One of the main tasks that arises during the design of the construction of a future building is calculating the load of the main structure on the foundation. The choice of foundation type and its configuration depends on the results obtained. This article is devoted to the features of the pile foundation of a house and its advantages. The conditions under which pile construction is most advantageous will be discussed, and examples will be shown of how to calculate the number of piles based on potential foundation loads and soil characteristics.

What is a pile foundation and what does it consist of?

The basis for this type of foundation is hollow steel piles, evenly distributed around the perimeter of the future load-bearing walls of the house. The outer surface is covered with a protective anti-corrosion layer based on zinc or polymer material, and the inner surface is protected with concrete poured into the installed pile. The upper part of the foundation piles is connected by welding to the cap, which in turn will support the grillage - a structure that combines individual piles into a single base. Most often, concrete, steel channels and I-beams are used to make a grillage, less often - wooden beams.

Unlike a strip or monolithic foundation, which is also loaded along the entire perimeter of the building, installation does not require a significant amount of excavation work. It is recommended to use a foundation on piles in the following cases:

- The soils located under the construction site are characterized by instability, high humidity, and shrinkage under the influence of seasonal factors;

- Construction is carried out in an area with complex terrain, where it is extremely difficult or impossible to install conventional foundations;

- The climatic conditions in the area, as well as the groundwater level, according to the current SNiP rules, force the construction of a massive concrete foundation, which requires significant financial investments;

- When constructing a frame building, as a rule, a pile foundation is used.

Types of foundation piles

There are two main categories that differ in the way they resist settlement of pile foundations: rack-mounted and suspended. The stability of a friction pile is ensured by the frictional force between the outer surface and the surrounding soil after immersion. Rack-mounted ones are equipped with a stop near their bases, which holds the structure based on the dense layers of soil underneath it. The blades of the screw piles also serve as a support, additionally compacting the soil during installation.

Separation of piles according to construction method:

- Driven type

As the name suggests, these piles are driven into the ground using special mechanisms (construction pneumatic hammers). Their peculiarity is the fact that when driving, the force acting on it is taken from the calculation of the pile foundation. Thus, it is immersed to a depth at which there is a fairly strong layer of soil capable of supporting the estimated weight of the house. This type is considered very stable; when driven, the soil around it and under it is further compacted. Installation of driven piles is practically not used in the construction of small houses and private cottages, as it requires the use of complex special equipment.

- Screw

The products consist of a steel pipe and blades welded at the bottom, or it is a one-piece construction (which is preferable in terms of durability). The blades facilitate penetration into the ground when it is twisted, and after installation they support the load on the pile foundation and prevent it from turning. At the top of the product there are special holes with which the pile is screwed into the ground. Moreover, this process can be carried out manually, controlling the vertical position during operation. The internal volume is filled with concrete to increase mass and protect against corrosion.

- Bored

The procedure for installing bored piles does not provide for the use of ready-made metal structures. The role of the pile in this case is played by concrete poured into a pre-drilled well. If the soil is not dense enough, formwork will also be required. This method is quite easy to use and suitable for individual construction. The only caveat: the calculated load on the pile may be too high for the soil layer chosen as the base.

In further examples of the article, illustrating how to accurately calculate a pile foundation, the maximum load parameters of screw piles will be used. The following table briefly lists the most common brands of these products.

Table 1

The principle of the structure of a pile-screw foundation.

A pile-screw foundation is a set of metal piles buried (screwed) into the ground to the calculated depth, which are connected from above into a single structure by a common grillage. The piles are equipped with blades, which become not only a “tool” for screwing a metal support into the thickness of the soil - due to their area, the blades compact the rock below them during excavation and become a reliable support that can withstand considerable loads.

The principle of the structure of a pile-screw foundation

This technology allows you to go through the surface layers of soil, unstable soil, so that, in the end, the pile “finds” stable rock at a depth, usually below the freezing level, in order to minimize the influence of frost heaving forces. Not only do the blades of the pile rest on compacted soil, but they also successfully resist the forces that pull the pile upward. Thus, with proper calculation and installation, the building receives a stable foundation in conditions where other types of foundations would be useless or extremely complex and expensive.

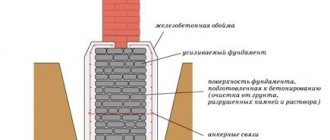

The internal cavity of the pipe-pile is most often filled with concrete along its entire height (without additional reinforcement) - this makes it possible to protect the walls from internal corrosion. The installed piles from above are cut to a level at one level in the horizontal plane, caps with mounting platforms are welded to them, on which a grillage is placed, which then becomes the basis for the further construction of external walls and internal capital lintels.

The grillage can be mounted from various materials:

| Illustration | Specification | Area of use |

| 1 – pile body (metal pipe); 2 – blade part; 3 – concrete filling of the pile; 4 – head with mounting platform; 5 – I-beam. | Frame, block or brick walls, houses made of logs or timber, buildings made of metal sandwich panels. | |

| 6 – grillage made of channel. | Frame, block or brick walls, houses made of logs or timber, buildings made of metal sandwich panels. | |

| 7 – strapping made of wooden beams (or lower crown); 8 – mechanical fastening of the strapping bars (corner); 9 – pin connection of strapping bars. | Frame houses, walls made of logs or timber, light outbuildings. | |

| 10 – monolithic concrete grillage (in some cases – even a slab); 11 – connecting embedded reinforcing structure. | Houses made of brick, aerated concrete blocks, walls made of metal sandwich panels, frame, logs or timber. |

This design ensures uniform distribution of loads across all supports and determines the main advantages of a pile-screw foundation:

- Minimum construction time - in terms of this parameter, pile-screw foundations probably have no equal. With coordinated actions by the team, and unless, of course, the soil “brings surprises” such as an impassable rock ridge at depth, work on constructing a full-fledged foundation for building a house can literally take a day or two. The waiting period for complete maturation of concrete solutions, characteristic of most other foundations, is completely eliminated.

Piles are screwed in without the use of special equipment - by the muscular efforts of several people using long levers

- Very often, the construction of a pile foundation can be carried out independently, without resorting to the services of special equipment, which significantly reduces the overall cost of construction.

True, if financial opportunity allows, and there is a desire to save yourself from difficult manual labor, you can also use the services of a special installation for screwing in such piles. The work will go even faster and better.

Prices for screw piles

screw piles

Using special equipment, installation of screw piles is simplified and accelerated to the limit

- The construction of a pile foundation is possible on almost all types of soil, including swampy and peat areas - the main thing is that the blade part reaches dense rock at a depth located below the freezing level. In this situation, frost swelling forces are unable to have any significant effect on the stability of the structure.

- A pile-screw foundation is one of the most successful solutions when it is necessary to build on a site with rugged terrain. Although the screw part of all piles should be located at the same level horizontally, their upper part can be easily trimmed at the level, also bringing it into a single plane before tying it with a grillage.

Pile foundations make it possible to simplify the construction of houses on areas with pronouncedly rugged terrain

- When using high-quality piles that have anti-corrosion treatment, such a foundation should last at least 50 years.

However, foundations of this type also have certain disadvantages :

- There are certain difficulties in installing close to newly erected buildings, for example, during the construction of an extension. The problem is solved by using special equipment.

- Existing limitations on the load-bearing capacity of screw piles. However, this drawback is not significant when conducting private construction - the built-in capabilities of piles, with their correct selection, are usually quite sufficient.

- It is not possible to equip a full-fledged basement or basement.

- Finally, the most important drawback is the effect of corrosion on metal piles, which can significantly reduce their service life. Of course, conscientious manufacturers provide possible measures to reduce such impacts - galvanized pipes and special polymer coatings are used. However, it is difficult to completely eliminate the influence of corrosion. In addition, it can be enhanced by the unfavorable chemical composition of the soil, the high probability of stray currents due to the proximity of the house to electrical substations, mines, high-voltage power lines or cell towers, and the railway.

In addition, some owners unknowingly “plant a bomb” with their own hands by connecting the house’s grounding circuit to the screwed-in piles. There are no words for how grounding this circuit is quite functional. But this is the trouble - in any emergency situation with electrical appliances, the current will flow through the pile, sharply activating corrosion processes, especially in the areas of welds.

However, let's return to the topic of our publication. With high-quality installation of screw piles, their correct placement and tying, the load from the building should be distributed evenly over all points of support. This means that to determine the number of piles it is necessary to have two fundamental parameters - the bearing capacity of the support and the total load that will be created on the foundation. Moreover, not only the mass of the building itself must be taken into account, but also operational and other external loads.

First, let's look at piles - the varieties produced and the permissible loads on them.

Details about the pile foundation with grillage

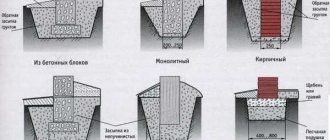

On the one hand, the grillage serves as a connecting element for individual piles, on the other hand, it is the basis for the rest of the building structure. The grillage and conditional foundation piles are combined in pairs (tape type of bundle) or all the heads are combined (tile type). A grillage for a home can be made from the following materials:

- Reinforced concrete. The concrete strip is laid on the pile heads located at ground level. During design, the locations for laying shallow trenches running deep into the grillage are also indicated.

- Concrete grillage of suspended type. A similar method in which a gap is left between the soil and the grillage. This gap allows you to compensate for possible ground vibrations (within normal limits).

- Grillage made of reinforced concrete. The basis is an I-beam and a channel (for installation under load-bearing walls, SNiP recommends) channel 30.

- Wooden beams. Lately they have hardly been used.

How to calculate the number of piles for a foundation

Correct calculation of the number of piles used requires preliminary geodetic survey. First of all, it is necessary to calculate the level of soil freezing in winter, taking into account that this indicator differs in different regions. To install the pile firmly, its lower end must be below this level.

It is also necessary to find out the degree of density of the soil layers. The higher the density, the shallower the depth of the pile should be laid at the design stage. For example, for semi-rocky and large-block rocks it will be minimal (but not less than 0.5 meters), and for sandy and clayey soils it will have to go as deep as possible.

To calculate the number and type of piles used, many parameters must be taken into account. To simplify the task, you can use a special online calculator, but for a general understanding of the process, it is better to go through all the stages of the calculation yourself.

1. Calculation of the potential ultimate load on piles

Before you start calculating the number of piles for the foundation, you should find out the bearing capacity of an individual pile. The general form of the formula is as follows:

In this case, W is the desired actual load-bearing force, Q is the calculated value of the load-bearing force, calculated for an individual pile based on the material, dimensions and characteristics of the soil; k is an additional “reliability factor” that expands the operational reserve of the foundation.

2. Calculation of the design load on piles

Next, we need to find the parameter Q, without which the calculation of a pile foundation is impossible. The design load is determined by the formula:

Where S is equal to the cross-sectional area of the pile blades, and Ro is an indicator of soil resistance at the depth of the blades. Soil resistance can be taken from the prepared table:

table 2

As for the “reliability coefficient” of a conditional foundation, its value can vary between 1.2-1.7. It is logical that the lower the coefficient, the lower the cost of the foundation at the design stage, since the use of a large number of piles will not be required to achieve a given value of the bearing force. To reduce the coefficient, a high-quality and reliable analysis of the soil at the construction site should be carried out, involving specialists.

And also for these purposes, the technique of screwing in a reference well is used. Its use is often required to calculate the settlement of pile foundations on industrial construction sites and during the construction of multi-apartment buildings, as required by SNiP. But if desired, a reference well can also be drilled during individual construction.

3. Calculation of the load from the building structure

At the final stage of designing a pile foundation, the number of piles is calculated. To do this, you will need to summarize all the structural elements of the building: from the main walls and ceilings, to the rafter system and roof. It is quite difficult to accurately calculate all components, so we recommend using one of the specialized calculators. And also operational loads are entered into the calculation calculator, including interior items, furniture, household appliances and even people living in the house.

4. Calculation of the required number of piles

Before calculating the number of piles involved, we need to obtain two values at the previous stages: the total mass of the building (M) and the load-bearing capacity of the pile (W) multiplied by the “reliability factor”. The value of the bearing capacity can be taken from Table 1. So, if the mass is 58 tons, and the adjusted bearing capacity of the SVS-108 pile is 3.9 tons, then:

As the calculation example showed, for a house weighing 58 tons, 15 piles of the SBC-180 grade will be required. It should be noted that this value is approximate and does not take into account the rules for the exact distribution of piles according to SNiP:

- The first should be installed at the intersection points of load-bearing structures;

- The rest are mounted evenly between the designated corners;

- The minimum distance between individual piles is 3 meters;

As a rule, during the design process it turns out that to comply with the above rules, a little more piles will be required than the calculations showed.

5. Installation depth of piles and distance between them

The basic value of the installation depth of the pile is calculated based on the depth of soil freezing in a particular region, plus 25 centimeters. And also before calculating the pile foundation, you need to find out:

- Pile strength level by material and design;

- Bearing capacity of the soil;

- Calculate the settlement of the pile foundation that occurs over time under the load of the building;

- Additional parameters (temperature conditions throughout the year, precipitation volume, wind loads, etc.).

Calculation of the bearing capacity of bored piles

Bored piles are often used when creating a residential building. Such foundation elements are created by concreting wells. To determine the installation depth of such structural elements, you need to know about the characteristics of the soil in the area and the freezing depth.

First, you should determine the load-bearing capacity of the foundation and the estimated weight of the finished house. The distance between them should be approximately two meters. It is also worth remembering about the correct connection of the piles to each other. A grillage is created to connect all the elements. It is necessary if the structure is made of wood, aerated concrete and foam blocks. It is worth remembering that to create a reliable grillage, you must use only high-quality concrete.