What is the best material to build a stove from?

When it comes to material for building stoves, different options are usually discussed. Among the materials mentioned are metal, natural stone and brick. Each material deserves attention in its own way.

The metal is most often used to make lightweight, portable stoves. But at the same time, it is not always appropriate to install such stoves in residential premises, and the reason here is very banal - the heat from such a stove can only be obtained while combustion is maintained in the firebox. Of course, there are long-burning models, but such stoves are not capable of heating a truly large house.

Natural stone is mainly used to decorate a stove or fireplace. It is completely unsuitable for laying a firebox. Under the influence of high temperature, the stone heats up unevenly, causing it to collapse. In addition, natural stone is a very difficult material for construction - it is very difficult to build even the simplest stove out of stone.

Another thing is brick for laying stoves. The simple rectangular shape allows the construction of stoves of different designs and purposes. The presence of several varieties of this material makes it possible to create stoves with a high efficiency. You can even decorate a building artistically, giving it a special look, using different types of bricks. True, before starting construction, it is worth thoroughly understanding which brick is best to build the stove from.

What kind of brick is the stove made of?

Who has never wanted to live in a wooden house? The atmosphere of warmth, coziness and comfort of such a home allows you to truly relax. The most favorite place in such a house is always the stove. Once you climb on it, you lie down and rest. And after a frosty street, your whole body will instantly warm up on it. And no pills or tea are needed. And people love these large and warm stoves so much that many began to seriously think about how to build them.

Necessary preparations before laying the stove

First, you need to choose and hire a stove specialist or, if you want to assemble the stove yourself, buy all the necessary literature. You need to decide for what purpose you want to build the stove. If you can cook on it and lie down, then it is better to lay it out entirely of brick. And if only for heating, then you can use cast iron and then lay bricks around it. After reading about how to lay stoves, chimneys and what bricks to use, you can start purchasing all the necessary materials.

How to choose a brick?

Undoubtedly, one of the main components of the future furnace is brick.

And choosing it is one of the main problems, because nowadays you can’t find the ideal material. Whether your stove will be warm and how long it will last you depends only on the correct choice. The choice of brick should be considered according to two indicators: density and frost resistance. Brick density varies from 100 to 500.

There are these types of bricks:

Types of thermal conductivity of bricks.

- Fireclay. It comes in completely different shades and is perfect for masonry, pipes, and the outer walls of the furnace.

- LODE. The best brick in terms of density and frost resistance. Its density is higher than all others - 500.

- Vitebsk workshop 1 and 2. If you are preparing for severe frosts, it is not recommended to buy it, since it has a low density, and its use is extremely limited (only in dry rooms where the furnace does not require strong heating).

- Borovichi. Average in terms of performance. Its density is 300. Such a brick can be laid if there is no LODE.

Now let's look at everything in more detail. All bricks are mainly laid in red. Only fireclay has different shades. The most ideal of all its types is a cream shade. When purchasing any type of brick, you should first pay attention to its edges. The most correct would be the presence of sharp corners.

Correct laying of the stove

Chimney laying diagram.

The most important thing is the correct laying of the chimney. For it, you should choose the most frost-resistant bricks. This is necessary so that when the stove is heated, the brick does not burst and retains heat well. If the chimney is laid out correctly, then you will never have smoke in the house. Also important is the construction of the correct chimney. Ideally, when lighting wood in a stove, there should be good draft (that is, air should circulate freely, which fans the fire in the stove). If you lay out the chimney and chimney correctly, then consider that half the battle is done. You can start building the furnace itself. To build a foundation, a brick should be chosen of medium density (and for a cast iron stove it is not needed at all). They lay a brick for the foundation, but if you don’t want to lay it, you can lay out special metal supports. Once its laying is complete, you can proceed to the construction of the outer walls. For laying outer walls, it is necessary to choose bricks with medium density and the ability not only to retain, but also to give off heat.

When laying bricks, you should never skimp on the fastening material - clay and sand. When heated, it tends to burn and tightly fasten the bricks together. The need to apply a large amount for bonding is due to the fact that this will provide a greater guarantee of the absence of holes.

And now the oven is almost ready. It is only necessary to cover it with whitewash on top, in order to once again be on the safe side about holes in the brickwork, and also to give it an attractive appearance. It is necessary to dry it thoroughly. To do this, you need to heat the oven.

Correct use of the oven

A stove, like a child, without proper care and supervision will wither and break. The most important rule for using a stove is the frequency of kindling and seasonality.

Checking chimney draft.

The frequency and seasonality of heating the stove depend on the time of year. In autumn and spring, it is recommended to heat once a day (preferably in the evening), but in winter - twice, in the morning and in the evening. It is better to heat the stove in the evening with wood rather than briquettes or coal. Why? Because the latter tend to release harmful substances. But during the day, on the contrary, briquettes are recommended, as they retain heat for a very long time. Before going to bed, you need to make sure that the fire in the stove has gone out and be sure to close the special dampers (when kindling they are moved aside, allowing the wind to circulate freely, igniting the fire), so that the wind does not blow out all the heat through the chimney. It is better to cook on it when the fire is burning well, and throughout the entire process you should constantly add firewood.

Before the cold weather sets in and there is a need for frequent heating, the stove needs to be prepared. To do this, the oven is carefully heated and warmed up for a couple of days so that all the debris and dust that has accumulated over the summer burns out. At the same time, this will be an additional check of the oven’s performance. It is also better to stock up on firewood in advance and for future use, so that you do not have to freeze in winter. Often they are sold by special organizations.

A stove is more than just warmth and a place to sleep. She is also a doctor. People with radiculitis recovered after lying on it for a certain period of time. The stove has always been the main character in many fairy tales. In them she acted as a nurse, an assistant, and a mode of transport. Place the stove correctly, and let your home always be warm and cozy.

What properties should a brick used for laying a stove have?

Kiln bricks must meet the following technical requirements:

- Resistant to high temperatures and open flames.

- The ability to accumulate heat and retain it for a long time.

- Sufficient mechanical strength.

- Resistant to significant temperature fluctuations.

Solid fuel stoves are built from ceramic bricks that meet the requirements of GOST 390-96. This standard came into force on July 1, 1997 and establishes the technical conditions that these products must comply with in shape and size. The regulatory document also defines the requirements for the use of products depending on the maximum ambient temperature.

Ceramic bricks intended for the construction of thermal units are subject to more stringent requirements than other building materials. In the firebox of furnaces, the flame temperature can exceed 1000 °C; therefore, its walls are subjected to significant thermal loads. The thermophysical parameters of the material used must be higher than the specified value.

During the operation of the furnaces, they are regularly cooled in some cases to negative temperatures. In this case, the brick is exposed to a significant temperature difference in the external environment, which leads to thermal expansion followed by compression. The product must have a sufficient strength margin to successfully withstand this phenomenon and avoid deformation and destruction. The brick used for laying stoves must have sufficiently high thermal conductivity and the ability to accumulate heat. The first property is necessary for quickly heating the room and transferring the energy of burned fuel to the external environment. The second quality allows you to maintain this process after the combustion in the furnace stops for a long time. This allows you to maintain a comfortable thermal regime for a long time.

What kind of brick is the stove made of?

The stove is made of bricks of a special composition. It must be fireproof, refractory, properly fired. It is not necessary to take just one type. If you know which brick to use for the stove in a certain part of it, you can save on expensive material without losing quality. For example, the firebox should be laid with fireclay bricks, for the body and chimney you can take a standard fireproof one, and the outer lining can be made of clinker or special cladding. This option is more economical than the entire construction made of fireclay.

Fireclay brick: properties, dimensions

The best material for laying a stove is fireclay brick. Its characteristics are unmatched among refractory materials:

- withstand t=1500ºC,

- have a low degree of hygroscopicity,

- large temperature changes do not affect the integrity of the structure.

Fireclay for masonry is made from fireclay mixed with fireclay powder. Its quantitative composition is 70%. Manufacturing requires adherence to the smallest details: overburning will make it glassy, and underburning will cause greater moisture absorption. Standard sizes of fireclay bricks:

- 250x124x65 mm,

- 230x114x65 mm,

- 230x114x55 mm.

The color is yellow-beige interspersed with red or brown. The composition is regulated by GOST 390-96. Fireclay brick is designated by the abbreviation ША or ШБ. It is this material that must be used to lay the combustion chamber. In metal furnaces it is used for lining the firebox.

How to put fireclay?

It should be noted that it is not enough to know what kind of brick the stove is made of; it is also important to understand the types of mortar for it. For example, fireclay brick requires the use of a masonry mixture with a similar composition. This means that the solution must contain fireclay in the same ratio . Such masonry ensures the same reaction of materials to heating and cooling, since they have the same expansion coefficient. This ensures the strength, reliability, and durability of the thermal unit.

Fire brick

Kiln refractory bricks are used for the construction of the body and chimney ducts, if the amount of fireclay is limited. Made from red refractory clay with the addition of quartz sand. Withstands temperatures up to 1000ºC, has increased heat capacity, fire resistance, and strength. It is second only to fireclay in terms of physical properties. Not intended for laying in places where the surface will come into contact with open fire.

This material can be used to cover a metal chimney above and below the roof. A brick chimney is also built from one of them. Available in red and brown shades. For masonry, a mixture of similar composition is used. This is also required to ensure equal expansion and contraction under thermal loads. It is better to use a ready-made mixture offered by the brick manufacturer.

Features of masonry

Fireclay and standard furnace materials always have a uniform, solid structure without cracks or voids. They allow you to reduce the thickness of masonry joints to the following figures:

- fireclay – 2 mm,

- oven fireproof – 4 mm.

Such parameters ensure minimal shrinkage of the finished thermal unit. Also, thanks to thin seams, the masonry does not collapse during strong heating. For comparison: a 10 mm thick seam shrinks by 1 mm. The minimum joint thickness is especially important in the following areas:

Modern technologies have made it possible to replace masonry mortar with special adhesive mastics that can withstand temperatures up to 1300ºC. They are made from natural minerals, therefore they are environmentally friendly, odorless when heated, and resistant to alkalis and acids. The laying is carried out by applying a layer of mastic 1 mm thick, which further increases the quality of the stove (fireplace) itself.

Advantages. Processing methods

Features of stove bricks: they accumulate heat and radiate it evenly into the room. This allows you to heat the house for a long time after the firebox has died out. It is enough to fill the firebox with wood once and burn it for 3 hours so that the stove continues to give off heat for 14 hours. Cutting kiln bricks by hand is difficult because they are very durable. In order to avoid errors and obtain accurate dimensions of the material, it is better to use a power tool: a circular saw, a cutting machine.

The use of different types of bricks for laying various furnace elements

Solid fuel stoves have a rather complex design, the components of which operate under certain conditions. The question arises, what kind of brick is needed for laying the stove and its elements?

The design of the heating furnace is as follows:

1. Firebox and vent.

The combustion chamber predominantly has two-layer walls, the inner one is made of fireclay bricks, the outer one is made of ceramic facing bricks. The firebox is built from fireclay bricks with maximum fire-resistant properties. The external finishing of the furnace operates under less stressful conditions and it is possible to use facing bricks that have excellent decorative characteristics.

2. Smoke channels.

The smoke channels are a large heat exchanger and the temperature in them, although lower than in the firebox, is still quite high. Fireclay bricks are used to lay these furnace elements. The outside of the structure can be covered with ceramic tiles or facing bricks.

3.Chimney.

The chimney is in direct contact with the atmosphere and experiences large temperature changes. Consequently, ceramic bricks with the highest possible frost resistance are used. Typically, this element also has a two-layer structure with a decorative outer finish made of ceramic bricks or a metal box.

The process of laying a furnace and an example of using fireclay bricks to build highly loaded elements and external cladding with ceramic bricks.

The use of bricks with appropriate characteristics for the construction of individual elements of the furnace will ensure maximum durability and excellent thermophysical properties. Experienced stove makers pay special attention to this issue when selecting materials. At the same time, a thorough inspection and rejection of bricks with large cracks and deep damage and chips is carried out.

Characteristics

The quality indicators characterizing fireclay bricks are strictly controlled by the state. GOST specifies indicators that reflect the weight of fireclay bricks and its dimensions, the composition of raw materials with the percentage of aluminum oxide, as well as technological properties: strength, geometric parameters, fire resistance, porosity.

The main indicators are shown in the table:

When manufacturing products, many manufacturers rely on their own specifications instead of the conditions prescribed by GOST. Therefore, when choosing a material, the question arises of which brick to take. Indeed, in terms of a number of characteristics, products manufactured according to GOST and according to the manufacturer’s specifications very often do not coincide. In this case, it is better, if possible, to purchase a product with a GOST mark, since it is of better quality.

As for geometric parameters, GOST specifies the size of a standard rectangular product as 230x113x65 mm, and this is considered the optimal material for the construction of brick structures. But today other dimensional characteristics are also acceptable, so the market is filled with a variety of products from different manufacturers.

The weight of products also has different indicators, and ranges from 2.8 kg to 4.5 kg, with the permissible weight according to GOST - 3.7 kg. When purchasing, do not forget about this, because the thermal conductivity of the material depends on the mass. To maintain heat in a room, you need to choose a material with more weight, because low weight increases its thermal conductivity.

Resistance to chemicals, alkalis and high temperatures depends on the quantitative content of aluminum oxide in the building material. The content of this element in the composition affects the structure of the material, making it porous. And porous brick heats up for quite a long time, but also cools down longer than usual, retaining the resulting heat.

At the same time, as porosity increases, strength decreases. Therefore it is worth choosing

material with an optimal density of 1700–1900 kg/m. Density also affects such properties as: moisture absorption, thermal insulation, adhesion to the mounting mortar and the weight of fireclay bricks.

You can determine the porosity of a brick just by holding various options in your hands.

To summarize, we can say that when choosing such a building material, production standards, dimensions, weight, aluminum oxide content and density should be taken into account. https://www.youtube.com/embed/Dn5APA4JuTQ

We recommend studying – Fashionable interior in Art Deco style

How to choose a brand of brick

In the construction of home stoves and fireplaces, quartz and fireclay red bricks are used. The last option is the most popular, since quartz at high temperatures changes its structure, thermal conductivity and volume - and this leads to destruction of the walls.

- Refractory red brick is designed for temperatures of about 1000 °C. Frost resistance is important for this material - especially for laying country stoves that are heated irregularly. The labeling must include the designation F35 (at least 35 freezing and thawing cycles). The size of the red stove brick is 250 x 120 x 65 mm.

- Fireclay brick. In addition to strength, this material is characterized by rapid heating and long-term heat retention. The most popular brands are SHA-5 and SHA-8. The letter A indicates the maximum permissible temperature (1400°C). ShB-5, ShB-8 can withstand 1350 °C and are noticeably cheaper.

Kiln brick size, standard and its requirements

A separate document has not been developed for bricks for stoves; there is only GOST 8426-75, which stipulates the dimensions and shape of clay bricks for chimneys. According to this standard, two standard sizes of straight brick are installed:

- single – 250 x 120 x 65 mm;

- thickened – 250 x 120 x 88.

Maximum temperature

The operating conditions of fireplaces and household stoves require direct contact of the brick with an open flame. In this case, the chimney pipes come into contact with very hot carbon monoxide gases. In this regard, materials that are resistant to high temperatures must be used for the construction of furnaces. Standards for each brand of brick are determined by GOSTs.

We advise you to study - Types of lining for interior and exterior decoration

The highest heat resistance is characteristic of various brands of fireclay bricks - the temperature range is 1633-1730 ℃. It is noteworthy that the requirements for other structural elements of the furnace are also high. In particular, materials for chimneys must be designed to withstand temperatures of at least 700℃.

Types of bricks according to manufacturing technology and materials used

The use of bricks for laying stoves largely depends on what material and technology the bricks were made from. The fact is that the use of solid, perfectly shaped bricks is not always advisable in laying stoves. A striking example of this is sand-lime brick.

When choosing which brick is best for building a stove, sand-lime brick is clearly not the favorite. Everything is quite simple here - this material is made from a mixture of quartz sand and limestone. During production, the material goes through a process of cleaning, molding and drying. The resulting structure meets all the parameters of the wall material. But alas, it is not worth using it for folding stoves. The ideal shape of the edges and corners does not fit well with clay, and the structure turns out to be fragile. When temperature changes, silicate changes its structure and begins to delaminate. Literally a few cycles after cooling, the brick begins to intensively absorb moisture, and during the heating process, intense evaporation only intensifies the delamination process. Silicate does not have sufficient heat capacity, so when heated it will require a large amount of heat to warm up, and then it will cool very quickly. Another disadvantage of sand-lime brick is its hygroscopicity - it is not suitable for foundation construction, it very quickly begins to absorb moisture and lose its strength.

Hyperpressed brick

This type of wall material is distinguished by its strength and durability. The basis for production is the fine fraction of rock screenings - marble, shell rock, limestone or dolomite. The binder is Portland cement. The process of molding and drying produces a material with high density and the ability to withstand up to 100-150 freeze-thaw cycles. The blocks are distinguished by the fact that during the molding process, edges with almost any texture can be obtained. But this material also finds limited use in the construction of furnaces. There are several factors precluding its use:

- Hyper-pressed brick is not used for laying stoves, first of all, because it is absolutely not a plastic material. When heated, it cannot withstand the heat load and simply bursts. And when lining the stove, it does not withstand shrinkage and cracks in the masonry;

- Just like silicate, this material loses its properties when heated - limestone begins to release carbon dioxide, and when cooled, it actively absorbs moisture;

- Bricks of this type are mainly produced in the M250 or M 300 grade; they are durable but too heavy, so they are absolutely not suitable for laying a chimney or firebox.

True, hyperpressed brick can be successfully used to decorate garden hearths and barbecue ovens. Here he will serve for many years.

Ceramic brick

Historically, it was this type of brick that was used for laying stove structures.

The main raw material for the production of ceramic bricks is clay. As with masonry mortar, not all types of natural clay are used for brick molding. Most often, fired ceramic bricks are used for laying the base, outer walls of the firebox, chimney, and decoration. For all structures, exclusively solid bricks of the M-150, M-200, M-300 brands are used. Solid blocks must not only have correct geometric shapes and uniform color; when broken, the inner part must be uniform in both color and texture, and the outer part without cracks. As for frost resistance, the blocks must withstand at least 35 freeze-thaw cycles.

The only place where it is not recommended to use red solid brick is at the ends of chimneys. In any case, without external masonry made of clinker or facing bricks.

When considering which brick is best for masonry, it is necessary to remember that red ceramic bricks differ in manufacturing technology, which determines its quality characteristics. Raw brick, made by atmospheric drying, is unsuitable for kiln work. It cannot withstand temperature changes, has a heterogeneous structure and does not have the necessary strength qualities.

What kind of brick should the stove be made of?

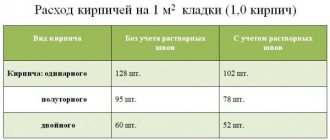

Ceramic brick is a brick obtained by firing clays and their mixtures in a kiln. In the Russian Federation, the following are produced: - single brick of standard size: 250x120x65 mm, - one-and-a-half brick of standard size: 250x120x88 mm. According to their purpose, ceramic bricks are divided into ordinary, facing and oven .

The fact that ceramic brick is called “ red ” is more a tradition than a real reflection of reality. Now, in addition to the standard red-brown, “brick”, there are options for white, apricot and even yellow brick - everything will depend on the clay. But, speaking about the color of bricks, it must be said that for construction it is better to immediately purchase a ready-made batch from one manufacturer, so that later you do not have to look for the same shade. Often, everyone's color scheme is a little different.

To save money and time on construction, so-called double brick is often used. Its dimensions differ from the standard single brick in height by a factor of two: single brick 250-120-65 mm, double – 250-120-138 mm. There is also an intermediate option - one-and-a-half brick (250-120-88 mm).

How to recognize a fake?

Obviously low-quality brick contains various impurities (for example, large pieces of limestone or stones). In the future, this can have a bad impact not only on the appearance of the house, but also on its safety. Also defective in ceramic bricks is “underburning”. It is easy to detect: an incorrectly fired brick makes a dull sound when struck and has a mustard color. .

Ceramic brick can be used almost everywhere: when laying foundations, erecting load-bearing walls and interior partitions, in stoves and fireplaces (except for those places where there is direct contact with fire), for cladding buildings and their interior decoration. At the same time, it is resistant to various external negative influences, which is time-tested. It’s not for nothing that, being one of the oldest building materials, it has survived to this day.

Refractory brick – white, smooth brick: – made from refractory clay, – having great strength and increased fire resistance, – used in furnaces for lining the inner surface of the firebox

Ordinary “red” (clay) brick cannot withstand intense heat. At a temperature of “white heat” (1200°C) it melts, and when cooled it crumbles. True, in an ordinary room oven the temperature does not exceed 800°C, and therefore in its manufacture it is possible to do without refractory materials. But if we take into account the high thermal conductivity coefficient of refractory brick and, accordingly, its ability to perfectly accumulate and release heat, then we will give preference to it in the manufacture of fireplaces and stoves in bathhouses. The beautiful appearance of geometrically regular, smooth, light brown or straw-yellow bricks with brown inclusions is also important.

In industry, at temperatures reaching 1400° and even 1800° (necessary in metallurgy, glassmaking, porcelain firing), refractory brick is indispensable. It is used to make vaults, floors, thresholds of blast furnaces and other special furnaces, in which oil, flammable gases, and pulverized fuels burn in an oxygen-depleted atmosphere.

To ensure that refractory bricks do not crack during firing, up to 70% chamotte (fired refractory clay) and sometimes coke or graphite powders or large quartz grains are added to their composition. This is how different types of refractory bricks are obtained, intended for different purposes. The choice of one type or another is determined not only by the temperature for which it is intended, but also by the chemical properties of the incandescent substance, as well as the properties of the ash or fuel.

There are four classes of refractory bricks: quartz, alumina (fireclay), basic and carbon.

Quartz brick is used where the walls of furnaces come into contact only with flames or metals. It does not tolerate contact with alkalis, lime, and iron oxides. Usually, the vaults of reverberatory stoves (for example, fireplaces) are made from it. Unlike ordinary brick, it is homogeneous and does not contain cavities. Consisting of pure sandstone or quartz cemented with a small amount of clay, after firing, this brick acquires properties close to natural sandstones.

Fireclay brick . As the name suggests, it contains a much larger amount of clay. Fireclay bricks resist the action of alkalis, such as lime, better than quartz bricks. It also withstands rapid temperature changes better. Refractory bricks of this class are easy to manufacture and therefore the most common. They are used where the temperature does not exceed 1000-1300° C.

Basic bricks (from the chemical term “bases”). Lime-magnesia fire-resistant masses are used in metallurgy - in the production of Bessemer steel from phosphorous ores.

Carbon bricks are used only in special industrial areas. In its simplest form, it is compressed graphite or coke used in blast furnaces.

As you can see, for household purposes it is best to use fireclay bricks, marked with the letter “Ш”. Subsequent designations in their brands determine the sizes.

For example: Straight brick – Ш-5, 230 ¤ 114 ¤ 65, Straight brick – Ш-8, 250 ¤ 124 ¤ 65, Straight brick – Ш-8, 250 ¤ 124 ¤ 65,

In addition to straight bricks, other forms of bricks are also produced, for example wedge-shaped, used for laying semicircular arches and vaults of various radii of curvature.

Its dimensions and brands are as follows: End wedge - Ш-22, 230 ¤ 114 ¤ 65/55, End wedge - Ш-23, 230 ¤ 114 ¤ 65/45, Rib wedge - Ш-44, 230 ¤ 114 ¤ 65/55 , Rib wedge – Ш-45, 230 ¤ 114 ¤ 65/45.

Remember that when laying refractory bricks, particularly careful grinding is necessary so that the seams are as thin as possible. The bricks are held together with a solution of refractory clay, to which crushed refractory brick is added.

Think for yourself, decide for yourself, but refractory brick is better for laying stoves. Maybe in your case “red” will do, because... everything will depend on the conditions and duration of operation.

Rejection and selection

Bricks that are clearly unsuitable for the kiln are discarded. signs, see figure:

- With dimensions that do not correspond to the module.

- Apparently cracked, with strong burrs and burrs from cutting, with foreign inclusions - left pos.

- Heavily burned, very dark, swollen, warped, with spots appearing on the edges - average position.

- Having traces of gas release during firing in the form of rounded shells (cavities) with a smooth inner surface, right pos.

Defective stove bricks

Note: for fireclay bricks, it is permissible to have up to 4 shells per brick, but no more than 1 per face, see fig.

Types of bricks

Ceramic bricks are sorted as follows, see next. rice:

The first grade (on the left in the figure) is moderately annealed brick with sufficient density, quantity and pore size. The surfaces are smooth, the color is bright, saturated, from pure red to slightly yellowish. The sound when tapped with a 50-gram hammer is metallic ringing. Cut marks – no burrs; the edges are not crumbling. Iridescent spots or a continuous film are often visible on the edges (this is the surest sign).

The second grade (in the center) is slightly under-burnt. Frost resistance is weak, porosity is increased, heat capacity is less than that of the 1st grade. Signs: a larger number of tons (up to 420 pieces versus 320-340 for the 1st), unsaturated color (pale brick). The sound when tapped is clear and short, but somewhat muffled. Shallow nicks from the cut and some chipping of the ribs are acceptable. There is never a rainbow film; if it is, then from polymer plasticizers; such bricks are discarded.

The third grade (on the right in the figure) is moderately burnt. It is dense (240-290 pieces per ton), but has little porosity and conducts heat too well. Poorly frost-resistant, but suitable for foundations. It is very strong in compression, but does not hold other loads well. Signs: dark deep to brown color. It rings when tapped, but the cut is jagged and the ribs are often crumbled.

Note: burnt bricks are often sold under the general name “iron ore.” But, as we see, in a furnace, iron ore differs from iron ore.

About the rejection of fireclay

The surest way to reject fireclay bricks is to drop them from a height of about 1 m onto the stone floor. The good one breaks up into large fragments; bad - crumbles into a bunch of small ones. In production, fireclay is sometimes checked this way, selectively several pieces from a batch. Then the merchant will not allow anyone interested in selling his goods. In this case, you should be guided by the following algorithm:

- If you run your fingers across the ribs, the brick does not crumble or become dusty - it is suitable for further inspection.

- The ringing sound when tapped is quite long - 1st grade, suitable for any firebox, incl. furnaces with intense thermal conditions: bell furnaces, Kuznetsov furnaces.

- The sound is clear, short, abrupt - 2nd grade, suitable for other fireboxes.

- The sound is dull - marriage.

What is the best way to finish?

If the stove has an independent meaning as part of the interior design, then it is best to use plastic-molded facing bricks to decorate it. It is almost always 2nd grade; this is exactly what is needed for the stove shell. When building a new furnace, the facing bricks are simply laid on the outside. Then the finishing happens by itself, and 3 birds with one stone are killed at once: the stove breathes deeply, takes on the appearance, as long as the seams are neatly cut, and comes out durable, because All seams are tied properly.

If you are covering an old stove, then you don’t have to think about bandaging the seams of the masonry with the lining, if only because the old ones have dried out. But the “thermal kicks” will eventually do their job and the lining will begin to peel off. Previously, in such cases, the stove was first lined with unglazed tiles on lime mortar, and on top of it - with bricks on the same mortar. The tiles played the role of a kind of damper. Now you can do it easier and cheaper: mix the masonry mortar of the cladding using the same aluminous cements.

What to cut with?

If you need to cut brick during the installation of the stove, it is best to use industrial stone-cutting machines . But since such a task is impossible at home, you can resort to an ordinary grinder . Cutting, abrasive or diamond discs are suitable for the job (the latter will last longer).

Before working with stone, you should make markings with a pencil. There are two ways to cut brick: dry and wet. When working with dry material, you need to be prepared for a lot of dust and stock up on a respirator and safety glasses in advance.

A cleaner process for cutting stone occurs if you first soak the building material in cold water for half an hour. The brick will become softer, more pliable and will not be bothered by dust.

Reviews from stove makers

Reviews and advice from experts relate to the technical characteristics of the material. If the stove is built according to all the rules and high-quality brick is used, then it will not create problems even in the distant future.

Temperature limit

Stove makers advise choosing heat-resistant materials for stoves and fireplaces, regardless of the place of use:

- for the installation of a firebox - 1800 degrees;

- for interior walls – 700-1200 degrees;

- for chimneys and pipes – 700 degrees;

- for cladding – 700 degrees.

Thermal conductivity

Solid stove brick has a high density and thermal conductivity, but each type has its own indicators under normal conditions (15-25 degrees):

- magnesite – 4.7-5.1 W/ (m*deg) at a density of 2600-3200 kg/m³;

- carborundum – 11-18 W/ (m*deg) at a density of 1000-1300 kg/m³;

- fireclay – 0.85 W/ (m* deg) at a density of 1850 kg/m³.

Experts advise choosing low thermal conductivity - this will make it possible to protect materials adjacent to the structure from high heat. Fireclay brick is capable of retaining heat, but at the same time its thermal conductivity is quite low. This material has the most positive reviews.

Resistance to aggressive environments

Based on reviews from stove makers, we can conclude that fireclay bricks react poorly to an acidic environment, so it should not be used where there is a risk of contact with acid. Quartz brick suffers from alkaline reactions - it is not used in places where it is planned to work with lime.

Water absorption

According to experts, the water-drawing effect of stove bricks is quite large. During firing, pores are formed in the stone that can accept moisture from the external environment. If a building material is left outdoors, in snow or rain, it can gain 30% of its original weight. Therefore, you should pay attention to the place where bricks are stored and exclude their contact with a damp environment.

Information about stove bricks will help you avoid making mistakes in choosing a building material. But even with theoretical literacy and complete study of the topic, it is better to entrust the construction of the furnace itself to a professional. Mistakes in such a matter can cost the health and lives of household members.

Types of kiln bricks

At the peak of the spread of stove heating, a wide assortment of stove bricks was used: hog brick, leschada, excise, mezhigorka, hearth - and many more specialized varieties. Today, two main ones remain from its former splendor: fireclay refractory brick and solid ceramic brick. Sometimes it is called kiln brick, but it is an ordinary solid ordinary brick of wet plastic molding, the so-called “red”. There are also very rare types, such as refractory Mstera products or clinker, but they are quite rare; the emphasis in the furnace business is not placed on them.

Actually, it is red brick that is interesting for household stoves. It resists heat well (withstands up to 1000 degrees) and stores heat well. It is also able to regulate the humidity in the room, absorbing excess water from the atmosphere of the heated room, which significantly improves the hygiene of the room. The trouble is that it is often difficult to choose a brick for laying a household stove. It’s just that such high-quality bricks are not required for general construction work. Something simpler is quite enough. Therefore, good stove bricks are quite rare.

If the stove is heated with high-calorie fuel (gas, coal, anthracite, etc.), the combustion of which produces too high a temperature (over 1000), then the firebox and a small area after it should be lined with fireclay refractory bricks, which can withstand heat up to 1600. Use fireclay brick and in the event that red brick of the required quality was not found for laying the furnace.

But here it is important to understand that household heating stoves are not made entirely of fireclay bricks for the simple reason that fireclay bricks have low heat capacity and thermal conductivity, noticeably inferior in these parameters to ordinary red ones. So, for example, the furnace of a Russian stove, which also works as an oven, should under no circumstances be made of fireclay - the stove will noticeably lose functionality

Actually, with fireclay everything is simple. It is easy to purchase, there are no problems with choosing. All fireclay products on the market have similar characteristics and a single production technology. Therefore, if fire-resistant brick is required, then they simply go and buy it. It’s more difficult to choose red ceramic.

Features of clinker

Brick made using clinker technology from highly melting grades of clay has great strength (more than M300) and frost resistance (more than F 100).

The specific features of clinker are indispensable when laying the base layer of the foundation and the internal chimney channel reaching the cap, provided that the cladding is decorated with a different material.

Making the main part of the stove out of clinker is an expensive and unjustified pleasure, especially since the structure will be massive and heavy.

If the owner plans to make a compact stove in a bathhouse, clinker brick will be an ideal material that will allow heating the space no worse than a thick-walled cast iron “potbelly stove.”

Short description

Refractory bricks for stoves are capable of not collapsing and deforming under the influence of high temperatures - the main difference from conventional building materials. It is made from several types of clay with the addition of substances that increase the heat resistance of products.

It is recommended to use several types of building materials when laying individual parts of the stove. To cover the outer layer, red ceramic or white silicate is used, and the firebox is lined with fireclay bricks

It is important to maintain the overall color scheme of the heater on the outside and inside

In order not to overpay, you should not buy parts with a grade above M-300 for a household oven. The digital value indicates the safety factor of the products. If the grade is below 100, the material is of poor quality with improper geometry and density of the material. M-500 bricks are used for laying industrial or powerful units.

We advise you to study - How to choose a spray gun - pneumatic or electric

How to avoid buying defective goods?

Refractory bricks are produced in accordance with GOST or technical specifications of enterprises.

Theoretically, defective products should not go on sale, although in practice different situations occur. Experienced craftsmen have their own methods for assessing quality. The most reliable, but not always acceptable, method is a unique method. You need to take a brick and drop it to the floor from a height of one meter onto a stone surface. If after the fall you get large pieces, it means the product is good. If a pile of small fragments forms, you should refrain from purchasing, although you will probably have to pay the cost of one brick.

The quality of brick products is clearly revealed when tapped. If the sound produced is quite clear and long-lasting, the product is good and corresponds to grade 1.

If, when tapped, the brick makes a clear, short sound, the product belongs to grade 2, which is also quite acceptable for most stoves.

If there is a dull sound, it is better to refrain from purchasing, because this is a sign of an obvious defect.

Purchasing refractory materials from manufacturers who specialize in this type of activity and have credibility with customers will avoid unpleasant surprises when laying stoves and their subsequent operation.