A formwork kit is a structure made independently or in a factory and consisting of a certain number of panel elements and blocks interconnected. Fixation is carried out in a certain order, due to which one hundred percent tightness is achieved and leakage of the concrete mass is eliminated. Dismantling of formwork is carried out within strictly established periods, which are even determined by some SNiPs. Dismantling of formwork is carried out taking into account the type of foundation, its parameters, and pouring depth.

Do I need to dismantle the formwork?

Is it necessary to remove the formwork after pouring the foundation? To begin with, the formwork elements are reusable sets, and if large-scale construction is underway, the formwork is removed and placed on a new site.

Removal of formwork is scheduled at the moment when the poured concrete gains the required (stripping) strength. It is not recommended to delay this type of work, because the turnover of the structure will decrease and the rate of adhesion (adhesion) to the concrete structure will increase. If the time frame for dismantling the formwork from the old foundation is unreasonably delayed, the efforts for such types of work will increase significantly in the future. The result is deformation of formwork panels and damage to the surface of concrete structures.

Why dismantle the formwork?

The formwork kit is installed during construction work for the construction of foundations, walls and ceilings. Removal of formwork occurs immediately after the poured concrete acquires the necessary strength. If you delay the deadlines, the mechanical properties of the structure will deteriorate, the adhesion rate will increase and the costs of dismantling work will increase. As a result: damage to the surface of the newly made concrete structure and various deformations of the formwork kit.

Another reason why formwork is dismantled is the nature of its use. Panel elements and blocks are a reusable set. And for this reason, they can be dismantled and installed for pouring a new building structure.

How long does it take to disassemble?

There is an opinion among many builders that it is only possible to remove the formwork from the foundation a few days after filling the trench with concrete. There are also experts who argue that the formwork should last at least a month. So what should be the minimum strength of concrete when dismantling the formwork? There is no clear answer, since the hardening time of monolithic concrete is influenced by its dimensions and the amount of mortar poured.

The main parameter that is used to determine the period of readiness of the formwork structure for dismantling is considered to be the tempering strength indicator.

This characteristic depends on certain conditions:

- type and design parameters;

- brand of solution being poured;

- air temperature;

- other hardening conditions;

- loading volume.

The main criterion for determining the time required for concrete hardening is the type. The value of the tempering strength for heavy concrete mass and mortar with porous components will be 50%, and for autoclave hardening this value will reach 100%. When the structure reaches its maximum strength,

it is permitted to dismantle the formwork. For other cases, a time interval of four weeks applies.

As indicated in SNiPs, removal of formwork after concreting is possible after the concrete has gained optimal strength. In addition, they also use visual signs - the behavior of plywood panels. Moving away from their original position, they signal that the concrete structure is losing moisture and the formwork needs to be dismantled. As a rule, gaps between the boards and the concrete base appear after seven to ten days. To understand how many days it will take to remove the formwork from the foundation, builders use monitoring tools. It calculates the viscosity of the concrete mass, the thickness of the structure, and takes into account the indicators of the fillers used. From all the data, the time for dismantling is determined.

Factors influencing the start date of work

The timing of concrete hardening and formwork removal is influenced by the weather, the brand of mortar, the expected load effects on the poured structure, and the amount of water in the concrete mass. It influences the start of dismantling work and the purpose of the frame, because formwork can be used for:

- foundation structures;

- pouring floors between floors;

- arrangement of walls and partitions, tunnels, large sewers and mines.

The composition of the mortar mass plays a role in determining the time when formwork is allowed to be removed after pouring concrete.

The fact is that concrete is a 100% mixture of mineral components, each of which has a special role. For example, strength depends on calcium silicate; the process of gaining it lasts more than one year. Dissolved to the required concentration, it performs its intended functions from the first hours of pouring. You can verify this by feeling a strong increase in the temperature of the poured structure, which begins to return to normal after a few days.

Calcium aluminate is considered a catalyst for reactions of a physicochemical nature. In addition, the maturation of concrete depends on air temperature. At thirty degrees Celsius, the foundation will reach eighty percent strength in five days, and if the temperature is within three degrees, it will take twenty-eight days to reach this state.

It is characteristic that it is allowed to dismantle formwork panels after the concrete reaches half of the required strength, but all construction work will begin after this figure approaches eighty percent.

Fillers play a certain role. Foundations made on rubble stone or crushed stone and filled with concrete will gain strength much faster.

Formwork dismantling work

The formwork structure is carefully disassembled so that it can be reused and the possibility of damage to the concrete monolith is eliminated.

From the foundation

How long can it take to remove the formwork after pouring concrete into the foundation?

The strip base is a structure in which stripping can begin when the concrete has gained fifty percent of its total strength.

The work process requires caution. The fact is that concrete at this moment does not have sufficient resistance to mechanical damage, and there is a possibility that chips will appear on its surface. In addition, the formwork is often planned to be reused, and the panel material can be damaged by forceful dismantling methods.

The algorithm of actions is as follows:

- Work should be carried out from the least loaded areas - corners and open edges, since here the concrete hardens faster;

- after this, the dismantling process continues from top to bottom - stops, strut elements and other parts that served as support are removed;

- Now comes the turn of the shield ties, located on the opposite side - studs and steel brackets, which are unscrewed or carefully cut.

If the formwork panels were pre-treated with oil or lined with film before installation, then the structure can be removed without much difficulty.

From the ceiling

Now let’s figure out how long it takes to dismantle the formwork on such structures.

As a rule, cast horizontal type floors are rare, because they are often poured on the ground, and only then mounted in the required places. To fill the ceiling, you will need reliable formwork with powerful supporting elements.

In accordance with SNiP technology, dismantling of the floor formwork should be carried out when the concrete reaches at least seventy percent strength. There are certain points to consider here:

- when the air temperature is from 30 to 35 degrees, stripping can be done after five days;

- if the daily average is 20 - 25 degrees, the concrete floor will gain strength by the end of the seventh day.

- if the thermometer does not exceed division 10, then the structure is dismantled after fifteen days;

- at the zero mark, stripping is carried out after a month.

It turns out that in the worst case, the formwork can be removed from the ceiling in twenty-eight days, to which it is best to add a few more days. This is especially important if the temperature or air humidity levels have changed during the concrete hardening period.

How to properly remove formwork from the ceiling? First of all, you will have to lower the load-bearing structures. The process will be simplified if racks with lowering heads were used, because sharply knocking out the elements is prohibited. When releasing large boards, it is recommended to use bolts, due to the rotation of which the boards themselves will move away from the concrete base, making dismantling easier.

After concreting

When can the formwork be removed after pouring concrete? Standards have been defined regulating when to begin this type of work. But who gives permission to dismantle the formwork? For this purpose, special laboratories have been created that issue conclusions based on studies of samples submitted for testing.

For private developers, a similar procedure is also possible, but the service is quite expensive; it is much cheaper to use special tables compiled on the basis of information from state standards.

Rules for dismantling formwork

When the concrete casting has formed and reached the required strength, you can proceed to dismantling the formwork. The dismantling process, in terms of sequence, is inversely proportional to the formwork assembly process. That is, the disassembly of the system components begins with separating the deck from the surface of the casting, followed by dividing it into components, the number of which depends on the type of formwork system.

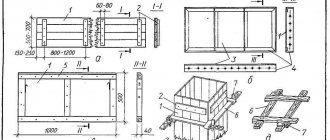

Dismantling of volumetric-adjustable formwork: a - horizontal removal through openings using slings; b, c - the same with the help of a traverse-grab; g - vertical extraction

Dismantling of the formwork should be carried out without the use of large construction equipment that could damage or destroy the casting. There are a number of rules, the implementation of which will allow you to remove the formwork quickly and preserve the integrity of the casting:

- tours, towers, beams and other supporting elements must be dismantled last, since they play the role of load-bearing structures;

- dismantling of racks and panels must be carried out with care. It is important to check the presence of areas with undried concrete, as well as those where the concrete has increased adhesion to the formwork panel;

- stripping must be carried out from top to bottom, with the corner fasteners removed first;

- if concrete takes a long time to gain strength, it is better to start pouring the next sections of the structure than to rush and ignore the requirements of the standards;

- Before using previously dismantled formwork, it is worth removing all existing traces of concrete and treating the contact surface with an adhesion-reducing compound. It is necessary to store formwork elements in strict accordance with technological and operational documents.

Formwork that has been dismantled

To perform a job efficiently, a builder needs to know all the intricacies when working with a material such as concrete. You need to know the hardening time.

Monolithic construction technology is currently used everywhere. Concrete and formwork are used to make walls, floors, garden pools, floors, etc.

Correct pouring of concrete into formwork is the basis for the quality and beauty of the future structure. Any business at the beginning requires a solid foundation -.