Terrazzo concrete mosaic floors in Moscow and the Moscow region are used for luxury housing - cottages, penthouses, architectural monuments, where high abrasive loads are expected and where the decorative component is important.

This coating is colored concrete with various fillers. Coloring is carried out in bulk, which allows you to obtain a uniform, stable shade that is resistant to external influences. Moreover, the color palette is not limited. Any additives that increase the attractiveness and create the texture of a marble floor can be used as a filler.

Stone chips from jasper and serpentine to rare types of Italian marble and semi-precious stones are used. It is also possible to fill the floor with terrazzo with glass chips of different colors; the recycled use of glass makes the planet cleaner and pleases the owner’s eye with a modern design in eco style. Terrazzo with bottle chips looks like an interesting solution.

We work with elite materials from major global brands BASF, Sika, Bautech, Ardex Pandomo. Thanks to them, Terrazzo for apartments and houses turns out to be elegant and original. Each design is unique and original, emphasizing the status and exclusivity of the interior. Terrazzo from Master Concrete can be completely SEAMLESS, without inserts or with decorative strips of copper, brass, or glass. A company logo or coat of arms can be seamlessly integrated into terrazzo floors.

There are also inexpensive options for industrial and public facilities.

Terrazzo coating: main advantages

Such floors with crumbs based on concrete mortar look very impressive and are characterized by increased strength. Among their advantages, it is worth noting wear resistance and immunity to abrasion and mechanical loads, which allows the finishing to be used even in places with very high traffic - for example, in an airport hall, a luxury hotel lobby, a museum. In addition, it looks very beautiful even in a single-color version, but you can also create a patterned floor, mosaic, and the choice of pattern is limited solely by your imagination!

Usually they post some geometric patterns or images, logos. For all its texture and depth, terrazzo remains smooth, absolutely seamless and easy to clean. They do not fade in the sun and meet all sanitary and hygienic requirements and fire safety rules.

Application area

Coatings with marble chips on a cement, polymer or polymer-cement base look best on large areas.

Therefore, installing a floor with a pattern is justified in the following rooms:

- expensive cottages, apartments, houses;

- luxury apartments, penthouses;

- SPA centers and clubs;

- temples, religious complexes;

- lobbies in medical centers;

- shopping centers and individual boutiques;

- hotel lobbies, exhibition centers, theater foyers;

- offices, business or service centers;

- premises with swimming pools.

Important benefits

Thus, we obtain products with our own unique style, which are also applicable in industry, including facilities with heavy wheel and pedestrian loads, as well as in rooms with increased fire safety requirements. The safety class of this product allows it to be used even in rooms with particularly dangerous, explosive and flammable materials, since the tiles are spark-proof and have a fire safety class “A”.

Terrazzo is popular in the European Union, where the requirements for surface slipperiness in areas where precipitation is possible are established at the legislative level. Terrazzo tiles remain non-slip even in rain and with any degree of surface polishing.

Price

- industrial terrazzo floor 30mm thick (from 500 sq.m.) – from 2,900 rubles/sq.m.

- decorative terrazzo flooring – from RUR 7,000/sq.m.

- terrazzo floor for an apartment - from 11,000 rubles/sq.m.

- chip terrazzo - from 14,000 rubles/sq.m.

- breccia flooring – from 6500r/sq.m.

- terrazzo with breccia - from 9,500 rubles/sq.m.

- terrazzo steps (with filling) – depends on complexity

- Venetian terrazzo with a pattern – from 28,000 rubles/sq.m.

- Palladian floors - from 15,000 rubles/sq.m.

By stages : 1. We look at your project, visualization 2. We evaluate the prospects of the project 3. We give a cost guideline 4. A specialist will visit the site 5. Providing samples or manufacturing for the project 6. Agreeing on the start date of work 7. Concluding a contract 8. Execution of work

We offer Terrazzo mosaic marble floors on a turnkey basis: we give the exact price per m2 of work after discussing the details of the project. Choose the desired color, filler, and we guarantee the use of high-quality materials and strict adherence to technology. The cost per meter of work with the material also depends on the volume of the order.

We can choose a universal solution or an inexpensive industrial option, or we can make a luxury coating - super glossy, expensive, like something out of an interior magazine.

Floor structure, materials used

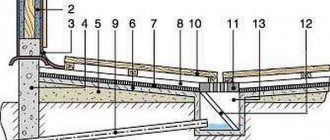

There are two options for installation in an apartment, house or public space.

The first is pouring the screed with the necessary components, and the second is a thin-layer self-leveling coating. In any case, you will need two basic components: filler (stone chips or colored quartz sand) and concrete (standard gray or white cement, if color purity is important).

There are also cement, polymer cement and polymer concrete (polymer) Terrazzo floors.

- The first option is made on the basis of Portland cement and coated with polyurethane impregnation for complete dust removal.

- The polymer-cement version is a solution based on Portland cement and polymer additives. It is obtained using a technology similar to the creation of a thin-layer screed.

- The last option, polymer, is made on the basis of compositions with an epoxy or polyurethane binder.

We also use ready-made two-component decorative mixtures from elite European manufacturers. They are polished to a shine and sealed with wax or varnish. The thickness of this floor is from 8 to 30 mm.

Terrazzo mosaic floors

Mosaic floors - other names: terrazzo, mosaic concrete, concrete mosaic covering, mosaic concrete floor - is a colored concrete surface with various decorative fillers. Mosaic floors perform two functions at once - leveling the base and forming a wear-resistant, highly decorative finishing coating.

For the installation of mosaic terrazzo floors, we offer complex additives for concrete Plastobeton-A, Plastobeton-B.

Additives for concrete Plastocrete provide the following main advantages:

- They increase the compressive strength of concrete by 1.7-2.2 times and increase the impact strength of the concrete floor several times.

- They allow the mosaic coating to be put into operation 6-8 days after laying the concrete.

- They make it possible to reduce the thickness of the mosaic floor to 15 mm, and in some cases to 6-8 mm.

- In fact, the minimum thickness of a mosaic floor can be determined by the size of the decorative aggregate!

- Reducing the thickness significantly reduces the price of a mosaic floor and makes it possible to use more expensive and beautiful fillers, pigments and other components.

- They allow you to produce much higher quality polished concrete in a shorter time frame.

We offer both the supply of concrete additives and the installation of turnkey mosaic floors.

Other concrete floors

Mosaic terrazzo floors have excellent decorative properties and, at the same time, high strength and durability. You can vary the color of the binder - for this, pigments are used that are introduced into the concrete mixture at the time of preparation and color the concrete over its entire thickness. You can choose various fillers: marble, granite, dolomite chips, river stone, colored quartz sand. If you need to get a “pure” color, then when making a concrete mixture you need to use white cement; if this is not a task, then you can prepare the mixture with gray cement.

Mosaic floors depending on the type of binder

1. Cement mosaic floor.

Portland cement is used as a binder. Almost terrazzo floors are made using the technology of laying “ordinary” concrete. Coating thickness from 50 mm or more. For certain tasks they can be reinforced. The filler size can be up to 20 mm or more. Concrete for mosaic floors of this type can be produced using RBU (mortar concrete units), which significantly reduces the cost of its production and increases productivity. After sanding, mosaic floors of this type are usually coated with polyurethane impregnation, which provides: manifestation of the surface pattern, complete dust removal, protection from aggressive substances, and ease of cleaning. A more expensive method is polished concrete.

2. Polymer cement mosaic floor.

Portland cements and special polymer additives are used as binders. The technology for laying terrazzo is similar to thin-layer concrete screeds. Coating thickness from 15 mm or more. The size of the filler is limited by the thickness of the coating and is up to 10 mm. Polymer-cement concrete is prepared directly on site in inertial or forced-type concrete mixers. Before applying such mosaic floors, the concrete surface is coated with a concrete contact primer. Concrete contact can only be applied to dry substrates. It is unacceptable for construction dust to settle on the applied concrete contact. There are two options for finishing the surface: applying polymer impregnations (see type 1) or polishing the surface.

3. Polymer concrete floors, another name is polymer concrete mosaic floor.

Polymers, usually epoxy or polyurethane compounds, are used as binders. They are made using the technology of self-leveling or quartz-filled polymer coatings. Thickness from 2 mm or more. Colored quartz sand or mixtures of sands of different colors are used as fillers. The filler size is from 0.5 mm or more. Chips, flocks, glitter (glitter), various objects (for example, coins), and even LED lighting elements can be used as additional decorative elements. The finishing layer of the mosaic floor is made of a transparent polymer compound.

Scope of application of mosaic floors:

Installation of floors in public and administrative buildings (offices, shops, lobbies, exhibition halls, corridors, staircases, etc.).

Another important advantage of our mosaic floors is that they are not afraid of moisture even if they are not protected by a finishing layer of polymer varnish, unlike the fairly common mosaic floors made with a magnesium binder. If even a small amount of water gets on magnesia mosaic floors, they begin to “rise”, breaking away from the base. Unevenness can be 50 cm or more, depending on the thickness of the coating and the configuration of the room.

Mosaic floor technology

Mosaic floors are laid on a concrete base with a grade compressive strength of at least M200. The technology of concrete mosaic floors at the laying stage is completely similar to concrete screed: concrete screed technology

Very important! The amount of filler in the concrete must be correctly selected, otherwise you will not get a uniform mosaic pattern even with deep grinding. It is almost impossible to obtain a uniform pattern on “ordinary” ready-mix concrete, which is supplied by RBU.

Strength and thickness of terrazzo concrete floors.

- Terrazzo using the concrete additive Plastobeton-A – 40 mm, compressive strength M500-M700.

- Terrazzo with an additive for Plastobetona-B concrete: minimum thickness - 15 mm, for moderate loads - 20 mm, for heavy loads - 30 mm. Compressive strength is up to M500-M750, and when using granite filler - up to M1000.

After laying the mosaic floor and curing it (strength gain), the concrete must be sanded. The holding time depends on the type of binder, temperature, humidity, etc. Grinding is carried out in several stages.

The first stage is grinding with an abrasive tool with large grains, the so-called roughing. Its purpose is to treat the surface until filler cuts appear. The grinding depth should be approximately 1/3 of the size of the filler, respectively: for filler 5-20 mm - about 5 mm, for filler 3-10 mm - about 3 mm, etc. The second stage is grinding with medium-grain segments. The third stage is finishing grinding of concrete with fine-grained segments.

After sanding, the mosaic concrete is coated with a clear polyurethane varnish to protect and improve its decorative properties.

Another option for finishing the surface of a terrazzo mosaic floor is polished concrete. It is performed with special machines and special tools. Depending on the required surface quality, it includes from 3 to 7 transitions. Polishing a mosaic floor is quite a labor-intensive and expensive process, but polished concrete is certainly very beautiful, strong and durable.

Objects of application of concrete mosaic floors.

- Trade and exhibition complexes (hypermarkets, supermarkets, etc.).

- Administrative and public buildings.

- Warehouse complexes and production workshops, including those with high traffic intensity.