The development of electrical networks and a significant increase in the number of consumers leads to numerous connections. Which is not possible to do with ordinary bare wires due to the danger of jamming and other factors. Therefore, the classic lines made with bare wire were replaced by SIP wire, which managed to occupy a niche for both household and industrial consumers. Such popularity of SIP was made possible due to a number of advantages in comparison with other brands.

Explanation of SIP markings

In comparison with other brands, SIP wire is a current-carrying element for transmitting electricity, which is deciphered by the three letters of the name:

- C – means that the wire is self-supporting;

- And - indicates the presence of insulation around current-carrying conductors;

- P - indicates that this is a wire, despite the presence of an insulating coating and branching along the cores, which is why it can be equated to a cable.

Consider an example of such a designation - SIP-1-3×20+1×25-0.4, here SIP-1 indicates the brand, 3×20 indicates that three insulated conductors have a cross-section of 20 mm2 each, 1×25 means that the neutral core has a cross-section of 25 mm2, 0.4 is the rated voltage for this model.

Depending on the specific brand, there are five main types of SIP wire, designated by the corresponding numbers after the letter designation. There may be one letter at the end, indicating design differences and operational features. These differences in SIP brands are determined by design parameters, so it would be more appropriate to consider them using specific examples.

Design

Structurally, all types of SIP wires contain cores made in a certain shape with a given number, one of which can serve as a carrier string for the line.

They differ in type as follows:

- SIP-1 is a four-core wire in which each of the cores is represented by conductors twisted relative to each other. In this brand of SIP, three of them are designed for three phases and are equipped with thermoplastic insulation, and the fourth is for the neutral terminal, but it is not insulated. In a neutral conductor, the central wire is made of steel and acts as a load-bearing wire. If there is a letter A (SIP-1A) at the end of the marking, the zero terminal will be equipped with insulation.

Rice. 1: SIP-1 wire design - SIP-2 is the same four-wire version as the previous one, with the only difference being that the neutral wire is insulated. In the classic version, the neutral core is insulated with thermoplastic polyethylene, and in the SIP-2A brand, with cross-linked polyethylene, just like the phase ones. The second option is used for areas with significant exposure to atmospheric factors. Like the previous brand, this SIP is used in lines up to 1 kV.

Rice. 2: SIP-2 wire design - SIP-3 - unlike previous brands, is a single-core version of the current-carrying wire. Structurally, in the center of this SIP there is a steel supporting wire, which is surrounded by aluminum current-carrying conductors. It is used in high-voltage lines with a voltage of 6 - 35 kV for laying phases over long distances.

Rice. 3: SIP-3 wire design - SIP-4 is a pair system in which each core has its own pair, but, unlike the previous ones, it does not have a supporting element and a neutral wire. Therefore, this brand cannot be used for installing lines, since there is a possibility of it breaking when exposed to wind loads. Thermoplastic polyethylene is used as insulation here. There is a version of the brand with the letter N (SIP-4N), which indicates that the current-carrying elements are made of aluminum alloy; if the letter H is absent, the specific brand uses pure aluminum wire.

Rice. 4: SIP-4 wire design - SIP-5 - completely identical to the previous brand - also has a paired number of cores and does not contain a neutral wire with a supporting element. The only difference is the type of insulation covering the conductors; in the SIP-5 and SIP-5N brands it is cross-linked polyethylene, which allows you to increase the operating temperature limit by up to 30%.

Rice. 5: SIP-5 wire design

Design of SIP wires and scope of their application

In order to better understand the advantages and disadvantages of this type of wire, we should understand their design, as well as areas of application. This is where we begin our story.

SIP wire design

There are currently five main types of wires of this brand on the market.

Let's look at each of them separately:

| This wire consists of several conductors twisted together. One of them is zero - the protective grounding is load-bearing. This wire is easy to identify visually, since, unlike the others, it does not have insulation. |

| The next possible option is SIP-2 wire. It has a design similar to the SIP-1 wire, only its zero load-bearing core also has insulation. For a conventional wire, it is made of thermoplastic light-stabilized polyethylene. But if you take a self-supporting wire with aluminum cores SIP-2A, then its insulation is made of cross-linked light-stabilized polyethylene, like the insulation of the main cores. This is very important and now you will understand why. |

| The fact is that you can find wire of the SIP-1A brand. For this type of wire, despite belonging to the first type, the neutral wire also has insulation, but it is made of thermoplastic light-stabilized polyethylene, like the insulation of the main cores. Thermoplastic polyethylene has slightly lower quality properties in contrast to cross-linked polyethylene. But these differences will be important only for professionals, and the average consumer will not notice them. |

| In addition, there is a self-supporting insulated wire SIP-3. Unlike the first two types, it is designed for voltages up to 35 kV. The first two types are used in networks up to 1 kV. SIP-3 is produced only as single-core and is used mainly in industry, so in our subsequent analysis of this type of conductor, we will throw it aside. |

| Self-supporting insulated wire SIP-4 and SIP-5 differ, again, only in the type of insulation. For SIP-4 it is thermoplastic polyethylene, and for SIP-5 it is cross-linked. Otherwise they are almost identical. They do not have a self-supporting core, which imposes certain restrictions on their use. |

Scope of application of SIP wires

As we said above, self-supporting insulated wire is a self-supporting insulated wire that is used quite widely. But there are also certain restrictions. So let's talk about this in more detail.

Line with SIP wire

Electrical networks with voltages up to 1 kV make up the lion's share of all distribution networks in our country. Mostly these are networks with a voltage of 380V, but there are others with a voltage of 660V. It is for such networks that the wire is intended.

- Wires of the SIP-1, SIP-2 brands and their derivatives are used for installation and reconstruction of overhead lines, as in the video. In addition, they are used when installing supply lines laid along building structures, as well as as descents to power electrical equipment.

Installation of the line using SIP-3 wire

- Wires of the SIP-3 brand are used for the same purposes, but in overhead lines with voltages up to 35 kV. The only difference is that this type of wire is single-wire, which means that for a standard three-circuit network you have to use four or even five wires of this type.

Using a two-core SIP-4 wire to connect a private household

- SIP 4 is a self-supporting insulated wire that cannot be used for installing overhead lines. Due to its design, it has a fairly low breaking force, so even with minor wind loads it can break. In this regard, it can be used exclusively as descents from overhead lines to power equipment, or for installation on building structures. In most cases, it is purchased to connect private households to overhead lines.

Note! To connect private households, SIP-4 4x25 or 16 wire is often used. Smaller cross-sections are unacceptable according to PUE standards, and larger cross-sections are impractical.

- The SIP-5 wire has a similar scope of application , which has very similar characteristics to the SIP-4 wire.

Specifications

When choosing a specific brand of SIP wire, it is important to pay attention to the compliance of the characteristics and parameters with the individual requirements of the consumer and the installation method.

To do this, the following technical characteristics are taken into account:

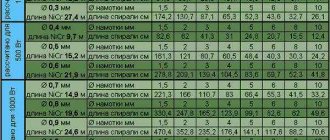

- Number of cores - as a rule, models with the number of current-carrying elements from 1 to 4 are used;

- Cross-section – for different SIP models, this parameter varies from 16 to 240 mm²;

- Voltage class - there are two categories in total - up to 1 kV (SIP-1, 2, 4, 5) and up to 35 kV (SIP-3);

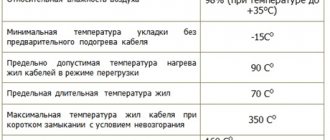

- Temperature regime - implies a normal operating temperature at which the wire will transmit electricity for a long time without losing its parameters;

- Permissible short-term heating - can occur in emergency modes, but should not exceed more than 8 hours of the annual load;

- Bending radius - determines the ability to bend the wire without compromising the mechanical strength of the insulation and its dielectric properties.

All technical characteristics compared for all brands are shown in the table below:

Table comparing characteristics of SIP brands

| Wire brand | SIP-1 | SIP-2 | SIP-3 | SIP-4 | SIP-5 |

| Number of current-carrying cores, pcs. | 1 ÷ 4 | 1 ÷ 4 | 1 | 2 — 4 | 2 — 4 |

| Core cross-section, mm2 | 16 ÷ 120 | 16 ÷ 120 | 35 ÷ 240 | 16 ÷ 120 | 16 ÷ 120 |

| Zero core, bearing | aluminum alloy (with steel cores) | aluminum alloy (with steel cores) | absent | absent | absent |

| Current-carrying core | aluminum | aluminum | aluminum alloy (with steel cores) | aluminum | aluminum |

| Voltage class, kV | 0.4 ÷ 1 | 0.4 ÷ 1 | 10 ÷ 35 | 0.4 ÷ 1 | 0.4 ÷ 1 |

| Core insulation type | thermoplastic polyethylene | light stabilized polyethylene | light stabilized polyethylene | thermoplastic polyethylene | light stabilized polyethylene |

| Operating temperature | -60оС ÷ +50оС | -60оС ÷ +50оС | -60оС ÷ +50оС | -60оС ÷ +50оС | -60оС ÷ +50оС |

| Permissible heating of cores during operation | +70оС | +90оС | +70оС | +90оС | +90оС |

| min wire bending radius | not less than 10 Ø | not less than 10 Ø | not less than 10 Ø | not less than 10 Ø | not less than 10 Ø |

| Life time | at least 40 years | at least 40 years | at least 40 years | at least 40 years | at least 40 years |

| Application | branches from overhead lines; — power supply to living quarters; - household construction laying along the walls of buildings and structures. | branches from overhead lines; — power supply to living quarters; - household construction laying along the walls of buildings and structures. | for installation of overhead lines with voltage 6-35 kV | branches from overhead lines; — power supply to living quarters; - household the buildings; — laying along the walls of buildings and structures. | branches from overhead lines; — power supply to living quarters; - household the buildings; — laying along the walls of buildings and structures. |

SIP - (Self-supporting insulated wire) - insulated conductors twisted into a bundle with light-stabilized plastic, and the supporting conductor can be either insulated or non-insulated.

The mechanical load can be perceived either by the load-bearing core or by all conductors of the harness. Performed in accordance with GOST 31946-2012 “Self-supporting insulated and protected wires for overhead power lines. General technical conditions" SIP is divided into 4 versions:

SIP-1 Self-supporting insulated conductor without insulation of the neutral core for the mains of overhead power lines (VL) and linear branches from VL for rated voltage up to 0.6/1 kV inclusive, with a nominal frequency of 50 Hz in air atmosphere of types II and III according to GOST 15150-69, including on the coasts of seas, salt lakes, in industrial areas and areas of saline sand. Laying is carried out in accordance with the PUE (7th edition, section 2, chapter 2.4) Wire according to design , technical characteristics and operational properties comply with the national standard of the Russian Federation GOST 31946-2012 “Self-supporting insulated and protected wires for overhead power lines. General technical conditions"

SIP-2 Self-supporting insulated conductor with an insulated neutral conductor for mains of overhead power lines (VL) and linear branches from VL for rated voltage up to 0.6/1 kV inclusive, rated frequency 50 Hz in an air atmosphere of types II and III according to GOST 15150- 69, including on the coasts of seas, salt lakes, in industrial areas and areas of saline sands. Laying is carried out in accordance with the PUE (7th edition, section 2, chapter 2.4). The wire design, technical characteristics and operational properties comply with the national standard of the Russian Federation GOST 31946-2012 “Self-supporting insulated and protected wires for overhead power lines. General technical conditions"

SIP-3 Self-supporting insulated conductor for overhead power lines with a rated voltage of 20 kV (for networks with a voltage of 10, 15, 20 kV) and 35 kV (for networks with a voltage of 35 kV) with a nominal frequency of 50 Hz in air atmosphere II and III according to GOST 15150- 69, including on the coasts of seas, salt lakes, industrial areas and areas of saline sands. Laying is carried out in accordance with the PUE (7th edition, section 2, chapter 2.5). The wire design, technical characteristics and operational properties comply with the national standard of the Russian Federation GOST 31946-2012 “Self-supporting insulated and protected wires for overhead power lines. General technical conditions"

Cable design SIP-3:

This self-supporting wire is made on the basis of an aluminum alloy core [2], around which a sheath of cross-linked light-stabilized polyethylene is applied [1].

SIP-4 Self-supporting wire without a zero load-bearing core (tension during suspension is distributed evenly across all cores), with aluminum conductors, with insulation made of light-stabilized cross-linked polyethylene for making branches from overhead power lines to the input, for laying along the walls of buildings or engineering structures on rated voltage up to 0.6/1 kV inclusive with a nominal frequency of 50 Hz in an air atmosphere of types II and III according to GOST 15150-69, including on the coasts of seas, salt lakes, in industrial areas and areas of saline sand.

Laying is carried out in accordance with the PUE (7th edition, section 2, chapter 2.4). The wire design, technical characteristics and operational properties comply with the national standard of the Russian Federation GOST 31946-2012 “Self-supporting insulated and protected wires for overhead power lines. General technical conditions"

Laying conditions

Due to the fact that laying SIP does not require any special skills, it can be done either at home or by the enterprise’s own resources without the involvement of a specialized organization. Laying can be carried out both on supports and on structural elements of buildings and structures. As a rule, fastening to walls is much easier than on a free-standing support.

Therefore, consider the conditions for installing SIP wire on reinforced concrete supports:

- Since the self-supporting insulating wire has an insulated sheath, it is important to provide a suspension that prevents damage to the dielectric layer. To do this, plastic rollers, grips and thimbles are installed, along which the wire can move freely.

- During the installation process, it is forbidden to drag the SIP along the ground or tree branches, as these can damage its insulation.

- To join different sections of SIP, sealed piercing-type clamps are used. Thanks to this design, it is possible to tap a line from an existing one even under voltage.

- Before fixing it on the support, the SIP wire must be pulled out through the moving element (for SIP brands from 1 to 3 using a dynamometer until the normalized load is set). After stretching, it is fixed at the fixation points.

All fasteners are factory-made, so they can be found complete with self-supporting insulating wire, which will greatly simplify the task.

Rice. 6: Example of fastening a SIP wire to a support

Application, advantages and disadvantages

Due to the presence of insulation, SIP has a fairly wide scope of application. It is most often used to introduce electricity into a building, and thanks to the outer layer of insulation, additional measures and devices are not required when passing through walls. Also, a self-supporting insulating wire can be used for local wiring of networks throughout the facility or when connecting subscribers to the lines of an energy supply organization. A separate area of application for SIPs are trunk lines that provide power supply to entire villages or distribution substations.

Compared to other brands of cable and wire products, SIP has a number of advantages, namely:

- SIP wire has significantly lower reactance compared to bare wires;

- Does not require the installation of additional insulators at points of attachment to supports, walls and when entering the building due to the presence of an insulating layer;

- Takes up less space due to the fact that the wires are collected together;

- Not subject to corrosive destruction due to the presence of a protective layer;

- Not afraid of overlap of adjacent phases under strong wind loads;

- Makes it difficult to illegally take power by throwing on wires;

The disadvantages of SIP wire include the greater weight of a linear meter, which is why the spans need to be reduced and supports installed more often. As well as the need to arrange additional insulation for certain categories of premises and consumers.

Advantages and disadvantages

Advantages:

- Easy to install. It is much easier to install than conventional wires without insulation. They do not require fastening to insulators.

- Reducing electricity theft. Connecting to lines with such wires requires certain qualifications; it is quite difficult and not accessible to everyone.

- No icing. The material from which SIP insulation is made does not retain wet snow and condensation. Ice formation on overhead lines is very small.

- Reduce the risk of electric shock. Thanks to insulation, the likelihood of electric shock during repair and maintenance of the line is sharply reduced. Many jobs can be done under voltage.

- Reduced installation and operating costs. Due to their design, the wires are less prone to breaks. Maintaining power lines with wires of this type is much cheaper. Wires of this type can be attached to the facades of houses. This allows the use of fewer supports.

- Low inductance. Such lines have very low reactance. Voltage and power losses in lines using SIPs are significantly less. Low inductance avoids interference and makes it possible to attach low-voltage and control cables to line supports.

Read also: Rules for connecting a dishwasher

Flaws:

- High price. Of course, such products are somewhat more expensive than bare wires, which are usually used for overhead lines.

- Lack of qualified specialists. Installation and maintenance of power transmission lines where these cables are used has its own characteristics. Such current-carrying products have appeared quite recently and have not yet become widespread. This is due to the lack of specialists who have the necessary skills and experience. In addition, domestic power supply systems are generally not suitable for a massive transition to current-carrying lines of self-supporting insulated wire.

Main manufacturers

To avoid troubles when purchasing a wire or cable, you should pay attention not only to the main parameters of the product, but also to its manufacturer. Since low-quality models may have a smaller cross-section, low dielectric resistance to various types of influence, etc. If you have already purchased a self-supporting insulating wire and are not sure of its quality, check whether the cross-section corresponds to that stated in the passport. How to determine the cross section at home is described in the corresponding article -.

If you are just going to buy SIP, pay attention to the following manufacturers:

- Kama cable;

- Rybinskcable;

- GC "Sevkabel"

- Moscabel.

Using wires from the above-mentioned factories, you can be sure that they comply with the declared characteristics.