General description of the substance brand

The use of concrete of this brand is the most optimal option in terms of price/quality ratio if the process of concreting a monolithic frame structure, arrangement of paths, platforms, or construction of buildings is underway, regardless of how many floors are planned to be built. Purchasing this mixture is also easy. The price for 1 m3 will vary depending on the quantity, quality and what kind of admixtures were used as additional components. B20 concrete is quite easy to mix even at home. The only thing that is important to consider is the change in proportions, since this raw material is quite sensitive to them.

Scope of application of concrete M250 B20

The use of M250 concrete is varied and applies to:

Helpful information:

- How to make decorative plaster for concrete

- Sand-gravel concrete (SGMC)

- What is Art concrete (decorative plaster)

- Concrete grade M300 - characteristics

- Polystyrene concrete - characteristics and scope of application

- Metal tile Monterrey: technical characteristics

- Flights of stairs, building floor slabs, reinforced concrete products, curb and paving slabs.

- It is used to fill all types of foundations, platforms, erect walls, blind areas and paths in the garden;

- Roads, airfield runways, concrete foundations;

- Other special cases.

Jokes aside, b20 or b20 concrete has high compressive strength and is actively used in construction. Available for free sale in any store. For ready-mixed concrete, you can ask the seller for accompanying documents: passport and certificate of conformity. The document states that the material has been tested and meets the required standards. Today, this building material is not subject to mandatory certification. The procedure is voluntary, but having a concrete certificate will only confirm its quality. A concrete passport is a more detailed paper that accurately describes the characteristics of a given product.

Concrete grade M300 - characteristics

Composition of the substance

The composition of the brand of raw materials is the simplest - cement, sand, crushed stone, water. However, it is important to note here that the type of coarse aggregate may change, due to which the density of the final composition can vary between 1800-2300 kg/m3. Concrete will have the lowest density if expanded clay is used as a filler. The composition, which includes B20 slag concrete, has a medium density. The composition with granite crushed stone as a filler is characterized by the highest density.

Concrete B20 is a standard grade of concrete that belongs to the mobility class P2-P4. The standard strength for this brand is 28 days. It is also worth adding here that some manufacturers of this product replace a certain part of the solid filler with mineral additives. This makes the final composition more plastic, but it also increases the cost of the finished product.

Concrete mix composition

The technical characteristics of M250 concrete are defined in GOST 7473–2010. To make it you will need the following components:

- Cement is the main component, the quality of which affects the final parameters of the concrete mixture. To produce the solution, grades M400 and M500 are used. It is important to choose high-quality material in compliance with the terms of use, as this also affects the characteristics of the resulting mixture. It is recommended to use Portland cement, which will help obtain a solution with the best parameters. But you need to take into account a slight increase in the price of the finished composition.

- Clean water, for example, from a well.

- Coarse aggregate. Most often, crushed gravel is chosen for concrete due to cost. Granite, limestone or dolomite types of crushed stone are also suitable for mixing.

- Sand is a fine aggregate. Cleared of foreign particles, such as clay, which negatively affects the resulting solution. Quarry sand of the first and second classes is used, with a fineness modulus in the range of 2-2.5.

- Additives that improve the characteristics of the mixture, for example, antiseptics, sealants, etc.

Peculiarities

It is worth saying that b20 concrete is an intermediate composition. It is slightly better than the M200 grade, which is considered a cheap raw material and is not used for the construction of long-term facilities. But at the same time, M250 (M50) is somewhat worse in its characteristics, and therefore cannot be used as a foundation for objects characterized by heavy load, like M300. Among the advantages of the M250 brand, one can highlight the fact that it successfully combines the optimal ratio of substances. If the proportion of solid filler is large enough, then the maximum tensile pressure that it can withstand after hardening is 20 MPa. However, it costs less and is also more flexible and lightweight than premium brands.

Raw materials and their ratio

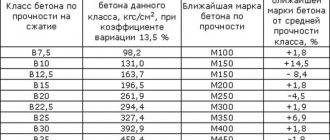

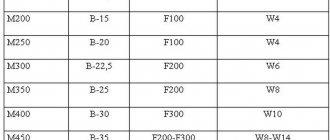

All technical characteristics and properties of the mixture directly depend on the composition of the material and the quality of the components used. Concrete B20 - what brand is it? Class B20 in strength corresponds to grade M250 and refers to heavy concrete. The density of concrete B20 varies from 2250 to 2400 kg per 1 m3.

In addition to strength, durability parameters are also determining for concrete: water resistance (w) and frost resistance (f). Material B20, made on dense aggregate, usually corresponds to grades w6 and f150-200.

Such designations indicate that a structure made from the M250 mixture is capable of withstanding at least 150 transitions through zero with complete freezing of water in the concrete body, as well as exposure to water under a pressure of 6 atmospheres.

Technical parameters of the material

Concrete grade B20 is characterized by the following technical characteristics. The strength level of raw material M250 is 260 kg/cm2. The frost resistance of concrete is within F150-200. It is worth adding here that this parameter can be increased artificially by adding more crushed stone from hard rocks to the composition, as well as introducing some strengthening additives. If we talk about the water permeability of the material, it ranges from W2 to W8. For example, there may be concrete B20 W6. This parameter can also be changed artificially if the necessary additives are introduced. As mentioned earlier, the density, as well as the weight of the substance, will directly depend on the selected solid aggregate. The mobility of the substance is P2-P4.

Properties and technical specifications

Concrete grade M250 does not have a high level of strength and belongs to class B20. The density of concrete is 2300 kg per 1 m3. Frost resistance is at an average level - F100, F150, F200. Mobility parameters are determined in the range P2-P4. Waterproof coefficient - concrete W6. The properties of a concrete mixture depend on aggregates and additives. Thus, granite mixture is the most durable. Compared to other brands, it has average characteristics in all respects, therefore it is used in different areas.

Where is the composition used?

The characteristics of B20 concrete have led to its main purpose being the pouring of monolithic foundations of any type. It is also successfully used for arranging blind areas, flights of stairs, lightly loaded walls and ceilings. The parameters of the material do not allow it to be used as a foundation, on which a high load is expected in the future. However, if you provide good reinforcement, you can build columns, foundation rings, and wells. The possibility of erecting the latter structure is possible due to the fact that b20 w4 concrete is characterized by good resistance to moisture and other aggressive environments, which is the main quality for the material used in the construction of a well. In addition, the use of this concrete is considered optimal if it is necessary to build a high-rise building. With its help, a monolithic foundation is poured. Another application is the production of reinforced concrete products, but for this it is necessary to use granite crushed stone as the main solid aggregate for the composition.

Technical description

What brand of concrete is B20? This is the M250. That is, if you see a solution with classification B20 or M250 on the shelves, keep in mind that this is the same thing. Now let's move on to considering its structure.

Structure

Components of concrete mortar

The amount of binder, water and fillers is regulated according to GOST 27006. Providing all the conditions in the specified document guarantees the appropriate quality of the solution.

Composition of concrete B20:

| Ingredient name | Purpose | Quantity required to create one cubic meter of concrete |

| Cement | Kamenea, connects all other components | 360 kg |

| Sand | Reduces porosity of the finished product | 536 kg |

| Crushed stone | Provides the structure with the necessary strength | 1141 kg |

| Water | Is a catalyst for the formation of cement stone | 133 l |

| Various modifying additives | Helps increase strength, frost resistance, water resistance | Depending on the attached annotation |

Advice: if the gravel used has a moisture content of more than one percent or sand has a moisture content of more than six percent, then it is necessary to reduce the amount of water used. Otherwise, the solution will turn out to be too liquid and with lower strength properties.

Elasticity

This is a very important parameter, which is responsible for how much pressure the finished structure can withstand. It is regulated by SNiP 2.03.01.-83, and the main determining factor is the size of the filler used:

| Average gravel size | Withstand pressure |

| 4 cm | 38.5 MPa |

| 8 cm | 41.5 MPa |

| 12 cm | 43.5 MPa |

Crushed stone is responsible for the elasticity index

Main settings

Technical characteristics of concrete B20:

- Frost resistance (F) . This is the ability to endure a certain amount of freezing and thawing without harmful consequences. BST V20 concrete is capable of withstanding one hundred such cycles. The use of special additives can increase this number to two hundred.

- The mobility of the concrete mixture in question is P2-P4 with a cone draft of about four centimeters.

- The average strength of this class is 262 kgf/cm2, which guarantees high resistance to any mechanical stress . It is noteworthy that 70% of its total value is gained in the first 28 days after filling and another 30% within six months.

Tip: after finishing the concreting process, it is recommended to cover the cement surface with plastic film and water it. This will improve the quality of setting.

Film-covered strip foundation to improve the strength-building process

- The specific gravity of B20 concrete is 2300 kg . It is very important to consider when using it to build walls.

- The density of B20 concrete is 2405 kg/m3 . But it should be remembered that this parameter depends on the performance of the solid filler and may change.

Sectional view of class B20 concrete block

- The moisture resistance of the material in question is W6 , but can be increased by adding modifiers to W.

- The price varies from 2800 rub. up to 3500 rub. Depending on the manufacturer and additives used.

Additional benefits

In addition to the fact that you will receive a reliable and durable structure that is resistant to any atmospheric conditions and mechanical damage, there are a couple more advantages to using B20 concrete:

- Availability of do-it-yourself concreting. The main thing is to prepare the formwork, install the reinforcement and order the required amount of mortar.

- Simple manufacturing instructions. To save money, you can use the proportions indicated above and prepare the desired mixture at home. It will, of course, be inferior in quality to the factory one, but it will be much cheaper.

Tip: if you decide to mix concrete yourself, it is recommended to do it using a concrete mixer. It will make your task easier and allow you to achieve the necessary uniformity.

Mixing the required solution in a concrete mixer

How to mix concrete M250

The solution is prepared either in a factory or at home using gravity concrete mixers. When producing M50 concrete, it is characteristic that the proportion of the binder element decreases, and at the same time the volume of mixing liquid increases. For this reason, in order to achieve the required strength of B20 concrete, it will have to be mixed thoroughly. In this regard, factory-made products always have an advantage over home-made ones. When preparing the mixture, it is best to use the following proportion: 1: 2.5: 4.6 (cement: sand: coarse aggregate). Naturally, cement is the basis for the solution. To prepare a high-quality mixture, it is best to take cement grade I/II 32.5 (the proportion of slag should be small).

An alternative option is Portland cement, which can also be used. The main requirement for any type of cement is freshness. If we talk about sand filler, then it is best to use river material with a particle size module of 2 or 2.5.

All the above proportions correspond to GOST 27006, which regulates the quality of the M250 (M50, b20) mixture. Generally speaking, to prepare 1 m3 of mixture you will need 536 kg of sand, 360 kg of cement, 1141 kg of crushed stone and 133 liters of water.

Composition of concrete M250 B20

According to GOST standards, a concrete mixture of 20 m250 should have only the following components:

- Cement m250;

- Gravel, granite chips or crushed limestone;

- Clean river or quarry sand without impurities;

- Water.

Beautiful concrete paths: step-by-step instructions and secrets

You can’t argue with GOST and conscientious manufacturers fulfill its requirements. But the composition of M250 concrete can be improved. To improve performance properties, anti-frost, waterproofing additives, dyes and other modifiers are added to the solution. They make the solution more obedient and pliable, and increase the density of concrete. The total amount can reach up to 5% of the composition of the mixture, but no more. This is not porridge that cannot be spoiled with oil.

Benefits and other indicators

The undoubted advantages of the composition include the following points:

- The use of the composition allows the production of prefabricated and monolithic structures for various buildings.

- The level of material costs for production is quite low, as local ingredients are used.

- It is possible to mechanize or automate the solution manufacturing process.

- It is characterized by high strength and fire resistance. Other important indicators can be increased depending on the requirements by changing the composition.

Another important factor that is often overlooked is convenience when placing concrete. This factor plays a decisive role if a concrete pump is used for laying. However, it is worth noting here that you will only have to use concrete b20, which belongs to class P4 in terms of its mobility.

How is it produced?

The concrete recipe for making M250 mortar is simple. It is important to maintain the correct proportions of materials. Then the output will be a high-quality solution, the technical characteristics of which meet the specified requirements. Before mixing the mixture, you need to prepare the materials: sand, cement, water, crushed stone and additives, in a ratio of 1: 2.1: 3.9.

If this ratio is correctly observed, the specific gravity of B20 concrete in the amount of 43 liters will be obtained from 10 liters of cement. To obtain a cube of the finished solution, use 330 kg of binder component, 740 kg of sand, 1.1 tons of crushed stone, 140 liters of water. The amount of mixture may vary depending on the quality of the components.

Binders and inert fillers

The composition of concrete M250 is usually written in kg per 1 m3 and consists of the following components:

- cement;

- sand;

- coarse aggregate;

- water;

- chemical additive.

Cement

Cement is the basis of the mixture; all the properties of artificial stone depend on its properties and consumption per 1 m3 of material. The most common in the construction industry are CEM cements of strength classes 32.5 and 42.5.

For the production of M250 concrete, it is more economically justified to use a binder with CEM I/II 32.5. In this case, the cement consumption at the most popular mobility P3 - P4 is at least 310 kg per m3, which fully ensures the specified grades for water resistance and frost resistance - w6 and f150.

Sand

Fine or medium sand of the first and second classes is most often used as fine aggregate. When using sand from a quarry, it is necessary to carefully monitor the clay content, because its presence significantly increases the water-cement ratio and reduces the quality of the material.

River sand most often has a small particle size, which increases the consumption of cement, and may also contain organic matter and silt particles as contaminants. The best option is to use washed quarry sand with a particle size modulus of 2 to 2.5.

Coarse aggregate

The coarse aggregate for class B20 concrete can be crushed lime and gravel or gravel in its pure form. If it is necessary to ensure water resistance at level w6 and frost resistance grade f150, crushed stone from dense rocks or gravel should be used.