The strip foundation is one of the most developed and studied types of supporting structures.

It is reliable, durable and capable of long-term service in any, even very difficult conditions.

At the same time, it is difficult to avoid mistakes without careful and professional calculations.

This especially applies to monolithic strips cast from reinforced concrete.

They are designed for the most difficult conditions and heavy loads, so it is necessary to exclude any possibility of miscalculations and errors that could cause irreparable damage.

To do this, first of all, you should have a sufficient understanding of the properties and parameters of the material used.

What brands and strength classes of concrete exist?

There are two quality indicators that characterize concrete:

- Class.

- Brand.

Concrete class means tensile strength in Megapascals.

Distinguish:

- Compressive strength class (denoted by Latin B).

- Axial tensile strength class (Bt).

Concrete class is a guaranteed strength value corresponding to GOST 26633-91. Depending on production conditions, technological features and other factors, the permissible error level is 13.5%.

There are classes from B3.5 to B80, but under normal conditions concrete with a class from B7.5 to B40 is used. This is due to the fact that extreme values are needed very rarely, low values are needed due to their weakness, and high values are used only on special structures and are redundant in normal construction.

The grade of concrete indicates the average strength value for a particular indicator. In construction practice, the brand is more often used, since the class value is not maintained by all manufacturers.

Taking into account the coefficient of variability, the quality of concrete of the same grade can belong to different classes that have close values to the real indicators of this material.

What concrete to order for a strip foundation

You can follow the rule “the higher the brand, the better” with an unlimited budget. For other cases, there are standards regulating the scope of application of concrete mixtures of different brands.

In the table we are talking about BSG - ready-made concrete mixtures produced at the plant and delivered to the construction site by a concrete mixer truck or dump truck.

It is important to note that the mixture must be unloaded on site no later than:

- 90 minutes after mixing (adding water) – when delivered by concrete mixer;

- 45 minutes – when using a dump truck, without continuous mixing.

A dump truck delivers mixtures with plasticity P1–P2 - “hard” concrete with a minimum of water and without the addition of plasticizers. The recommended plasticity for pouring the foundation is P3, so they usually focus on 1 point.

When ordering a mixture, you need to think about:

- the ability to comply with the time interval, taking into account the distance from the place of shipment to the facility;

- access routes for pouring concrete into the foundation formwork.

In theory, compliance of branded BSG with standards is achieved through:

- quality components (cement, aggregates, water);

- maintaining proportions;

- quality control - from the stage of preparation of materials to unloading at the construction site;

- personnel qualifications and precise partings.

Concrete proportions: how to mix correctly

Companies often ignore standards and technical conditions for the production, storage and transportation of components and ready-made mixtures. As a result, concrete for the foundation, matured in the “correct” conditions, shows only B15 instead of the declared class B22.5. At the same time, even an experienced builder cannot always evaluate the mixture “by eye”.

Usually the difference in strength is explained by the manufacturer’s desire to save money on the most expensive component of BSG - cement.

There are three ways to protect yourself from such “suppliers”:

- prepare concrete yourself, without precision instruments, but in compliance with standard proportions;

- buy the mixture from a super-reliable manufacturer with recommendations;

- play it safe - when ordering concrete, deliberately increase the grade, strength class, frost resistance and water resistance by 1-2 gradations. For example, instead of M300 V 22.5 F150 W6, order M350 V 25 F200 W8.

The last recommendation is also relevant if the house is planned to be built on soil with weak bearing capacity (heaving).

Conclusion: in addition to building standards, it is worth taking into account the experience of pouring and operating strip foundations in different regions of the country.

Moreover, work on systematizing and generalizing such information has already been carried out. From the table below you can find out which concrete is better, based on the practice of private developers:

The table shows that for the foundation of a brick house, a mixture of M350 is required. At the same time, a private house made of timber of the same number of storeys will support a foundation made of M250. In addition, you should clarify:

- for a one-story house made of aerated concrete, grade M300 is needed;

- for a one-story house made of foam blocks - depending on the construction technology and density of the material - from M200 (for structural thermal insulation blocks) to M300 (for structural foam concrete).

For the foundation of a two-story house, you need a concrete mixture of a grade higher than the tabular one. The exception is M400 - it is not worth increasing it, regardless of the number of floors and type of soil.

Due to the price and their specific characteristics, concrete grades above M400 are not used. In addition, it is not recommended to prepare such mixtures yourself.

Sometimes people refuse to buy a ready-made mixture due to:

- remoteness of the object;

- unreliability of local manufacturers.

Then you can take on the work yourself by preparing:

- raw materials for the entire volume of concrete;

- equipment - concrete mixer, measuring containers, shovels.

Work on preparing and pouring the mixture is carried out continuously - in one shift. You need to calculate in advance how many people are needed to operate the concrete mixer, laying and compacting concrete. It is desirable that the number of workers starts from 5.

There are technologies for gradually pouring the foundation - layer by layer or with vertical joints. But in fact, this is already a monolithic block strip foundation. Such a foundation is only appropriate on dry ground, in the absence of a usable basement floor.

What does the brand mean?

The grade of concrete means a quantitative indicator of a particular property.

Exist:

- Strength grade (M).

- Frost resistance grade (F).

- Waterproof grade (W).

In practice, the M grade is most often used, which provides the most important information about the quality of the material.

There are values from M5 to M800, indicating the compression limit in kgf/cm2.

Scope of application of various types

The scope of concrete is determined by its strength and resistance to external loads. The main criterion for the quality of a material is its ability to withstand pressure.

This indicator determines the area of use:

- Concrete grades from M5 to M35 are intended for filling voids in auxiliary elements or footings.

- M50-M100 are used for the preparatory layer before pouring concrete bases (the so-called footing).

- M150 is used for the manufacture of non-critical structures in low-rise construction.

- M200-M300 is the most common material in private or low-rise construction and is capable of solving most problems in this area. Used for foundations, wall structures and other elements.

- M400 is used for monolithic foundations of large multi-storey buildings, structural elements, floors, etc.

- M550 and higher grades are used for the manufacture of critical elements of special structures, used in the construction of subways, hydroelectric power stations, etc.

In private construction, the M200 and M250 brands predominate, the quality of which is quite sufficient to solve existing problems.

NOTE!

Brand is an old classification system inherited from Soviet times. Today's standards operate with the concept of “class,” but most builders have not yet adapted to the change in units of measurement, so the concept of “grade of concrete” is still relevant.

Concrete composition for a reliable foundation

The variety of concrete mixtures, even with a quick acquaintance, is simply off the charts. There are a lot of proposals - all that remains is to decide which concrete to choose. It is used to make the foundations of buildings, garages, bathhouses, fences, ceilings in basements, construct stairs, build load-bearing structures, walls, etc.

To decide which brand of concrete to use for the foundation, you need to know what basic indicators are decisive for the qualification of concrete solutions.

The photo shows the process of pouring a strip foundation

Binding components of concrete

There are 3 key indicators for the qualification of concrete solutions:

- For binders;

Additives for concrete

- Concrete with silicate additives. Lime is used and is rare in construction;

Binder additives for concrete

What concrete is best to use for the foundation, and how to mix it correctly

- Cement concrete is the most common option, which is used for internal and external work, without which construction production from the foundation to the roof is indispensable;

- Binders such as gypsum and clay can also be used to make concrete , but they are not used for pouring foundations.

Attention: To the classification of concrete mixtures by binders, you can add polymer-cement, slag-alkaline and concrete of a special composition (resistant to acids and alkalis), but we will only talk about those types that are used for foundations.

Density of concrete

Foundations can be strip, slab, pile, columnar, so it makes sense to consider concrete according to the density of the batch, that is, according to the second key indicator:

The filler for heavy concrete is rocks, gravel, crushed stone.

- Modern construction life cannot do without heavy concrete: monolithic construction of buildings, prefabricated bridge structures, road slabs, foundation blocks, etc.;

- Which concrete to choose for the foundation is a clear question. This should be a heavy concrete mixture that has the following advantages:

- Unique strength after drying;

- The price is affordable for consumers;

- Durability;

- High density;

- Convenient feeding and placement of material.

- The constituent ingredients of heavy concrete are represented by cement, special additives, aggregate, clean sand, and water.

| Strength class | Concrete grade kg/cm³ | Cement, kg | Sand, kg | Crushed stone, kg | Water, l |

| At 15 | M200 | 260 | 900 | 1084 | 155 |

| IN 20 | M250 | 320 | 860 | 1040 | 165 |

| At 22.5 | M300 | 360 | 830 | 1040 | 165 |

| At 25 | M350 | 420 | 795 | 1000 | 175 |

| BSG V 30 | M400 | 470 | 760 | 1000 | 175 |

The composition of heavy concrete is calculated for 1 m³ and is divided according to strength class

What brand of concrete to make the foundation from:

- M500 - heavy concrete is used in the construction of subways and bridges;

- M400 - hydraulic structures, bank vaults and bridges;

- M350 - airfield plates;

- M250, M300 – pouring monolithic foundations;

Attention: In individual construction, it is common to use M150 (B12.5) for concrete footings, and M200 (B15) - M300 (22.5) for pouring concrete pads and foundations.

Many people are also interested in the following question: is it possible to use lightweight concrete to build a foundation for a house:

- Lightweight concrete contains fillers of 2 groups - natural (natural) and artificially produced.

- Whether they are structural, heat-insulating, structural-thermal-insulating, lightweight concrete is not used for pouring the foundation.

- They are used for the construction of floor walls, load-bearing structures, thermal insulation, or perform a combined function that combines both of the previous ones.

- The only type of lightweight concrete that is used, for example, for the production of FBS foundation blocks is the option with expanded clay as a filler. But it is stipulated that its density must be at least 1800 kg/m3.

Advice: It is not a fact that if you make it yourself, you will be able to achieve the required parameter, so it is better not to take risks and make heavy concrete. But in the case of using permanent formwork made from factory-made hollow blocks, you can safely use homemade expanded clay concrete to fill the channels.

An option in which you can use lightweight concrete

What requirements must it meet?

The main requirement for concrete is high strength and the ability to withstand external loads. The greatest forces acting on the belt are the weight of the building, the loads of frost heaving of the soil, acting on the sole (from bottom to top) and on the side surfaces.

The monolithic concrete strip must withstand all emerging loads and impacts, including the possibility of moisture saturation and freezing. Most of them manifest themselves in winter at low temperatures when interacting with groundwater.

The criterion is the predicted loads, taking into account the weight of the house, the effects of frost heaving, soil movement in the off-season, etc. The choice of material is made based on the totality of these indicators, which are subject to specialized calculations or determination using tables in the appendices of SNiP.

Proportions in concrete for the foundation

The required proportions are determined in two ways:

- calculated - taking into account the W/C and type of aggregates, using reference tables. They start with proportions by mass, then, knowing the density, move on to volumes;

- using a ready-made mixture composition calculator;

- from ready-made tables for popular brands.

For cement PC400:

Mass ratios are needed for purchasing raw materials, and volume ratios are needed for mixing. Before adding the components to the mixer, it is enough to divide the volume from the tables by the volume of the measuring bucket.

Table for PC500:

The approximate volume of water is taken from the table of permissible W/C. Real - determined by eye, based on the plasticity of the mixture.

Frost resistance

Frost resistance is an indicator characterizing the ability of a material to withstand a certain number of freezing-thawing cycles without changing its performance. It is designated by the letter F and has a range of values from 50 to 2000 cycles.

Frost resistance increases with increasing grade of concrete. For example, if concrete M250 has an F value of 100, then M350 has an F value of 200. At the same time, there is no direct relationship, which is due to the high coefficient of variability of the material.

This means that concrete of relatively weak grades can have high F values, but the probability of such a combination is very low. With a full guarantee, the expected F value can only be obtained with higher grades (or classes) of concrete.

How to calculate the load

The load on a strip foundation is calculated by adding up all the impacts on the strip.

Are taken into account:

- Self-weight of the base.

- The weight of the house, the total weight of the walls, ceilings, roof, structural elements, increased by a special coefficient (taking into account the weight of furniture, property and other interior items).

- Loads from the weight of snow in winter.

- Wind loads.

- Impact of frost heaving.

It is strongly not recommended to perform independent calculations of these impacts. Without experience in such calculations, errors are inevitable, the consequences of which can be fatal for the foundation or the entire structure.

It is necessary to contact a specialized organization and order a qualified calculation of the loads and load-bearing capacity of the belt.

IMPORTANT!

Alternatively, you can use an online calculator that is available on the Internet. They are able to provide fairly accurate data; this is usually sufficient for the construction of a private house. For greater reliability, you should duplicate the calculation on several calculators to protect yourself from miscalculations.

Which brand is suitable for the strip foundation of a private house?

The grade of concrete that best suits the existing conditions can be determined using the following criteria::

- Design load on the base.

- Qualitative indicators of the soil on the site, its type and composition.

- Depth of groundwater (GWL).

The main indicator is the load on the belt, the impact of soil and soil water - additional parameters that allow you to clarify and supplement the data obtained. It is noteworthy that detailed and detailed calculations are necessary for heavy and large buildings.

Private houses are predominantly lightweight and practically do not require too detailed calculations. In most cases, concrete grade M200 is used; for more difficult conditions, M250 or M300 is chosen.

The need to use heavier material arises extremely rarely, since the weight of a private house is not too large, and in the presence of very problematic soils, the solution to the problem is to change the foundation design from strip to pile-strip or pile-grillage.

It is not advisable to use concrete of stronger grades in these cases, since the soil pressure becomes too high and unstable, and relying on the strength of the tape becomes dangerous.

Concrete proportions

The composition of concrete includes:

- Cement.

- Sand.

- Water.

- Filler (crushed stone of different fractions depending on the brand of concrete).

If it is necessary to produce concrete grade M200, per 1 m3 of material you will need:

- Cement M400 - 325 kg.

- Crushed stone - 1300 kg.

- Sand - 1300 kg.

- Water - 205 l.

For concrete M250:

- Cement M500 - 320 kg.

- Crushed stone - 1280 kg.

- Sand - 1280 kg.

- Water - 205 l.

Attention! The amount of crushed stone is indicated for a fraction of 10 mm. From different manufacturers, the composition of the material may vary slightly, which is due to different quality of the components.

Choosing concrete for the foundation

The choice of concrete grade is dictated by performance characteristics and economic feasibility. A strong foundation, if it is not necessary, will lead to unjustified construction costs, so it is important to correctly determine what grade of concrete is needed. As a rule, private housing projects in Russia offer strip foundations (more than 70% of the total are being built). To determine the grade of concrete for a strip foundation, you need to take into account everything that affects the foundation.

- M200 and M250 are a grade of concrete for strip foundations for small brick houses up to 2 floors. This is partly explained by the complex hydrogeological conditions of construction. On strong rocky or sandy soils, you can limit yourself to the M150 grade of concrete, but such soils are rare. Clay soils and loams are characterized by high heaving. At negative temperatures in winter, such soils increase in volume, and unevenly due to different groundwater levels. In this case, foundations are often deformed, so the laying depth must be below the freezing level of the soil.

- In flooded soils and near bodies of water, it is important to ensure the watertightness of the foundation. The need for reliable insulation is also necessary when constructing basements. Preventing the filtration of water under pressure through the foundation concrete is achieved by installing external coating waterproofing or using concrete of a higher grade. In such conditions, it is necessary to compare costs and choose a less expensive option.

- It is also promising to use waterproofing additives in concrete. Such additives, when interacting with water, form complex water-insoluble salts with a crystalline structure. These crystals fill microcracks and pores in concrete. Concrete becomes more dense and does not allow water to pass through even at high pressure. Such compositions are added to a mixer with concrete at a construction site or when preparing the mixture.

General recommendations for choosing the grade of concrete for the strip foundation of a house include:

- M150 - lightweight wooden houses, houses made of aerated concrete, foam blocks, warm ceramics, country houses, outbuildings, garages, shallow foundations;

- M200 and M250 – brick 1-story houses with monolithic and reinforced concrete floors;

Pouring the foundation for a house

- M300 and M350 are brick cottages of 2-3 floors with thick walls and reinforced concrete floors, designed for long-term high loads.

To determine the grade of concrete for building a foundation, you need to use the recommendations outlined, then take into account additional construction conditions and, depending on them, make a final decision on the grade of concrete.

How to mix it correctly

Making concrete with your own hands is advisable only for small buildings with a shallow immersion depth of the tape and, accordingly, a small amount of material. The technology requires pouring the entire tape at one time, so for large bases it is better to order ready-made concrete delivered in a mixer directly to the site.

This option will allow you to avoid delays in pouring, which can be dangerous due to the appearance of poorly connected areas. A tape with such flaws will not be able to withstand operational loads.

If you decide to make concrete yourself, you will need to prepare all the necessary components and a concrete mixer. It is not necessary to purchase it; you can rent it for a couple of days.

You will need a sieve to sift sand, which may contain various clogging elements . In private construction, it is customary to use an armored mesh from a bed, which is installed obliquely above the receiving container.

Sand is thrown with a shovel through it into a container (box or trough), debris and foreign elements remain on the mesh. The best option is washed river sand without clay inclusions.

A gravity concrete mixer is capable of producing from 60 to 500 liters of solution per batch, depending on the volume. The volume must be known in order to be able to ensure the correct ratio of components.

The required amount of sand, crushed stone and cement is placed in a concrete mixer and mixed until a homogeneous mass is obtained, after which water is gradually poured in. Ready-made concrete is a plastic mixture with evenly distributed filler and the absence of lumps of sand or cement.

NOTE!

When mixing concrete in small batches, you should start laying with sand, to which cement is gradually added and then filler. This will allow the sand to be mixed with cement better and will eliminate lumps from the solution.

Proportions of components for concrete

The recipe for different grades of concrete is made up of different proportions of PC 400 cement, crushed stone and sand (cubic capacity/mass):

- M100. 1: 7: 4.6/1: 6.1: 4.1.

- M150. 1: 5.7: 3.5/1: 5: 3.2.

- M 200. 1: 4.8: 2.8/1: 4.2: 2.5.

- M 250. 1: 3.9: 2.1/1: 3.4: 1.9.

- M 300. 1: 3.7: 1.9/1: 3.2: 1.7.

- M 400. 1: 2.7: 1.2/1: 2.4: 1.1.

When using PC 500 cement, the following proportions are used:

- M 100. 1: 8.1: 5.8; 1: 7.1: 5.3.

- M 150. 1: 6.6: 4.5; 1:5.8:4.

- M 200. 1: 5.6: 3.5; 1: 4.9: 3.2.

- M250. 1: 4.5: 2.6; 1: 3.9: 2.4.

- M300. 1: 4.3: 2.4; 1: 3.7: 2.2.

- M400. 1: 3.2: 1.6; 1: 2.8: 1.4.

Water-cement ratio PC 400 for concrete grade:

- M100: 1.03;

- M150: 0.85;

- M200: 0.69;

- M250: 0.57;

- M 300: 0.53.

The same for cement PC 500:

- M100: 1.2;

- M150: 0.99;

- M200: 0.79;

- M250: 0.65;

- M 300: 0.61.

Excess water either evaporates, creating pores in the concrete structure, or remains in liquid form and destroys the concrete by freezing in winter. And a lack of water is harmful: not all cement enters into a chemical reaction.

Mixing concrete in a mini concrete mixer.

All ingredients should be mixed so that each grain of crushed stone and sand is moistened with cement paste over the entire surface. They operate in this order:

- Wet the concrete mixer with water, or better yet, liquid cement mortar, stirring it for several minutes.

- Sequentially load 15% water, sand and cement into the mixer in full.

- After mixing is complete, pour out all the crushed stone and remaining water.

Mix the mass for a short time - from 0.5 to 1.5 minutes. If the process is delayed, most of the liquid will evaporate and the concrete will lose strength.

In a mini-concrete mixer (up to 0.5 cubic meters), the mixture is prepared differently:

- dry mix the sand in full and half the crushed stone;

- load the entire portion of cement and mix thoroughly again;

- add water;

- pour the remaining crushed stone to break up the lumps.

The work is planned in such a way that the filling is completed in one shift.

How to calculate quantity

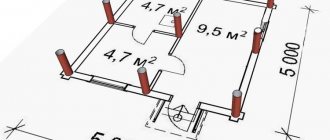

Calculating the amount of concrete is necessary in order to stock up on all components in the required volumes. Experts recommend calculating each straight section of the tape separately and then summing up the obtained values.

In this case, it turns out that the corners are counted twice, but this is good, since it allows you to get a small supply of material.

The calculation begins with calculating the cross-sectional area of the tape. To do this, its height is multiplied by its width.

All calculations must be made in the same units, preferably in meters . Then the volume of material will be expressed in cubic meters, which allows you to simply and without errors calculate the number of components.

The cross-section of the tape is sequentially multiplied by the length of all straight sections of the tape, measured along the outer perimeter. Areas located under internal walls are calculated according to the length of the center lines.

The volumes of all sections are added up, the resulting value will represent the required amount of concrete with some margin.