How to replace the socket box without ruining the wallpaper?

Accordingly, in this case, there is no need to tear off the wallpaper, unroll it, then re-glue it, grease it - spoil the newly created interior. All this is nonsense and there are no unsolvable cases.

When you pull out the old socket, select a socket box that is as close in diameter as possible to the old hole - so that it fits as tightly as possible. And if there is any play left (very small), use foam double-sided tape. But remove the protective strip from the tape only on one side. Glue, wrapping around the entire circumference. So you will add this missing millimeter of diameter. And that’s it, it will fit tightly into the hole and most importantly it will not slip.

Because you won’t be able to guess which one will suit you in the end.

And an experienced master himself may not be able to guess by eye: even if one seems to initially fit, then during the final installation it may not fit properly. That’s why an electrician walks around with these several “spare” socket boxes.

It’s better to trust such things to people who specialize in this and do it on an ongoing basis, so as not to store a bunch of unnecessary construction rubbish later. As they later write on the Internet, “I’ll give away the remaining building materials.”

What can replace a pleasant and professional installation? - nothing! Therefore, do not save a penny on socket boxes and use good socket boxes.

Andrey Bely. REMONT-EKSPERT.RU

When using materials from AXIOMPLUS.COM.UA

All rights reserved. Copying is permitted only with reference to the source

Theoretical basis

The main thing to remember when carrying out any work with electrical appliances is safety precautions. Before connecting the wires to the outlet, be sure to turn off the electrical current. To do this, you need to turn off the corresponding switch located on the panel, or unscrew the plug from the meter. Then check the operation of the electrical network and voltage by trying to turn on the light.

In fact, the socket connection diagram is quite simple. Only two wires are used here - zero, phase. For sockets that provide grounding, you need to connect a third wire.

It is necessary to ensure the presence of reliable contact, as well as to exclude the possibility of a short circuit. To do this, protect that section of the wire that is located at the entrance to the terminal.

If there is an excessive stripped section of the wire, it must be cut using wire cutters to the required length. The exposed part of the wire is located exclusively inside the socket and should not protrude from the terminal.

At the next stage of work, you need to tighten the clamping screws well. Check that the wire is securely fastened in the terminal. The mechanical reliability of such a connection is very important. It is not permissible for the wire to fall out of the terminal even if force is applied.

By applying this theoretical knowledge, you will not have problems connecting sockets. If you doubt your abilities, it is recommended to watch video instructions on how to connect any type of outlet.

Triple socket - economical option

Triple socket with grounding

No electrician in his right mind would advise you to install such triple sockets on a permanent basis. They can serve normally as a carrying extension, but nothing more. However, on the market you can often find products from Kuntsevo Electro and similar companies that offer you 3 sockets at once for a price of less than $4.

Advantages of this solution:

- They take up less space than the options described above - three sockets fit into a 95*95cm block;

- Price. The mechanism of a normal Legrand socket costs $4, but here, together with the housing, the price is the same for three pieces.

Here are the disadvantages:

- Due to its design, the socket cannot be properly attached to one standard socket box and will constantly fall out of it. No matter how carefully you use it, it will definitely fall out!

- The quality of the plastic used. Self-respecting companies do not produce sockets of this format, and all the others, including Kuntsevo Electro, use cheap flammable plastic, so the use of such sockets even as “makeshift” is very dangerous.

- Contacts. There is no copper, bronze or brass inside these sockets. Only painted tin. This is how cheap goods are made. After watching a video about the production of sockets in Kuntsevo and even disassembling such a socket, you will see supposedly brass in the contact groups, but everything immediately falls into place if you check this “brass” with a magnet. After some time, tin contacts stop springing, transfer electricity through the plug worse, heat up, and rust. In general, they do everything that a tin should do in unusual circumstances.

Do not install such sockets unless absolutely necessary for yourself or the customer. In both cases it will cost you more.

Comments:

VELES

I installed a triple socket like the one in the last picture and warned customers that it would not last long. As a result, after 2 weeks they called me again and I inserted a single normal socket into their broken-down socket. It’s better to have one with a remote tee connected than a triple one in one glass.

Sasha

Explain to me why they use a level when installing a socket block? What is the need for this? Isn't it enough to simply focus on the floor or other surface? On the edge of the baseboard, for example.?

Karim

Sasha, that's what I usually do. If the floors are not level and the sockets are set to the horizon, then the customer will see that you installed the socket crookedly. Therefore, it is better to rely on the actual floor, and even better on the baseboard

Andrey

I installed triple Turkish Vi-ko sockets with a bar on the reverse side of the old Soviet sockets (they fit perfectly) so that the socket would not bend due to hooks. They have been working for 17 years. Nothing hangs loose or falls out. I connect a vacuum cleaner, computer, laptop, phone chargers, etc. Everything is fine.

Leave a comment Cancel reply

Related Posts

How to choose the right machine according to load power for an apartment

Connecting a double socket into one socket box

Installation height of sockets in a modern apartment

Height and placement of sockets in the kitchen in a modern apartment

When there is no socket at all

Rarely, but it also happens - the socket dangles, and when you take it apart, it turns out that it simply rests with spacer tendrils against the wall, preferably a concrete one.

There is only one correct solution to the problem - to install a socket box, since the steel tendrils will eventually crumble even the most durable concrete and the socket will fall out.

If there is no other choice but to fix the socket in the wall (there is no socket box and nowhere to buy one), then you can make a homemade mount for the socket. To do this, you will need to make chopsticks: from thick linoleum, sandpaper or a couple of pieces of wooden board - preferably not overdried, so as not to crack when tightening the fastening bolts.

- You need to try on where the spacer antennae rest against the wall and carefully hollow out small recesses there.

- Choppers are cut to fit the size of the resulting pits. If it is linoleum or sandpaper, then it is advisable to fold them in half, with the smooth side inward, so that the rough side touches the wall and the fastening antennae. The tree is simply given the desired shape - unlike classic chopsticks, which are made cylindrical, these need to be made rectangular.

- Next, the choppers are inserted into the fastenings, a socket is connected to them and the bolts are tightened, which pushes the fastening antennae apart.

This method can be effective even for walls not made of the hardest material, such as adobe brick, but if possible it is still recommended to make the correct fastening using socket boxes.

Installation of a socket box

If a solid socket with three sockets was selected for installation, only one socket box may be needed. A block with three separate mechanisms is fixed on single socket boxes. Difficulties may arise when installing the unit on a brick and concrete wall, since additional devices may be required. It is easier to make socket boxes with drywall.

- hammer drill or drill (for concrete, drywall and brick);

- a nozzle in the form of a rounded crown with incisors;

- two types of screwdrivers: straight and figured;

- hammer;

- Master OK;

- chisel;

- voltage measuring device.

Stages of placing socket boxes:

- Using a drill or hammer drill and a nozzle, make a round hole in the wall (you should drill until the crown is completely immersed in the wall).

- On the back of the socket box, press out three holes for the prepared cables.

- Drill two holes for the wires between the three holes for the main cable.

Working with drywall and brick requires compliance with basic safety rules. It is important to remember that such building materials are very fragile and often crumble when working with them.

In order for the socket boxes to stay in place well, they need to be secured with a thick aqueous solution of alabaster. Before installing a socket box in the wall, the hole made must be lubricated with the resulting mixture. The devices usually hold up well on a well-prepared mixture, but if they fail, more alabaster should be added to the solution. After electrical installation, the solution must be left to dry for two to three hours.

Do not forget about high-quality grounding - it is important not only for ease of use, but also for safety purposes.

Diameter of the socket box, its dimensions, installation features

If an apartment or house is being renovated, it is often necessary to install new sockets, change switches and even electrical wiring. In the case of walls made of concrete or brick, this can be difficult to do.

It is important to correctly determine the diameter of the socket box, its size, and select the necessary tools

Among the things that may be required is a special crown for processing the concrete surface. Such equipment is also suitable for drilling brick walls, concrete with additional reinforcement, stone, natural and artificial. A high-quality crown penetrates the structure of the material to an impressive distance - up to one and a half meters.

Important! It is better to avoid standard drills intended for processing metal and wood. They are not suitable, as in such conditions they quickly become unusable

Determining the diameter

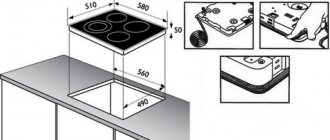

If a triple socket is installed in one socket box, it is important to correctly determine the diameter. These indicators are determined by the size of the crown, as well as other factors:

- The design of the equipment is the diameter of the socket box and its dimensions. Knowing these characteristics, you can safely go shopping for the right crown;

- To avoid mistakes, it is advisable to check for which socket boxes a particular crown is suitable;

- If we are talking about standard concrete sockets, their sizes may vary, but the diameter is 68 millimeters. All modern sockets and other similar equipment correspond exactly to them. Thus, you can safely choose 68 mm crowns for drilling;

- Equipment with a diameter of 70-75 millimeters are used much less frequently.

Where to begin

Before you begin, you should assemble the crown, doing it carefully and carefully - first fix the drill itself using bolts, then fix the threaded bowl. Among the main requirements for assembly are density and absence of inconsistencies. Neglecting these recommendations can lead to deformation of the bowl or even the drilling element. In the worst case scenario, the person doing the work could be seriously injured.

Then you can begin the drilling process using a hammer drill. An alternative to a hammer drill can be an impact drill. A regular drill will not work. You should first apply markings that will be easy to navigate. In addition, for each piece of equipment there are corresponding installation rules. Here are a number of standards that modern specialists try to adhere to in their work:

- In residential premises - about 30 cm from the floor. We are talking about the European standard, and the depth of the socket box is calculated in accordance with it

- Kitchen - about 100 cm from the countertop

- Bathroom with washing machine - about a meter from the surface of household appliances

- Pass-through type switches - about 90 cm from the floor line.

Important! The given standards are not strict rules. It's about recommendations

Hole Size Correction

It happens that the diameter of the concrete socket matches the same parameters of the crown perfectly. In the case of depth, discrepancies may be noted. However, this is easy to fix. All you need to do is adjust the depth so that the socket falls slightly into the hole - not too much, just a few millimeters. The reserve is needed so that not only the equipment itself, but also alabaster and another fixing solution can be placed in the hole.

After fixing the socket box, its protruding section is carefully cut off - thus, the element will be recessed to the required depth and will be flush with the concrete or brick wall. The design will look neat. To connect the wire to the electrical outlet, a groove is made - it should be located at the top. It can be easily done using a hammer drill or even an ordinary chisel - it depends on the characteristics of the material from which the wall is made

It is important that the wire is placed neatly. The socket is turned over, you need to find a slot on it into which the wire will be placed. The best option is to fix the wire at the back

Thus, it will be much easier to install the equipment. The wire is inserted into the socket box and in this form is placed in the previously prepared hole.

Important! The hole must have the reserve mentioned above. You may be interested in:

You may be interested in:

prokommunikacii.ru

Triple socket block

For now, we are interested in a simpler and more economical option - installing a block of three sockets in one mounting hole. Frankly speaking, this is not the wisest way to increase the number of consumers per wire, and there are arguments for this opinion, but for now let’s consider the positive aspects of such an installation:

- A triple socket in one block takes up minimal space - approximately 10x10 cm.

- A block triple socket, the price of which is not much higher than an expensive single socket, may be in no way inferior in quality to more expensive separate options.

However, there are serious restrictions on the use of such sockets. Firstly, very often people are caught being stingy by slipping in poor quality contacts. Before purchasing, you need to make sure that all contacts are certainly brass. Then you should pay attention to the quality of the plastic cover and the material of the case. Ideally, the core should be ceramic and the cover material should be non-flammable plastic.

Connecting sockets with a cable

The main nuance that causes heated debate among electricians is whether it is possible to connect an outlet with a cable?

And on this issue, many are divided into 3 camps: absolutely not

possible in some cases

you can always if the design of the socket allows it

Most modern sockets always have two terminals for each wire: phase-neutral-ground. Total 6 contacts.

It is assumed that in a walk-through socket all six ends of the wires (3 incoming + 3 outgoing) can be safely inserted into the terminals, clamped and be sure that everything is done correctly.

That is, phase and neutral working conductors are connected via a loop without problems, but for the grounding conductor, according to adherents of a categorical ban, this is unacceptable.

It is necessary to make a branch for it. Moreover, it is advisable to do it in a screwless manner so that there is no need for further maintenance (tightening). And this means sleeving by crimping, or soldering or welding.

The easiest and most convenient way to do this is by crimping. Add up the final cross-section of the three cores that will be connected by crimping and select the appropriate sleeve.

For example, you have a 3*2.5mm2 power cable. Incoming cable core 2.5mm2 + branch to socket 2.5mm2 + outgoing cable core to adjacent socket 2.5mm2. Total theoretically – 7.5mm2.

Due to the fact that the actual cross-section of the cores does not always correspond to the declared one, and loosening of the contacts is not acceptable here, select a sleeve with a slightly smaller cross-section than the calculated one - GML-6.

Place the vein into the sleeve and press the press with pliers.

Always cut off the excess length of the sleeve so that it does not take up free space in the socket box.

The resulting connection is best protected with heat-shrinkable tubing.

Although, of course, no one forbids applying several layers of high-quality electrical tape.

Especially if you have a powerful heat gun without smooth temperature control. With such a device, you can inadvertently melt certain parts of the socket box.

Power to the bottom comes from the top. If there is a break or violation of the grounding contact in the very first of them, then the “ground” will automatically disappear on the others. Which is categorically unacceptable.

However, many electricians are confident that the ban on such daisy chaining applies only to sockets located in different blocks, at a distance from each other. And this rule in no way applies to double sockets located in one block, united by a single frame.

That is, in fact, such a block is a kind of connector that has a single housing. This means that it can be considered as a single electrical installation product.

Most doubles, tees and even extensions are made in this way.

You will not be able to disassemble a single product without disconnecting the plugs from adjacent connectors. And since you have disconnected these plugs, then breaking the grounding conductor at the very first point will not affect anything.

But if the socket blocks are located far from each other and do not have a common body, then it is absolutely impossible to connect them with a cable.

Well, third interpreters of paragraph of the rules of the PUE 1.7.144 reasonably notice that in the PUE itself, nothing is said about the prohibition of “loops”. There is not even such a concept for sockets.

It says that the “Pe” conductor must be electrically continuous (the essence is in this word - electrically). And that the current-carrying elements of the device cannot be connected in series to the grounding conductor circuit.

There is neither one nor the other in the train. In most of these sockets, under one terminal, both conductors are immediately clamped. Moreover, in an acceptable way (screw or spring).

Now, if the socket had a ground input on one side and an output on the other (from under another independent contact), then yes - it’s impossible! Moreover, the PUE does not consider the socket contacts as open conductive parts, so clause 1.7.144 has nothing to do with it.

Even if you are forced to dismantle one of the looped sockets in this way, then in addition to the protective wire, you will also break the phase and neutral conductors.

Which of these opinions is true and how should you mount it?

If you are doing what is called for yourself and “for centuries”, so as not to look into the socket box for decades, then install a sleeve and make a branch, not a cable.

Well, if you are firmly convinced that the cable is not a violation at all, and it is not for nothing that manufacturers of sockets initially included the possibility of such a connection in their products, then at home you are free to act as supporters of the second and third methods.

In the end, this is your own home, and no one has the right to forbid you to do this and not otherwise.

Triple sockets with grounding

You also need to remember that socket designs can, in principle, be of two types:

- Type C5 is an ordinary shovel socket, without grounding, sometimes with a non-standard diameter of holes for the plug, which is simply indecent today. Even if the house does not have grounding, it is better to install more modern sockets of a different type.

- Type C6. The so-called Euro-socket, which may not have a grounding, but their sizes are strictly standardized, they have a more attractive design and, most importantly, they can withstand loads of up to 15 A, unlike old sockets that could heat up already at 5 amperes of load .

All this fully applies to triple sockets with internal fastening. You can also go the other way - buy three separate sockets, and hide them with a triple frame for sockets.

It all depends on the design features of the wall. If the wall is plasterboard, then drilling two more holes using a special crown will not be problematic. But if the wall in the house is concrete or brick, then this entails costs both in time and in work that are almost identical to minor repairs. Which option to choose is up to the master to decide.

Safety instructions

Connecting wires by soldering

When deciding to connect a built-in module, follow the safety requirements:

- Turn off the electricity and break the circuit.

- Use devices and tools with rubber or plastic insulation on the handles.

- Connect the wires with solder.

- Check the cable insulation and, if necessary, place it in a plastic tube.

- Cut the long strand or twist it into a ring and hide it in the wall.

- Extend a short wire, hiding the contacts.

- To prevent a short circuit, check that the socket and wire match the power and current in the circuit.

- Install the triple module in a wooden house only in a metal socket box.

- Place the module near the door so that the switch is closer to the opening than the socket.

Compliance with safety precautions will help to carry out installation work efficiently.

Preparing and installing the outlet

Wiring

A triple surface socket installed outdoors poses a certain danger. After all, atmospheric influences on wires, cables or the outlet itself have an extremely negative effect.

Therefore, in order to avoid negative consequences, this should be taken into account during installation. Below we will provide only the basic rules for installing wiring, and more detailed instructions can be found in other sections of this site.

So:

- External wiring can be done in both open and hidden ways. However, the use of metal pipes is not allowed in all cases. To protect against the effects of precipitation, PVC corrugation or non-metallic boxes are used. At the same time, according to 2.1.63 PUE, installation must be carried out in such a way as to exclude the possibility of moisture accumulation.

- Overhead triple sockets and wires cannot be installed at a distance of less than 1 meter under the window and balcony. In addition, clause 2.1.75 of the PUE prohibits the installation of wires and cables closer than 0.75 m along the window and 1 m along the balcony.

- When installing inputs on insulators, the distance between the roof and the wire in accordance with clause 2.1.79 must be at least 20 cm. When connecting small building forms such as pavilions, temporary booths, etc. the distance from the input to the roof must be at least 0.5 m.

Socket installation

After you have completed all the preparatory activities and your triple surface socket is ready for installation, you need to decide on the type of surface on which it will be installed. If it is a combustible or difficult-to-burn surface, then before installation you need to install a lining made of non-combustible material.

This may be asbestos sheet or steel plate. If it is a fireproof surface, then additional gaskets are not needed.

So:

- If you are using a triple overhead socket, then first secure the box. This can be done using self-tapping screws. Some models have a special seal at the attachment points, which increases the moisture resistance of the outlet.

- The next step is to insert the cable into the outlet box. This is done through a special rubber seal, which is included in the socket. You simply make a hole in it large enough for the cable or wire to pass through and feed the conductors through it.

- Now you can cut the cable and go directly to the connection. If your electrical network meets the PUE standards, then you will have three wires connected to the outlet. One of them is phase, the second, blue, is neutral and the yellow-green wire has a protective function. We connect the neutral and phase wires to the power contacts. The protective conductor is connected to the corresponding terminal. Typically, all triple overhead sockets have the designation “PE” or a grounding sign for this input.

- Now we install the power part into the box on the appropriate fastenings and close it with a lid. That's it, our triple overhead socket is ready for use. After applying voltage to the power line of the outlet, you can check its functionality.

Installation and connection of triple sockets

Of course, at the moment you can find triple internal sockets designed for one mounting box. But their quality is not always at the proper level and corresponds to the specified nominal parameters.

Therefore, it is more advisable to install three sockets, which can then be covered with a decorative cover. Thanks to this, they look like a single whole.

Installation of embedded boxes

According to clause 6.5.20 of the PUE, all devices installed in a hidden way must have special casings or be enclosed in boxes. These boxes are called mortgages. And it is their correct installation that will allow you to place the outlet beautifully and correctly.

Correct installation of embedded boxes

So:

- At the first stage, it is important to measure and mark everything correctly. After all, a mistake may not allow you to fix the decorative trim on the socket or lead to non-perpendicularity to the floor or wall.

- To install the embedded box, we must first drill a niche for them. This is done using special attachments for the hammer drill. They cope quite well with brick and some concrete walls. But sometimes they give up too. In this case, we recommend pre-drilling many holes around the perimeter of the niche with a regular concrete drill. And then use the nozzle.

- After all three niches are ready, you can secure the embedded boxes. Our instructions recommend doing this using a self-tapping screw in the central part of the box. But it is also possible to fix it using ordinary gypsum mortar or alabaster.

Note! At the time of attaching the embedded boxes, the supply wire should already be inserted into them. Otherwise, you will have to run it on top of the boxes, which is ugly and wrong.

Connecting the socket

Now our triple internal socket can be connected. This is quite simple to do and does not require special qualifications.

You just have to follow the safety rules and not be a hero. Remember, no professional electrician will perform work under voltage if it can be removed. And you shouldn't do this either.

The photo shows a diagram for connecting a triple socket

- Therefore, the first step is to remove the voltage from the group to which we plan to connect, as well as from all neighboring ones that are laid in this junction box.

Note! If you are installing additional sockets in an existing lighting group, then you should replace the group circuit breaker with a more powerful one. If the circuit breaker is already rated at 25A (circuit machines with a higher rated current are not allowed, according to clause 6.2.6 of the PUE), then you should use sockets of this group with restrictions. Indeed, as a result of an overload, not only can the group circuit breaker turn off, but also the wiring can burn out.

- Now you can open the junction box in which the connection will be made. We find the phase, neutral and protective wire feeding this group. We connect the cores of our cable accordingly.

- Now on the socket we connect the phase and neutral wires to the power contacts, and the protective wire to the grounding ones. For almost all sockets, it does not matter which power contact the phase wire will be connected to. But usually he is placed on the left output. The only exception is electric ovens, but you can read about this in other articles on our website.

- This completes the connection. We install sockets. We cover them with a decorative overlay. Close the junction box and apply voltage. If you did everything according to our recommendations, then everything should work flawlessly.

Socket block without decorative trim

If the socket box does not fit into the wall

In this case, the repair method is selected depending on what kind of electrical outlet is installed and what the wall is made of.

If the socket box was not “seated” on the mortar, then the size of the hole in the wall is “butt” and it needs to be expanded a little so that there is room to spread the plaster or cement mixture. Next, you need to inspect the socket itself - modern models have slots for threading the cable. They are located over the entire area, and if the putty is pressed through them a little, then this will be an additional fastening. If the socket box is smooth, then you can make notches on its outer side, which the solution will grab onto.

As a last resort, if you don’t have the necessary materials at hand, and it is advisable to repair the socket urgently, then you can simply screw the socket box to the wall with screws. There is only one nuance here - drill holes for the dowels from the corner and place them diagonally so that they do not become loose over time.

In some cases, you can try to fix the falling out socket box with liquid nails, as shown in the following video:

Example of installation in drywall

Plasterboard for walls is usually of standard thickness - 12.5 mm. Just in one such fragment I can show how it works to show exactly what its advantage is.

We take our socket box for drywall, clamp the antennae with our hands and insert it.

This is what it looks like from the back. These antennae are not yet clamped.

Now we perform a simple manipulation - we tighten the screw with a screwdriver (or a grandfather’s screwdriver, whichever is more convenient for you), and the tendril itself moves and (presses) until it stops.

We see how on the reverse side the socket box screwed itself in like this. And he presses himself with these very mustaches. It “fits” very well, very tightly, and it won’t go anywhere.

What it looks like from the front: two screws hold the antennae, and two more screws are left to secure the socket.

Now we install the finished socket boxes.

Some without cable wire. It is pulled into the box after the fixing solution has dried. The reason is that in some circumstances the cable can knock the socket block away from the desired level. There is no right option - you should do what is most convenient.

Installation of socket boxes

The most rational installation path is a triple socket in one socket. The latter is a block with three slots on a common frame. The installation of a composite housing of three sockets and a whole module (triple at once) is identical.

Tools required for installation

:

- hammer drill or drill (depending on the wall material - concrete or brick, respectively);

- special attachment (crown with special incisors and a radius of 35 mm);

- hammer with chisel;

- screwdriver;

- spatula (preferably two - narrow and medium).

Stages of work

:

Drill a hole. Take a hammer drill (drill) and a crown. The drill bit of the tool is pressed against the designated centers and drilled until the bottom of the nozzle touches the wall. It is recommended to break the concrete remains (when the hole is already ready) with a chisel (built into a hammer drill or a hammer). Make a groove. This is a hole for routing cables. Holes should be pressed on the back panel of the socket box. Their number is similar to the number of cable cords (that is, three). Another groove is needed for the power cable. The diameter depends on the latter. Make holes for the wires. They are made between two cable holes. It is necessary that the diameter of the drill matches the diameter of the corrugation where the wiring will be inserted. You can resort to corrugated pipe, but this is not necessary. Fix the socket box in the wall. To do this, the box is secured with alabaster (it holds better and dries faster). The mixture is used to cover the inner walls of the opening. Then place the block there and keep it there for a while (for a strong fixation)

It is important to take care of the amount of mixture, otherwise it will seep out or the socket will hold weakly. The consistency should not be too thick or thin

Complete drying of the mixture will take from 1 to 2 hours.

How to install socket boxes for a triple socket

The installation process begins with determining the location of the block of three outlets. The functionality of the structure will directly depend on the correct location. For example, in the kitchen, it is convenient to install three sockets in one socket above the countertop. This way, you can simultaneously connect your microwave oven, multicooker and other household appliances without worrying about the length of the cord.

In a room, it is better to install such a unit behind the TV, skillfully masking all connected wires with a wide screen. It is possible to install such a block of sockets in bathrooms, but here it is important to comply with fire safety requirements. In particular:

- The minimum distance to flowing water is 60 centimeters (zone 3);

- The socket group must be sealed and moisture-resistant with an appropriate degree of IP protection.

Having decided on the installation location, you need to prepare the tool and you can start marking the walls. To install a triple socket in one socket box you will need:

- 1. Construction level;

- 2. Roulette;

- 3. Pencil or marker;

- 4. A hammer drill with an attachment for punching walls and a crown.

Please note that it is better to install a block of three sockets at the initial stages of repair work, until the finishing is applied to the walls.

Wall marking

Please note that this is a very important stage of work, on which the geometry of the sockets and the ease of connecting the wiring will depend. Therefore, marking walls must be approached with maximum responsibility. When marking, you need to be guided by the number of sockets combined into a block.

When carrying out work, be sure to use a building level: this way you will gain confidence that the structure will be perfectly level and there will be no problems with installation and connection. If a block of three sockets sits crookedly, the mistake made will immediately be evident.

There are certain requirements for marking walls for installing electrical outlets. For example, the distance between the centers of the socket boxes is exactly 72 mm. Take this into account when applying markings. Failure to comply with this parameter will lead to the fact that the decorative panel simply will not “sit” in its place.

In addition, the groove for laying wires must run strictly horizontally or vertically from the socket box. Only after meeting these requirements can you drill holes and tap the walls.

Drilling a hole in the wall

After the walls are marked, you need to make a mounting hole for the socket box. This is not difficult to do, the main thing is to have a good hammer drill with a special diamond bit for concrete on hand. Such “crowns” are used for drilling holes of a given diameter in brick walls and concrete floors.

The algorithm for working with a crown is simple and intuitive, so even a novice master usually has no problems. The nozzle is inserted into the chuck and drilling of a hole in the desired location begins. Drilling ends when the bottom of the bit touches the wall. The remaining concrete is knocked down with a chisel.

If you are installing socket boxes in a plasterboard wall, then you will need a special nozzle for plasterboard walls to drill holes. You can also use a utility knife.

Also, do not forget about the power cable; it is also necessary to make a groove for it. The width of the groove depends on the thickness of the cable that will be connected to the sockets (whether it will be corrugated or not). Our socket group will require a cable with a cross-section of at least 2.5 mm2.

We fix the socket box in the concrete wall

In order for a triple socket in one socket to be kept in the wall, it is necessary to fix the box with alabaster. Here it is important to correctly calculate the amount of mixture that will be applied to the back and side walls. If you overdo it, then the excess alabaster will stick out; an insufficient amount of the mixture will not be able to ensure reliable fixation of the socket box. The amount of alabaster is determined individually, depending on the type of partition.

The consistency of the alabaster mixture should not be too liquid, as it will spread when applied. But you also don’t need to make it too thick, otherwise it will be difficult to apply and smear (besides, the thick mixture will quickly set and dry). I always prepare the mixture by eye, in small portions.

This material will provide better adhesion of the socket box to the wall and will dry quickly. By the way, it is precisely because of the drying speed that alabaster should be preferred to other types of building mixtures.

The process of installing a socket box in a concrete wall is as follows: a diluted mixture is applied to the inner walls, a block is inserted and securely fixed for a while. At this stage, it is important to observe the geometry and align the structure to a given level. Please note that the mounting screws must match both the vertical and horizontal level of the sockets.

When installing a socket box for a triple socket, do not forget about the power cable; we also insert it into the hole. Some craftsmen, on the contrary, fix the socket boxes without a cable and push it into the box only after the solution has dried. Explaining this by saying that the cable, bending, knocks the box out of level. There is no significant difference in this and you can do it the way that is easier and more convenient for you. It's easier for me to install the cable right away.

The alabaster will dry for about two hours, when the mixture sets, you can start connecting the wiring.

Design features

The design of the socket consists of a body and an internal (working) part. Functionally important elements are terminals with attached springs for the plug and contacts. Most models are equipped with a grounding connection. This helps reduce voltage from connected equipment and improve system safety.

There are numerous types of products on the current market. When selecting specific modifications, the peculiarities of using electrical appliances should be taken into account. A significant number of them are compatible with products of type C6 (euro). But standard devices like C5 (Soviet) are still in demand. They differ from each other not only in appearance, but also in design features. In addition to a more attractive design, Euro sockets can withstand high current (up to 16A, standard ones - up to 6A). Older models are not equipped with grounding contacts. Round holes in Euro sockets have a larger diameter for the corresponding plug rods.

Triple sockets can differ in types of contacts. They come in petal and spring types. The first ones are considered not very reliable. Over time, the petals lose their rigidity and elasticity. Then, when inserting the plug, they notice a spark. Spring contacts are characterized by greater wear resistance. They can be safely used for several decades.

When connecting a triple socket to a power source, it is best to know that it is equipped with brass contacts. The high quality of the product is complemented by a lid made of heat-resistant plastic and a ceramic core.

Main varieties

Manufacturers offer triple sockets in various shapes. Craftsmen often opt for devices that have a square shape. Such models are considered more universal.

Triple socket is:

- internal;

- external or external;

- built-in;

- overhead.

To install all modifications, use the block assembly method. This method allows you to connect three electrical appliances to one power cable at the same time. Experts recommend abandoning external frames for autonomous sockets, replacing them with one common cover. It is selected to match the contours of the inner part.

The triple socket equipped with a switch attracts special attention from consumers. The design allows you to de-energize the unit for a short or long period. This eliminates short circuits or other malfunctions when occupants are not in the room

This eliminates short circuits or other malfunctions when occupants are absent from the premises.

Installation of a triple socket is carried out using a horizontal or vertical panel. Structurally, these blocks are made on 1 frame or on 3 autonomous devices under a common cover.

Triple socket design

The products are made on the basis of a housing and a working part - terminals with springs for the plug and contacts, a grounding device. Modern European sockets can withstand currents of up to 16 A, standard ones - up to 6 A. Sockets in one housing are distinguished by a large diameter of round holes for plug rods. The device cover is made of heat-resistant plastic, the core is made of ceramic. For installation, a special horizontal and vertical panel is used.

The modules are located on a common frame or on 3 autonomous ones connected by a common panel. Today, two modifications of the triple socket block are used:

- C5. Design without grounding in a square housing. It is placed under old Soviet devices and connected to a 220 V network.

- C6. Euro socket that can withstand voltage of 230-380 V. Compatible with equipment with Euro connectors and plugs.

Depending on the manufacturer, the triple module has a width from 212 to 220 mm, a height from 72 to 80 mm. The size of the device together with the overhead frame is 160 mm in height.

Phase left or right

Next, all that remains is to connect the wires to the outlet itself and install it inside.

Here you may encounter the following point, which also causes disputes and contradictions among electricians. Where exactly in the outlet should I connect the wires? If everything is clear with the ground, there is a place for it in the middle, then where should we start the zero and phase?

On the left contact or on the right? Each electrician does this at his own discretion. Because, again, in the rules, there is no clear indication of where the phase should be connected in the socket.

The most important condition here that you must meet is to connect all the outlets in the house or apartment in the same way.

For example, it would be incorrect to connect the phase to the right terminal for sockets in the living room, and to the left terminal in the bedroom. If you have already connected one according to some scheme, connect all the others in the same way.

As for the colors of the connected cores, it is already necessary to comply with the current standard.

yellow-green wire - ground

blue or white-blue – zero

multi-colored or white – phase

After connecting, gradually pack the wires. To do this, bend the socket towards you and down, then press the wires to its back and insert the entire structure like an accordion into the socket.

Use the mounting screws on the sides to perform preliminary fastening. Next, use a compact electrician’s level to check that the installation is horizontal.

If everything is fine, tighten the screws completely. After this, be sure to tighten the two more internal mounting screws.

When they are tightened, the claws extend, with which the socket seems to cling to the inner walls of the socket box.

In high-quality and expensive copies, manufacturers make such paws double on each side.

All that remains is to install the front panel and trim frame.

Some brands, such as Legrand, have interchangeable frames.

That is, the fastening mechanism itself remains in the socket box, but the insert element can be changed. For example, instead of a regular model with curtains, install a waterproof one (for the bathroom), or vice versa.

Another point concerns the frames. If you are installing a socket block, keep in mind that not all brands have a square front panel. Most often it is rectangular.

This means that you will not be able to insert it into a decorative frame as you please.

For example, to rotate 90 degrees, you will have to pick out the fastening element with latches from the frame and also turn it at a right angle.

Only after this, everything is fixed without problems.

Thus, the same frame can be placed both in a vertical block of sockets and in a horizontal one.

Double and triple sockets made from ordinary

The meaning of this connection is that the phase and neutral wires are connected from the distribution box to one of the sockets, and the third is connected from its terminals with the next wire, and so on. In essence, these are not double, but double (triple) sockets, which are connected into a separate block, which is still powered from one wire.

A series of sockets connected in this way can be easily repaired - if any part of it fails, then only the broken part will have to be replaced.

The wire connecting the blocks of sockets is selected with the same cross-section as the one that comes to the first of them. If there is no such thing, then without any problems you can take wires with a conductor of a larger cross-section, but in no case vice versa - with a load greater than gentle, the wire connected to such contacts will soon begin to heat up and oxidize. Socket blocks are generally installed in places where the use of a large number of powerful devices is not expected, although if the supply and connecting wires are of sufficient cross-section and the contacts of the sockets are well clamped, then they will easily withstand the operation of the heater in tandem with several other devices.

There is one more nuance when installing socket boxes - they can be installed one at a time, or you can find a whole block that is immediately inserted into the holes drilled in the wall. Otherwise, everything is done in the same way as with a regular outlet.

A detailed story about connecting the socket block in this video:

Pros and cons of triple sockets

The number of household appliances in modern apartments is constantly increasing. This happens at such a speed that the number of installed sockets does not meet the growing needs, especially if it alone is forced to supply a large area. In this regard, apartment owners install blocks of three or more outlets.

Most often this happens in the kitchen, where it is not always possible to use an extension cord, and the need to use several devices at the same time arises quite often.

Triple sockets have gained popularity due to several advantages:

- Reliable and safe fastenings.

- No additional wiring required.

- The ability to quickly switch from single sockets to triple sockets while simultaneously improving the overall functionality of the home electrical network.

- Easy and quick repairs if any malfunctions occur.

- Simple installation, convenient operation, relatively low cost.

However, despite the obvious advantages, most people prefer to install several separate outlets in one place rather than use a single block. This is primarily due to the specific disadvantages characteristic of such products.

Among the disadvantages are the following:

- The mechanical load on the socket increases significantly. Gradually it will begin to collapse and fall into disrepair. This will cause certain negative processes, including short circuits.

- Increased electrical load since the triple socket itself is designed to power multiple devices. If the permissible load is not taken into account, then not only the installation product will fail, but also the electrical wiring.

- Significant overall dimensions increase the risk of mechanical damage. This especially affects the quadruple socket, as well as blocks with even more sections.

However, with normal load calculations made with a certain margin, the triple block of sockets will perfectly cope with its functions, creating more convenient and comfortable conditions when using household electrical appliances.

Who keeps things burning and who doesn't?

All “experimental” ones were produced in Russia or Ukraine. And as you know, we can have very different types of plastic, and the result is unpredictable. I will simulate heating of the wiring and fire.

To do this, it is enough to first warm them up slightly and see how they behave under heat. And then expose them to open fire. After heating them evenly with a burner for literally 20 seconds, the plastic of all cases began to melt. And after another 20 seconds it easily caught fire.

Absolutely everything is burning. And they burn and spread fire beautifully. They are not self-extinguishing. And even Schneider and Legrand are on fire. If your wiring starts to heat up, it will heat up the plastic until it catches fire, they will support it perfectly...

The only thing that has a positive effect on burnout time is the thickness of the plastic wall. Those that are more expensive and thicker ignite later than others and burn longer. And what does not spread combustion is not true. Our producers surprised me. Everything burns almost the same. There's no difference.

We can only hope that you have high-quality automation that will work before the socket warms up to ignite. Here, of course, it is better to take thick-walled models.

Related Posts

- Rules for the location and installation of sockets on the kitchen apron

- How to replace an outlet in an apartment yourself

- Parallel and serial connection of sockets and switches: how to connect a grounded socket with your own hands

- Installing a grounded outlet

- How to connect a double socket

- Socket in a concrete wall: installation rules

- How to move a socket with your own hands: advice from professionals, a guide to action and 110 photos of transfer options

- Baseboard and floor electrical sockets. device and installation

- How to install a socket

- TV socket

- How to check grounding

- Twisted pair or how to connect an Internet outlet: 7 stages of installation

- Socket in the bathroom

- Wiring diagram and installation of electrical wiring in the kitchen

- How to install a socket box correctly?

- Design, connection methods and installation of the socket block

- Connecting the plug to the hob

- Smart gsm socket

- Open wiring: installation, types of fittings

- Pugnp and punp wires: characteristics, differences, prohibition of use

- How to choose a surge protector with a surge protector

- Cable current cross-section

- Wire cross-section for home wiring: how to calculate correctly

- 380 volt 3 phase private house circuit diagram. connecting electricity to the house

- All about plug sockets, classification, degrees of protection, selection criteria, installation features

Read with this

- Rules for the location and installation of sockets on the kitchen apron

- How to replace an outlet in an apartment yourself

- Parallel and serial connection of sockets and switches: how to connect a grounded socket with your own hands

- Installing a grounded outlet

- How to connect a double socket

- Socket in a concrete wall: installation rules

- How to move a socket with your own hands: advice from professionals, a guide to action and 110 photos of transfer options

- Baseboard and floor electrical sockets. device and installation

- How to install a socket

- TV socket