The implementation of activities for the construction of a private house is inextricably linked with the implementation of calculations. They allow you to accurately determine the need for building materials for the basement of a building, main walls or foundation. Let's consider the basic methods for calculating a plinth made of various types of bricks. Knowing how to correctly calculate the brick for the plinth, depending on the chosen masonry method, you can promptly purchase the building materials necessary for construction, which will significantly speed up the completion of construction work.

Basement brick - sizes, types, terminology

When planning the construction of the basement of the building, you should decide what building material will be used for the masonry. Professional builders for these purposes recommend using solid brick, which has the following advantages:

- increased resistance to mechanical loads;

- resistance to the effects of high humidity.

Ceramic solid plinth brick

Let's figure out what types of bricks exist:

- ceramic, for the production of which clay and quartz sand are used. The manufacturing technology involves high-temperature annealing, which increases the strength properties and moisture resistance of ordinary clay bricks;

- silicate, which is easily distinguished by its white color. Produced by autoclave processing in chambers where high humidity and temperature are maintained. Strongly absorbs moisture and is not used for basements and basements;

- fireproof, which maintains integrity when heated to 1.5 thousand degrees Celsius. Refractory brick has a yellowish tint and is made from fireclay. The material is used in the construction of furnaces and retains its structure during repeated heating and subsequent cooling.

Of the indicated types of bricks for masonry construction, it is better to use ceramic ones marked M250, produced by high-temperature firing of clay. Such a building brick can withstand a force of 250 kg per square centimeter of area and has a standard size of 25x12x6.5 cm. Externally, the product is a rectangular parallelepiped, each side of which has its own name:

- bed. This is the largest part in area, having dimensions of 25x12 cm;

- spoon part. Spoon – larger end with a size of 25x6.5 cm;

- butt plane. The butt is a reduced end with dimensions of 6.5x12 cm.

Hyper-pressed plinth solid single-face brick

The dimensions of different types of brick products differ and are:

- for a single brick – 25x12x6.5 cm;

- for one and a half - 25x12x8.8 cm;

- for a double brick block – 25x12x13.8 cm.

Knowing the sizes of the blocks used for plinth masonry, it is easy to independently calculate the number of bricks per plinth.

Brick selection

Now that we have understood all the basic properties and requirements for bricks, we can focus on specific options and choose the most suitable one.

There are a lot of questions online about what is the best material to choose in order to lay out a high-quality base.

This question can only be answered after evaluating all available options. This is the only way to really understand which option is better in general terms, and which one is right for you specifically.

When building basement walls, it is wise to use brick:

- Regular red burnt.

- Acid resistant.

- Silicate.

- Clinker.

Let's look at each sample, its properties, possibilities for using it yourself, etc.

Red brick

Red building brick is used almost everywhere. Its size, shape and color are known to everyone.

Red brick is used almost everywhere. With its help, repairs and construction of buildings, construction of walls and basements are carried out.

Sand-lime brick in different variations

If you are planning to lay it out of this material with your own hands, it is recommended to lay it in solid brick. It is stronger than hollow samples, it is not as susceptible to moisture, and requires repairs less often. Its size is almost ideal for building a base in two rows .

Unfortunately, brick is susceptible to moisture. It needs high-quality waterproofing. Moreover, waterproofing of the base must be carried out both externally and internally. It will also withstand fewer defrosting cycles, and in general, it is an order of magnitude weaker than its competitors.

Its advantages are accessibility, low cost, uniform size, ease of processing with your own hands, familiarity to the average user, and speed of production.

Acid resistant brick

The acid-resistant sample is produced exclusively full-bodied. Its characteristics are truly impressive.

The material is very resistant, able to withstand pressure from both light buildings and huge multi-story buildings. You can make anything out of it.

Acid-resistant brick almost does not absorb moisture and does not react to dampness. Therefore, it does not need full waterproofing. It is quite heat-resistant, very durable and reliable.

The size of an individual product is identical to the size of standard samples. Repairs for structures made from acid-resistant blocks are very rarely required. And if it is required, it comes down to the banal strengthening of the masonry with mortar.

Among the minuses, we note the poor thermal conductivity and the rather high price of the product.

Choosing the best brick for building a basement (video)

Sand-lime brick

The use of sand-lime brick in the construction of the basement is fully justified. The properties of silicate material are better than those of ordinary red brick.

Sand-lime brick has higher strength, is more durable, and survives more defrosting cycles. A silicate base also requires waterproofing (otherwise it will quickly need to be repaired, and the repair will be expensive), but only basic, consisting of one layer.

The remaining properties of the silicate material and its dimensions are identical to the standard ones. You can make several halves out of it, since the brick is easily divided into parts with your own hands.

Clinker brick

If you want to make a durable basement wall with excellent visual characteristics with your own hands, then it is best to do this using clinker bricks.

Clinker brick differs from ordinary bricks, since in essence it is more of a facing material. Builders are trying to lay out the outer part of the wall from it. It does not require waterproofing or regular repairs.

When fired, clinker clay becomes almost waterproof. Repair of clinker after at least twenty years of operation is a rare case. Most often, it can withstand at least 50 years of service life without a single crack.

It has only one drawback, but a significant one - it is very expensive. Therefore, if you are afraid of external waterproofing, finishing and possible repairs of the structure, but are not afraid of the high price of construction, choose clinker bricks. Otherwise, turn your attention to more affordable solutions.

Getting ready to calculate the amount of bricks for the plinth - preparatory work

Before calculating the brick for the plinth, you should decide on its design. It can be different:

- protruding beyond the contour of the wall;

- corresponding to the width of the wall;

- recessed 50–70 mm relative to the wall of the building.

Construction of a brick plinth

If you want to correctly calculate the brick for the plinth, you need to prepare the initial data:

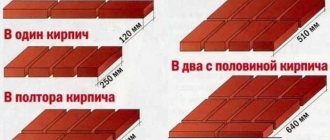

- thickness of the base. In most cases, the width can be 0.5, 1, 1.5, 2 or 2.5 bricks;

- height of the basement wall. The height dimension is determined according to the requirements of the project, taking into account climatic factors and must exceed 50 cm;

- perimeter of the base. It is calculated by adding twice the length and width of the building being erected;

- dimensions of the brick used to build the basement. The amount of building material depends on the size of the basement brick;

- dimensions and number of openings. If there are openings located in the basement of the building, then the need for building materials for masonry is reduced;

- thickness of the mortar joint. The correct calculation of the amount of material depends on taking into account mortar joints;

- type of masonry used. The calculation of bricks for the plinth differs, depending on the characteristics of the brickwork.

Using the necessary information, you can perform calculations using various methods:

- using an online calculator or programs posted on specialized websites;

- manually when independently performing the necessary calculations using a conventional calculator.

Let us dwell in detail on the methodology for performing calculations independently.

Brick bonding in the basement and waterproofing

My friend laid a layer of concrete on top of the waterproofing layer and pressed the mesh into it. Now I was laying the base. I need a helper to prepare the solution. But Vadik wanted to try to do everything with his own hands. He asked me to choose a site that was simpler, along a straight line without corners. He carefully aligned the outer row along the stretched cord and then laid the rest of the brick tightly. After a couple of hours I got used to doing everything myself. I secured 2 boards at each corner close to the masonry. Now all that remained was to lay the brick, pressing it against them. Nails for the outer line cord were easily driven into the wood. This device comes in handy when you need to repair the corners and façade of a house.

Laying a brick plinth with your own hands

Every 4 rows, now I, as a helper, laid the mesh for strength. While the concrete mixer was working, I marked openings for vents - holes for ventilation of the underground space of the house. I prepared the top layer of waterproofing, which was additionally laid under the wall masonry.

I advised Vadik to choose masonry with a bandage half the width of the brick. Our outer layer alternated with transverse and longitudinal rows. Now, when laying, the joints did not match. This made the base durable and eliminated any repairs in the near future.

How to calculate the number of bricks per plinth based on the volume of masonry

Knowing the volume of brickwork, it is easy to calculate how many bricks are needed for the base. To do this, the volume of the basement wall is calculated, and the resulting value is divided by the volume of one brick block. Having correctly performed the calculations, the result will be the amount of building material that will be required to build the basement base. Let's analyze the calculation algorithm using a specific example.

Number of bricks per plinth by volume of masonry

Initial data for performing calculations:

- dimensions of the building's basement are 5x6 m;

- height of the base base – 0.6 m;

- wall thickness in the basement part – 0.25 m;

- size of the connecting seam – 10 mm;

- type of masonry performed - one brick;

- dimensions of the building material used – 0.25x0.12x0.065 m.

Perform the calculation following the given sequence of calculations:

- Determine the perimeter of the base by doubling the sum of the sides - 2x(5+6)=22 m.

- Calculate the volume of the masonry by multiplying the perimeter by its thickness and height - 22x0.25x0.6 = 3.3 m3.

- Calculate the volume of the brick block by multiplying the dimensions - 0.25x0.12x0.065=0.00195 m3.

- Determine the need for material by dividing the total volume of masonry by the volume of bricks used - 3.3: 0.00195 = 1692 bricks.

The above calculation algorithm does not take into account the thickness of the seam, the size of which slightly affects the amount of building materials required. If openings are supposed to be made in the basement of the building, then their volume must be subtracted from the volume of the masonry. By repeating the simplified calculations, it is easy to determine the need for brick blocks.

Calculation of bricks per plinth by volume

Calculator for calculating the amount of bricks for laying a plinth

When building a foundation for a future house, this approach is often practiced - the lower part of the base is a reinforced concrete monolithic strip, placed just above ground level, and then the base is laid out of brick to the required height. This significantly lightens the entire foundation structure, making it “warmer”, which is extremely important for maintaining a comfortable microclimate in the premises of the first floor.

Calculator for calculating the amount of bricks for laying a plinth

Expert opinion: Afanasyev E.V.

Chief editor of the Stroyday.ru project. Engineer.

Many owners prefer to carry out most construction work, if possible, on their own, and laying a brick plinth is no exception in this regard. But once such a decision is made, it is necessary to correctly determine the amount of materials required. A calculator for calculating the amount of bricks for laying a plinth will be an assistant in this matter.

Brick prices

brick

Some brief explanations on working with the calculator will be given below.

Calculator for calculating the amount of bricks for laying a plinth

Go to calculations

Explanations for the calculation

The principle of calculation is simple: the total volume of the brickwork is determined and then compared with the volume of one brick. But there are several important nuances:

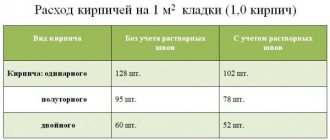

- The calculation is carried out only for building bricks - single (65×120×250), one-and-a-half (88×120×250) and double (130×120×250). Numerous formats of finishing bricks are not included in the program - simply laying out the base from facing material seems like an unreasonably expensive undertaking.

- In the corresponding input field, you must indicate the thickness of the masonry, expressed “in bricks,” that is, “a brick,” “one and a half bricks,” and so on. Laying “half a brick” when creating a plinth is not practiced, but, nevertheless, it is also indicated in the general range of options.

- The height of the masonry is in accordance with the expected height of the base.

- The program adjusts the size of each brick for the presence of joints filled with masonry mortar. The most commonly used seam thickness is 10 mm.

- The length of the base is indicated as the total length, measured along the outer perimeter. If the building plan contains internal foundation lintels, on which a brick base is also erected, then their length should also be included in the overall value.

- Finally, the number of internal and external corners of the plinth is requested. This data is necessary to make adjustments to the total volume of brickwork. If there are areas of abutment or intersection of the walls of the plinth, then they are also indicated in the “external corners” field.

- Usually, when calculating any building material, it is customary to include a certain reserve. Its value may depend on the level of qualification of the master, on the quality of the purchased material and on other reasons. In this case, the user has the opportunity to independently choose what supply of bricks to include in the calculation - from 0 to 15%.

The calculation result will be indicated in pieces.

How to learn to do proper bricklaying?

You should not assume that building a brick wall is a simple task, and the matter will immediately go smoothly. Practice shows that before obtaining impeccable masonry, a novice master will still have to go through a considerable “training” path. To help those who are taking their first steps in this field - an article from our portal “How to lay bricks” .

How to count bricks for a plinth based on the size of the basement of the building

Using the initial data given in the previous section, we will consider an alternative calculation procedure that takes into account the dimensions of the base base. Let's compare the result obtained with the previously determined need for material and evaluate the accuracy of the calculations.

The calculation algorithm involves determining the amount of building material at one level of brickwork with the subsequent calculation of the total requirement. Perform calculations in the specified sequence:

- Calculate the total length of the basement of the future building by adding the dimensions 5+6+5+6=22 m.

- Determine the number of brick blocks in one row by dividing the result by the length of the end part (for masonry made in one brick) - 22: 0.12 = 183 pieces.

- Calculate the number of horizontal rows by dividing the height of the base by the thickness of a standard brick block - 0.6:0.065 = 9.2 rows.

- Determine the need for material by multiplying the number of blocks in a row by the number of rows rounded to 9 - 183x9 = 1647 bricks.

The resulting calculation result for the wall area (1647) differs slightly from the material requirement determined by the volumetric method (1692). In both cases, the thickness of the bonding solution, equal to 1 cm, was not taken into account. If it is necessary to obtain more accurate values, it is necessary to take into account the thickness of the seam, taking into account the configuration of the masonry.

Laying work

The most important stage at the beginning of the construction of the basement is the construction of the corners. The first row must be laid strictly across the entire width of the building. The solution of cement, water and sand should have the following proportions 1:3:3.

The brick basement is insulated from the inside as desired, but the outside requires mastic, which is applied with a brush, roller or specialized apparatus. Laying is carried out with constant monitoring of the level and cord.

Setting the corners

Setting the corners when laying the plinth is one of the main tasks; incorrectly placed corners will lead to curvature of the walls!

To do this, place a dry row of bricks in the corners and determine the desired width of the plinth. All corners must be level.

Using twine or a tape measure, you need to measure the length of all sides and 2 diagonals - if the angles are set correctly, then the dimensions should be identical.

Laying a brick plinth on top of the foundation

You can begin installation only after all measurements have been made. To secure the bricks, a cement-sand mortar in a ratio of 1:3 is required, diluted with water to the required thickness of the mortar.

The main condition for this work is to carefully fill the vertical or horizontal joints with the prepared mortar to ensure the strength of the foundation.

Base insulation

To insulate the foundation, waterproof materials such as polystyrene foam are required, which must be used to treat the entire outer surface, secured with a special glue - which does not contain acetone and solvents - which harm it.

Basement waterproofing

Before you start building the structure, you need to make sure that all waterproofing materials are in stock - plaster, stone, ceramic tiles.

Waterproofing methods:

- Waterproofing is carried out at 2 levels - at the very bottom, before the first brick laying, and on top of the bricks. The easiest way is to lay roofing felt in two layers. The first layer ensures the wall is protected from moisture, and the second layer provides protection.

- Extruded polystyrene foam, which is fixed to the outer surface of the base. Due to the fact that this material has zero water absorption, it has high protective properties. It also has thermal insulation, and therefore will give the building additional protection.

- Bitumen lubricant is applied to the entire surface of the bricks in a thick layer in several approaches. Various plaster mixtures.

Ventilation

The foundation masonry must have holes that are located at a height of 15 cm from the ground, which will ensure good ventilation. You need to cover the holes with a metal mesh or flaps.

Brick base protection

Protection is required if construction work must be stopped. To do this, a film is laid on the structure being built, which protects the frame from various unfavorable environmental conditions.

Despite the fact that this article describes detailed instructions on how to lay a brick plinth, they will not help if you do not have even a little experience working with these materials.

Calculation of stairs - general information

At the design stage, after specifying the dimensions of the plinth and studying the layout of the interior, calculations of staircase structures are performed. Before starting construction of the basement, you should evaluate how the internal stairs will be located and whether it will be necessary to adjust the size and shape of the basement of the building in the project.

Calculation of staircase structures

At the design stage, the following points are taken into account:

- dimensions and area of the interior;

- height difference between the floor and ceiling;

- features of the internal layout;

- coordinates of the location of doorways;

- location of internal partitions.

Important factors when designing and linking staircase structures are:

- angle of inclination of a flight of stairs. The optimal value for safe use and comfortable operation is 28–34 degrees;

- size of the step support. The indicated value is 25–30 cm, which ensures ease of movement;

- height difference between adjacent steps. The requirements of the state standard provide for the value of this parameter to be 18–20 cm;

- width of the stairs. This characteristic is 0.9–1.1 m, which ensures comfortable operation.

When deciding on the design of a staircase, first of all you need to pay attention to safety, reliability and increased safety margin.