall, which will subsequently connect the partition and the load-bearing structure. The anchor is inserted 80–100 mm into the load-bearing wall, and 500–600 mm into the partition.

- A layer of solution is applied to the surface of the first row.

- A cord is stretched parallel to the first row, along which the next rows are laid. After laying each subsequent row, the cord rises. With this installation method, the height of the partition should not be more than 3 meters, the length should not be more than 5 meters.

- To enhance the strength of the masonry, lime is often added to the solution.

Recommendations

We already know whether it is possible to lay a brick on its edge. It remains to consider the advice of specialists in order to carry out all installation work correctly.

Do not complete more than four rows of masonry in one go; take breaks in work for three to four hours. After the next fourth row, perform reinforcement by connecting the partition to the main wall with an anchor, the role of which will be played by a reinforcing rod twenty to twenty-five centimeters long. One end of it is laid on a brick row, the second is driven approximately fifty percent into the prepared hole. It is allowed to use mesh reinforcement, but laying it on a brick edge requires a narrow strip, which is not very convenient and reliable.

The masonry row located on top is filled with mortar and wedged with pieces of brick. If a seam is formed that is more than three centimeters thick, you will have to cut the stones lengthwise and lay out an additional row in flat pieces.

It is prohibited to use wood when wedging, because such material dries out after some time and begins to rot, negatively affecting the wall rigidity.

If you decide to paint or wallpaper a brick wall in the future, its surface will have to be pre-plastered to make it even. For a room that is expected to have high humidity levels, you should consider finishing with ceramic tiles.

A brick wall, even laid on edge, creates a significant load on the ceiling and other structural elements of the building. It is possible to reduce its mass if you use hollow bricks. Unfortunately, it will not fit into the bathtub and toilet - they will have to be built from solid clinker material.

What is required to start construction?

This material can be of 2 types: single and one-and-a-half. The wall is usually built from blocks of both the first and second types, with the width being half a brick. Thanks to this method, the most optimal consumption is formed: 52 pieces per 1 m² of masonry. You can reduce it even further by placing the brick on its edge.

This technique is suitable in the case of a single brick, since saving one and a half bricks will take too much effort. A single brick made of clay (both hollow and hollow) is usually placed on the spoon. In order to begin laying bricks on edge, it is worth preparing the following tools:

Bricklaying tools.

- container (for example, a 20-liter trough) for cement mortar;

- construction trowel;

- stone pickaxe;

- level for construction;

- wooden blocks;

- long rope;

- board (the entire length of the wall);

- thick pieces of wire;

- medium power hammer drill;

- several scaffolds;

- grinder with a metal disc;

- hammer.

The following is allowed as a building material:

- cement with grade 400;

- sandbags;

- superplasticizers;

- lime;

- brick materials;

- reinforcement rods or wire.

Having prepared all the necessary materials, you can proceed directly to work.