Which boards to choose for formwork construction?

When pouring the foundations of buildings, structures and other monolithic concrete structures, removable formwork made of wooden boards is often used. It is able to give the solution the correct shape and will not allow it to completely occupy the volume of the dug trench. It is characterized by ease of installation, repairability, and low cost. Therefore, boards are the best option for one-time use in private buildings. In the future, they may be needed for subfloors, temporary buildings or other similar needs. When planning multiple uses, it is better to order plywood for... Its price is higher, but it can withstand up to 1000 fills.

Material requirements

The boards are relatively light in weight, durable, reliable, easy to process, simple and quick to install, and easy to trim. They are available in different sizes in stores and from manufacturers. However, they are not very convenient if there is a need to obtain formwork with rounded trajectories. When choosing them, take into account the load created by the solution, otherwise there is a risk of bending or destruction.

When deciding what formwork to use for pouring the foundation, it is important to remember that this is a temporary structure, often for one-time use. Therefore, they do not require significant quality from it; the main ones are strength characteristics and relative evenness. More often, class 3 or 4 wood is used, the cost of which is not too high.

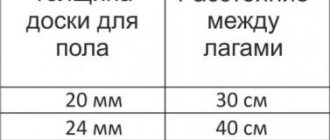

Semi-edged or treated boards are suitable. The latter are preferable, since they have specific dimensions and the time for preparatory work is reduced. Special requirements apply to length and thickness. The first is determined based on the length of the trench and a margin of 2–3 cm. The second should not be less than 20 mm, otherwise under the pressure of concrete, deflections may form and the foundation will turn out uneven. Many experts, when asked: what thickness of product to use for formwork, answer that 30–50 mm. The width is chosen arbitrarily by the buyer; 20–25 cm is considered the best option. In this case, time is saved on knocking down the shield.

It is very important to choose wood with the correct moisture content. This figure must be at least 25%. Compliance with this requirement is mandatory, because such boards:

- will not absorb moisture from the solution and will not affect the quality of the finished foundation;

- are not saturated with concrete, making them suitable for reuse after disassembly.

Recommendations for buyers

The formwork is in direct contact with the concrete, so it is necessary to choose the right type of wood. Oak has significant acidity and interferes with the normal hardening process. In addition, the cost of boards for pouring the foundation will be unnecessarily high. Birch is also not suitable for formwork; it is prone to cracking, is too weak and will not withstand loads.

Coniferous wood is ideal for private buildings, but is not strong enough for massive, capital structures - sagging is possible; in this case, it is better to choose hardwood boards.

When purchasing, pay attention to the porosity of the wood. The higher it is, the stronger the adhesion to the solution and, therefore, the more difficult the process of separation (removal of formwork). Chips and cracks that will become leakage points for the poured mixture are unacceptable. There is a high probability that a damaged board will not withstand the load and will bend or break. It is desirable that the surfaces are smooth. Otherwise, to ensure a level foundation, the side in contact with the concrete will have to be planed and sanded well.

When installing formwork for a foundation from edged boards, bars with a cross-section of at least 5x5 cm are also used. They are necessary for connecting individual elements into panels and additional fastening of the structure. Their number is 30–40% of the number of boards. In addition, you should buy:

- construction nails 15 cm long - screws are not suitable, as the concrete can squeeze them out;

- plywood - to obtain particularly smooth foundation surfaces;

- hand saw or circular saw.

Assembly Tips

To obtain a level foundation, it is important to carry out high-quality preparatory work:

- remove debris and excess soil from the trenches;

- drive bars into the corners, to the inside of which the formwork will be attached;

- determine the required dimensions of the boards and cut them;

- the nails are driven in from the pouring side of the foundation, they should protrude from the fastening bars by 4–5 cm, the ends are bent with a hammer;

- if there is a large load on the formwork walls, it is recommended to install additional spacers (from the outside) at a distance of 70–90 cm;

- During installation, it is important to check the level and plumb for horizontal and vertical, otherwise the foundation will be uneven.

To obtain higher quality monolithic concrete structures, experts also advise taking into account a number of subtleties. If the boards are too dry, then they are generously moistened with water before pouring the solution. To preserve moisture, protect against leaks and allow the formwork to be reused, polyethylene, roofing felt or other similar material is fixed on the inside using a construction stapler. When choosing plywood for smooth pouring of concrete, it is nailed with nails with a wide head, 40 mm long. For each m2, 16–25 pieces are required.

Before buying boards for the foundation, you should first calculate their quantity and make a small reserve (5–10%) for trimming and possible defects. To do this, the total length of the future concrete structure is measured and the height of the shields is determined. The first value is divided by the length of the board, the second by the width. The results are multiplied among themselves and the required amount is obtained.

You can purchase boards for installing formwork at any hardware store that sells wood. If you want to save money, it is better to negotiate directly with the manufacturer at the sawmill. If you need small pieces, you should contact local furniture shops. The boards have different thicknesses and widths with a standard length of 6 m (sometimes other options are offered), so the price is usually indicated per cubic meter.

[content-egg module=GdeSlon template=compare]

Types of formwork and their application

When constructing strip foundations, formworks of various types and designs are used. The choice of a specific type depends on the configuration of the base and its size, depth and height above ground level, as well as on the financial capabilities of the developer. Almost all available forms for pouring monolithic tapes can be classified according to the following criteria:

- designs;

- material of manufacture;

- manufacturing method.

By design

Structurally, the formwork used in arranging a strip foundation is divided into 3 groups, depending on the accessibility of dismantling:

- Removable;

- Fixed;

- Combined.

A removable formwork type device is a set of panels mounted into a single structure, which allows the base strip to be filled with concrete mixture. After the concrete has set, the form can be easily disassembled into basic elements that can be reused.

The second group - permanent forms - is made of polystyrene foam blocks. During the pouring process, they are filled with concrete, subsequently forming a single structure with a monolithic tape. The use of such formwork allows you to reduce the construction time of a strip foundation and save on the installation of thermal insulation of the base. Some types of permanent blocks can serve as waterproofing for the base of a building.

The combined type of devices intended for casting strip foundations and other monolithic elements are two-layer panels. The outer layer, consisting of a removable mold, provides strength and rigidity. The inner layer consists of thermal insulation boards based on foamed polystyrene. After the concrete mixture has set, the outer layer is dismantled. In this case, the thermal insulation boards remain.

A common type of formwork for constructing a strip foundation among private developers is the first option. You can make removable shields from waste materials that cost little money. At the same time, many people very often cast the buried part of the base directly in the prepared trench, using waterproofing film and extruded polystyrene slabs.

According to the material of manufacture

The material for the manufacture of formwork for a monolithic base tape can be:

- wood: edged board 30-40 mm thick or plywood sheets 8-15 mm thick;

- metal: steel frames covered with sheet steel or aluminum sheet mounted on a steel or aluminum frame;

- composite material.

Metal panels are rarely used when constructing strip foundations in private construction - they belong to the industrial group, finished products are expensive, and independent production is costly.

The plastic modules for assembling the casting mold look very seductive. They are lightweight and quick to install. But a home craftsman cannot make such a construction set. If there are construction organizations near the development site that are ready to rent out plastic formwork, take advantage of this opportunity, and you will not regret your decision.

The installation of formwork from wooden panels is considered cost-effective when constructing a foundation from monolithic reinforced concrete strips. The use of lumber in the manufacture of removable molds is justified from the point of view of reuse. Boards and sheets of plywood from removable formwork can be used, for example, in the manufacture of a house rafter system.

Formwork installation according to manufacturing method

According to the manufacturing method, formwork forms intended for constructing strip-type foundations are divided into the following types:

- to the factory;

- to homemade.

At factories, casting mold elements are produced in compliance with technological requirements. All dimensions are calculated in accordance with the expected loads. Naturally, having purchased finished products, you can be sure: no unpleasant surprises await you during the pouring of the monolith. All you have to do is follow all the manufacturer's instructions.

The use of homemade modules when constructing foundation formwork is always at risk. Incorrectly selected material for manufacturing, incorrect spacing between racks, thin struts may not withstand the pressure of the concrete mass and collapse. For this reason, the private developer is responsible for the result.

What kind of board is needed for foundation formwork? We compare, evaluate and draw the right conclusions

Before installing a strip foundation under a house, it is important to know exactly which board is needed for the foundation formwork. These wooden guides, used for a long time, are extremely necessary to obtain a high-quality base, which will guarantee the long-term use of the home. Formwork is used both to give the desired shape to the strip foundation and to prevent the entire trench from being filled with concrete. Then the structure is quite easily dismantled and a ready-made foundation remains, which is used as the basis for construction.

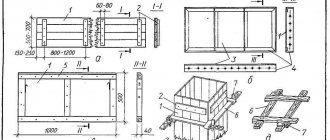

Step-by-step installation of formwork from wooden panels

Formwork panels are installed along the perimeter of the future foundation strip:

- along the edge of the trench - on solid soils;

- along the bottom of the trench - on soft soils.

First, stakes are driven in at a distance of 1 meter from the edge of the ditch, to which the slopes are subsequently nailed. Further:

- mounted and installed panels are connected with clamps;

- Spacers are placed inside the structure;

- the assembled formwork is strengthened by bevels;

- the inner surface of the wooden walls is lined with waterproofing material.

During the assembly of the formwork, in order to maintain the design geometric dimensions of the strip base, it is necessary to control the vertical and horizontal position of its elements. Permissible deviations:

- deck planes from the vertical axis - no more than 5 mm/meter of height;

- displacement of the structure axes from the design – up to 10 mm;

- local irregularities – up to 3 mm.

At the joints between boards and boards, gaps of no more than 2 mm are allowed.

Choosing boards for formwork

Formwork is the most important element of the foundation. The strength and service life of the entire building depends on how correctly it is erected. It consists of a deck, scaffolding and fastening elements - everything must be strong and durable. The formwork board is also of great importance; there are a number of requirements for this building material, its cross-section and characteristics. To choose the right board for formwork, use the information provided in our article.

Features of formwork and formwork boards

Formwork is a removable temporary structure consisting of wooden boards. With its help, builders give shape to the foundation. It is made from wooden panels made from knocked down boards and is used to maintain the shape of the concrete solution during hardening.

As practice shows, the type of board used for formwork does not matter. Formwork for the foundation is temporary, and it is not rational to use valuable rocks. The optimal solution is pine boards of 3-4 grades.

Boards can be edged or unedged. The main criterion in their selection is the flat surface of the front side of the board facing the concrete mass. This is the key to a strong construction of the future foundation. Also pay attention to other material selection criteria:

- Wood species that are too soft (mostly deciduous) are not suitable for construction because they can crack under load. In addition to pine boards, materials from fir or spruce can be used;

- despite the widespread belief that oak is excellent for formwork, this species creates an alkaline environment that is contraindicated for concrete hardening;

- In construction practice there is repeated use of the same formwork. If you have to reuse it, choose higher quality wood of at least second grade.

What boards are used?

Lumber from low-cost wood varieties is most often used to make formwork;

This is due to the fact that wooden structures are more susceptible than others to harmful climatic influences and cannot always be reused. The formwork can be assembled from edged and unedged boards, but one of the sides (the one adjacent to the concrete) must be sanded and, if possible, free from knots and damage.

Basic parameters of formwork material:

- The length depends on the length of the trench so that the edge of the board protrudes beyond it by 10-20 cm;

- The average width is 15 cm (depending on the height of the foundation, it may be higher, but not lower). The maximum width is 25 cm. If this size is exceeded, there is a high probability of bulging of the board and the foundation will be waved;

- The thickness of the board determines the maximum permissible level of load on it; The wider the foundation slab, the greater the load. Shields knocked down with boards 25-50 mm thick can ensure the stability of the structure;

- For more serious structures (buried foundations), boards up to 80 mm thick can be used.

It is also important to take into account the moisture level of the material - it should be at least 25%. This ratio will not allow the wood to become saturated with cement mortar. Otherwise, it is guaranteed that it will not be reusable.

Video: Formwork board

Properties of lumber for fixing formwork

Many professional builders and beginners are trying to reduce the cost of building their own house/bathhouse or utility structure, so many prefer to use reusable metal elements. They are quite difficult to adjust to certain dimensions; the use of metal formwork is not so practical. And from an economic point of view, reusable wooden shields are cheaper. In addition, changing their design is not difficult.

Edged board for formwork

Wooden formwork has been considered the best construction solution for several generations, as it has the following advantages:

- reliability and strength;

- high installation speed compared to a metal frame;

- boards 2.5 - 5 cm thick cope even with high concrete pressure;

- light weight;

- Due to the moisture content of wood materials of about 25%, the concrete solution does not stick to the formwork.

The only drawback of lumber for formwork is the inability to build a round-shaped structure with your own hands. But this problem can also be solved by ordering a product of the required shape at a specialized point of sale.

We purchase the best lumber for formwork

To make the right choice and save your money, experts recommend approaching the choice of lumber for formwork with all responsibility. When purchasing boards, pay attention to the following characteristics:

- crack resistance. To prevent loss of wood integrity, do not purchase softwood (birch and other hardwoods);

- neutral acidity. For example, the increased acidity of oak complicates the process of “setting” the concrete solution;

The best lumber for formwork

- affordable price. Buying expensive disposable wood species is unlikely to help you save on construction;

- humidity about 25%. A lower rate absorbs much more moisture from the concrete solution - this leads to a decrease in the bearing capacity of the foundation.

Technological requirements for formwork and formwork boards

Due to the fact that the construction of residential buildings requires increased quality of the foundation, there are a number of characteristics that formwork must have. It is best to use smooth lumber - unevenness and irregularities in geometric dimensions contribute to the formation of cavities and air bubbles in concrete. The connections must be quickly removable, not crack throughout the entire time the concrete hardens, and not allow moisture to pass through. Regarding the surface in contact with concrete, the formwork should not spoil the texture of the base. Experienced builders recommend:

- apply a special lubricant to the formwork;

- treat wood with absorbent linings;

- use solid fibreboards.

Regarding the requirements for boards, their geometric dimensions must be accurate. After all, the texture, shape and even color of the foundation after hardening depends on which boards are used for formwork. Strength to bending loads is also important - too thin and weak panels sometimes cannot withstand the load of the concrete mixture.

Before you start constructing the formwork, pay attention to:

- the verticality of the shields, their parallelism, horizontality and perpendicularity. As practice shows, it is this simple requirement that masters most often neglect;

- static and reliable fastening of panels relative to the ground and other structures. The formwork should not diverge at the joints when pouring and vibrating the mixture;

- tightness and thickness of formwork boards, moisture should not escape from fresh concrete through cracks in the panels;

- resistance to moisture, a properly assembled shield must withstand at least 1 pouring cycle;

- the ability to dismantle the structure for reuse;

- ease of assembly/disassembly, system alignment, modularity.

How to make a structure from boards

Forum members advise how to make formwork panels. To assemble horizontal panels, it is recommended to use an edged board measuring 100x25 mm and 150x30 mm, and for vertical panels, take a 100x50 mm beam, resting it against the panel with its edge .

The vertical installation step is transverse (beam 50x100 mm) - from 70 to 100 cm. To make the formwork more rigid, two 50x100 mm beams are installed horizontally on each side, top and bottom.

With a well-thought-out design and competent execution, the strength of boards of these standard sizes is sufficient to withstand the pressure of large volumes of concrete mixture on the walls of the structure.

When choosing boards for this design, you must immediately consider the option of their further use. Because formwork for the foundation will require more than one cube; it is irrational to use boards only once. In order for the boards to remain “industrial wood” after dismantling, it is necessary to protect them from direct contact with concrete.

About the use of boards on formwork

Formwork is something that should be prepared at the very beginning of construction work. This is a necessary basis for building walls/columns from scratch, installing floors and pouring a foundation. In addition to the removable formwork, which was mentioned earlier, there is permanent formwork - it is often used in monolithic construction and is not removed after the concrete has hardened. Acts as the so-called “skeleton” of the building. The device of permanent formwork is:

- frame - consisting of panels and fastening elements, with a high rigidity index;

- beam - built from beams, scaffolding, formwork slabs and fasteners. Although such a system is cheaper, it is not as rigid.

The first option is more preferable in private construction; you can make such formwork from boards yourself. You will need boards measuring 10x4 cm, as well as bars 4x4 cm. First, you should clear the site of construction debris and level it, and if necessary, remove the top layer of soil.

Application of formwork boards

Next you need:

- knock down boards from boards using bars, nails and screws or a construction stapler. Nail heads should be placed on the front side of the boards;

- place (drive into the ground) shields around the perimeter of the previously prepared trench;

- At the junctions of the boards, install struts as a support and secure them with pegs driven into the ground;

- make wooden clamps to give the structure additional rigidity, secure them in the middle of the segments between the struts.

Kinds

Traditionally, two types of construction are used - non-removable and collapsible .

In the first case, the formwork remains with the foundation after the mortar hardens. Builders save time and labor by eliminating the need for dismantling.

Collapsible formwork is more economical . Its design consists of individual elements that can be reused after the concrete has hardened.

This construction option takes more time and requires special attention from the craftsman to the tightness of the seams. Collapsible devices are convenient when working with complex foundations, as well as when constructing individual elements of structures.

We recommend: Repair of balconies and loggias

Recommendations for using boards on formwork

- Wooden formwork is used to lay the foundation and screed the floor. Before screeding the floor in your apartment, divide the room into square or rectangular sections (maps). One card must be filled in 1 day. The map is fenced off with removable formwork made of damp wood. The height of the formwork must correspond to the level of the screed.

- To ensure that the future structure is durable, pay attention to the quality of the materials used and their compliance with environmental conditions. For example, if you have to build a foundation in conditions of high groundwater levels, use waterproof concrete.

- The formwork can be used at any time of the year - you can improve the pouring characteristics by using additives in the solution in winter. These include antifreeze additives and hardening accelerators.

- Formwork with decoration is a practical option for insulating a house made of expanded clay concrete blocks. Each module of permanent formwork is assembled directly on the wall being built. It consists of facing plates, plastic ties and L-shaped hooks. Insulation is placed in each of the blocks, the modules are mounted using seamless masonry

- If formwork is used in the construction of a brick house, pay attention to favorable environmental conditions. You will learn about the temperature at which brick laying can be done in the article on our website.

- How you lay the foundation under the balcony determines how to cover the balcony for the winter: frameless double-glazed windows, metal profile frames, vertical awnings, PVC/fabric curtains or a construction protective awning.

- If you plan to prime, you need to know what concrete contact is. This type of adhesive primer is popular among many users, but requires careful preliminary cleaning of surfaces from chalk and dirt.

Please note that you should not use knocked down formwork panels that are too massive in size - two people should be able to dismantle the frame without additional help. The maximum length of the shield should be 6 m, and the weight should be 70 kg.

Board formwork

The installation of wooden formwork for a strip foundation begins with the preparation of the required amount of boards 3 meters long and bars - vertical posts. Their height is half a meter higher than the size of the shield. The lower end of the bars can be sharpened: this will make it easier to install them when installing the formwork.

The boards need to be planed on one side. Otherwise, disassembling the casting mold will be difficult. Pay attention to the moisture content of the lumber: it should be 22%. If the board is dry, it must be watered generously.

There should be no cracks or sags in the finished deck. To assemble the outer and inner sides of the shirt under a strip-type foundation, you can use nails or self-tapping screws. But in any case, the head of the fastener should be on the side in contact with the concrete.

The rigidity of the mounted structure is ensured using U-shaped clamps and struts. The struts are installed at the vertical posts, and the clamps are in the middle of the segment connecting them.

Formwork board - which one to use?

Using formwork structures, concrete solutions are poured. They are used in the construction of foundations of various types, structures and columns. The structures consist of panels and fastenings made of plastic, cardboard, metal materials or wood. The latter option is available not only in private construction, but also in the arrangement of industrial facilities. The formwork board must fully meet established standards and be of sufficient thickness to withstand load forces without being deformed. Successfully prepared wood panels are used for concreting many times and are easily assembled and disassembled.

Choosing the type of wood for formwork

So, which board to use for formwork?

The edged boards from which it is planned to construct formwork panels must have a certain degree of hardness - soft wood can crack when pouring the mixture.

Deciduous wood is not recommended. Christmas tree, pine or fir are suitable for preparing shields. It is important to choose the right type when plans include repeated use of formwork panels.

It is allowed to use any type of wood material for the manufacture of small-panel formwork systems. Regarding the grade, for reusable kits it is necessary to select second-class material, no lower. In other cases, it is allowed to use whatever is available for the formwork.

Optimal dimensions and moisture content of the board

When choosing a board for foundation formwork, special attention is paid to its thickness. The length is selected taking into account the length of the foundation ditch; it is also necessary to ensure that during installation of the panels they protrude somewhat beyond the expected boundaries of the foundation being poured.

The dimensions of the board thickness should be optimal to effectively withstand the load created by the poured concrete solution. Builders advise using boards with a thickness of 2.5 - 5.0 cm. It is also allowed to use thicker boards, since the likelihood of their destruction is negligible.

Regarding the optimal width of the board for foundation formwork, choose a fifteen-centimeter parameter.

Note that it is omitted to use wider materials. In accordance with GOST, in terms of humidity, a board is selected whose water content reaches twenty-five percent or more. This decision is explained by certain factors:

- with such a moisture content, the strip foundation formwork board is not impregnated with cement laitance and remains quite suitable for reuse;

- the concrete composition completely retains its strength indicator, since it is the fastening components that are absorbed first by wood.

Installation of plank formwork

We have decided what kind of board we need. Now let's look at the procedure for calculations and installation work.

To start making formwork panels from boards with your own hands, you need to make preliminary calculations on the need for material, so as not to spend extra funds and not to purchase additionally the missing amount during the work.

The need is defined as follows:

- first determine the total length of the foundation strip, the height of the base;

- study the range of boards sold, determine suitable dimensions for foundation formwork;

- divide the available perimeter length by a similar parameter of a unit of material, obtaining its requirement for one row;

- using the same scheme, determine the number of boards vertically, dividing the height of the base by the width;

- the calculated data on length and height are multiplied to determine the required amount of lumber.

To determine their number in pieces, you must perform the following steps:

- first determine the volume of one board by multiplying its parameters by length, width and thickness;

- dividing the cubic meter by the learned result, we get the quantity in pieces.

Having found out how much material is in a cubic meter, we determine its need for the manufacture of one formwork panel.

Additional materials will be required for installing plank formwork:

- bars measuring 50 by 50 mm, in the amount of thirty-five to forty percent of the volume of lumber;

- plywood sheets;

- polyethylene;

- screws or nails.

Correctly performed calculations help optimize future costs. In addition, the time required for additional purchases is saved.

When preparing panels for formwork, you should take into account the weight of the concrete solution. Due to its high value, a weak structure may not be able to withstand the pressure and collapse, which will entail an increase in labor and financial costs.

Work on installing formwork from boards of 25 mm or more is carried out in several stages:

- The site allocated for construction is being prepared. Garbage is removed, crumbled soil is removed from the ditch;

- in the corner sections of the ditch, pegs are driven in to serve as supporting elements;

- knowing the parameters of the boards for the strip foundation, we prepare boards of the required length;

- preparing connecting bars for panel elements;

- we carry out the assembly, during which nails are driven into the boards selected for the panel formwork from the side of the concrete pour and bending the ends;

- formwork is installed. Spacer elements are installed at the required distance to compensate for future load effects. The pitch of their installation is seventy to ninety centimeters;

- The quality of the placement of formwork panels is checked using a building level.

To ensure a smooth surface of the foundation strip, it is recommended to cover the internal surfaces of the boards with plywood sheets, nailing them down with nails. In addition, all internal surfaces are covered with polyethylene material to minimize water loss from the concrete solution being poured.

Calculation of the required amount of material

Before making formwork from boards, you need to calculate the required number of boards so as not to increase costs and not to purchase additional material during the construction process. Calculate the required volume in the following way:

- determined by the total length of the perimeter of the structure to be poured and its height;

- choose from commercially available products which boards are suitable in size;

- dividing the perimeter by the length of a unit of lumber, you get the required quantity in one row;

- by dividing the height of the structure by the width of one board, determine the required number of boards vertically;

- By multiplying the resulting quantity by length and height, the required result is found.

We recommend: Blocks for partitions in an apartment - the main types, their pros and cons

The material is sold by cubic meters. To find out how many boards are in a cube, do this:

- find the volume of one: to do this, multiply its length, width and thickness;

- dividing 1 m3 by the resulting number, the desired result is obtained.

Knowing how many units of material are in a cube, they calculate its required volume to create shields: divide the required number of boards by their number in 1 m3.

Material for making shields

To make formwork you will also need the following materials:

- wooden blocks;

- plywood;

- plastic film;

- nails or screws.

The dimensions of the bars should be at least 5*5 cm, and their number is approximately 35–40% of the number of boards.

Correct calculation of the material required for work helps to optimize costs. At the same time, no time is wasted on additional purchases.