Undoubtedly, internal partitions can be built the old fashioned way - from brick or thick blocks. GCR looks more attractive in terms of speed of construction, but the material does not have excellent strength and sound insulation.

slabs remain a common option.

, which has long been used very well in residential and commercial construction.

What are tongue-and-groove slabs made of and what are they?

If we talk about tongue-and-groove slabs as special wall materials, then there are two types.

Gypsum tongue-and-groove slabs

Please immediately clarify that the tongue-and-groove slab absolutely meets eco-friendly requirements. security. The key element during manufacturing is considered to be cement and gypsum of grades G-4 and G-5, which are classified as environmentally friendly. The composition contains additives that increase reliability and water resistance.

According to the manufacturer's advice, the length of the wall should be no more than 6 m. The largest height of the structure is 3.5 m. Then the swing is guaranteed. reliability of the partition.

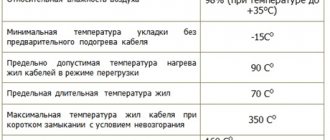

Physical and technical properties of gypsum materials

The technical properties of the tongue-and-groove slab may vary, depending on the raw materials used and the structure of the finished partition block (hollow and solid). However, when purchasing, you can be guided by these parameters:

| Index | Unit change | Plates according to specifications | |

| Conventional TU5742-007-16415648-98 | Hydrophobized (moisture resistant) TU5742-014-03984362-96 | ||

| Density, no more | kg/m³ | 1250 | 1100 |

| No more water absorption | % | 26-32 | 5 |

| Slab weight | kg | 24 | 29 |

| Compressive strength limit | MPa | 5,0 | |

| Strength limit in bending | MPa | 2,4 | |

| Thermal conductivity index, λA Thermal conductivity index, λB | W/m °C | 0,29. 0,35. | |

| Specific productive activity of radionuclides, no more | Bq/kg | 370 | |

| Soundproofing | dB | 43 | |

| Flammability | group | NG | |

Gypsum moisture-resistant boards

Traditional tongue-and-groove slabs are used to construct partitions or decorate walls in dry or normal moisture levels. For rooms where there is humidity, special moisture-resistant boards are needed, which are easily distinguished by their distinctive green color.

This point should first be taken into account when purchasing material. If you place an ordinary tongue-and-groove gypsum board in a humid environment, the partition will “crawl” over time.

Dimensions of gypsum slabs

Before starting work, it is important to calculate the amount of material for construction, otherwise even practically cheap tongue-and-groove slabs lose their material appeal. With tongue-and-groove slabs everything is very easy and looks like this:

| Technical conditions | dimensions , mm | Number of slabs in 1 m? | ||

| Length | Width | Thickness | ||

| Conventional TU5742-007-16415648-98 | 667 | 500 | 80 | 3.0 |

| Hydrophobized (moisture resistant) TU5742-014-03984362-96 | 900 | 300 | 80 | 3.7 |

Possible deviations from the nominal dimensions: length ±3mm; width ±2mm; thickness ±1mm.

- Whole slabs per 1 m3 – 37 pcs.

- How many on a pallet – 32 pcs.

Weight of gypsum boards

Due to the standard size, the weight of the tongue-and-groove slabs is also reduced to uniform values. Especially:

- Standard and moisture-resistant solid slabs naturally weigh 24 and 29 kilograms.

- The lightweight version (hollow) weighs 22 kilograms.

Thanks to these parameters, installation can easily be carried out by one person.

Silicate tongue-and-groove slabs

Due to the presence of large players in the market and available raw materials, wall boards of this type are more affordable than gypsum boards ( the profit is more than 100 rubles per 1 m2 ). They can be used in rooms with high humidity, and their remarkable geometry makes it possible to do without plaster.

The slabs, like white brick, are made from quartz and quicklime using the pressing method. Such boards have a higher density than gypsum boards, which, on the one hand, gives a very high thermal conductivity coefficient, and on the second, very high strength.

Technical properties of silicate partition slabs

- Density – from 1225 to 1870 kg/m? (depending on emptiness).

- Reliability – M 150.

- Thermal conductivity index is about 0.045 W/(m*C).

- The airborne noise insulation index is from 47 to 52 dB.

Dimensions and weight Silicate tongue-and-groove slab

These slabs have good geometry, but the overall dimensions

samples manufactured by various companies may differ slightly (see table below).

The dimensions

of the slab are slightly smaller than those of gypsum.

| Manufacturer | dimensions , mm | Weight, kg | Number of slabs in 1 m? | ||

| Length | Width | Thickness | |||

| Silicate plate "YAZSK" | 498 | 248 | 70 | 15,3 | 8 |

| Silicate slab (hollow) “YAZSK” | 498 | 248 | 70 | 14,5 | 8 |

| Silicate plate "YAZSK" | 498 | 248 | 115 | 19,5 | 8 |

| Silicate slab (hollow) “YAZSK” | 498 | 248 | 115 | 18,2 | 8 |

| Silicate plate JSC "KZSM" | 500 | 250 | 88 | 20 | 8 |

The material with a thickness of 115 mm is recommended by manufacturers to be used as inter-apartment.

- Quantity on pallet 54 pcs.

- Glue consumption ~ 50 kg per 1 pallet

Types of construction tongue-and-groove slabs: solid and hollow (porous)

It is recommended to install partitions made of hollow slabs on wooden logs (see photo). Will the wall stand on a concrete base and support a heavy mezzanine? Then full-bodied material is your choice!

Both gypsum and silicate slabs are replenished in two ways: solid and porous (hollow). Simple Stove

made in the shape of a solid parallelepiped and is considered very strong. Porous due to empty spaces has better sound insulation and low weight.

Tongue-and-groove slabs are highly rated by builders with extensive experience and are in steadily growing demand. However, there are no wonderful building materials. Thanks to this, we will consider the important advantages and disadvantages of wall slabs.

Why know the weight of a tongue-and-groove slab?

The question of knowing the weight of tongue-and-groove slabs is more rhetorical than practical. The weight of any building material needs to be known to select delivery vehicles, calculate the load on the floor, purchase fasteners and determine labor costs when working with it.

For example, you chose siding to decorate and protect the facade of your house. Vinyl siding panels have excellent characteristics, easy to install, durable material with one excellent parameter - it is lightweight. Even with large volumes, heavy equipment is not needed to deliver it. The same can be said about GGP slabs. They weigh much less than brick or stone blocks.

The weight of tongue-and-groove slabs is also important because PGPs are more often used in the renovation of premises and are installed on existing floors, which may well have load restrictions. In addition, PGPs are produced in different types and brands, and the weight of the slabs from different manufacturers may differ, which you do not need to know when purchasing them.

Advantages and disadvantages of slabs for installing partitions

Positive traits:

- Relatively small thickness and weight.

- Large strength reserve of the material and reliable design of fastening the plates.

- Fire safety.

- Immunity to any microflora: fungus and mold. The opinion that they can arise in the middle of hollow slabs has not yet been proven.

- Simplicity in finishing: the slabs can be cut with an ordinary hacksaw.

- High speed of the installation process: The tongue-and-groove slabs are joined using the tongue-and-groove principle (construction time is 20% higher than brickwork).

- Minimum seam thickness (only 2mm).

- Financial benefit when compared with other materials.

Flaws:

- Not suitable for the construction of supporting wall structures.

- Relatively low sound insulation.

- When the concrete base drops by 3mm or more, a leveling layer is needed.

- Subsidence of the base plate and/or walls can lead to the collapse of the entire partition - the structure should be insulated with a specialized elastic (damper) tape.

As can be seen from the comparative analysis, the tongue-and-groove slab material has its own specifics, which should be taken into account during installation.

Read more about the advantages and disadvantages of the material in this article >>>

Types of construction PGP: solid and hollow (porous)

The construction of wooden logs requires the use of hollow blocks. If the structure will be fixed on a concrete base, heavy decorative items and shelves will be hung on it; it is necessary to choose more reliable solid slabs. They are stronger, of higher quality, and can withstand significant loads.

Slab blocks made of silicate or gypsum are produced in two variations: hollow and solid. The standard slab is produced in the form of a solid parallelepiped blank, characterized by high strength. The porous structure of the voids increases the soundproofing characteristics of the partition with a small mass of one block.

Tongue-and-groove slabs are popular in the construction industry due to their advantages and accessibility. But they also have negative characteristics.

How to stick, plaster, prime and paint so that everything doesn’t fall off

Which glue to choose for a good installation process

This type of material requires a special glue, which will not only simplify the work, but also ensure the strength of the structure. There are several proven brands of adhesive compositions on the market that are suitable for installing tongue-and-groove partitions. In particular, the boards can be glued:

- Volma-montage

- KNAUF FUGEN (Knauf Fugenfueller)

- WEBER. CEL GIPS

- IVSIL PLAST

- BOLARS Gypsum contact

Average glue consumption

There are no clear indicators, but it is better to stick to the proportion of 1.5 kg/m2 or, as mentioned above, ~ 50 kg per 1 pallet.

How to plaster a finished wall

Another recognized positive quality of the tongue-and-groove slab is the absence of the need to plaster the walls. The slabs have a smooth structure, thanks to which, with carefully sealed joints, finishing can be carried out directly on the base. If there is a need to plaster the walls, and this only happens if, for example, chips have arisen from a sloppy installation process, then a regular mortar of cement and sand is more suitable. It is better to use gypsum-based plaster, rotband, concrete contact or finishing layer.

How to prime the surface

The surface is primed to increase adhesion. To do this, you can use an ordinary primer, which is applicable for blocks based on gas silicate and similar materials. The author of the publication had to use Tiefgrund, an acrylic-based primer mixture, to treat a gypsum wall before wallpapering, with excellent results.

Painting walls

The tongue-and-groove board can be painted with water-based, oil-based, polyurethane, resin, and epoxy resin-based paints containing polymer materials. Limestone paints and paints based on liquid glass cannot be used.

Time-tested manufacturers

Tongue-and-groove slabs are available in a very large assortment. Thanks to this, we provide a list of well-known manufacturers whose products you should trust.

- KNAUF . A German company specializing in the production of dry mixes and building materials. The tongue-and-groove slabs from this manufacturer are distinguished by their full geometry, which makes installation very convenient. The thickness of the products varies between 80-100 mm. It must be emphasized that this is the highest quality and very expensive product on the market.

- Volma . Volgograd enterprise, whose products occupy more than 40% of our building materials market. The manufacturer produces standard and water-resistant tongue-and-groove slabs, 80 mm thick. In essence, this is a good replacement for the previous manufacturer, which attracts consumers with its affordable price and good quality.

- LLC "Magma " This is a relatively young manufacturer that announced its existence in 2012. The company uses proven technologies and modern equipment for the production of tongue-and-groove slabs. The main positive quality of this company’s products is considered to be the production of its own glue, which in most cases comes in a set with the slabs.

- JSC "Gipsopolymer" . A Russian company engaged in the production of dry mixtures for construction work since 1953. Using the accumulated experience, the company produces good tongue-and-groove slabs that boldly compete with Western analogues.

- GIFAS . This is a trademark of the Sverdlovsk Gypsum Products Plant. The company has been operating since 1959, and nowadays it specializes in the production of hollow and solid tongue-and-groove slabs, 80 mm thick.

The products of these companies absolutely meet international quality standards and Russian GOST standards.

Weight of tongue-and-groove slabs

Before talking in detail about the weight of the GWP, let us remember that the slabs are produced solid and hollow. There is no fundamental difference between these two types of slabs, except for the weight of the slabs. Also, a partition made of a hollow slab is more resistant to fire and convenient for laying hidden utility lines.

In addition to the design of the GGP slab, its weight will also be affected by the dimensions of the slabs. There is an obvious increase in the weight of the slab due to the increase in its size.

Weight of Knauf tongue-and-groove slab

GGP Knauf weighs:

- Moisture-resistant solid slab 80 mm thick, weighs 29 kg, weight 1 sq. meter of single-layer partition will be 87 kg.

- A standard Knauf slab with a thickness of 80 mm weighs 28 kg, the weight of a meter of partition is 84 kg.

- Moisture-resistant solid slab 100 mm thick, weighs 38 kg, weight 1 sq. meter of single-layer partition will be 114 kg.

- A standard Knauf slab with a thickness of 100 mm weighs 37 kg, the weight of a meter of partition is 111 kg.

Weight of Volma tongue-and-groove slab

- The Volma slab is hollow, 80 mm thick, weighs no more than 22 kg. Hollow slabs 100 mm are NOT produced by Volma.

- Full-bodied Volma PGP weigh: 80 mm thick - 30 kg, 100 mm thick - 36 kg.

- The moisture resistance of the slab does not affect its weight.

Rusean tongue-and-groove slabs

- The weight of 80 mm hollow slabs from Rusean is 20 kg, and moisture-resistant slabs - 22 kg.

- Solid Rusean slabs weigh: 80 mm - 28 kg, moisture resistant 80 mm - 30 kg, 100 mm slabs weigh 37 kg.

Installation rules

The installation of interior tongue-and-groove partitions begins after the construction of load-bearing structures. The work is carried out in the following sequence:

- The base is leveled and cleared of debris caused by construction work.

- The initial row of slabs is laid down, with glue first applied to the joint groove. The recommended seam thickness is no more than 2 mm.

- Further rows can be fixed to the surface of the walls with dowel nails or brackets.

- The remaining gap between the wall surface and the ceiling must be filled with installation foam or a specialized elastic tape must be installed.

- It is recommended to improve external corners with a perforated profile.

After the construction of the partition, grooves are made in it for wiring, switches and sockets, puttied and finished.

How to cut material

- Angle Grinder . It will cope with the task, but it will be quite noisy, dusty and unsafe. First of all, you need to spend a couple of minutes studying the publication about this wayward tool.

- Specialized hacksaw . If you don’t mind the tool, then you can use an ordinary one, but it’s better to buy a specialized high-hardness saw with a self-sharpening tooth.

- Electrobrick . If you don’t have anything else at hand, it will do, but it requires qualifications. Even with an excellent canvas, the cut noticeably “walks.”

We hope that the note was useful to you. We are always happy to receive feedback through the contacts listed on the “About” page. Good luck on the construction site!