Types of masonry mixture

There are four main types of masonry mortar used in construction:

- Cement-sand . A classic mixture of cement, sand and water. If the proportions are correct, the solution will be strong.

- Limestone . Here, instead of cement, slaked lime is added. After drying, the seams can “go limp” from getting wet, so usually this mixture is used only for the construction of internal walls and partitions.

- Combined . That is, both cement and lime are added to the solution, which makes it possible to use the solution for the construction of external walls.

- With the addition of plasticizers . In fact, these are all three varieties indicated above, to which a liquid polymer additive is simply added, which increases the plasticity of the masonry mortar.

The most expensive ingredient in mortars is cement. Accordingly, cement-sand will cost the most, since it contains more of this binder. If the goal is to save money, then it is better to choose a combined solution, and for partitions - lime mortar.

The best option is with the addition of a plasticizer. The additive, of course, increases the cost of the solution, but not by much. Plus, the plasticity of the mixture increases, which helps to achieve an accurate thickness of the mortar layer, as well as its uniform distribution over the brickwork.

Classic masonry mortar based on cement and sand Source masteravannoy.ru

The main problem in preparing a high-quality solution is to know exactly and follow the proportions. But recently, manufacturers have made life easier for customers by offering ready-made dry mixtures that simply need to be diluted with water. Mixtures of the M50-M200 brand are suitable for laying bricks. On the packaging, the manufacturer must indicate the consumption of the solution per masonry.

Types of mixtures and their purpose

There are several types of mortars for laying bricks:

- Cement, characterized by high strength and rigidity;

- Cement-clay, where pure clay introduced into the solution provides high water-repellent qualities;

- Cement-lime, prepared with the addition of milk of lime. Characterized by high ductility and good adhesion.

- Lime mixtures are not the best, as they have reduced strength, are fragile and are therefore indicated for use in low-rise construction.

The masonry composition is obtained by mixing dry fillers with water. If this is a factory mixture, compliance with the instructions is mandatory. Reducing the consumption of the mixture depends on the speed of laying out the material, so it is much better to prepare small portions of the composition in order to process them before drying.

Universal mixture

Indicated for construction work with bricks, it is made on the basis of cement, sand and water. Sometimes the composition contains plasticizers, for example, special anti-frost additives, which allow you to work with the composition even during periods of severe temperature drops. The concept of versatility applies to many types of compositions; for example, dry masonry is also included in this register.

Type of brick

The modern variety of bricks requires a special approach to solving the issue of mortar consumption for brickwork. And if previously wall brick, also known as ordinary brick or solid brick, was mainly used, today manufacturers offer several options.

The first one is hollow. The design of the product contains cavities, which increase the thermal insulation characteristics of the brick wall. But you need to understand that during the laying process these cavities are partially filled with mortar, which increases its consumption.

For example, a solid ordinary brick will require 0.00063 m³ of mortar. For hollow – 0.0007 m³.

Brickwork made from hollow bricks, in general, is no different Source nica-kirpich.ru

See also: Catalog of companies that specialize in the construction of brick houses

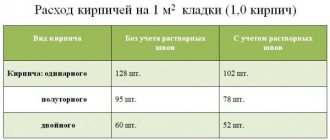

The size of the bricks also influences the consumption. Today, three types are used in construction:

- single with dimensions 250×120×65 mm;

- one and a half – 250×120×88;

- double – 250×120×138.

Here the ratio is as follows - the smaller the dimensions, the greater the consumption of mortar per cube of brickwork. In this case, it is necessary to take into account the thickness of the wall itself. And it can be half a brick, a brick, two stones or two and a half. There is no need to make it thicker.

So, if the wall is built using half a brick, then per one cubic meter of masonry, 0.189 cubic meters of mortar will be required. If the masonry is single-brick, then the consumption will be 0.221 m³. For one and a half bricks, which is 38 cm wide, the mixture consumption will be 0.234. At two – 0.24. And at two and a half - 0.245 cubic meters. Please note that the calculations were carried out taking into account ordinary ordinary bricks. And 440 pieces of it are used in one cube of masonry.

Double solid brick Source mastermario.ru

Calculation of wall area

The basis for all construction calculations is the following indicator: in 1 cubic.

meter – 480 pcs. red standard brick size 250*120*65. This indicator is convenient when calculating the required quantity, and when purchasing from a warehouse and during transportation.

To find out the brick consumption per 1 m2 of masonry, you need to know the thickness of the walls, which depends on the laying of the material:

- in half a brick - 120 mm; in one brick - 250 mm; in one and a half bricks - 380 mm; in two bricks - 510 mm; in two and a half bricks - 640 mm.

For the Russian climate, the best option is to lay walls with two and two and a half bricks. Several other parameters should be taken into account: the number of storeys (height) of the building, the type of floors, and the individual characteristics of the building. After specifying the thickness, you need to determine the length of the building along the perimeter and its height.

The product of these quantities will result in the perimeter area of the house. But at the same time, you should remember about door and window openings, the area of which should preferably be subtracted from the total area of the walls. The result is the total area of the structure being built, from which the amount of material required for its construction is determined.

We recommend these articles: What is the volumetric weight of brickwork? What are the dimensions of Lego bricks?

Thickness of joints in masonry

Another parameter that affects the consumption of masonry mixture. There are standard dimensional parameters for the thickness of the gaps between bricks, which craftsmen must adhere to. It is these dimensions that ensure the strength of the entire structure. Here are their parameters:

- horizontal seams should have a thickness of within 12 mm;

- vertical 10;

- longitudinal in the range of 12-15 mm;

- transverse 8-10.

It is not always possible to adhere to these indicators. Causes:

- low skill of the workman;

- climatic conditions;

- geometric unevenness of bricks.

The last reason is considered the main one. Most often, this is a criterion for excessive consumption of masonry mixture. To lay the stones evenly, you have to increase the mortar in some areas to hide the unevenness of the blocks.

So, everything is clear with the thickness of the seam. The thicker it is, the more solution you will have to use.

Thickness of joints in brickwork Source etokirpichi.ru

Cement consumption

Usually, when constructing private houses, builders use cement-sand mixtures. And the main component in them is cement. Moreover, it is also the most expensive. Therefore, in order to save money again, you need to know the consumption of cement per cubic meter of brick laying.

Firstly, there is a dependence on the brand of cement that it was decided to add to the masonry mortar. Usually this is either M300 or M400. The first will have to be added in larger quantities than the second. But the second is more expensive than the first. So this indicator has little effect on saving money.

Secondly, the brand of the solution itself. The lower it is, the less cement is required. For example, there is a classic solution, which is determined by the ratio of binder to sand as 1:3. That is, to make such a mixture, one part of cement and three parts of filler are required.

Masters do this in different ways, most often using buckets. Because the specific gravity of the two materials is the same and equal to 1400 kg/m³. That is, one ten-liter bucket is filled with 14 kg of material. If you count it into bags of cement, which is 50 kg, then one bag fits 3.5 buckets. Based on this, you can accurately calculate the required number of bags.

Cement consumption for different types of mixtures Source greenbuilding.rf

There is another way. Here, the calculation of cement consumption for masonry is based on the volume of each material. To do this, take one cube of sand as the main ingredient. And the required volume of cement is calculated: 1:3 = 0.333 m³. In liters it will be 333. Or 33 buckets.

Now about the consumption of cement and mortar in general. As mentioned above, for laying 1 m³ of wall, where ordinary solid stone is used, 0.221 m³ of solution is required. And if a mixture of the classic ratio of 1:3 was used for this, then cement was added to it: 0.221:4 = 0.055 m³. Let's convert the figure into kilograms: 0.055x1400=77.

Mortar consumption per cubic meter (1m3) of brickwork

The mortar is used to bind the bricks together in the masonry.

In construction, several types of mortar mixtures of varying strength and ductility are used to build walls; they are selected depending on the purpose of the building. The composition of any solution includes a binder (cement or lime), as well as fine aggregate. Usually it is sand, less often clay. When building a house or outbuildings, there is a need to count building materials. Undoubtedly, in masonry walls, the largest percentage of costs is brick, but in some cases, when people buy ready-made building mixtures, there is a need to calculate the amount of mortar per cubic meter (1m3) of brickwork, because this is also a monetary cost. It should be noted that the construction mixture consumption figures indicated below are approximate, because when performing rough masonry with ordinary ordinary bricks, it is difficult to maintain the same thickness of the seam.

Mortar consumption per masonry cube of 1 brick

If you use ordinary clay bricks with standard dimensions of 25 × 12 × 6.5 centimeters, for laying walls one brick thick you will need 0.22 cubic meters of mortar; if the laying is done in half a brick, the amount of mortar will be reduced to 0.19 cubic meters.

In the case when it is necessary to build a wall one and a half bricks thick with a size of 38 centimeters per cubic meter of masonry, 0.235 cubic meters of mortar will be needed, for load-bearing fences 51 centimeters thick - 0.24 cubic meters.

Mortar consumption for 1 m3 of masonry per 1.5 bricks

Now let’s consider the consumption of the mortar mixture when using one-and-a-half bricks with overall dimensions: 25 centimeters in length, 12 centimeters in width and 8.8 centimeters in height.

When building a wall the width of half a brick, it is necessary to prepare 1.6 m 3 of mortar, if the wall is laid along the length of the brick - 0.2 m 3 of mortar. In the case of the construction of load-bearing walls measuring 51 and 64 centimeters, the consumption rate of the mortar mixture will be 0.22 and 0.227 m 3, respectively.

It should be noted that when using double bricks, cement consumption will be even less. In this case, not only the number and length of seams within the wall are reduced, but also heat losses are reduced. As for the use of bricks with voids, this material, with similar dimensions, will use a little more mortar. To reduce costs, special meshes are installed in the rows of masonry, which also perform another function - increasing the strength of the building being constructed.

Briefly about the main thing

The consumption of mortar for the construction of a brick wall depends on the type and brand of the mixture, geometric evenness, type and size of the brick, and the thickness of the joints.

Calculation of consumption during the construction of a private house is carried out either in cubic meters or kilograms.

Cement, as the main component of masonry mortar, is the main expense item in the construction of walls. Its consumption depends on the brand and the amount applied. For example, when mixing cement and sand in a ratio of 1:3, ¼ cube of the solution is added as a binder. That is 0.25 m³.

Ratings 0