The first electric lighting device, which was invented at the end of the 18th century, was the incandescent lamp (Il). This light source is still popular for lighting residential, industrial premises, streets, etc.

This device has a simple design and operating principle.

There are different types of filament light bulbs on the lighting market.

Despite the fact that energy-saving light bulbs are now becoming increasingly popular, devices with incandescent filaments are in no hurry to lose ground.

Incandescent lamp design

The design of different types of incandescent lamps differs slightly, but three common elements can be distinguished: the incandescent body, the glass bulb and the current inputs. They differ in the design of the filament body holders (hooks), the type of bases, some of them may be baseless.

To avoid destruction of the flask when the spiral breaks during operation, the LN is equipped with a ferronickel fuse, which is usually located in its leg. In the area where the filament body breaks, an electric arc is formed, due to which the remnants of the spiral melt and fall on the glass surface, then the risk of violating its integrity increases. Fuses help stop the melting process. However, now they are rarely used because their effectiveness is low.

An electric lamp has the following basic elements:

- flask;

- filament body;

- electrodes (current leads) on both sides of the spiral;

- hooks that hold the spiral;

- leg;

- current input;

- base;

- base insulator;

- contact at the bottom of the base.

A glass bulb protects the spiral from the destructive effects of air; when it is destroyed, the filament oxidizes and breaks faster. The composition of the device flask is different; its cavity can be filled with a vacuum or a mixture of gases. The first LNs were produced with an airless tank, but their power was low. To fill a modern light bulb, a nitrogen-argon mixture or only argon is used. Some types of devices may contain krypton or xenon. The heat transfer of the device depends on the molar mass of the substance with which the flask is filled.

This is interesting! A separate category includes halogen light bulbs, the bulb of which is filled with special gases. During operation of the device, metal evaporates from the coil, which reacts with halogens. The substance obtained as a result of their interaction is destroyed under the influence of high temperature and settles on the surface of the filament body. As a result, the efficiency increases, as does the service life of the device.

Depending on the functional purpose, the shape of the LN spiral is different: a wire with a round cross-section or a ribbon conductor.

The filament and glow of the first devices were provided by carbon rods; modern incandescent lamps are equipped with a tungsten spiral. The conductor can be created from an alloy of metals (osmium and tungsten).

Newer models are equipped with bi-spirals or tri-spirals, which are obtained by repeated twisting. Such devices have high efficiency and generate less heat.

The shape and size of the incandescent lamp base are standard, so there are usually no problems with replacing the lighting element after it breaks. Most often, light sources with sockets E14, E27, E40 are used. The letter E in the marking indicates the name of the inventor (Edison), and the number after is the outer diameter in mm.

Fluorescent lamps

Fluorescent lamps (LL) - low-pressure discharge lamps - are a cylindrical tube with electrodes, which is filled with an inert gas and a small amount of mercury. When turned on, an arc discharge occurs in the tube, and the mercury atoms begin to emit visible light and ultraviolet light. The phosphor applied to the walls of the tube emits visible light under the influence of ultraviolet rays.

The basis of the luminous flux of the lamp is the radiation of the phosphor; visible mercury lines make up only a small part. The variety of phosphors (mixtures of phosphors) makes it possible to obtain light sources with different spectral composition, which determines the color temperature and color rendering index.

Fluorescent lamps provide soft, uniform light, but its distribution in space is difficult to control due to the large surface area of the radiation. To operate fluorescent lamps, special ballasts are required. The lamps are durable - service life up to 20,000 hours.

Luminous output and service life have made them the most common light sources in office lighting.

Principle of operation

An incandescent light bulb works by heating a substance while current flows through it. Electricity passes through a refractory conductor, heating it. The heating temperature depends on the voltage supplied to the light bulb. According to Planck's law, a heated radiating conductor can create electromagnetic radiation. The higher the temperature, the shorter the wavelength. Visible radiation, which the human eye can detect, appears when the conductor is heated to several thousand degrees. If the device is heated to 5000 K (Kelvin), neutral light appears; as the temperature decreases, radiation from yellow to red predominates in the spectrum.

Incandescent lamp - operating principle, types, characteristics

An incandescent lamp is a simple and cheap light source with a color tint that is pleasant to the human eye.

The incandescent lamp has been used as a lighting source for over a hundred years. This is the patriarch among other lamps that illuminate human homes all over the world. However, it is still far from being published. Despite the fact that there is constant talk about the irrelevance of using incandescent lamps in the modern world. So what is this lamp?

Incandescent lamp - operating principle

An incandescent lamp consists of a glass bulb and a base connected to each other. The base is designed for contact with the mains supply. The glass bulb contains a spiral - a filament. During operation, the filament, when electric current passes through it, heats up to a high temperature. As is known, it can reach 3000°C. Therefore, the spiral is made of a refractory metal, usually tungsten. The melting point of tungsten is 3422°C, which is quite enough to operate an incandescent lamp.

The filament inside the bulb is usually attached to two nickel contacts - electrodes. It is also additionally supported by molybdenum hooks – holders located on the glass rod.

The electrodes in contact with the filament are connected to two contacts on the lamp base. The location and type of contacts on the lamp base depends on the type of base used.

Sometimes a special thinning is made on one of the electrodes, enclosed in a glass cavity. This thinning serves as a fuse. In an emergency, it burns out first, which avoids the explosion of the glass bulb of the lamp.

Incandescent lamp - device (Click to enlarge)

Air is pumped out of the flask itself through a glass tube called a rod. After this, the end of the rod is sealed. A vacuum is needed to preserve the lighting spiral. Because air contains oxygen, which supports combustion. As a result, the tungsten helix would burn out when operating in the air without lasting even a second. As a result, creating a vacuum inside the bulb significantly extends the life of the incandescent lamp.

But this is only true for low-power lamps up to 25 watts. For more powerful lamps, some inert gas is pumped into the flask, in addition to pumping out air. For example, it could be xenon, argon or krypton. Krypton, which is cheaper than xenon, is mainly used. Or even cheaper argon, mixed with nitrogen for greater savings. The inert gas allows the filament to last longer. This general arrangement of incandescent lamps varies only slightly among different types of lamps.

Varieties

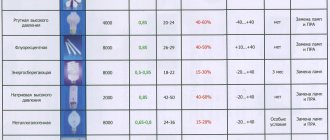

Before you get acquainted with the types of LN, you need to study their characteristics:

- The power of household lamps ranges from 25 to 150 W, and others - up to 1000 W.

- The temperature of the heating element is up to 2900 – 3000° C.

- Light output – from 9 to 19 Lm/1 W. This characteristic has its own range, for example, a 40 W light bulb can emit a luminous flux of 415 - 460 Lm.

- Voltage 220 – 230 V and 127 V.

- Base diameter – 14 mm for E14, 27 mm for E27, 40 mm for E40.

- Base type – screw, pin (with one or two contacts).

- Service life - 1000 hours (if the voltage is 220V) or 2500 hours (at 127V).

The main parameters of different types of incandescent lamps differ.

There are various types of devices on sale, which are distinguished by shape, filling or coating of the flask, purpose, etc.

Taking into account the filler and coating of the inner surface of the bulb, the following types of light bulbs are distinguished:

- Vacuum ones are the simplest devices with low power.

- Argon - filled with argon.

- Krypton - the gas of the same name is injected.

- Xenon-halogen with infrared reflector.

- Lamps coated with phosphor, which converts infrared rays into visible light.

Depending on the functional radiation, the following types of lamps are distinguished:

- general purpose. This is the largest group of devices that are used for general, local and decorative lighting. The local device has the same design as the general one. It differs in that it is designed for less voltage. Install local light bulbs in portable lamps, machines, etc.;

This is interesting! Now the production of incandescent lamps is being reduced in order to save electricity.

- Decorative light bulbs differ from ordinary ones in the shape of the bulbs and the placement of the incandescent body. Often used to decorate retro-style designs;

- illumination. The bulbs of these devices are painted in different colors using inorganic pigments or colored varnishes. Usually their power is low - up to 25 W;

- mirrored The bulb of an incandescent lamp has a special shape; the inside is partially coated with a thin layer of sprayed aluminum. These devices emit a more directional light output;

- signal. These are low-power light bulbs that are installed in lighting devices. Now they are being replaced by LEDs;

- transport. This is a large group of lamps that are used for installation in cars, motorcycles, airplanes, marine vessels, etc. They are durable, have a special base and are designed for an electrical network from 6 to 220 V;

- double-helix. They are used in cars (one thread is responsible for the low beam, and the second for the high beam), airplanes, and railway traffic lights.

Kinds

There are several criteria for classifying incandescent lamps, which will be discussed below.

Depending on the lighting efficiency, incandescent lamps are classified (from worst to best):

- vacuum;

- argon or nitrogen-argon;

- krypton;

- xenon or halogen with an infrared reflector installed inside the lamp, which increases efficiency;

- with a coating designed to convert infrared radiation into the visible spectrum.

There are many more varieties of incandescent lamps related to their functional purpose and design features:

- General purpose - in the 70s. of the last century they were called “normal lighting lamps”. The most common and numerous category is products used for general and decorative lighting. Since 2008, the production of such light sources has decreased significantly, which was due to the adoption of numerous laws.

- Decorative purpose. The flasks of such products are made in the form of graceful figures. The most common types are candle-shaped glass vessels with a diameter of up to 35 mm and spherical ones (45 mm).

- Local appointment. The design is identical to the first category, but they are powered by a reduced voltage - 12/24/36/48 V. They are usually used in portable lamps and devices that illuminate workbenches, machines, etc.

- Illumination with painted bulbs. Often the power of products does not exceed 25 W, and for coloring the internal cavity is covered with a layer of inorganic pigment. It is much less common to find light sources whose outer part is painted with colored varnish. In this case, the pigment fades and crumbles very quickly.

- Mirrored. The bulb is made in a special shape, which is covered with a reflective layer (for example, by spraying aluminum). These products are used to redistribute the light flux and increase lighting efficiency.

- Signal. They are installed in lighting products intended to display any information. They are characterized by low power and are designed for long-term operation. Today they are practically useless due to the availability of LEDs.

- Transport. Another broad category of lamps used in vehicles. Characterized by high strength and vibration resistance. They use special bases that guarantee strong fastening and the ability to quickly replace them in cramped conditions. Can be powered from 6 V.

- Spotlights. High-power light sources up to 10 kW, characterized by high luminous efficiency. The spiral is laid compactly to ensure better focusing.

- Lamps used in optical devices, for example, film projection or medical equipment.

Special lamps

There are also more specific types of incandescent lamps:

- Switchboards are a subcategory of signal lamps used in switchboards and performing the functions of indicators. These are narrow, oblong and small-sized products with smooth parallel contacts. Due to this, they can be placed in buttons. Marked as “KM 6-50”. The first number indicates the voltage, the second indicates the amperage (mA).

- Incandescent or photographic lamp. These products are used in photographic equipment for normalized forced mode. It is characterized by high luminous efficiency and color temperature, but a short service life. The power of Soviet lamps reached 500 W. In most cases, the flask is frosted. Today they are practically not used.

- Projection. Used in slide projectors. High brightness.

The double-filament lamp comes in several varieties:

- For cars. One thread is used for the low beam, the other for the high beam. If we consider lamps for rear lights, then the threads can be used for the brake light and side light, respectively. An additional screen can cut off rays that in the low beam lamp can blind oncoming drivers.

- For airplanes. In a landing light, one filament can be used for low light, the other for high light, but requires external cooling and short operation.

- For railway traffic lights. Two threads are necessary to increase reliability - if one burns out, the other will glow.

Let's continue to consider special incandescent lamps:

- A headlight lamp is a complex design for moving objects. Used in automotive and aviation technology.

- Low inertia. Contains a thin filament. It was used in optical-type sound recording systems and in some types of phototelegraphy. Nowadays it is rarely used, since there are more modern and improved light sources.

- Heating. Used as a heat source in laser printers and copiers. The lamp has a cylindrical shape, is fixed in a rotating metal shaft, to which paper and toner are applied. The roller transfers heat, causing the toner to spread.

Marking

All types of lamps have their own letter designation, but this should not be confused with the type of base, for example, E27.

The marking of light bulbs with filament contains:

- The first letters (from 1 to 4) indicate important physical properties or design features: V-vacuum, G - gas-filled monospiral with argon filling, B - gas-filled double-spiral, K - filled with krypton, MT - flask with a matte coating, etc. Special incandescent lamps do not have these letters in their markings.

- The second part of the designation consists of 1 - 2 letters and indicates the purpose of the device: A - automobile lamp, Zh - railway lamp, KM - switchboard, PZH - floodlight, etc.

- The first digital part indicates the rated voltage and power, and the second indicates the development number, if it is repeated. For example, B235 - 245 - 60 means that the lamp is bispiral, powered by a voltage of 245 V, rated at 60 W.

If a person knows how to decipher the markings, then he will be able to choose a suitable incandescent light bulb.

Materials used in incandescent lamps

Metals

The main element of incandescent lamps is the filament body. To make a filament body, it is most advisable to use metals and other materials with electronic conductivity. In this case, by passing an electric current, the body will heat up to the required temperature. The material of the filament body must satisfy a number of requirements: have a high melting point, plasticity that allows drawing wire of various diameters, including very small ones, a low evaporation rate at operating temperatures, which ensures a long service life, and the like. Table 1 shows the melting temperatures of refractory metals. The most refractory metal is tungsten, which, along with high ductility and low evaporation rate, has ensured its widespread use as the filament of incandescent lamps.

Table 1

Melting point of metals and their compounds

| Metals | T, °С | Carbides and their mixtures | T, °С | Nitrides | T, °С | Borides | T, °С |

| Tungsten Rhenium Tantalum Osmium Molybdenum Niobium Iridium Zirconium Platinum | 3410 3180 3014 3050 2620 2470 2410 1825 1769 | 4TaC + + HiC 4TaC + + ZrC HfC TaC ZrC NbC TiC WC W2C MoC VnC ScC SiC | 3927 3927 3887 3877 3527 3427 3127 2867 2857 2687 2557 2377 2267 | TaC + + TaN HfN TiC + + TiN TaN ZrN TiN BN | 3373 3307 3227 3087 2977 2927 2727 | HfB ZrB WB | 3067 2987 2927 |

The evaporation rate of tungsten at temperatures of 2870 and 3270°C is 8.41×10-10 and 9.95×10-8 kg/(cm²×s).

Among other materials, rhenium can be considered promising, the melting point of which is slightly lower than that of tungsten. Rhenium can be easily machined when heated, is resistant to oxidation, and has a lower evaporation rate than tungsten. There are foreign publications on the production of lamps with tungsten filament with rhenium additives, as well as coating the filament with a layer of rhenium. Of the non-metallic compounds, tantalum carbide is of interest, the evaporation rate of which is 20–30% lower than that of tungsten. An obstacle to the use of carbides, in particular tantalum carbide, is their fragility.

Table 2 shows the main physical properties of an ideal filament body made of tungsten.

table 2

Basic physical properties of tungsten filament

| Temperature, K | Evaporation rate, kg/(m²×s) | Electrical resistivity, 10-6 Ohm×cm | Brightness cd/m² | Luminous efficacy, lm/W | Color temperature, K |

| 1000 1400 1800 2200 2600 3000 3400 | 5,32 × 10-35 2,51 × 10-23 8,81 × 10-17 1,24 × 10-12 8,41 × 10-10 9,95 × 10-8 3,47 × 10-6 | 24,93 37,19 50,05 63,48 77,49 92,04 107,02 | 0,0012 1,04 51,2 640 3640 13260 36000 | 0,0007 0,09 1,19 5,52 14,34 27,25 43,20 | 1005 1418 1823 2238 2660 3092 3522 |

An important property of tungsten is the possibility of producing its alloys. Parts made from them retain a stable shape at high temperatures. When the tungsten wire is heated, during the heat treatment of the filament and subsequent heating, a change in its internal structure occurs, called thermal recrystallization. Depending on the nature of recrystallization, the filament body may have greater or less dimensional stability. The nature of recrystallization is influenced by impurities and additives added to tungsten during its manufacturing process.

The addition of thorium oxide ThO2 to tungsten slows down the process of its recrystallization and provides a fine-crystalline structure. Such tungsten is strong under mechanical shocks, but it sags greatly and is therefore not suitable for the manufacture of filament bodies in the form of spirals. Tungsten with a high thorium oxide content is used to make cathodes for gas-discharge lamps due to its high emissivity.

For the manufacture of spirals, tungsten with an additive of silicon oxide SiO2 is used together with alkali metals - potassium and sodium, as well as tungsten containing, in addition to those indicated, the additive of aluminum oxide Al2O3. The latter gives the best results in the manufacture of bispirals.

The electrodes of most incandescent lamps are made of pure nickel. The choice is due to the good vacuum properties of this metal, which releases gases sorbed in it, high conductive properties and weldability with tungsten and other materials. The malleability of nickel allows welding with tungsten to be replaced by compression, which provides good electrical and thermal conductivity. In incandescent vacuum lamps, copper is used instead of nickel.

The holders are usually made of molybdenum wire, which retains elasticity at high temperatures. This allows the filament body to be maintained in an extended state even after it expands as a result of heating. Molybdenum has a melting point of 2890 K and a temperature coefficient of linear expansion (TCLE), in the range from 300 to 800 K equal to 55 × 10-7 K-1. Molybdenum is also used to make inserts into refractory glass.

The terminals of incandescent lamps are made of copper wire, which is end-welded to the inputs. Low-power incandescent lamps do not have separate terminals; their role is played by elongated terminals made of platinite. To solder the leads to the base, tin-lead solder of the POS-40 brand is used.

Glass

Stems, plates, rods, flasks and other glass parts used in the same incandescent lamp are made of silicate glass with the same temperature coefficient of linear expansion, which is necessary to ensure the tightness of the welding points of these parts. The values of the temperature coefficient of linear expansion of lamp glasses must ensure the formation of consistent junctions with the metals used for the manufacture of bushings. The most widely used glass is the SL96-1 grade with a temperature coefficient of 96 × 10-7 K-1. This glass can operate at temperatures from 200 to 473 K.

One of the important parameters of glass is the temperature range within which it maintains weldability. To ensure weldability, some parts are made from SL93-1 glass, which differs from SL96-1 glass in its chemical composition and a wider temperature range in which it retains weldability. SL93-1 glass is characterized by a high content of lead oxide. If it is necessary to reduce the size of the flasks, more refractory glasses are used (for example, grade SL40-1), the temperature coefficient of which is 40 × 10-7 K-1. These glasses can operate at temperatures from 200 to 523 K. The highest operating temperature is quartz glass of the SL5-1 brand, incandescent lamps from which can operate at 1000 K or more for several hundred hours (temperature coefficient of linear expansion of quartz glass is 5.4 × 10-7 K-1). Glass of the listed brands is transparent to optical radiation in the wavelength range from 300 nm to 2.5 - 3 microns. The transmission of quartz glass starts at 220 nm.

Inputs

The bushings are made of a material that, along with good electrical conductivity, must have a thermal coefficient of linear expansion, ensuring the formation of consistent junctions with the glass used for the manufacture of incandescent lamps. The junctions of materials are called consistent, the values of the thermal coefficient of linear expansion of which in the entire temperature range, that is, from the minimum to the glass annealing temperature, differ by no more than 10 - 15%. When soldering metal into glass, it is better if the thermal coefficient of linear expansion of the metal is slightly lower than that of glass. Then, when the solder cools, the glass compresses the metal. In the absence of metal with the required value of the thermal coefficient of linear expansion, it is necessary to make unmatched joints. In this case, a vacuum-tight connection between metal and glass over the entire temperature range, as well as the mechanical strength of the solder, are ensured by a special design.

A matched junction with SL96-1 glass is obtained using platinum leads. The high cost of this metal led to the need to develop a substitute, called “platinite”. Platinite is a wire made of an iron-nickel alloy with a thermal coefficient of linear expansion lower than that of glass. By applying a layer of copper to such a wire, it is possible to obtain a highly conductive bimetallic wire with a large thermal coefficient of linear expansion, depending on the thickness of the layer of applied copper layer and the thermal coefficient of linear expansion of the original wire. Obviously, this method of matching the temperature coefficients of linear expansion makes it possible to match mainly the diametrical expansion, leaving the temperature coefficient of the longitudinal expansion unmatched. To ensure better vacuum density at the joints of SL96-1 glass with platinite and to enhance wettability over a layer of copper oxidized over the surface to cuprous oxide, the wire is coated with a layer of borax (sodium salt of boric acid). Sufficiently strong solders are ensured when using platinum wire with a diameter of up to 0.8 mm.

Vacuum-tight soldering into SL40-1 glass is obtained using molybdenum wire. This pair provides a more consistent connection than SL96-1 glass with platinite. The limited use of this solder is due to the high cost of raw materials.

To obtain vacuum-tight leads in quartz glass, metals with a very low thermal coefficient of linear expansion are required, which do not exist. Therefore, I get the required result thanks to the input design. The metal used is molybdenum, which has good wettability with quartz glass. For incandescent lamps in quartz flasks, simple foil bushings are used.

Advantages

Incandescent lamps have the following advantages:

- Low cost compared to other types of lamps (fluorescent, LED).

- Compact sizes.

- They operate with minor voltage drops.

- They operate without special equipment and emit light immediately after switching on (no warm-up time is needed).

- When operating on alternating current, flickering is present, but the human eye cannot detect it.

- They emit light that is pleasant to human vision, and the color rendering coefficient is at a high level.

- An ordinary light bulb can operate at low temperatures, so it is used for street lighting.

- There are no toxic substances in the flask, so it can be thrown into the trash.

- They operate silently (no noise, crackling, hum), and there is no radio interference.

- The device is not sensitive to connection polarity.

- The filament of the device emits relatively little UV rays.

These are the main advantages of incandescent lamps.

History of the light bulb: stages of discovery.

Let's take a closer look at the history of the creation of the lighting device. A common lamp is one of the simplest electrical devices. Electrical engineering became a separate science almost immediately after the discovery of electricity in the second half of the 18th century. The history of the light bulb should begin with the invention of a chemical current source - the first galvanic cell. It was designed by the Italian scientist Alessandro Volta in 1800. Almost immediately, the St. Petersburg Academy purchased an entire electric battery for experiments, consisting of 420 pairs of galvanic cells. Professor Vasily Petrov conducted experiments with it for several years. As a result, in 1808 he discovered the electric arc: a discharge that occurs between electrode rods separated at a certain distance. Petrov suggested that this glow could be used for lighting. The English scientist Humphrey Devy came to the same conclusion two years later. Electrodes were used, both metal and carbon. The latter shone brighter, but quickly burned out. It was also necessary to constantly move the electrodes to maintain the required distance. Scientists failed to create a lighting device, but their works served as the basis for further research.

In 1838, the Belgian scientist Jobart managed to create a working prototype of a lamp with carbon electrodes. But they quickly burned out, since the glow took place in the air.

In 1840, a member of the St. Petersburg Academy of Sciences Warren Delarue (English by birth), designed a lamp with a platinum spiral. The device worked for quite a long time and successfully illuminated the room, but due to the high cost of materials, production did not go beyond the prototype.

In 1841, the Irish scientist Frederick de Mollane received the first lighting device. The device consisted of a platinum coil placed in a vacuum.

In 1844, John Starr received an American patent . His lamp worked on the basis of a carbon filament. Due to the death of the scientist, research stopped.

<>Another ten years later, in 1854, a scientist from Germany, Heinrich Goebel , developed the first prototype of a modern lamp: charred bamboo sticks were used as electrodes, placed in a flask with evacuated air. The scientist managed to create a device with which he illuminated his own store. Unfortunately, Goebel was unable to obtain a patent for his device.

In 1860, English physicist Joseph Wilson Swan presented his version of a lighting device. His patent lamp operated in a vacuum with carbon fiber. Due to the difficulties of maintaining the required vacuum, the technology did not gain further distribution.

Finally, in 1874 Russian engineer Alexander Lodygin invents and receives a patent for a filament lamp. He chooses a carbon rod as the incandescent element. The filament was placed in a sealed glass vessel with air evacuated. This solution immediately increased the service life of the lamp to 30 minutes and made it possible to use it outside laboratory walls. A year later, scientist Vasily Fedorovich Didrikhson made important improvements to Lodygin’s design: he placed several filaments in one device. When one carbon rod burned out, the next one began to work automatically.

Electrical engineer Pavel Yablochkov in 1875-1876 that led to the invention of arc lamps. The scientist studied the properties of kaolin (white clay) and saw that under certain conditions it glows in the open air. The design of the “Yablochkov candle,” as they were called then, is simple. It consisted of two parallel carbon rods coated with kaolin. The rods stood on a candlestick-type stand. The electrodes were connected by a thin carbon bridge. It burned the moment the lamp was turned on, heating up the kaolin, which subsequently glowed. The world community showed great interest in Yablochkov's invention. Almost immediately, his lamps began to be used to illuminate the streets of Paris, and then other capitals. Unfortunately, the service life of the Yablochkov candle was short, and they were gradually replaced by incandescent lamps.

Meanwhile, Joseph Wilson Swan continued his work and in 1878 patented a new lamp design with carbon fiber placed in a rarefied oxygen atmosphere.

American inventor Thomas Edison did not remain aloof from the problem of creating a lamp. By studying world experience and his own many years of experiments, in 1879 the scientist patented his lamp. At first Edison used a platinum helix, but then returned to carbon fiber. And in 1880 he creates a lamp with a service life of as much as 40 hours. The device operated in a sealed housing with evacuated air. The electrodes were made using a special technology from charred bamboo fibers. The lamp shone brightly and did not blink. However, production was too expensive. To reduce the cost, Edison replaces bamboo with cotton threads. Along the way, the scientist invents a switch, a base and a socket for light bulbs. The screw design of the latter made it possible to quickly and safely replace the lighting fixture.

In the late 80s of the 19th century, Lodygin emigrated to the USA, where he continued his scientific works. In the 1890s, he came up with the idea of using refractory metals as filaments for light bulbs. As a result of experiments, Lodygin settled on threads of tungsten and molybdenum, twisted into a spiral. He also experimented with gas-filled lamps. In particular, Lodygin made a device with a carbon filament in a nitrogen atmosphere. Subsequently, in 1906, the scientist sold the idea of using tungsten filament to the Edison company. Lodygin himself focused on the electrochemical production of refractory metals. This method was highly expensive. Because of this, tungsten filaments were rarely used until William Coolidge made them cheaper to produce in 1910. From this moment on, tungsten filaments replace all other filament options.

A year earlier, the problem of rapid evaporation of filament in a vacuum was solved: in 1909, the American scientist Irving Langmuir began filling the bulb of an incandescent lamp with inert gases. Argon was most often used. All this led to a significant increase in the operating time of the incandescent lamp.

Over the past hundred-plus years, their design has not changed fundamentally: a sealed glass flask filled with argon and a tungsten helix. Despite the emergence of new lighting devices (LED, fluorescent and others), the incandescent lamp does not lose its position and is widely used all over the world. It is all the more pleasant to realize that many Russian scientists had a hand (and head) in the invention of such a popular lighting device.

- Related Posts

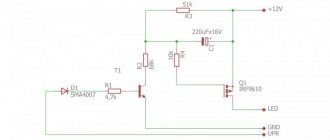

- What is a driver and why do LEDs need it?

- Lamps with e40 base: the most powerful, advantages and disadvantages, circuit diagram of LED lamps

- Types of T8 tubular lamps: comparison of ll with led, how to replace and connect

Flaws

There are also quite a few disadvantages to an incandescent light bulb:

- The device emits a lot of heat and little light.

- The service life is relatively short, especially during power surges.

- At low voltage the light becomes dim.

- Consumes a large amount of electrical energy.

- There is a risk of fire as the surface around the bulb can reach temperatures of up to 330°C.

- The flask may explode and injure nearby people with fragments.

- Regular light bulbs are fragile to vibrations and very loud sounds.

Important! The disadvantages of incandescent lamps explain the decline in their popularity in recent years. Now they are being replaced by more durable, long-lasting and economical LEDs.

Marking of light bulbs and base

For specialized lamps there is an alphanumeric coding.

The first letter determines the design and physical properties. For example: b – argon without a spiral;

The second speaks about the purpose: a - automobile, pzh - searchlight. Next, the rated voltage and power are indicated.

Lamp bulbs for household purposes are marked only with voltage, power and year of manufacture. The diameter of the base in millimeters can be indicated on the packaging: E14, E27 and E40.

| Marking of a standard socket for a regular light bulb - E27 |

Advantages

The incandescent lamp design has a large number of advantages, which makes it so popular, let’s consider some of them:

- cheapness;

- compactness;

- low sensitivity to the quality of the supply voltage;

- turn-on speed;

- no flickering effect with backlit switches;

- easy to adjust lighting brightness;

- simplicity of design;

- no toxic elements;

- works at any temperature;

- works on any type of current;

- absence of parasitic inductive reactance;

- no radio interference;

- does not respond to electromagnetic pulses;

- of all lighting devices has the lowest level of ultraviolet radiation.

It is especially economical in places where short-term, periodic lighting is required (bathroom, pantry, cellar).

Flaws

Unfortunately, there are also disadvantages:

- short service life;

- only a small part of the power consumed by the lamp goes to lighting;

- the durability of the lamp directly depends on the voltage;

- fire hazard – the temperature of the cylinder can reach 330 °C;

- if the lamp malfunctions, the bulb may explode;

- a sharp jump in current when turned on;

- sensitivity to shocks and shocks.

Another disadvantage is associated with the departure from the standard of some manufacturers. For the manufacture of the base , zinc-clad steel was used, which created safe operating conditions.

Recently, aluminum has been used. If you look at how an incandescent lamp socket is designed, then the problem will be clear. The fact is that the cartridge contacts are made of brass; upon contact with aluminum, oxidation processes occur that disrupt the contact.

When sparking, the aluminum melts and sticks to the socket legs, after which it is almost impossible to unscrew the lamp.

Main conclusions

Until recently, filament lamps were widely used in various spheres of life, but now they are being actively replaced by modern light sources. However, many consumers still remain loyal to LN. If you are one of them, then when choosing a light bulb, consider its important characteristics and markings. You should also take into account that devices with a filament body differ in the shape of the bulb, its coating, filling, and also its functional purpose. The main advantages of incandescent light bulbs include low price, ease of use, pleasant color temperature, and the disadvantages are a short service life, high energy consumption, incandescent lamps produce a lot of heat and little light. Whether or not to use an incandescent light bulb to illuminate your living space is your choice.

Previous

Lamps and lampsTypes and principle of operation of a fluorescent lamp

Next

Lamps and fixturesHow to change fluorescent lamps with different bases

Main types and characteristics

The main types of incandescent lamps include:

- General purpose lamps. Denoted by the abbreviation LON. Typically these are devices with a power of 25, 40, 60, 75 and 100 W. The most common are 60 W. But LONs are commercially produced with a power of 150, 200, 500 and even 1000 W.

- Halogen incandescent lamps. Manufactured to operate from a high-voltage network of 220 or 110 V and from a low-voltage network. In this case, they are powered by a step-down transformer.

Low voltage incandescent lamp

Types of low-voltage halogen LNs:

- capsule, have the form of all-glass tubes with different caps - end pins GY6.35 or G4;

- reflective, having a reflective element, with a diameter from 35 to 111 mm, GZ10 base with options.

High voltage. Main voltage 220-230 V, 50 Hz. These lamps have more options:

- linear in the form of a glass tube with R7S sockets;

- cylindrical – sockets E27, E14 or B15D;

- with a remote or additional flask.

In the latest model, a small-sized halogen capsule lamp or tube is rigidly mounted inside the lamp. It is welded to the central rod of a regular LON flask and has flexible leads connected to a standard Edison socket E27 or E14. With a power consumption of 70-100 W, it provides a luminous flux 20-30% greater than a conventional incandescent lamp.

These models have higher energy efficiency, reaching 12-25 Lm/W, while conventional LONs have a light output from 3-4 to 10-12 Lm/W.

The service life of halogen models ranges from 4-5 to 10-12 thousand hours.

Separation of lamps by purpose and design

Classification of incandescent lamps by purpose.

Decorative lamps

In recent years, retro lamps have appeared that imitate old Edison LNs.

In addition, with the shape of a flask they imitate a “candle”, “candle in the wind”, “cone”, “pear”, “ball”, etc.

Edison lamps - with a color temperature of 2000 K, with filaments of different shapes, with different bulbs.

Mirror

Mirror lamps have part of the bulb coated on the inside with a reflective layer. Most often this is a coating of metal - silver, aluminum, gold, etc. This layer can be thin, translucent or thick, opaque.

Mirror infrared lamp.

Mirror structures are used in production for absolutely clean process heating, for example in semiconductor production with the highest purity of materials. In this case, the disadvantage of incandescent lamps - a large flux of infrared radiation - becomes their unsurpassed advantage.

Such lamps are used in lamps with a narrow rotating beam of light.

Design, classification and advantages

Despite the variety of light sources with filament body, the main design elements are:

- flask made of honeycomb or frosted glass of different sizes and shapes. It protects the filament body from environmental influences;

- the filament body, as a rule, is a wire of a certain diameter or metal strips;

- plinth of standardized sizes. Lamps for household use have the symbol E14, E27 and E40 (threaded), where the number indicates the size of the outer diameter in mm. For halogen products, the base is designated by the following abbreviation - G4, GU9, GU10, GU5.3, GU6.35, R7S, E14 and E27.

Lamp bulbs are evacuated and filled with inert gases, halogens or their compounds.

Some types of incandescent lamps are made without a base. Such products are especially widely used in the automotive industry.

All products are classified according to the following criteria:

- functional purposes (local, general purpose, decorative, transport, mirror, spotlight, signal, illumination, optical). In addition, manufacturers produce a wide range of light sources for special purposes. These include projection lamps, double-filament lamps, incandescent lamps, heating lamps, low-response lamps, switch lamps and special-spectrum lamps. A special niche is occupied by vintage incandescent lamps - products imitated as antique.

- type of filling of the flask (vacuum, nitrogen-argon, xenon-halogen, krypton, with a special coating for converting infrared radiation into the visible spectrum);

- flask shape (drop-shaped, candle-shaped, mushroom-shaped, cylindrical, linear, etc.);

- designs of filament bodies (round diameter and strip);

- type of base (threaded, pin, single- and two-pin);

- color of execution (transparent, matte, blue, red, yellow, green, purple);

- scattering angle (10, 38 and 60 degrees);

- overall dimensions (standard version, miniature, subminiature);

- power (from 15 to 20000 W);

- voltage (12, 36, 127 and 220 V).

The design of some models may contain a reflector (reflector) to direct the light flux.

The main advantage of incandescent lamps compared to other types of light sources is their price. It is the lowest, which made them the most used and in demand. The advantages include no blinking during operation, low sensitivity to power surges and power failures, an eye-pleasing emission spectrum, a high color rendering index, and instant switching on. The main disadvantages include 2 factors - short service life (1000 hours) and low efficiency (5 - 7%).