Any builder, when carrying out repair work, should always be confident in the quality of the purchased building material. A lot depends on this: how long the service life of the constructed building will be, seismic resistance, possible loads on the building, etc.

In recent years, bricks have become in great demand in construction. Due to its properties, this material helps to achieve durability, and unlike concrete structures, a brick building retains heat. Largely for this reason, this building material is used in the construction of residential buildings.

But this is provided that all technical characteristics are met during the production of bricks. The production of any construction product has its own standard called GOST. What is the state standard for ceramic brick 530 2012?

A number of advantages of brick include:

- the material can be used in various areas of construction: laying walls, fireplaces, stoves and other things;

- affordable price for the product;

- Thanks to different shapes and types, brick can be used to decorate the external facade of a building.

Required documents for ceramic bricks

When choosing a building material, the buyer must make sure that the bricks comply with generally accepted technical standards . For this, there are special documents that contain all the necessary information in detail:

- certificate of technical conditions or specifications;

- GOST certificate.

If the manufacturer has all the documents that the buyer can review, you can be confident in the quality of the purchased building materials.

What should be included in the content of the document? Any manufacturer issues a technical certificate based on the following points:

- technological process of brick production. It should indicate here what is included in the mixture, as well as a scheme for manufacturing the material;

- product safety, that no radioactive substances were used in its manufacture and the brick is safe and environmentally friendly;

- the environmental friendliness of the material guarantees protection of the environment and will not harm it;

- production control of product quality and reception procedures. This describes what kind of testing only the manufactured bricks undergo to evaluate their quality;

- technical data on how the material must be transported and stored;

- in what areas it can be used;

- manufacturer's warranty.

Taking into account the general rules for drawing up the document, the manufacturer has the right to independently draw up this document and, at its discretion, indicate the characteristics of the brick.

Therefore, there is no guarantee that the manufactured ceramic bricks comply with the standards. To be on the safe side, the buyer must make sure that the manufacturer has a GOST certificate.

This document is issued after a thorough examination of the produced material in specialized laboratories for a period of three years.

By carefully studying the GOST certificate, make sure that it is issued specifically for the products you need. The first three digits indicate the name of the product, the rest indicate the year in which the document was issued.

Certificate

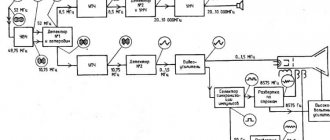

GOST 530 for ceramic stone and brick meets the requirements adopted in 2012 . And it looks like this.

Its content:

- document number and its validity period;

- name of the body that certified the product;

- a complete listing of the products that have been studied with full descriptions and technical characteristics;

- what exact requirements do ceramic bricks meet according to GOST;

- full name of the product manufacturer;

- to whom this document is issued;

- description of the documents on the basis of which the certificate was issued, research protocols;

- seal and signature of the responsible person.

Features of application

According to GOST 530-2012, brick and ceramic stone are best suited for masonry and cladding of various walls. Products intended for wall cladding are not recommended for use when laying building elements that are heavily exposed to moisture.

You should not use building bricks for laying fireplaces and stoves - there is a special fireproof material for this purpose.

When constructing chimneys, foundations and basements of buildings, it is recommended to use only solid brick.

It is prohibited to use hollow products when constructing the base of a building or basement walls in high humidity conditions.

Characteristics

The above-mentioned standard has been applied since 2013 and includes the following building materials:

- ceramic stones and bricks used for the construction of building walls and façade decoration;

Ceramic

- clinker bricks are used in the construction of foundations and strengthening of walls on which significant loads are planned. Here is the size of the red brick for the foundation;

Clinker

- kiln brick. Here is its size.

Pechnoy

Also, established standards divide bricks into characteristics:

- purpose of material . There are ordinary and facing bricks. The first is used when constructing walls with subsequent cladding with another material;

Private

- facing bricks are used only for finishing the external façade of walls. Here's about this brick. The color and texture of brick building material does not matter;

Facing

- the new GOST contains standards separately for solid and hollow characteristics;

- technical characteristics of ceramic bricks GOST 530 2012 also include differences in compressive strength from M100-M300. This characteristic indicates the ability of the brick to withstand heavy loads;

M-100

- the F number indicated in the document indicates resistance to sudden temperature changes and the number of cycles that the material can withstand from 25 to 300. But these numbers are not always the limit; some manufacturers, thanks to special technology, can achieve frost resistance of up to 1000 cycles;

- The standard also specifies the density that each product must comply with. All brick is divided into a number of thermal groups. Their characteristics range from highly efficient, with a density of 0.7-0.8, to low-efficiency, with a density of 2.0-2.4;

- It is necessary to match the dimensions of the brick. Only minimal retreat is allowed.

Here are some types:

- single brick dimensions – 250*120*65;

Single

- euro brick – 250*85*65;

Euro

- dimensions of one-and-a-half thickened - 250*120*88;

One and a half

- modular single – 250*138*65.

The names of each side of the brick and its purpose with characteristics (spoon, poke, bed) are also described.

Names of parties

As for the weight of the product, there are no restrictions or standards here; everything is left to the discretion of the manufacturer, and depends on the materials used in production.

There are some requirements for the appearance of ceramic bricks. They can be of any color and type, this directly depends on the additives included in the mixture.

Here are its pros and cons. As for defects, there should be a minimum number of them, for example, the presence of cracks on the facing brick indicates a defect.

Defective

If we take into account ordinary bricks, then there can only be two of them, otherwise the quality of the future structure will be significantly reduced.

A certificate of compliance with the Gost standard can be issued by any organization that has been accredited by Gosstandart.

For more information about the characteristics of ceramic bricks, watch the video:

Ceramic brick: technical characteristics

The new GOST began to operate in 2013; it applies to the following building materials:

- ceramic bricks and stones used for the construction and cladding of any walls;

- clinker bricks for the construction of foundations and walls subject to significant loads;

- brick, which is intended for laying stoves and chimneys .

In addition, current standards classify bricks according to different technical characteristics.

- Purpose : ordinary, used for rough construction of walls or facing. In this document there are no restrictions on the color and texture of stones.

- The new GOST defines solid, hollow bricks and additional elements.

- Ceramic bricks GOST 530-2012 vary in compressive strength from M100 to M300, this is the ability to resist any loads without destruction.

- Frost resistance is designated F with a number indicating the number of cycles withstood from 25 to 300. But these indicators are not the limit; some manufacturers achieve values up to 1000.

- GOST defines the density of each product . All bricks are divided into groups according to thermal characteristics: from high efficiency with a density of 0.7-0.8 to low-efficiency bricks with a density of 2.0-2.4.

- The dimensions are strictly defined , deviation from them is allowed only to a minimum, so the brick can be single with dimensions of 250x120x65 mm; “Euro” –250x85x65mm; thickened – 250x120x88; modular single – 250x138x65.

- The sides of a brick are also : what is a poke, a spoon and a pastel.

It is interesting that GOST does not provide regarding the weight the weight of bricks can be absolutely any. The requirements for appearance stipulate that the color and type of the front face can be any , the presence of defects should not exceed the specified values, so there should be no cracks on the front bricks at all, and two cracks are allowed on ordinary bricks. has been accredited by Gosstandart can issue a quality certificate in accordance with GOST .

Basic standards GOST 530 2012

Here are the main provisions of the GOST characteristics for bricks.

The density of the stone largely depends on the density of the class to which the building material belongs.

- 0.7 – up to 700kg/m3;

- 0.8 – up to 800kg/m3;

- 1.0 – up to 1000k/gm3;

- 1.2 – up to 1200 kg/m3;

- 1.4 – up to 1400 kg/m3;

- 2.0 – up to 2000kg/m3;

- 2.4 – up to 2400 kg/m3.

Permissible deviations in product density for class: 0.7, 0.8, 1.0 no more than 50 kg/m3. For other classes no more than 100k/m3. As for the thermal conductivity characteristics, they are assessed by the masonry coefficients in dry mode. The strength grade of a brick depends on the possible compression and bending of the product.

Characteristics

The moisture absorption of ceramic bricks can only be within appropriate limits - no more than 6%. The initial water absorption of the product should be in the range from 0.10 kg (m2*min) to 3.00 kg (m2*min). As for the facing brick for the facade of the building, there are no restrictions.

A mandatory criterion for characterizing the quality of ceramic bricks should be the frost resistance of the material. The product must withstand low temperatures even when completely saturated with water.

There should be no damage such as cracking, crumbling, peeling or chipping.

The coefficient depends on the values specified by the manufacturer from 25 to 300. Ceramics are recognized as a non-combustible material, so they must comply with this. The value of specific radionuclide activity should not exceed 370 Bkkg

Regarding the methods for testing the quality of ceramic bricks, they are also prescribed in GOST standards, and take into account a number of requirements that the tested specimen must withstand in order to meet the quality.

All test results are indicated in the relevant documents, which are submitted for making a conclusion on the quality of the brick being tested.

Here are some points:

- compliance with the declared size : length, thickness, height;

- if the product is hollow, then the correspondence of the dimensions of the voids is acceptable during production. To determine void size, at least three cavities are measured and the largest value is recorded.

GOST standards

The characteristics of GOST 530-2012 include many parameters. It is worth highlighting several main points:

GOST 530-2012

- density - depends on the class indicator of the building material (for example, 0.8 - up to 800 kg/m3);

- thermal conductivity - according to GOST, is assessed exclusively in dry mode;

- strength - its determination is influenced by the possibility of bending and compression of the product;

- moisture absorption - this parameter of quality products does not exceed 6%;

- frost resistance - ceramic material must withstand the lowest possible temperatures.

GOST specifies methods for testing bricks to determine quality. During testing, the compliance of the declared dimensions of the voids and the product itself must be determined. After all requirements are met, the building material with the certificate is ready for sale and further use.

Related video: Ceramic brick - its pros and cons

Publications on the topic

Standard sizes of one and a half bricks

Overview of the capabilities and technical characteristics of the Akros 530 combine harvester

Pros and cons of ceramic bricks

Production and properties of technical bricks

In many ways, technical indicators of product quality depend on production methods, so it is worth paying attention to this point. Each manufacturer uses its own method for producing ceramic bricks.

There are two popular production methods:

- plastic . When using this method, a plastic method of brick formation is used. Clay is used in production, the humidity of which should be no more than 30%. The bricks are formed on special equipment, and then they are sent under a belt press;

- When the pressing process is completed, the product is sent to a special oven for subsequent firing. This is how ceramic bricks are made;

Firing in a kiln

- semi-dry method. Here a press is used to shape the future brick. Clay is used as the raw material, whose moisture content should not be higher than 10%.

Classification – hollow and solid

When choosing ceramic bricks, you should decide what type you need. The buyer is offered a number of possible options to choose from:

- solid brick GOST 530 2012. Here is its size;

Full-bodied

- hollow brick GOST 530 2012.

Hollow

So solid brick is a strong material, but has more weight. Therefore, the final structure will weigh significantly more than the same structure in the construction of which hollow building materials were used.

Weight characteristics are of great importance during construction. Therefore, more and more construction companies are using a version of hollow ceramic bricks during construction, with the same characteristics as solid ones.

GOST 530_2012 Brick

GOST 530-2012

Preface

The goals, basic principles and basic procedure for work on interstate standardization are established by GOST 1.0-92 “Interstate standardization system. Basic provisions" and MSN 1.01-01-2009 "System of interstate regulatory documents in construction. Basic provisions"

Standard information

1 DEVELOPED by the Association of Ceramic Materials Manufacturers (APKM), Limited Liability Company "VNIISTROM Scientific Center of Ceramics" (VNIISTROM NTsK LLC)

2 INTRODUCED by the Technical Committee for Standardization TC 465 “Construction” 3 ACCEPTED by the Interstate Scientific and Technical Commission for Standardization, Technical Norms

regulation and conformity assessment in construction (Addendum 1 to Appendix B of Protocol No. 40 of June 4, 2012)

The following voted for the adoption of the standard:

| Short name of the country | Country code according to MK | Abbreviated name of the national government agency | |||

| according to MK (ISO 3166) 004-97 | (ISO 3166) 004-97 | gift construction management | |||

| Azerbaijan | AZ | State | Committee | urban planning | And |

| architecture | |||||

| Armenia | A.M. | Ministry of Urban Development | |||

| Kazakhstan | KZ | Agency for Construction and Housing | |||

| utilities | |||||

| Kyrgyzstan | KG | Gosstroy | |||

| Moldova | M.D. | Ministry of Construction and Regional Development | |||

| Russian Federation | RU | Ministry of Regional Development | |||

| Tajikistan | T.J. | Agency for Construction and Architecture under the Government | |||

| quality | |||||

| 4 This standard | corresponds to: | ||||

EN 771-1:2003 Definitions concerning wall stones – Part 1: Brick regarding requirements for average density, voids, thermal properties, rate of initial water absorption, acid resistance;

EN 772-1:2000 Methods of test for masonry units - Part 1: Determination of compressive strength;

EN 772-9:1998+A1:2005 Methods of test for masonry units - Part 9: Determination of volume and percentage of voids and net volume of clay and calcium silicate masonry units by sand filling (Test methods for building blocks - Part 9. Determination volume and percentage of voids, as well as net volume of ceramic bricks and silicate blocks by filling with sand);

EN 772-11:2000+A1:2004 Methods of test for masonry units — Part 11: Determination of water absorption of aggregate concrete, autoclaved aerated concrete, manufactured stone and natural stone masonry units due to capillary action and the initial rate of water absorption of clay masonry units (Test methods for building blocks. - Part 11. Determination of capillary water absorption of building blocks made of concrete, autoclaved cellular concrete, artificial and natural stone, initial water absorption of ceramic bricks) regarding the method for determining the rate of initial water absorption.

| 5 By order of the Federal | technical regulation agencies and | metrology from | |

| December 27, 2012 No. 2148-st | interstate standard GOST 530-2012 was put into effect as | ||

| according to the national standard of the Russian Federation from July 1, 2013 | |||

| 6 INSTEAD GOST 530-2007 | |||

| Information about the entry into force (termination) of this standard and amendments | |||

| opinions on it are published in the “National Standards” index. | |||

| Information about changes | to this standard is published in the index (catalog) | ||

| "National Standards" | and the text of the changes is in the information signs | "National | |

standards." In case of revision or cancellation of this standard, the relevant information will be published in the information index “National Standards”

Standardinform, 2012

In the Russian Federation, this standard cannot be fully or partially reproduced, replicated and distributed as an official publication without permission from the Federal Agency for Technical Regulation and Metrology

II

Price offer

The availability of brick products makes this material more popular in the market than others. Many brick factories offer their products, so if you need to purchase a large batch of goods, you can contact the factory closest to you and place the appropriate order.

When a large batch of bricks is purchased, the factory may provide free delivery , please check this before purchasing.

The price of the products depends on the type of ceramic brick you need. For example, facing material will cost much more than ordinary ordinary brick. Here is the size of the facing brick. The brand of brick also affects the cost, so high-quality products are more expensive than low-quality ones, by 30% on average.

The cost of the most inexpensive standard brick starts from 6 rubles. per unit, but it may vary depending on the region. Here is its size. The price for facing will be from 15 rubles , if you purchase the most expensive imported one, then the cost will be from 40 rubles per piece.