Home |Construction |Bricklaying at sub-zero temperatures

Date: November 14, 2017

Comments: 0

Brick is a traditional building material used in the construction industry. It is used for the construction of residential buildings and industrial facilities. Work on the construction of brick walls is carried out throughout the year, regardless of changing weather conditions. However, bricklaying in winter has its own characteristics associated with performing work in winter. The main problem in this case is the slowdown in cement hydration and changes in the properties of the solution during the cold season. Let's consider what methods can be used to overcome these problems.

Is it possible to lay brickwork in winter?

There is a misconception that the temperature of bricklaying should only be positive, since in the cold the properties of the cement mortar change, its hardness decreases, as well as the stability of structures.

Indeed, without the use of special construction techniques, work in winter is associated with the following points:

- slowing down the hardening process of the cement mixture;

- crystallization of water included in the binder mixture;

- loss of elasticity of the mortar, making it difficult to seal masonry joints;

- significant reduction in strength characteristics.

The construction of brick buildings and structures in winter is greatly complicated by weather conditions

Mandatory conditions for high-quality construction of brick structures:

- using a warm working mixture;

- use of dry building materials;

- absence of ice and snow on the surface of the bricks.

To achieve operational strength, it is necessary to ensure that the solution hardens for four weeks. With deep freezing and repeated thawing, a significant decrease in strength, shrinkage and reduction in the stability of walls is possible. What to do in this situation?

At the same time, today it is possible to construct brick walls in frosty weather, thanks to the following construction techniques and progressive methods:

- introduction of antifreeze additives into the cement mixture;

- the use of special methods of electrical heating;

- using the freezing method.

At the same time, the strength characteristics of the brickwork and the properties of the binder mixture are preserved.

The technology for erecting brick walls in the cold season, as well as laying aerated concrete in winter, is not fundamentally different from performing work in the spring-summer and summer-autumn period. At positive temperatures and in frosty weather, building material is always placed on a binder solution. However, during the cold season, there are certain nuances associated with the use of a heated mixture and the creation of special hardening conditions.

Professional builders answer the question in the affirmative about the possibility of erecting brick walls in winter.

If you follow certain rules, brickwork can continue in winter even at low temperatures.

Choosing the time of year

High-quality brickwork is performed only at positive temperatures and normal air humidity. The lower the reading on the thermometer, the worse the brickwork mortar hardens, and at minus values this process stops.

You can learn how to use single solid building brick m 150 from this article.

At low temperatures, the water contained in the cement composition can freeze and turn into ice. Therefore, there can be no talk of any interaction of chemical components.

What is the size of a single brick is indicated in this article.

If the reaction managed to occur before the frost and the solution holds the masonry, it may turn out that it did not harden, since it was prevented by the same water, which turned into ice. Because of its shape, it lost its usual plasticity, and the seams between the bricks were poorly sealed. After thawing and hardening of the cement composition, the strength characteristics of the brickwork are noticeably reduced.

Even at low positive temperatures, the solidification time of the solution increases four times, let alone negative ones. It just sets and freezes. But with the arrival of a warm period, it begins to defrost and lose its strength characteristics. If the air temperature rises gradually, then after a week they are completely restored. Naturally, their performance will be lower than the masonry produced in the summer, but they will be able to remain at the proper level.

What is the size of the red facing brick is indicated in the article.

The video explains at what temperature bricks can be laid:

What is the consumption of cement for laying bricks can be found in this article.

Problems with bricklaying in winter:

- the state of water in the solution takes the form of ice, because of this it increases in volume by 10%, and upon thawing it decreases again, thereby causing shrinkage of the entire structure;

- difficulties in maintaining the strength of the masonry;

- at unstable temperatures, which are observed during cold periods, there is a possibility that cracks will appear in the building due to empty bubbles created in the solution;

- the brick may become covered with frost, this is facilitated by the same temperature changes;

- reduction in the quality of masonry in comparison with the same indicator in the summer;

- loss of some of the astringent properties due to ice formed in the mortar and frost frozen over the entire width of the brick. At above-zero temperatures they will begin to melt and the adhesion between them will noticeably deteriorate.

These and other features must be taken into account when deciding to do brickwork in winter.

Bricklaying at sub-zero temperatures - general principles

One common technique is preheating the solution. The processes of cement hydration occur at positive temperatures, and after freezing and thawing they resume. To implement the freezing principle, it is necessary to first develop a project and perform strength calculations.

The working design of a building, the construction of which is carried out in winter conditions, contains special requirements for the performance of work on the construction of brick buildings

:

- the maximum permissible height of walls erected under winter construction conditions is indicated;

- there are recommendations for installing temporary structures to secure walls during thawing;

- contains recommendations on the specifics of work and the use of certain brands of solution.

The brand of mortar used is determined depending on the conditions under which construction is carried out:

- the markings of mixtures used at temperatures above minus 3 ⁰C and at positive temperatures are the same;

- if it is necessary to perform work in winter conditions with air cooling to -20 ⁰C, a mixture grade increased by one value is used;

- An increase in the marking of the mortar by two gradations is made if it is necessary to lay masonry in frost with temperatures below minus 20 ⁰C.

For work at air temperatures down to -15 °C, experts recommend using formate or sodium nitrite

When performing work in winter, modified cement compositions with the introduction of organic additives are used. Working mixture temperature requirements:

- with a significant cooling from minus 10 to minus 20 ⁰C, the temperature of the binder composition increases from plus 5 to plus 15 ⁰C;

- carrying out work in windy weather with gusts up to 10 m/s requires the use of a solution heated 5 ⁰C above the standard value;

- When preparing a heated mixture, you cannot use water heated above 80 ⁰C and sand heated above 60 ⁰C.

To maintain the required degree of heating of the cement composition, it is delivered to the construction site in insulated containers.

Brick laying problems in winter

Many people ask the question: “Why can’t you lay bricks in the cold?” Let's remember the composition of the solution and physics. So, for laying bricks, a mixture consisting of water, sand and cement is used. It is water that plays the key role here. This is what slows down the whole process. At sub-zero temperatures, water takes on a solid state and turns into ice. Therefore, no hydration process occurs between the masonry and the mortar. Even if the water in the masonry does not have time to freeze, some of the bricks will be covered with ice. When the air temperature rises and the ice begins to melt, the strength of the masonry will drop by half. The water that was inside the entire structure will also melt, and the entire structure will collapse quickly. And yet at what temperature can bricks be laid? In order for ordinary cement mortar to set and dry, the temperature outside must be at least -5°C. Otherwise, in the spring the building will collapse.

Brickwork in winter - technology features and heating methods

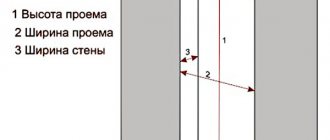

When performing winter masonry, you must adhere to the following technological recommendations:

- erect walls around the perimeter of the building, maintaining the general level;

- make a shrinkage seam at the border of the work area;

- install reinforced concrete reinforcement elements in the area of window openings;

- ensure the immobility of the formwork in the area of the openings using wedges;

- maintain a stable thickness of seams in the horizontal and vertical plane;

- fill vertical joints with cement when work is temporarily stopped;

- protect unfinished masonry from moisture using sheets of roofing material;

- remove frozen mortar, snow and ice when resuming bricklaying;

- Monitor compliance with the verticality of the erected walls when performing work.

Compliance with these requirements will ensure the strength of brick walls.

In addition to anti-frost additives, plasticizers are used when laying bricks in winter.

In order to ensure favorable conditions when performing construction work on the construction of walls, various methods are used:

- heating plant device. This method involves the construction of a temporary frame structure made of wood or metal. It protects the work area from precipitation and is covered with film or tarpaulin. A heating device is installed inside to maintain favorable conditions. Heaters powered by gasoline, diesel or electric power, as well as those powered by wood, are used. This is a costly method, since the temperature must be maintained throughout the entire hardening period;

- electric heating with electrodes. To implement the method, you need a step-down transformer and experience in working with electricity. Electric heating is effective in limited areas. It is carried out by installing rod electrodes made of steel reinforcement. They are introduced with a binding solution at intervals of no more than half a meter and connected to a source of voltage reduced to 60 V. Such heating accelerates hydration at a significant cost of electricity.

The determination of the optimal method for carrying out construction activities is made taking into account the specific conditions of the construction site and an assessment of the overall level of costs associated with the increased need for energy resources.

Bricklaying at subzero temperatures - special requirements

To ensure the stability of brick walls built at low temperatures, special measures are used:

- in the areas where brick walls adjoin capital structures, expansion joints are made;

To preserve the heat generated by the mortar and heated bricks, heat-insulating materials are used

- reinforce door and window openings with a width of more than 150 cm with steel rods with a diameter of 6–8 mm;

- install special supports to ensure the stability of walls erected by freezing cement mortar;

- uses cement mortar of the same brand, consistency and temperature for masonry;

- thermally insulate the surface of the working containers for the mixture and install insulated lids on them;

- use special heating means to accelerate the drying of the brick and remove ice;

- produce a heated solution for 30–40 minutes and continuously carry out the laying;

- Do not use defrosted mixtures, as well as compositions additionally diluted with hot water.

Compliance with these recommendations ensures the strength of brick structures.

At what temperature can bricklaying be done with the introduction of additives?

The use of special anti-frost additives makes it possible to lay bricks in winter conditions when the air is cooled to minus 25 ⁰C. They have the following properties:

- reduce the hardening time of the mixture;

- ensure the normal course of the hydration process;

- increase the mobility of the cement mixture;

- improves strength characteristics.

The following additives with antifreeze properties are popular in the construction industry:

- calcium chloride;

- sodium nitrite;

- potash (potassium carbonate);

- sodium and calcium formates.

The introduction of additives into the solution should be carried out according to a recipe tested in practice. A mandatory requirement when working with chemically active additives is compliance with safety precautions. When working with toxic substances, it is necessary to use personal protective equipment.

At what temperature are bricks laid?

To make structures durable and beautiful, bricks must be laid under conditions of optimal air humidity and temperature. In this regard, the question at what temperature it is permissible to lay brick blocks is gaining great popularity. Experienced builders assure that erecting a structure with a minus value on the thermometer causes a number of difficulties, one of which is problems with the hardening of the solution. Therefore, it is important for people who decide to start construction in winter to take into account all the nuances of working with bricks and sand-cement mixture.