Why is it necessary?

DNAT lamps are old and time-tested light sources that emit intense light at a minimum power level. They are actively used in street and greenhouse lighting. Due to insufficient color rendering and strong flickering, they are not used in lighting living rooms.

IZU for DNAT

To connect the DNAT, you need to use a special IZU triggering device with a ballast and a capacitor. The first is required to create a high voltage pulse and form an arc. At the same time, it must be selected taking into account the power of the light source up to 400 watts.

Increasing the DNA voltage as a function of the IZU

Pulse Ignition Devices IZU for HPS and DRI lamps

In 2012, Novazavod LLC began serial production of IZU for DnaT lamps

and DID (MGL). The line of manufactured IZUs covers all types of lamps, both in power: from 35W to 2000 W, and in base type: E27 and E40. A special series IZU-Agro is also produced, designed to run DnaZ 400/600 W lamps, widely used in greenhouses and those having the specificity of “tight ignition”.

Compliance with GOST R IEC 926-98, GOST R IEC 927-98

Advantages of IZU "Novazavod" compared to manufactured analogues:

- use of components from the world's leading manufacturer NXP (Philips);

- automatic installation of components on the board using MYDATA MY-9 equipment (Sweden);

- the use of inductive components, which are the “heart of the IZU” from EPCOS (TDK) with a closed loop, allows you to calibrate the IZU power with an accuracy of up to 5% for each type of lamp;

- The pulse amplitude and its shape are monitored on an HP Hewlett-Packard oscilloscope.

All of the above, as well as the practically absent “manual labor”, allows us to produce IZU at the level of the world’s leading analogues with a failure rate of 0.5% and an 18-month guarantee

.

The ideal pulse shape, adjusted for each type of lamp, allows for a “soft start” mode, which increases the life of the lamp up to 2 times

.

Example of IZU designation for DNAT

when ordering: IZU-100/400 - Pulse Ignition Device for HPS lamps with power from 100 to 400 W.

Price list for products as of 08/01/2021. Certificate of Conformity No. ROSS RU. АВ86.Н01670

Prices apply for long-term deliveries or for one-time orders of 200 pcs.

| IZU type | Lamp type | price, rub. VAT included | Size, L*W*H/weight, g. |

| IZU 35/70 | DNAT/DRI 35-70 W | 150 | 55*40*35/ 55 |

| IZU 100/400 | DNAT/DRI 100/400 W. | 150 | 55*40*35/ 60 |

| IZU 100/1000 | DNAT/DRI 100/1000 W | 150 | 55*40*35/ 60 |

| IZU-T 100/1000 | DNAT/DRI 100/1000 W | 200 | 55*40*35/80 |

| IZU 1000/2000 | DNAT/DRI 1000/2000 W, 380V | 250 | 55*40*35/ 75 |

| IZU Agro400/600 | DnaZ 400/600 W | 250 | 55*40*35/ 90 |

Pulse ignition devices - IZU are designed for igniting high-pressure sodium gas-discharge lamps of the DnaT type and metal halide lamps of the DRI (MGL) type when they are turned on together with ballast-inductive ballast. There are IZUs for working with a voltage of 220V and a voltage of 380V (usually for lamps with a power of over 1000 W). Power of DnaT, DRI lamps from 35 to 2000 W. The most common in street lighting: IZU 250 for DnaT lamps

, DRI: 100W-400 W., in greenhouse lighting: IZU 600 W -

IZU 1000

W. Typically used in housing and communal services lamps, ZhSP lamps, sodium lamp floodlights

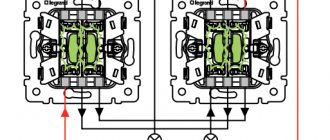

Typically, IZUs are divided into three types: With two terminals, also called parallel type, the simplest circuit design, have been manufactured since the early 80s. - simultaneously with the advent of HPS lamps, IZU connection diagram

- Fig. 1. But despite the simplicity and reliability of such IZUs, they have a number of problems that are not solved in these circuits: - failure of the IZU in the absence of a lamp or if a burnt-out lamp is installed.

- exit from the stationary state of the ballast, since pulses from the IZU up to 5 kV are supplied continuously and the inductor windings burn out sooner or later. A solution for protecting ballasts exists - installing ballasts with thermal protection, but due to its high cost and the absence of Russian GOST standards for its mandatory installation, it is installed extremely rarely. Buy IZU

the outdated type is simpler, but this will further affect the costs of maintaining the lamp as a whole. -The distance from the IZU to the ballast is limited to 1-2 meters.

With three terminals or “serial type”. Connection diagram of the IZU device

sequential type is shown in Fig. 2.

Advantages: operability of IZU and ballasts in the absence or combustion of the lamp. — The IZU-EPRA distance is unlimited. A huge disadvantage: towards the end of the life of the lamp, the rectifying effect begins to appear, which leads to abnormal operation of the ballasts, the IZU also works continuously, trying to light the lamp, which leads to the failure of the entire IZU-PRA

. The most modern IZUs of both types have a digital timer, which turns off the IZU after a specified time in the following cases:

-lamp missing

-the lamp has burned out.

- an unsuccessful attempt to light an old lamp operating in abnormal mode.

IZU price

in this case, it increases by 40-60% of the price of conventional IZUs, but an increase in the cost in absolute terms by 30-50 rubles leads to a colossal gain in the operation of the entire PRA-IZU - Lamp system. IZUs are usually divided by lamp power: For example,

IZU 400

— IZU 600, as well as the most modern, lamp base type E27, E14. The pulse amplitude ranges from 2.5 kV to 5 kV depending on the type of base and lamp power, which greatly increases its resource.

Rice. 1 circuit diagram of IZU

In total, all of the above can be defined as:

IZUs are divided into two types: parallel and serial

1 Pulse ignition devices IZU

for DnaT, DRI, DNaZ, DRiZ parallel type

Pulse ignition devices IZU are designed for igniting high-pressure discharge lamps of the DnaT (sodium arc) and DRI (metal halide arc) types with power from 70 to 2000 W. The ignition mode of the lamps is provided by the IZU when switched on with an EMPGRA - Electromagnetic Start-Regulating Apparatus, a “choke” in an alternating current network with a nominal frequency of 50 Hz, 220-230V.

Distinctive feature from devices that are on the market:

a) high ignition ability;

b) the lowest cost of service.

2. Pulse ignition devices IZU

for DnaT, DRI serial type

Pulse ignition devices IZU are intended for ignition of high-pressure discharge lamps of type DnaT, DRI with power from 70 to 1000 W.

The ignition mode of the lamps is provided by the IZU when switched on with an Electromagnetic Start-Regulating Apparatus, a “choke” in an alternating current network with a nominal frequency of 50 Hz, 220-230V. A special feature of this IZU compared to those on the market is the use of cores for pulse transformers made of a special alloy from EPCOS, which is many times higher in technical characteristics than similar cores. Tags: Izu for dri, Izu price, Izu pra, Izu manufacturer, buy Izu, Izu 2000, Izu 150, Izu 70, Izu 250, Izu 1000, Izu 600, Izu 400, Izu for dnat, Izu

Technical parameters of the IZU

When buying a pulse ignition device, you need to know the value of the maximum permissible current, the maximum frequency pulse voltage, voltage, automatic shutdown function of the device and the maximum cable length. The permissible current should not exceed twice the operating current, the maximum frequency pulse voltage should not be up to 3.5 kilowatts at the output. In the event of a device failure, the pulse ignition device must have an automatic shutdown function. The maximum cable length should be about 2-3 meters.

Specifications

Technical characteristics of the IZU

| Photo | vendor code | Name | Power, W | Package |

| SCHWABE HELLAS 16 uF 250V (HQI100) Capacitor | ||||

| WTB 60 µF ±5% 420V d55 l128 M12x12 (Aluminum case/Wago/-40С…+100C) Capacitor | ||||

| WTB 45 µF ±5% 250V d50 l95 M8x10 (Plastic body/Conductors 250mm/-25С…+85С) Capacitor | ||||

| SCHWABE HELLAS 40uF 250V (HQL700,SOX180) Capacitor | ||||

| SCHWABE HELLAS 6 uF 250V (HQI35,SOX26) Capacitor | ||||

| Z 1000 M 220-240V 600-1000W 12A 4-5kV 1 meter SCHWABE HELLAS – IZU | ||||

| SCHWABE HELLAS 50uF 250V Capacitor | ||||

| DSBE 2X36/220-240 300x30x30 SCHWABE - electronic ballast | ||||

| WTB 40 µF ±5% 250V d45 l90 M8x10 (Aluminum body/Wago/-40С…+85С) Capacitor |

Advantages and disadvantages

The advantages of connecting a pulse ignition device to a light source are that the HPS operates for up to 30 thousand hours and the quality of lighting does not decrease, the lamp does not consume a minimum of electrical energy. The efficiency of the lamps reaches 30%.

Note! The disadvantages of connecting this equipment are the resulting low color rendering, temperature limitation, sensitivity to electrical surges, long turn-on time and high current pulsation of the light source.

Ease of connection is a plus

Flaws

There are certainly disadvantages to such lamps.

- luminous flux drops slightly after 15,000 hours of continuous operation

- cumbersome control circuit

- at the end of its service life, the color of the glow begins to change

The change goes from yellow towards orange with redness or even completely red.

- many are also not satisfied with the long startup process - up to 10 minutes

- the throttle itself emits a constant hum after prolonged operation

How to connect and check correctly

You can assemble the kit for connecting the light source yourself. To answer the question of how to connect a sodium lamp to the network, you should indicate that this requires a circuit with a lamp, ballast, a pulse igniter and condensate. Typically the connection diagram is located on the choke housing for the light source.

You might be interested in this: What is a floodlight with a motion sensor and how to use it

Correct network connection

How to check and connect the IZU for DNAT with your own hands

HPS lamps are the oldest and most time-tested light sources.

They continue to be actively used despite the fact that the lighting equipment market is actively filled with LED devices. The popularity of sodium lamps is due to the fact that they emit an intense luminous flux with minimal power. They are actively used for street lighting and for growing plants in greenhouse conditions. However, due to the low quality of color rendering and strong flicker, HPS is not used for lighting residential buildings and industrial premises.

To connect the HPS, you need to purchase a special starting device (IZU), a ballast (electronic ballast, choke), and a capacitor. When the ignition device is started, a high voltage pulse is created and an arc is formed. IZU for HPS must be selected taking into account the lamp power (from 35 to 400 W). Ignition devices are of parallel or series type, that is, with two or three contacts. It is important to know which device is best suited for HPS and how to connect it correctly.

Connection diagrams

The diagram shows a ballast with an incoming phase, which is conducted to a pulse ignition device and then connected to the source. In order for the light bulb to light up, you need the devices listed above and a voltage of 220 volts. Otherwise, the source cannot be started.

Connection diagram with capacitor

Two-point IZU

Ignition devices with two terminals are connected in parallel to the lighting device. This means that after the throttle installation, a charged conductor must be connected to the terminal of the pulse ignition device, and the other conductor must be connected to a core that has a negative charge. In this case, the neutral cable can be taken from the cartridge element.

Experts do not recommend using multi-pin chargers to connect light sources, as they can damage the inductive ballast. Because during startup, the voltage supplied not only to the light source, but also to the ballast increases. As a rule, two contact pulse igniters are used for several low-power lamps up to two kilovolts.

Two-point IZU

Three-point IZU

The kit for connecting a HPS lamp can be assembled in a panel with the lamp body. Before carrying out work, it is necessary to check the insulation of the ballast with the capacitor. To do this, switch the multimeter to the maximum resistance indicator. This is necessary for personal safety.

For lamps with a power of 400 watts, a two-phase circuit breaker is required. It is needed to supply and disconnect electrical power and protect parts. It must be installed before the main work. In addition, its body must be grounded.

The steps for connecting a three-terminal pulse igniter to a sodium lamp are as follows:

- Connect the conductor with a negative charge from the shield to the light source, and the second element to the same type of clamp on the ignition device.

Note! Place the node only in the discontinuous part of the phase, which goes to the source, and not to zero. Otherwise, there will be a short circuit and fire of the throttle.

- Open the phase and connect to the choke. The core that comes out of the contact must be connected to terminal B on the ballast.

- Connect the middle conductor to the light source socket.

The capacitor device will be connected in parallel to the entire electrical circuit. To do this, the cable must be connected to the phase conductor, and the second to the neutral conductor.

You might be interested in: How to properly make lighting on a balcony

Three-point IZU

Types of IZU

Two-contact device

Ignition devices can be of series or parallel type. Parallel type devices two contacts . During their operation, the voltage is supplied not only to the lamp, but is branched off to the inductor. As a result, breakdown is possible: the insulation of the ballasts cannot withstand such voltages. In addition, if there is no lamp in the circuit or the lamp burns out, the two-pin device will break. The recommended distance from the protective device to the ballasts is only 2 m. However, such devices are cheaper.

serial type device has three contacts . When connected in series, if the light source burns out or is missing, the protective device continues to operate. The distance between the inductor and the pulse device is not limited. But towards the end of the service life of the light source, a rectifying effect appears, which leads to incorrect operation of the ballasts. In this case, the pulse protective device operates constantly, which leads to failure of the entire system.

To indicate possible problems, a timer is built into three-pin devices. The timer turns off the device after a set time in cases of absence/burnout of the light source or an unsuccessful attempt to light the lamp.

There is also a division according to power and type of base E27 and E14.

What are the possible connection errors?

When connecting, the ballast on the four contacts may be installed incorrectly. To prevent this mistake, you need to use the connection diagram for Dnat 400 with a capacitor.

Incorrect connection of the four-pin choke

Cracks may appear on the device body as a result of installing the source with bare hands. To avoid this, wipe the lamp with a clean cloth before starting it up.

A choke from an arc mercury phosphor source can also be used when using a different type of ballast. Then the lamp will be unusable. To prevent this from happening, you need to select the inductor based on the type of lamp. Technical parameters will help for this.

Technical characteristics of DNA lamps

In general, an IZU is a device aimed at increasing the voltage to several kilovolts to form an arc. The equipment has a two-pin and three-pin design. The IZU produces high voltage pulses for efficient operation of a high pressure sodium lamp.

Main conclusions

A pulse protective device is a necessary element for connecting gas-discharge light sources. It is selected based on the type of lamp and its power.

Follow the connection diagram indicated on the housing.

Two-pin devices are cheaper, but less safe. When using them, it is necessary to connect a ballast with insulation that can withstand high voltages, otherwise there is a high probability of breakdown. If you turn on the circuit with non-working lamps, the additional equipment will fail.

Three-pin devices do not have these disadvantages. However, when the lamp life is exhausted, they may begin to work continuously and fail. To prevent this, you should choose protective devices with a shutdown timer.

- Related Posts

- Sodium lamp (HPS) features and characteristics

- Lamps with e27 base: the most powerful, advantages and disadvantages

- Lighting in the kitchen: tips and ideas

Typical frequently asked questions from readers

There is a DNAT-400 that recently stopped turning on. Could this be due to low voltage in the final electrical circuits?

Alternatively, it is possible that the voltage level in the final electrical circuit is not enough, but I would like to know more detailed details. Does the lamp not light up at all or does the warm-up time last longer than usual? Are there any light effects when you turn it on or does the lamp not even flicker?

In addition to such a possible cause as low voltage in the electrical terminals, the lamp should be checked for the following faults:

The ignition device is faulty - due to natural wear and tear of the elements or with frequent switching without waiting a break between switching on, the ignition device may fail. Replacing with a new one can completely solve the problem, but you need to select something similar.

The cartridge has burned out - many connection points in gas-discharge lamps suffer due to the increased voltage supplied to the lamp. Therefore, the cartridges may not withstand the electrical load and simply burn out. To eliminate the problem, replace the cartridge with a new one.

Connecting wires also burn out in the area from the IZU to the lamp due to high voltage and the load applied to them. Such a malfunction can be determined even by visual inspection.

The lamp itself has burned out - this can be checked by visual inspection or by replacing it with a similar working one.