Adhesive mixtures and their advantages

Aerated concrete adhesive has several advantages over conventional sand mixtures. When using it, the humidity of aerated concrete blocks does not increase. Hardening occurs without shrinkage, and the adhesive mixture can be used as a putty.

The only point that you should pay attention to when constructing masonry is the setting time. The adhesive for aerated blocks hardens within 10-15 minutes. For this reason, you need to be careful when working and maintain the required speed.

In addition, adhesive for gas concrete has several other advantages:

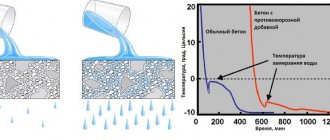

- due to a more complex composition and polymer-based additives, masonry can be done at sub-zero temperatures,

- no complex preliminary work is required when preparing the mixture,

- constant adhesive composition, which gives the same adhesion properties and the possibility of using thinner seams,

- the solution consumption is four times lower than the sand mixture,

- Thanks to the possibility of using thinner seams, the overall level of heat loss is reduced.

Components

In terms of their composition and the presence of various components, adhesives for aerated concrete are quite diverse. There are also special brands that have various additives that allow them to work at low temperatures. All mixtures for gas silicate blocks are based on the following components:

- fine sand,

- high quality cement,

- modifiers that prevent cracking due to temperature changes,

- polymer-based additives that reduce thermal conductivity and allow the adhesive composition not to freeze at temperatures down to minus 10 degrees.

Frost-resistant adhesive used for masonry in winter contains additional components that increase resistance to low temperatures.

Selection options

There is a wide selection of adhesive compositions on the market designed for laying aerated concrete blocks. When choosing a particular brand, first of all, it is worth considering the conditions under which the masonry will be carried out.

Obviously, for work at low temperatures, frost-resistant mixtures should be purchased. The temperature range for which the adhesive composition is designed is indicated on the packaging. An equally important parameter that people pay attention to when choosing is the setting speed.

Let's not forget that most mixtures begin to set within 10 minutes, and complete hardening occurs within 2 hours. Depending on the brand, these parameters may vary, but these are the average indicators. If you do not have good skills in laying gas blocks, then it is better to purchase glue with a longer hardening time.

Glue consumption per 1 m3

The consumption of mortar for laying one cubic meter of cellular blocks depends on several indicators. To make a more accurate calculation, you can use a special calculator, which is available on many construction websites. Also, the consumption per 1 m3 is calculated according to the formula: S = [(L + H)/L x H] x B x 1.4, where:

| Variable name | Variable value |

| S | total mixture consumption |

| L | block length |

| H | block height |

| B | seam thickness |

| 1.4 | dry glue consumption coefficient per 1 m2 with a 1 mm seam |

Also, the mortar for laying aerated concrete can be consumed more or less depending on the following factors:

- block surface quality,

- climatic conditions under which masonry is carried out,

- tools used during work,

- presence of reinforcement.

To a large extent, the consumption of the solution is also influenced by the level of training of the worker.

Advantages of using glue for gas silicate (aerated concrete) blocks

The use of special adhesive for foam concrete is almost always more profitable than a conventional cement-sand mixture for the following reasons:

- the glue has better adhesion, which increases the strength of the structure;

- it is simple and convenient to work with;

- adhesive for foam concrete has an optimal setting time;

- has high frost resistance and moisture resistance;

- glue consumption for gas silicate blocks is several times less than cement mortar;

- the glue is resistant to temperature fluctuations and tolerates both high and low temperatures equally well;

- the level of thermal insulation of the building increases.

Preparation of mortar for aerated concrete

The technology for preparing an adhesive solution with your own hands is quite simple. Water is poured into the preparation container in the required volume and the dry mixture is gradually poured in with constant stirring. The required proportions can be found on the packaging.

Mixing the solution can be done manually, but the most convenient option is to use a special drill attachment. It is necessary to achieve complete homogeneity of the mass. Next, the finished solution is allowed to stand for about 10 minutes and mixed again.

Kneading must be done in small portions, since the glue sets quickly enough. During operation, the mass is periodically mixed, while adding water to the finished solution is strictly prohibited. The finished solution begins to be applied to the second row, since the sand mixture is laid on the first to achieve initial leveling.

Composition and characteristics

When choosing an adhesive, it is advisable to carefully read its composition, since there are other similar mixtures. Cement adhesive for aerated concrete usually includes the following components:

- Portland cement;

- washed and clean fine sand;

- polymer additives;

- modifiers.

Each of the listed components has its own characteristics and is responsible for specific properties. This concerns strength, ductility, moisture resistance, durability and other qualities.

The list of the most important indicators of adhesive for aerated concrete sides includes the following most important characteristics:

- time delay - 15 minutes;

- resistance to high humidity - 95%;

- operating temperature - within -25+25C;

- block adjustment period - 3−5 minutes;

- layer thickness - 1−8 mm;

- hardening time - 1−4 hours;

- size of 1 filler grain is 0.67 mm.

READ Paint for concrete on the street and concrete paths in the country

You should know that the choice of type of adhesive composition will depend on the ambient temperature. In winter, frost-resistant products must be used. Experts recommend choosing an adhesive that can be applied with the minimum thickness recommended by the manufacturers.

Thanks to special additives, the adhesive is obtained with the lowest degree of thermal conductivity. Such properties of the composition are very similar to polyurethane foam.

Main advantages

The lightness and good performance characteristics of aerated concrete have made it popular and in demand in construction. Special glue is used to install it. Manufacturers produce this composition of good quality, since it includes polymer additives, modifiers and sand sifted in a special way.

Polymer additives help improve the thermal conductivity of the composition and its adhesive properties. Due to modifiers, protection against cracks occurring at elevated outdoor temperatures is ensured. It is worth noting other advantages when laying aerated concrete with glue:

- plasticity and fine-grained filler make it possible to carry out masonry with a joint thickness of 2-3 mm, which makes it possible to reduce consumption by at least 4 times and makes the joints thinner, eliminating heat loss in the structure;

- for a bag weighing 25 kg you need to add only 5-6 liters of water, which is why the humidity of aerated concrete does not increase significantly;

- the same and uniform composition of the mixture ensures similar gluing performance;

- anti-frost additives guarantee moisture resistance and frost resistance of the material;

- due to the fact that the composition can be used as putty, its residues after completion of the work are eliminated;

- it is convenient to mix a certain amount of glue required for masonry;

- the type of adhesive composition for the cold season makes it possible to carry out masonry at low temperatures;

- ability to harden without shrinkage.

In addition to the undeniable advantages of such a tool, it has only one disadvantage. The setting time is about 10 minutes, and if a beginner is doing the work, it will be difficult for him to use the ready-made solution at the first stage.

Factors affecting product consumption

The amount of composition spent during masonry work per 1 m3 will depend on several components. This is, first of all, the composition of the adhesive mixture. For example, if it contains more modifying additives and sand, then the consumption will be higher. The high content of binding components will prevent overconsumption and save on material.

READ Concrete dyes: types of pigment and DIY production

Proper installation is important, because young craftsmen often spend more than the required amount. However, this indicator does not contribute to quality work. If there is a reinforced layer on the working surface, then the consumption of the composition will increase.

Sometimes aerated concrete blocks with defects are found in treasure. In this case, the consumption also becomes higher due to a defect in the material, since in order to obtain an effective result it is necessary to spend a larger amount of the working mixture.

The overall consumption will also be affected by the geometry of the surface of the blocks outside and weather conditions. In practice, on average, no more than 1.5 bags of dry adhesive mixture are used per 1 m3.

Criterias of choice

There is a wide variety of formulations available on the modern market. This factor puts consumers in a difficult position. They most often do not know which adhesive for aerated concrete is best to choose. Experts advise conducting a simple test before purchasing.

In the first case, you need to buy several types and glue 2 blocks of aerated concrete with each of them. After about 24 hours, break the resulting connection and look at its fracture. It will pass along the seam, then such glue is not suitable for work. Partial fracture and deformation of the blocks themselves usually raises doubts about the quality of the product. The best composition is considered to be one in which the seam remains intact, and only the gas block becomes unusable after an impact. This composition should be preferred.

The second version of the test is to prepare a ready-made mixture of 1 kg of each type. After that, they fill identical containers. The mixture hardens within 24 hours, then it must be weighed. The best solution is considered to be the one with the minimum weight. This indicator indicates that the composition contains little moisture and the glue has the property of low thermal conductivity.

READ Review of dowels for aerated concrete: types, selection of anchors

Such testing will be troublesome and costly. However, to carry out masonry work you will have to spend much more money, so it is preferable to do tests at the initial stage of construction. Professionals recommend using special tools during the installation process to help reduce mixture consumption.

Rating of the best brands

Despite the huge selection of adhesive mixtures offered on the shelves of construction stores, it is worth listening to the advice of experts. Thanks to their experience, they know more and can determine which adhesive for aerated concrete blocks is best to choose.

According to professionals, it is better to give preference to several companies involved in the production of glue. Many types of products have managed to earn trust for their quality and characteristics. The following brands enjoy a good reputation

- Benolith appeared relatively recently and contains components with antifreeze properties.

- Moment - has high adhesive qualities relative to the building material.

- Volma - has good resistance to low temperatures, which allows you to work with the mixture at -10C.

- Kreisel 125 is a universal composition suitable for laying not only aerated concrete blocks, but also other materials.

- Creps - suitable for external and internal installation and retains all its qualities for 4 hours.

- Ytong is a high-strength polyurethane adhesive that holds water well, has excellent adhesive properties, and is available in two popular types for winter and summer work.

- Real - allows you to carry out construction work at +5 and up to +30C, suitable for work outside and inside.

- Ceresit CT 21 is an excellent option for indoor and outdoor work, as well as for finishing as putty.

- AEROC - under this brand the company produces white and gray masonry mixture for indoor and outdoor work.

It is recommended to choose fine-grained compounds for laying aerated concrete blocks. This will help avoid the appearance of cold bridges due to the homogeneity of the solution. It is recommended to store the composition of any manufacturer at low humidity in a heated room. This will preserve all the properties and suitability of the material.

Tool for applying glue to aerated concrete

The tools used for laying aerated concrete blocks use quite a few simple devices. The main ones are:

- trowel,

- notched spatula,

- toothed bucket,

- carriage.

It’s worth saying more about the carriage. It belongs to professional tools, and the purchase of this device is justified if there are large and constant volumes of work. The carriage allows you to maintain a constant thickness of the seam and simplifies the application of glue due to a special container.

How to lay aerated concrete blocks - step-by-step instructions

Laying walls made of aerated concrete blocks is somewhat different from work carried out using sand mortars. The main rule that is observed during work is to apply the adhesive only to a carefully prepared surface of the block. It should be free of dust, ice and other foreign substances. The main stages of work consist of the following steps:

- inspection and cleaning of blocks,

- preparation of adhesive composition,

- applying the solution to the blocks,

- installation of blocks and their alignment,

- cleaning masonry from excess glue.

It is worth noting that preliminary moistening of aerated concrete blocks during work is not required. However, in hot weather it may be necessary to slow down and stabilize the hardening of the mortar. It is advisable to cover the finished masonry with a tarpaulin or burlap until the glue has completely set.

Composition: technical characteristics

A high-quality mixture should be made on the basis of high-grade Portland cement.

To get all the possible positive properties that adhesives have, you don’t need to skimp. Only a manufacturer that complies with all the standards provided for by state standards can offer the consumer an effective product, so the principle “price is an indicator of quality” works in this matter. In the case of an effective drug, the aerated concrete adhesive composition should consist of the following components:

- high-quality cement or Portland cement;

- quartz sand of a certain fractionation;

- polymer substances to improve adhesive properties;

- frost-resistant modifiers;

- additives responsible for adapting the material to high temperatures;

- moisture-resistant substances;

- synthetic fixatives.

The technical characteristics of adhesives for aerated concrete have the following positive properties:

When using a gray composition, structures can be erected even in winter.

- Plasticity of the material. The glue adheres well to the surface of the block and is well distributed over the surface, which makes it possible to make thin and neat seams.

- Protection against frost and moisture. Modifiers work to actively resist aerated concrete to the negative influence of atmospheric and climatic phenomena.

- Seasonality of work. The gray composition allows construction with aerated concrete even in the cold season.

- Non-shrink solidification. The structure constructed from aerated concrete blocks is not characterized by the effect of shrinkage after hardening of the material.

Specifics of work in winter

Work on the construction of walls in most cases does not stop with the end of the warm period. Adhesive compositions for foam blocks allow masonry to be carried out even in winter due to special silicate and polymer additives.

Even when using glue with frost-resistant components, certain rules should be followed. The solution must be kept warm during operation, and its temperature should not fall below zero degrees. The entire prepared glue solution is used within 30 minutes, and it is better to insulate the container in which it is located.