Screed device

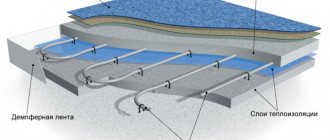

There are classic and floating screeds. In the first case, the concrete slab is not equipped with a layer of sound-proofing or heat-insulating materials. Floating floors require pouring the solution directly onto the layer, thereby preventing the product from being fixed to the subfloor. A floating screed with a soundproofing layer is installed mainly in apartments on floors above the first. A floor base with a heat insulator is made in private homes. Concrete screed installation in detail:

- Reinforced concrete slabs are installed first;

- heat insulators or soundproofing materials (mineral wool, polystyrene foam or expanded clay) are laid second;

- damper tape is glued around the perimeter of the room in places where the wall meets the floor;

- the surface of the insulation is covered with polyethylene film or roofing felt;

- this cake is supplemented with reinforcing mesh;

- then a concrete screed is made;

- at the end finishing work is carried out (grinding and polishing).

Typically, the thickness of a concrete floor is at least 4.5 cm and no more than 10 cm. To ensure a better quality base, it is recommended to use class 32.5 cement. Crushed stone is selected M300. The sand should not contain debris or other dirt.

Components for creating a solution

Concrete according to the standard is made from water, cement, sand and crushed stone in a certain ratio. They are mixed with a concrete mixer into a single liquid mass. Screed without crushed stone, as a rule, is made up to 4 cm thick. If the homeowner wants his floor to be light, then lightweight materials with a porous structure are used - vermiculite and perlite. Special fillers significantly reduce the weight of the screed. Such floors are widely used on 4th or 5th floors.

Porous fillers have the ability to strongly absorb moisture. Therefore, water for making the solution should be added in a minimum volume. It is necessary to bring the solution to a plastic state. When creating a solution, the ratio of components must be accurate. Expanded clay screeds are also used in private homes, since such a porous material has insulating properties.

For private houses, the thickness of the light screed is 10-15 cm. Then a crushed concrete floor is installed on top. The quality of the coating is affected not only by the brand of cement and crushed stone. In order for the product to be used for a long time, you must adhere to the exact ratio of components: cement - 1 part, sand - 2 parts, crushed stone (M400) - 3-4 parts.

There are different markings of crushed stone and classes of cement. Mostly builders use crushed stone M300-M400. Cement class - 32.5. Too much excess crushed stone is undesirable, but its small concentration is not recommended. If there is not enough crushed stone and the floor thickness is 10 cm, then the concrete may crack.

Do not use cement that has expired. Such material collects in lumps. Even if all proportions are observed, the screed will turn out to be of poor quality; it will crumble and crack. Therefore, when purchasing cement, you should always pay attention to the date of manufacture. There are fewer requirements for sand and water. The sand must be sifted, and the water must be clean and free of dirt.

Crushed stone in flooring

Based on the above classification of crushed stone, we understand that for the installation of floors, namely:

- Crushed stone of fraction No. 3 is used to construct the underlying layer of a concrete floor on the ground and high-strength concrete floors.

- For the installation of concrete screeds in houses, less often apartments, crushed stone of the third fraction is used.

- For the construction of a slab foundation, an insulated slab foundation, crushed stone of a fraction of 5-20 mm, No. 3 is also used.

Section articles: Level the floor

- Reinforcement of floor screed: selection of material for reinforcement

- Concrete screed, purpose and application

- Concrete floors with a hardened top layer: liquid and dry hardening technologies

- Do-it-yourself concrete floor in the garage

- Types of floor screed for apartments and houses

- Damper connection for screed

- Mixing and laying expanded clay concrete screed

- Mixing the screed mortar

- How to level the surfaces of walls and floors

Types of concrete foundations

Builders mainly produce floating and classic screeds. However, there are slightly more varieties of concrete floors:

- floating;

- rough;

- related;

- finishing.

The rough foundation is made of reinforced concrete floor slabs. It mainly serves to raise the floor or level it. Its average thickness is 7 cm. If a workshop or similar structure is being built, the solution is created from M300 crushed stone. A reinforced frame must be installed. For private houses, expanded clay is mainly used, which serves as an insulating layer.

Clean concrete floor screed is designed to eliminate the smallest defects. This creates an ideal surface. Then flooring material is installed on it: tiles, linoleum, parquet. This floor is made only from sand and crushed stone. Plasticizers are used to increase the viscosity of the solution. The layer of finishing base does not exceed 3 cm. Fiber fiber or thin metal mesh is used as reinforcement.

A tied screed is considered a quick way to make a floor. It is made on a rough base and adheres firmly to the surface of the slabs. There is one drawback: if the house shrinks slightly, the screed will begin to crack. This should be kept in mind before choosing this type of product. The problem can be solved by using a waterproofing layer. To do this, a built-up roofing material is taken and attached to the rough concrete surface. A damper tape is installed on the walls to the thickness of the screed. A floating floor is not at risk of cracking because it will not adhere to the base and walls of the house.

Types of concrete screed

Depending on the purpose and method of pouring, concrete screeds are divided into several types:

- rough;

- finishing;

- related;

- floating.

Types of concrete screed

The rough rough screed is poured directly onto the floor slabs, as well as onto the sand-crushed stone cushion if the floor is earthen. It serves not only to level and strengthen the surface, but also to raise the level of the floor base. Its thickness is usually from 4 to 10 cm, and the composition necessarily contains crushed stone or porous fillers. When the thickness of the concrete layer is more than 40 mm, reinforcement must be performed.

A finishing screed eliminates minor defects and provides a perfectly flat surface on which various types of floor coverings can be laid. Most often, a cement-sand mixture is used for its production; in some cases, plasticizers are added to the composition. The layer thickness is 3-20 mm; For reinforcement, metal mesh or special fiber fiber is used.

Polypropylene fiber

The bound screed is poured onto the rough base and adheres firmly to it due to adhesion. This method is convenient and faster, but it should be remembered that even with slight shrinkage of the building, cracks appear on the concrete floor. To avoid this, it is recommended to make a floating screed by pouring the solution onto the waterproofing layer and insulation. There is a damper tape between the walls and the screed, so the concrete does not adhere anywhere to the base itself, which means that shrinkage of the building will not lead to cracking.

Tied tie

Process requirements

When carrying out such work, certain rules must be observed: there should be no drafts in the room, the room should not be exposed to temperature changes, the reinforcing mesh must be installed correctly, rough chips and cracks must be eliminated in the rough base. Before work, the surface is cleaned of debris and dust. The latter should be removed with a damp cloth.

The screed should not be made too thick, otherwise it will negatively affect the load-bearing walls. Therefore, it is recommended to make a simple project, which will indicate the thickness of the floor, the amount of material used, etc. When constructing multi-story buildings from scratch, the following sequence of work must be followed:

- water pipes are laid out, plumbing fixtures are installed;

- Reinforced concrete slabs are cleaned of debris and dirt;

- the zero level of the base is calculated and measured;

- the subfloor is treated with a primer and dried.

If a dacha is being built from scratch, the surface of the earth is leveled, watered and compacted. A 15 cm layer of crushed stone and sand, the layer of which is 10 cm, is laid on the ground. Each laid layer is spilled with water and compacted. Then specialists make markings and find the zero level. Then the surface is covered with waterproofing and a metal frame is built for subsequent pouring.

After the operational life of the concrete screed has expired, it is necessary to begin its restoration. The floor covering is removed, the concrete is inspected, large cracks and other defects are identified. The cracks must be opened and filled with concrete. After repairs, the base should be filled with a self-leveling screed.

A do-it-yourself floating concrete screed involves applying a built-up roofing material to the rough coating. Then a metal mesh is installed. A novice concrete worker will be faced with the need to seal pipe outlets from under the floor. On concrete around protruding communications, you need to coat the gaps with sealant or mastic. Damper tape is glued along the perimeter of the walls. Thermal insulators are installed at the request of the home owner. If the floor has a thermal insulation layer, then a primer is first applied to the coating, polyethylene film is laid and insulation is laid.

Concrete floors with crushed stone

One of the most popular non-metallic building materials is crushed stone. In the production of concrete floors it is used as a filler. For the construction of concrete floors, crushed stone can be of different types, for example, granite, the distinctive characteristic of which is high hardness. Granite crushed stone consists of feldspar crystals; it may also contain mica, quartz and other minerals.

Less durable is crushed gravel, which is obtained by sifting and crushing rocks. A distinctive feature of such crushed stone is the minimal radioactive background. In addition, such crushed stone is cheaper than granite.

Because of its low cost, the so-called secondary crushed stone, which is obtained by dismantling and recycling old concrete structures and construction waste, is popular.

Another type of crushed stone is slag. It is obtained by processing slag in metallurgical production. Such crushed stone has a specific chemical composition, so it is not always possible to use it for industrial flooring.

Concrete floors are most often filled with granite crushed stone, since it provides the greatest strength to concrete. When installing concrete floors on the ground, crushed gravel can also be used.

When filling concrete floors with crushed stone, you should remember its properties. Crushed stone is durable and frost-resistant, so concrete floors filled with crushed stone are not afraid of low and even negative temperatures, significant mechanical loads, including transport ones.

Crushed stone is distinguished by its flakiness, which refers to the degree of flatness of the crushed stone depending on the percentage of lamellar and needle-shaped grains it contains. The greater the flakiness, the less durable the concrete floor is, since voids form between such grains, which, when poured with concrete, are filled with the mixture.

Another characteristic of crushed stone is strength. It depends on how strong the original rock from which the crushed stone is made is. The strength of crushed stone affects the resistance of future concrete floors to mechanical stress.

An important characteristic of crushed stone is its radioactivity. It determines the possibility of using crushed stone as a filler for concrete floors in rooms where people work, in industrial and domestic premises. The low radioactivity of crushed stone must be confirmed by special certificates.

The choice of crushed stone as a filler for concrete floors is determined by the size of its fractions, that is, the size of individual grains (stones). For the construction of concrete floors, crushed stone with a fraction size of 5–20 mm is usually used.

In order for a concrete floor filled with crushed stone to meet all technology requirements, the specifics of preparing the concrete mixture should be taken into account. Ready-mix concrete usually contains one part cement, two parts sand, four parts crushed stone and half water. In this case, sand and crushed stone play one of the main roles, ensuring the strength of future floors.

Crushed stone can be laid as a bottom layer, which is filled with concrete or cement. The requirements for laying crushed stone boil down to the need to level it and install waterproofing made of polyethylene film.

In addition to the strength and durability of concrete floors, crushed granite stone as a filler provides sufficient thickness of the floor covering and, if necessary, sound insulation, which is important in industries with high noise loads.

Step by step work

In this example, a floating floor will be constructed in a private house on pre-laid reinforced concrete slabs with insulation. First, the rough surface is cleaned. It is advisable to perform it in turn in each room. If you clean all the rooms at once, and the process of installing the screed takes some time, then the remaining rooms will become covered with dust, and this is a violation of technology.

Next, material for work is purchased, which must immediately be unloaded into a place convenient for carrying. The concrete mixer is installed near the entrance to the room. It should be closer to the work area, otherwise carrying concrete from a long distance will quickly wear you down. Metal profiles are purchased. As a rule, they have a T-shape. Now the necessary tools are prepared:

- level at least 200 cm long;

- tape measure, which can be used to measure the entire length of the room;

- minimum length rule: 200 cm;

- damper tape;

- self-tapping screws;

- perforator;

- dry mixture Rotband;

- cord.

First, roofing material is fused onto the slabs. It is advisable to install the guide screws as accurately as possible. The permissible error is 4 mm. The installation process looks like this:

- First, self-tapping screws are screwed into the concrete slabs. Their caps should rise 10 cm above the surface of the slabs. The distance between them is maintained at the length of the rule - 200 cm.

- Using a cord you need to measure the general plane of all screws. If somewhere the thread clings to the cap, then the screw must be screwed in and adjusted to the level of the cord.

- Guides for pouring expanded clay have been made. Now all that remains is to make expanded clay mortar. For 6 buckets of bulk mixture, add 1 bucket of cement. The solution is brought to a liquid state.

- Now the filling is done. You need to start it from the far side of the room and end with the door. A certain area is poured and immediately leveled using the rule. It is enough to scrape off the excess mortar with a tool, relying on the protruding screws.

In this way, a warm concrete floor screed is made with your own hands. The expanded clay base dries in about a week.

Installation of mesh and beacons

Now beacons and reinforcing mesh are mounted on the expanded clay surface. It is advisable to choose a frame without rust. Beacons should not be arched. Correct step by step work:

- First of all, a damper tape is installed around the perimeter of the room at the junction of the wall and floor. Next, a mesh is laid on the floor surface. Small metal items are placed under it. The mesh should rise 4 cm above the surface level. Screws are screwed in along its perimeter and in the center. The frame is tied with wire to self-tapping screws.

- The next step is to install beacons. If the rule is 200 cm long, then the distance between the beacons should be 180 cm. Self-tapping screws are screwed in every 50 cm. You should get rectangular cells 180 cm wide.

- Mixed Rotband is applied at the screw locations. The solution dries quickly, so it is advisable to install beacons quickly. After this, beacons are installed on the screws. Take a spatula and coat the guides with it.

Job is done. All that remains is to check the evenness of the guides using a thread. They must be in the same plane. An error of no more than 2 mm is allowed.

Concrete production

If M300 crushed stone is used, then take 1 bucket of cement, 2 buckets of sand and 3 buckets of crushed stone. A little detergent is added to the solution - this will provide viscosity to the concrete. You can use a plasticizer. Technology for pouring concrete screed:

- First, a bucket of water is poured into the concrete mixer. Then cement and sand are added. They should be mixed until smooth. After this, crushed stone is poured. All components are added gradually. Water is not added immediately, but little by little.

- The solution is poured into a bucket and transferred to the work area. A certain small area is spilled. If you fill a large area, you will have to walk on the liquid mixture.

- The concrete poured between the beacons must be leveled. It is enough to install the rule on the guides, and then carry it out, thereby collecting the excess solution.

This way the entire area of the room is flooded. During the work process, it is advisable to compact the concrete with a trowel. This promotes the release of oxygen and fluid from it. At the final stage, you need to make a solution of water, 1 part cement and 2 parts sand. The resulting liquid mixture must be poured onto the concrete and leveled using the rule. This will help enhance the coverage.