A private house is not an apartment in which the floors are slightly heated due to the residential lower floor. In your home, cold air penetrates from below, from the floors, through cracks. The situation is aggravated if the building does not have a basement and is built directly on the ground.

To make your living space warm and comfortable, the floors need to be well insulated. Properly carried out insulation will help you reduce heat loss and heating costs of the building. What is the best way to insulate floors and how to do it yourself? Technology secrets and work tips are given in the article.

Is the floor insulated in your house?

Not really

How to insulate the floor in a private house with your own hands?

Before choosing an insulation method and material, consider the following parameters:

- Is there a basement or basement in the building?

Please note: if the building has a basement, then start the insulation process from there. Apply insulating material to the wall up to the base of the foundation, and then cover the part that is out of sight with earth;

- number of storeys of the building;

- the material from which the house is made.

Before starting work, make sure there are ventilation holes between the floor and the wall in the room (about 1 cm). They will subsequently be covered with a plinth.

To carry out work without opening the floors, apply thermal insulation from the side of the basement wall.

The cheapest way to retain heat in a house is a screed. The materials themselves and the pouring work will be inexpensive. But if you just make a screed, the cold will still not disappear. The concrete base will be cold and you won’t be able to walk on it barefoot. To solve this problem a little, you need to put insulation under the screed.

The base insulation process looks like this:

- Take care of waterproofing. Otherwise, moisture coming from the soil will simply contribute to the appearance of mold and mildew. Waterproofing can be a polyethylene film or a water barrier, which is attached to the base using bitumen mastic.

- Make an expansion seam. It is needed to ensure that the screed does not crack during operation. To make it, glue a special strip of foam vinyl along the entire perimeter of the walls at a height of 10-15 cm from the base.

- Lay the insulation (tightly together). Fill the cracks with foam.

- Apply screed and do not forget about reinforcement (rebar or metal mesh).

Anton Makarov

Expert of our site. She has been selling and installing floor coverings for over 7 years. Can give really valuable advice.

Ask a Question

The mesh cell width is no more than 5 cm. The composition of the screed must be strong, so it is better to make the solution in a ratio of 1:4 rather than 1:3. Add a plasticizer to the mixture to prevent the cement from cracking.

The least economical option is to install a “warm floor” system (electric, water, infrared). Its effectiveness is very high and time-tested. Start installing the system by laying the base with foam plastic, then with foil insulation (heat-reflecting screen), reinforcing mesh, and on top with heating pipes (laying step 10-15 cm). Finish the installation of the “warm floor” by pouring a screed into which you add fiberglass.

The “warm floor” system cannot be installed in a house that has a wooden floor. In this case, the flooring will have to be dismantled.

Insulation on joists

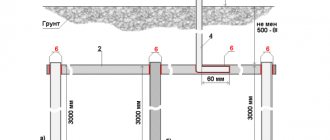

If the house is old, then before insulating the floor, you often have to dismantle the ceiling and go deeper into the ground.

After this, a rough, most often wooden, covering is laid. A layer of waterproofing is installed on top of it: this can be mastic or rolled materials. They will protect the insulation and joists from moisture.

Then logs (boards or blocks of wood) are installed on the subfloor with waterproofing. All wooden elements must first be treated with an antiseptic.

Installation of mineral wool

To insulate wooden structures, it is better to use mineral wool (it does not burn). If the material is in a roll, then it is unrolled in one piece and laid without first cutting it into pieces.

Fix the cotton wool with a stapler. Mats or slabs are placed tightly in the spaces between the joists.

Vapor barrier and flooring

A layer of vapor barrier is laid on the insulation. This can be thick polyethylene film or professional membranes.

Then the finished floor is installed, leaving a ventilation gap between it and the insulation. Experts recommend installing a fine-mesh metal mesh underneath; it will prevent rodents from entering the house.

Insulating the floor in your own home is a job that can be done by one person. The main thing is to choose the most suitable and high-quality insulation and follow the thermal insulation technology.

One of the most important parameters for a comfortable life in a private home is the air temperature. This is especially true in winter, when cold air from the street penetrates into the room from every unsealed crack. Of course, this problem can be easily combated with the help of special heating systems, some of which can even independently maintain a comfortable temperature in the house for you. But due to rapidly rising electricity prices, many people have to abandon this method and find a cheaper and more reliable analogue. That is why owners of private houses install new metal-plastic windows in their homes that do not let air in from the outside, unlike wooden ones, and create thermal insulation for attics, roofs and floors. It is especially important to insulate the floor in a house made of foam blocks, because most of the coolness comes from there. Thanks to proper thermal insulation, you can forever forget about drafts and warm slippers, without which it is impossible to walk around the house in winter.

How are floors insulated in a wooden house?

A wooden house itself will be warmer than a brick one or one made of concrete floors. But to increase energy efficiency and heat retention, you can take one more step.

Interesting article on the topic: How to soundproof the floor in an apartment and forget about the neighbors below

The choice of insulation for the floors of a private house is very large. There are expensive materials, and there are those that can be used to insulate floors cheaply. It all depends on your budget and wishes.

Anton Makarov

Expert of our site. She has been selling and installing floor coverings for over 7 years. Can give really valuable advice.

Ask a Question

Advice: there is a downside to insulating a wooden floor - disruption of natural ventilation, and this can lead to rapid destruction of the wood. Therefore, do not forget to put waterproofing underneath.

Insulate the floor with sawdust

To create comfortable living conditions in the house, you need to insulate the floors along the ground. Sawdust is a natural, environmentally friendly material and is perfect for those who love eco-style. Sawdust allows you to fill even the smallest holes and cracks. Choose the smallest chips - they can provide a high level of thermal insulation. Before laying, let the sawdust dry a little.

Before laying the chips, decide on their thickness. For a wooden house, about 30 cm of sawdust is enough. The following installation steps:

- installation of a timber structure (with a cross-section of no more than 3-4 cm);

- laying sheets of plywood on joists;

- covering plywood with waterproofing material (polyethylene film). It is attached to the plywood using nails;

- filling the base with sawdust and compacting it;

- checking the surface for cracks. If there are any, cover them with wood shavings;

- applying a vapor barrier film. Be sure to leave a small gap to allow air circulation;

- finishing screed.

Do not forget to treat the sawdust with an antiseptic so that later they are not affected by mold, mildew, or insects.

Sawdust has low thermal conductivity, is available (you can get it at any sawmill, sometimes even for free) and is inexpensive.

Any sawdust can dry out over time, begin to rot, and mold, microorganisms or fungus may appear in it. To prevent this from happening, add protective materials to the sawdust: clay, lime, cement or boric acid.

Interesting article on the topic: Waterproofing wooden floors in a private house

Insulation with expanded clay

Expanded clay is balls of baked clay. It performs a leveling and thermal insulation role, and also absorbs excess moisture.

Installation tips:

- Use expanded clay as bedding.

- Use this material if you have ground floors.

- To make the effect even stronger, add this material to the cement-sand mortar (concrete screed).

- Use expanded clay in combination with polystyrene foam (to achieve optimal room humidity and thermal insulation).

- To make the floors more durable, it is advisable to place a reinforcing mesh between the concrete screed and expanded clay, and add modern additives to the concrete mixture itself.

- The expanded clay layer should be at least 10 cm and it is laid on top of the rough screed.

- The floors should dry within a week, and the final structure will be ready for laying the final floor covering only after a month.

How to insulate with penoplex?

Penoplex is foamed polystyrene. It is suitable for insulating any surface and is characterized by a long service life, durability and ease of installation. 5 cm of penoplex replaces 1.5 m thick brickwork. It can be used even in the most severe climatic areas.

The installation process is the same as with other materials. Be sure to apply a finishing screed on top of the penoplex.

The main thing you should pay attention to when buying penoplex is its indicators:

- flammability - marking must be G1;

- water absorption (indicated on the package as a percentage) - the lower, the less moisture the material can absorb;

- thermal conductivity - the lower, the better the thermal insulation of the floor is provided by penoplex, which means the likelihood of a cold floor is minimized;

- density - the higher this indicator, the stronger the floor structure will be and the greater the load the material will be able to withstand.

Insulation of the floor in the basement with penoplex under screed

Add sand, level and tamp

Laying insulation

We reinforce

Filling the screed

Floor insulation with mineral wool

In order to retain heat in a wooden room, it is better to cover the floors with mineral wool. This material does not burn, and also has good noise insulation and low thermal conductivity, and is resistant to temperature changes. Its minimum service life is at least 30 years.

Interesting article on the topic: Waterproofing wooden floors in a private house

Mineral wool is sold in stores in the form of individual slabs or a solid sheet in a roll. The material is tightly laid on the timber structure, fastened with a construction stapler, covered with a mounting mesh on top and filled with concrete screed.

Warning: since mineral wool can easily absorb moisture, take care of high-quality waterproofing.

The process of floor insulation with mineral wool along joists

Insulation with foil insulation

Foil insulation is an environmentally friendly material. Insulating the floor in a private house with this material is recommended even in children's rooms, since it is non-toxic. The material consists of 2 layers:

- The insulation itself is polystyrene foam, polystyrene foam (pumpan), penofol.

- Foil with a heat-reflecting effect, which prevents heat from escaping, and water-repellent properties.

Installation steps:

- surface preparation. Place the material only on a clean base, free of debris and dirt;

- cutting into pieces of the desired size;

- leveling the material;

- fastening sheets using bars. Individual elements can be glued together with tape;

- creating a sheathing for air circulation between the material and the finishing coating;

- surface finishing (floor covering).

How to insulate floors in a private house with polystyrene foam?

This is the most popular insulation option. It has high thermal insulation, sound conductivity, low cost, and durability. However, there are also disadvantages: high flammability and not a very strong structure. The material crumbles and breaks easily.

Anton Makarov

Expert of our site. She has been selling and installing floor coverings for over 7 years. Can give really valuable advice.

Ask a Question

Feature: the foam plastic is attached to the timber structure and only then it is poured on top with two screeds (rough and finishing) or first sheets of plywood are laid, and then the finishing floor covering itself.

It is advisable to combine polystyrene foam with expanded clay due to the fact that the material can contribute to an increased level of humidity in the room.

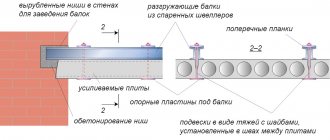

Insulation of floors between floors

Insulation of the floor between floors needs to be done only when the rooms located on both sides of the floor have different temperature conditions. This method of insulation is also suitable for a house with an attic. The choice of insulating component depends on the method of its application, on joists or on floors.

Sequence of work

- Laying a vapor barrier layer between joists or on slabs.

- Fastening the insulation in such a way that there are no gaps between its sheets. In some cases, installation with overlapping seams is allowed.

- Application of waterproofing material.

- Laying the finished floor.

If there is an attic in the house as a non-residential space, a windproof structure is laid on top of the insulation.