How to decipher PPV wire

Each letter of a product means its properties and composition. The abbreviation PPV is very easy to decipher and can be read as follows:

- “P” – the first character means that this product is a wire (if the name does not contain the letter A, then the wire is made of copper);

- “P” – flat type of wire (without this sign the product would have a round cross-section);

- “B” - indicates the outer shell of PVC material;

- “ХЛ” – additional symbols that indicate that the wire can be used in different climatic zones (heat, cold).

What the product looks like

In addition to the letter value, the marking may contain numbers. Which means the cross-sectional area, the number of cores and the length of the product.

For example, we can cite the PPV 5x3-220 wire - this indicates that it contains five copper wires with a cross-section of 3 mm² each, and the product can be used for networks with a voltage of 220 Volts.

The most popular types of PPV wire:

- 3x1.5;

- 2x1.5;

- 3x2.0;

- 3x2.5;

- 3x4.5.

Important! The larger the cross-sectional area of the cable, the more expensive it will cost.

PPV wire technical specifications

PVA wire structure

PVA wire consists of copper insulating conductors twisted together and enclosed in a PVC sheath. These cores are also placed in a common polyvinyl chloride sheath. The cross-sectional shape of the wire is round. The insulating material contains special additives. They perform a protective function (in case of fire they do not support the combustion process).

One copper core consists of several thin wires. As a result of their twisting, a tourniquet is formed. According to GOST 22483-77, the core class cannot be lower than 5. This standard also regulates the thickness of the wires that form the core of each individual section. Standard PVA wire has cores with a cross section of 1 mm2. According to current standards, the diameter of the wires used to create it cannot be less than 0.21 mm.

According to the GOST 7399-97 standard, the PVS wire has 4 versions: two-, three-, four- and five-core. The cross-sectional area can range from 0.75 mm2 to 16 mm2. Cables with the maximum cross-section are produced only at cable factories.

GOST 7399-97 presents standards according to which the cross-section of the PVA wire should be in the range of 0.75-2.5 mm2. The twisting of the cores should be in the left direction. When performing “twisting”, no filler is used.

In most cases, insulation is performed using materials of different colors. This approach makes electrical installation work much easier. Core insulation can be of the following colors: blue, brown, white, red, green, yellow, yellow-green, etc.

For example, to mark phase conductors it is customary to use brown, white, and red colors. For neutral conductors, blue and light blue markings are used. For grounding, yellow-green wires are used.

Absolutely any color can be used to paint the general insulating shell.

The topmost layer is a PVC shell. To apply it, the extrusion method is used. When laid alone, such a shell will not support combustion. It fills the gaps formed between the wires and makes the wire round. The maximum eccentricity of PVC insulation is 10%.

Product technical parameters

The main technical parameters that can be used to describe the wire will be the constant resistance per 1 km of the product and the resistance of external insulation at a temperature of 15 degrees.

The temperature range for normal operation is from -50 to 70 degrees. At a critical temperature of 170-200 degrees, it is necessary to turn off the power to the wire to prevent a short circuit.

Current conductivity depends on what cable cross-section was chosen.

Important! If the cable cross-section is too small for a particular network, the wire will begin to heat up, which may result in a fire or short circuit.

Due to the too close arrangement of the wires, the permissible power limit and permissible current loads are significantly reduced.

Thus, before purchasing a wire, it is necessary to calculate the amount of power that will be consumed by electrical devices installed on the current section of the circuit. The electrical strength of the product depends on the material of manufacture and the thickness of the insulating layer. With a cross section of no more than 1 mm, it is 0.6 mm, from 1.5 to 4.0 - 0.7 mm.

You may be interested in this Features of heat-resistant cables

Other technical specifications can be found in the product specifications.

Cable design

How to check the wire before purchasing

Before purchasing, you need to test the quality of wired products. First you need to ask the seller for a copy of the factory certificate of conformity. Verification does not require special knowledge or skills. The tools you need are a caliper and an electrical tester:

- The data on the product of the certificate, the factory tag on the coil, must completely match the markings on the wire sheath;

- Using a caliper or micrometer, measure the geometric dimensions of the wire, the thickness of the insulation, and the dimensions of the dividing tape. Measurements may be less than 0.05 mm;

- The diameter of the core is checked, having previously specified it from the cross-sectional value. An understatement of more than 5% is not allowed;

- On the cross section of the wire, a pure copper color should be visible without dark or light spots or inhomogeneities;

- High-quality copper springs weakly when bent. PVC is separated from the metal easily;

- Using a lighter or match, check the insulation for the spread of fire. The flame may slightly melt and wrinkle the insulation, but it should not catch fire.

- The tester checks the absence of wire breaks in the selected piece.

A defective or falsified wire can threaten life and lead to large material losses.

Scope of application of PPV cable

This product is often used for laying electrical wiring and power plants. Suitable for use in panels with a constant voltage of 380 W and a frequency of up to 350 Hz. If alternating current, then the wire is used at voltages up to 1000 W.

The scope of application depends on what the outer layer of the cable is made of. The wire can be used for permanent and inflexible installation. It is advisable to lay the PPV cable in corrugations and cable ducts. The scope of application is quite wide, even in industry or nuclear power plants. The main places where the PPV cable is used:

- Wiring outside the premises;

- Residential and office buildings;

- Industrial enterprises.

The same wire is used for machine tools, apparatus, lighting devices, and electrical installations.

Cable marking

The main advantages of using PPV cable for wiring:

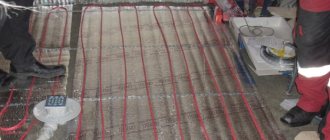

- If the wire is placed inside a concrete wall and disguised under a layer of finishing material, it will have high fire safety. This is explained by the fact that air does not circulate inside the wall and therefore combustion will not spread;

- The cable is protected from touch and careless mechanical influences. Hidden laying allows you to increase the service life of the wire, because exposure to negative environmental sources is eliminated;

- When laid hidden, the cable will not spoil the appearance of the room.

But this product has its disadvantages:

- If a mistake is made when laying the wire hidden, you will have to open the entire wall to get to it. As a result, you will have to repair the wall again, and this is not cheap;

Three-core PPV

- Extension of cables by twisting leads to an increase in resistance and the formation of sparks, especially if powerful equipment is connected to the network. Because of this, the cable overheats greatly, which can lead to a fire;

- Problems that appear during the search for cables or when installing old wiring. You have to break down the entire wall to find the wire.

Application area

As we said above, the RKGM brand wire is heat-resistant and can also withstand voltages of up to 660 Volts. Due to this, this conductor is used in the following conditions:

- Installation of electrical circuits indoors and outdoors in moderate climates.

- Manufacturing of windings in powerful electrical installations, as well as variable-speed machines.

- Application in chemical industry enterprises (since rubber insulation does not dissolve when exposed to chemicals).

- Installation in places prone to mold and mildew.

As for domestic conditions, most often the RKGM wire is used for laying electrical wiring in a bathhouse, sauna, as well as for connecting equipment located in rooms with elevated temperatures

Therefore, if you do not know which cable to use for wiring in a bathhouse, pay attention to this brand. A cross-section of 2.5 mm2 is suitable for a socket group if powerful electrical appliances will not be connected, and a cross-section of 1.5 mm2 will be quite sufficient for installing lighting (connecting lamps in a steam room, etc.)

In addition, the RKGM wire can be used to conduct electrical wiring in the bathroom or basement (technical characteristics allow use in places with high humidity).

Please note that the conductor is heat-resistant, however, it is not recommended to use it in low-temperature environments, because the shell has low resistance to minus temperatures

How to choose the right PPV cable

The first step is to decide from what composition to choose the cores.

Most electricians prefer copper conductors. The main advantage is that copper consumes less aluminum and also has a longer service life.

Important! Copper products will be more expensive, but they fully pay for themselves with their safety.

You can purchase wires of mixed types, made of copper and aluminum. But then, you need to combine them using a terminal block.

Terminal blocks for combining

If the wires come into contact with each other for a long time, they will quickly oxidize and their resistance will increase. Because of this, the cable quickly heats up and fails. In the worst case, contact may result in a fire at that point.

You may be interested in this Color coding of wires

Next, the wire is selected for flexibility and rigidity.

A rigid product mainly consists of one core, and a flexible one consists of many.

Important! The greater the number of wires inside the cable and the smaller each wire, the softer the product will be.

Flexibility can be divided into 7 categories, single-core is category 1, and stranded is category 7.

Rules for connecting PPV

When laying wires, you need to remember several important rules:

- The stiffness of the wire directly depends on the number of cores.

- The bend radius during wiring should not exceed 10 outer diameters. Exactly 10 bends are allowed at right angles with a return to the starting point;

What does a copper core look like?

- If bends are not needed, then they should be avoided;

- PVC is a chemically resistant composition. Therefore, such cables can be laid through brick or concrete walls and disguised with finishing materials. When laying in the wall, you do not need to use corrugation;

- Many building compositions contain various impurities and additives, which over time can destroy the insulation shell. If the composition of the mixture is unknown, then it is better to place the cable in corrugations for additional protection;

- When laying PPV cable under plasterboard, plastic bases or laminated chipboards, it is necessary to use a cable channel;

- It is allowed to pull the wire through the air, but most craftsmen recommend using canopies or other systems to protect the wire from ultraviolet rays;

- Due to its hygroscopicity, PPV wire can be used in places with a high percentage of humidity (bath, sauna, steam room).

Important! Before connecting the cables, it is recommended for a beginner to study as much literature as possible and watch video tutorials on the Internet. But any experienced master will recommend seeking the services of professionals.

Corrugation for additional wire protection

Wire PPV 3x1.5 | OVS group of stores

PPV 3x1.5 - flat wire with copper conductors and PVC insulation, with a dividing base. The conductor is copper, single-wire, class 1 according to GOST 22483. Insulation is made of PVC plastic.

PPV 3x1.5 wire design:

1. Copper single-wire round conductor, class 1 according to GOST 22483*; 2. PVC insulation,

— insulation color for all sections: white, yellow, red, blue, green, brown, black.

Explanation of the PPV 3x1.5 wire:

P - Wire P - Flat B - PVC insulation 3 - number of cores

1.5 - core cross-section

Specifications:

— Type of climatic modification OM and HL, placement category 2 according to GOST 15150-69.

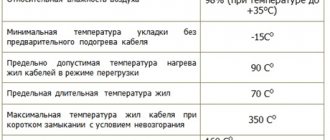

— Operating temperature range: from -50°C to +70°C — Relative air humidity at a temperature of +35°C ……100% — Wires are resistant to mold fungi — Wires are resistant to mechanical shock, linear acceleration, bending, vibration loads, acoustic noise - Wires do not propagate combustion - Installation of wires must be carried out at a temperature of: not lower than -15°C - Bending radius during installation must be: at least 10 wire diameters - Long-term permissible heating temperature of the cores should not exceed: +70°C — Construction length of wires: not less than 100 m — Warranty period: 2 years from the date of putting the wires into operation.

— Wire service life: at least 15 years

Scope of application of PPV 3x1.5 wire:

The wires are used for electrical installations for stationary installation in lighting and power networks, as well as for installation of electrical equipment, machines, mechanisms and machine tools with a rated voltage of up to 450 Volts (U0/U=450/750 V) with a frequency of 400 Hz or constant voltage up to 1000 Volts .

note

The wires are manufactured for use in areas with cold, temperate and tropical maritime climates, including for ships with an unlimited navigation area.

The wires are intended for use under a canopy or in rooms (volumes) where fluctuations in temperature and air humidity do not differ significantly from fluctuations in the open air and there is relatively free access to outside air, for example, in tents, bodies, trailers, metal rooms without thermal insulation.

Wires can be used as built-in elements inside complete products, the design of which eliminates the possibility of moisture condensation on the built-in elements (for example, inside electronic equipment). Wires of the PPV 3x1.5 brand are intended for non-flexible installation. Wires do not spread fire.

The wires are resistant to mold fungi.

Cable storage and transportation conditions

For any cable products, you must follow a number of rules for storage and transportation. Store wires only in a dry room with low humidity. Otherwise, mold or mildew may form on the product. It is advisable to make sure that there are no rodents in the warehouse that could damage the insulating layer. Storage is allowed at temperatures from 15 to 25 degrees. It is allowed to place cable reels outdoors, but away from direct sunlight.

Important! Cable drums must not be placed on their sides.

Specifications

A feature of any cable is the time during which the wire is operated at a stable voltage with a certain load in the network. The PPV is selected taking into account the cross-section that corresponds to the load:

- at 1.5 mm 18 Amperes, and a three-core cable - 15 Amperes;

- at 2.5 mm - 25 Amperes, three-wire - 21 Amperes;

- at 4 mm - 32 Amperes, three-wire - 27 Amperes.

The PVC sheath does not burn, but high temperatures destroy the electrical insulating qualities, which affects its integrity and leads to short-circuiting of current-carrying conductors. According to the characteristics of PPV, it is resistant to moisture, elevated temperatures, steam and condensate. Such features make it superior to other products. Mold, mechanical stress, fungus - all this does not affect such a cable. The product is produced in skeins of 100 meters.

When choosing a PPV, the cross-section and characteristics of the product are taken into account. According to the cross-section, the load indicator on the PPV brand wire is determined. In networks for a three-wire conductor, a load of 27 Amperes is allowed.

Polyvinyl chloride is an insulation material that is characterized by strength. The use of a special component allows you to repel rodents from the wire. This type of insulation is self-extinguishing.

Twin-core

It is found in old buildings, country houses, garages, where it is used to design simple lighting networks. When using a two-wire model, a load of 32 Amps is allowed.

Three-core

When operating three-phase networks with a voltage of 380V, it is recommended to use a cable with three cores.

This option is also used for a conventional building with single-phase alternating current, but only there must be a ground loop. Modern houses provide a similar design. During connection, the outermost conductors are “phase” and “zero”, while the middle one is the grounding tap. Three-core PPV is provided by lighting systems with a connection via two lines, for example, a chandelier with several lamps.

Service life of PPV brand cable

The average service life of the product is 15 years. If there is any mechanical damage on it, then its service life is reduced. Laying is permitted only at temperatures not lower than -15 degrees.

You might be interested in this: Checking phasing

Proper storage in a reel

If it is frosty outside, the cable must be warmed up indoors before installation. If all storage and use rules are followed, the wire will be able to serve without overlays.

Checking the PPV wire (step by step instructions)

When purchasing new cable and wire products, using wires removed from another facility, or that have been unused for a long time, it is necessary to check the product for a broken current-carrying conductor, short circuit between the conductors, and the condition of the insulation. This must be done because damage during transportation or storage is possible, and manufacturing defects cannot be ruled out. Verification steps:

- For this event you will need a digital multimeter tester. The device wires with probes are installed as follows: black to the “com” socket, red to VΩ. The switch is set to the diode continuity position (resistance measurement sector). When the probes touch each other, a buzzer signal should sound - the device is working.

- Now you need to close the ends of one of the cores at the beginning and end of the bay with probes. If the wire has no breaks, a signal should sound.

- In the same way, the absence of a short circuit between the cores is checked. If the multimeter continuity test is triggered when the probes touch two different wires, the insulation is broken and the conductors are shorted together.

- The last stage is to test the insulation for combustion; high-quality products do not do so. When a wire is exposed to open fire, the insulation on it may melt slightly, wrinkle, but not burn. Otherwise, the product does not meet safety requirements.

Manufacturers of PPV brand wire

Currently, there are many factories producing cable products. To avoid buying a fake, it is recommended to choose the most reliable ones. If the consumer does not know which factory to give preference to, he can always visit the forum of electricians, who will tell you exactly which companies are most in demand.

When choosing cable products, you must pay attention to the certificate that the seller must provide. It states the manufacturing plant, the date of manufacture of the cable and the expiration date. If the seller refuses to provide this document, then the product may be counterfeit. Today there are more than 50 large factories, so before purchasing a product you need to study reviews about each of them.

Below is a list of leaders in the Russian market.

JSC "Electrokabel"

The plant was founded in the Moscow region in 1949 of the last century. Today, there are more than 100,000 thousand types of wire sizes available. The company cooperates with large companies in the Russian Federation and abroad, delivering by airlines and railways.

Manufacturing process

Kamsky Kabel LLC

A huge cable production plant is located in Perm. Produces cables for the largest enterprises in the country. The assortment includes more than 55,000 thousand types of products. The plant has gained wide popularity not only in Russia, but also abroad. Industrial factories in Asia and Europe use the services of this company. This manufacturer owns 14% of the entire cable business in Russia.

Important! The main advantage is that all products presented on the site are always in stock. The company quickly produces custom-made wires of any length.

OJSC "Sevkabel"

One of the oldest factories in our country, founded in 1879. The range includes more than 30,000 thousand standard sizes of wires. By the end of 2021, the enterprise plans to complete a large-scale modernization. The latest equipment is installed in the workshops, and there is also a testing center on the territory of the plant. Therefore, all products are of high quality. The plant has many awards and positive reviews.

Correct transportation

In conclusion, it should be noted that the PPV wire is often used for laying lighting in residential premises and connecting various equipment. The cable is used not only for domestic purposes, but also in industrial enterprises. During installation, it is advisable to seek help only from trusted professionals with extensive experience in this field.

Features of decoding markings

Clearly marking the cable with letters and numbers makes it easy to work with. Marking is carried out according to the following features:

- To determine what the current-carrying part is made of, you should pay attention to the markings. If the letter A is indicated, then the core is made of aluminum. If the letter is missing, then the material is copper.

- If the marking consists of two letters, the first of which is P, then the letter indicates that it is a wire, and the second letter indicates the type, for example, flat.

- The letter designation is also used to indicate the shell material. B – polyvinyl chloride.

- The number indicates the number of cores and cross-section.

- The maximum possible voltage is indicated.

Taking these features into account, the marking PPV 2x4-380 stands for flat wire, two-core, core cross-section 4 mm2, with a permissible voltage of 380 Volts.