Advantages

The reliability and durability of the planned structure depends on the correct choice of foundation. To evaluate the advantage of screw piles, it is necessary to analyze a number of factors:

- Price . Unlike the use of conventional columnar supports and shallow tape, the installation of screw piles will cost the developer 20-30% less. And if we are talking about the need to lay a reinforced concrete strip or monolithic slab to a considerable depth, then the savings will be much greater.

- Difficulty of construction . Labor costs for installing a pile-screw foundation directly depend on the type of structure of the future building, as well as the need to bury the supports below the frost line. In areas with particularly unstable soil, it is advisable to additionally install a drainage system. If you plan to build a small-sized building with low weight, then 3 people are enough to install screw piles. But for large-scale construction you will have to hire special equipment. hydraulic excavators, drilling rigs and other machines.

- Installation speed . To install the presented type of foundation, no excavation work is required. In addition, after screwing in the piles, you can immediately proceed to the next stage of construction. As a rule, installation of such a foundation does not take longer than 2 days.

- Seasonality . The installation of piles can be done at any time of the year, which is a definite advantage, because working with concrete mixtures in winter is accompanied by additional costs for anti-frost additives.

- Relief of the site . The use of screw piles is especially advisable if the site is characterized by large differences in height (up to 8 m). Reinforced concrete foundations also cope with this task, but it will cost the developer several times more.

- Soil subsidence . Screw piles are best suited for building foundations in conditions with moisture-saturated soil masses subject to heaving forces.

- Maintainability . If for any reason one of the supports bursts during operation, it can be quickly replaced with a new one without compromising the integrity of the structure.

- Thermal and waterproofing . The design feature of this type of foundation involves an air gap between the ground surface and the zero floor of the house. Thanks to this, the humidity and temperature of the earth do not in any way affect the structure itself.

- Prospects for the developer . In the future, if the owner of the house wants to increase the area of the building, it is possible to screw in additional supports to strengthen the structure.

- Life time . High-quality metal supports, the body of which is complicated by blades of various configurations, can last up to 80 – 100 years.

Application area

Initially, pile-screw foundations were used in the construction of piers. But the military developed this idea, significantly expanding the scope of use. And today this type of foundation is widely used in private construction. The production technology of screw piles has been significantly improved - special high-strength steel is used to create them. In addition, some piles have special blades on the head, which allow additional compaction of the soil layer adjacent to them.

Therefore, this type of foundation can be a good choice when building in difficult areas. This can include:

- areas with slopes, hills, depressions;

- areas with heaving soil;

- peat areas;

- regions with deep soil freezing.

Conducting construction on all these sites and using traditional types of foundations (monolithic, columnar or strip) is quite problematic. In addition, even with proper installation, in such areas an ordinary foundation can be destroyed within a few years - due to seasonal changes in groundwater, as well as soil freezing. But a pile-screw foundation can easily last in such circumstances for several years.

Flaws

Along with the advantages of a foundation on screw piles, there are always disadvantages and limitations that need to be taken into account before starting construction.

The disadvantages of metal supports that are screwed into the ground include the following factors:

Not used for the construction of permanent multi-storey structures. This is primarily due to the fact that the installed piles are in no way connected to each other and are exposed to varying degrees by the influence of the soil.

Uneven shrinkage of the foundation does not lead to the formation of cracks and deformations in the walls of wooden houses, which cannot be said about brick and concrete structures.- Not suitable for all soils . The supports are not recommended for use in areas with rocky soil, a high content of stone layers and limestone deposits.

- Difficulties in constructing basements . When using screw piles, you can build a basement, but it will be a separate structure with its own walls. This option will lead to an increase in the cost of construction as a whole.

- Low quality metal . Many pile manufacturers skimp on the quality of metal and anti-corrosion coating. This leads to premature rotting and destruction of the supports, as well as possible deformations during installation. If the soil contains a large amount of chemically aggressive substances, the service life of the pile is reduced to 50 years.

- Susceptibility to bending loads . In areas with moving soil, metal supports may become deformed during operation, which will generally weaken the entire structure.

Disadvantages of a pile-screw foundation

If miscalculations are made during preparation for construction, the following negative phenomena are possible:

- destruction of a metal pipe - due to poor-quality anti-corrosion coating;

- subsidence of the system - due to unequal shrinkage of each screw; if the load exceeds the calculated value or the depth of soil freezing is not taken into account;

- deformation of the base - when driving piles instead of screwing them in or when installing them in pre-dug holes, unequal level of screw placement;

- floor insulation requires a complex and costly set of works.

A clever meter that saves electricity. Pays for itself in 2 months! Everyone needs to know this in order to save!

Foreign experience shows that screw piles last for at least a century: analysis after their removal from the ground showed the possibility of further operation. In our country, screws have been used in foundation construction for no more than 15 years. During this time, a few complaints from homeowners were received regarding corrosion and displacement of piles, which was due to errors by builders and poor quality of coating of supports.

Calculation of material for the foundation

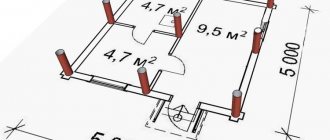

When planning the installation of screw foundations, you should calculate the number of piles and draw up a diagram of their location. For this purpose, initial data is prepared.

1. Total load (weight of the house). It consists of the following components:

- weight of building materials for walls, floors, ceilings, roofing, finishing;

- payload - created when people are in the house; for residential premises, according to SNiP, its average value is 150 kg/m2 of living space;

- snow load - normalized depending on the climate of the region; for the 3rd snow region of Russia it is 180 kg/m2 of roof.

20% (safety factor) is added to the received amount.

2. Minimum design load per pile - selected from reference books or calculated according to a geological study of the site. The deeper the screw is screwed in, the more weight it can support. For example, for a VSK 108x300x2500 pile with a depth of 1.7 m, the average calculated minimum load is 2,500 kg/m2.

The weight of the house is divided by the minimum load on one pile and the required number of supports is obtained. The distance between them (1.5 - 3 m) is selected according to the project, they are placed evenly, always being installed at the outer corners and nodes of the internal walls.

Owner reviews and typical mistakes during construction

Builders who undertake to build a foundation with their own hands, without qualifications and experience, often violate technology, which negatively affects the service life of the structure itself.

Mistakes that are most often made during the construction of a pile-screw foundation:

- Refusal from concreting the internal cavity of the pile. If the support wall thickness is less than 4 mm, then the metal may tear during service as a result of severe freezing of the soil. Therefore, the inside of the pile must be completely filled with solution, preventing the development of internal corrosion. The reinforced structure will also provide the necessary rigidity to the foundation.

- Piles at different depths. This occurs due to the heterogeneity of the soil in the area. As a result, the uniformity of the bearing capacity of the foundation is disrupted. To avoid this, the piles are screwed all the way into solid ground.

- Deviation from the vertical plane. In the process of deepening a metal pillar, builders may stumble upon underground obstacles and the axis of the pile will shift to the side. The permissible deviation should not exceed 2 degrees, otherwise the stability of the structure will be impaired.

Shortcomings in pre-design calculations can lead to house swaying and other troubles. The reason for this can be found on the forum.

For those who doubt the choice of foundation, it will be useful to read the reviews about houses on a pile-screw foundation, presented on the construction forum in the topic: “What is wrong with screw piles?”

Carrying out preparatory work

Having arrived at the site, specialists inspect the area and also study the type of soil. If necessary, test drilling is carried out. Only on the basis of the data obtained, an individual project is drawn up, suitable for a specific house in a specific area. Based on this project, a pile-screw foundation is being installed.

First of all, the number of piles is determined. This depends not only on the size of the building and the main material used (and therefore the weight of the entire structure), but also on the characteristics of the soil. On normal soils, piles are installed at a distance of three meters, but on soft soils this number is significantly reduced. Therefore, it is extremely important to correctly calculate how many piles to use during construction.

In addition, a preliminary inspection allows you to select the optimal materials. For example, after carrying out the necessary calculations, specialists accurately determine the diameter and length of the piles. These parameters are directly affected by the depth of freezing and heaving of the soil.

Finally, the most suitable tip type is selected. Today in construction they use cast and welded tips with blades of different sizes and shapes. You can choose a specific option only by examining the soil characteristics.

When the project is drawn up and materials are selected, construction of the foundation begins.

In what cases is a foundation on screw piles suitable?

The choice of foundation is directly related to the type of construction of the future structure, the physical and chemical properties of the soil on the site, as well as the owner’s desire to save on construction.

The use of technology associated with screwing screw piles into the soil is beneficial if:

it is planned to build a wooden, frame, panel house or other lightweight structure;- hard soil rocks are not very deep and there is no need to build up piles;

- the soil on the site is saturated with moisture, prone to freezing, but no noticeable horizontal movements of the earth layers are observed;

- The terrain of the site is uneven, with large differences in height.

Given the restrictions on the use of piles, it is necessary to carefully analyze the geological conditions. In some cases, it is advisable for the owner to hire a team of installers rather than do the construction with his own hands, or choose a different type of foundation.

What is a pile foundation

Pile foundations are intended for light low-rise buildings: frame, panel and wooden buildings, cottages made of foam concrete and aerated concrete. In connection with the development of pile production technologies, it became possible to build heavy brick and monolithic concrete houses on such foundations.

The basis of this type of foundation is piles vertically buried in the soil - concrete or metal rods with a length of 3 m. They are mounted under the entire perimeter of the house, as well as under critical internal structures (partitions, columns, stoves). As a rule, the distance between piles in a pile foundation is one meter. The main purpose of piles is to transfer the load from the house to the underlying dense layers of soil.

Most often, the piles are connected from above with a grillage - a belt made of reinforced concrete or metal. This frame gives the structure stability, allows you to evenly redistribute the load from the house onto the piles, and also holds each pile in a given position.

Insulation of a pile foundation

The issue of insulating the grillage of a pile foundation is always acute, because piles raise the base of the house above the ground and leave a gap that can easily freeze and be ventilated. Compared to other types of foundations, where the monolithic base forms a closed insulated contour, the uninsulated base of a pile foundation is a disadvantage. However, this problem can be solved quite simply.

To begin with, a sheathing is installed around the perimeter of the building at the base, into which a layer of insulation is subsequently laid (not forgetting to leave vents for proper ventilation), then a finishing cladding is installed in the form of base panels, slate or plywood sheets, thus solving the question of how to cover the pile foundation outside. Such a protective shell will prevent the floor and communications from freezing, and the additional installation of a blind area around the house will protect the soil under the house from freezing.

Classification of piles for pile foundations

The strength and service life of a pile foundation depends on the material of the piles. If concrete pillars last 80-100 years, then wooden ones - no more than 30. In weak soil conditions, the structure is in water for most of the year. Wood, even impregnated with hydrophobic agents, begins to rot.

Reinforced concrete beams are more reliable: concrete only becomes stronger under the influence of moisture. Reinforced concrete piles are driven, that is, they are driven into the ground using special driving equipment. The disadvantage of driven piles is the impossibility of installing them near other buildings, since when driving them, due to constant pressure on the ground, the foundation of nearby buildings may be damaged.

According to the principle of load transfer, such supports are divided into rack piles and hanging piles. The racks transfer the weight of the building to dense layers of soil, resting against them with their tip. The hanging beam holds the structure by friction of its side surfaces with the ground. In the first case, there is a pronounced combination of two methods: the pile-rack transfers the load through lateral friction and bearing on deep layers.

Solid metal piles are not considered in the construction of private buildings - such a foundation will be expensive, and the installation of such piles is complicated and impractical. But steel pipes are used in various combinations. One of the methods is this: the pipe is lowered into a pit, three-quarters filled with concrete, and a wooden beam is driven in on top to simplify the installation of the piping.

The advantage of this type of piles is the relative cheapness, and the disadvantage is the relative complexity of installation, since all work will have to be done manually.

One of the modern technologies that has become widespread recently is the construction of bored piles. A bored foundation with a monolithic grillage, built on such piles, can be easily installed with your own hands, significantly saving on materials, and at the same time build both a light frame and a heavy brick house on it. All the pros and cons of this technology are described in the article about the bored foundation.

Another technology that has quickly taken root in low-rise construction is the pile-screw foundation. Its basis is screw piles made of metal. The lower part of the rods has a sharp end and blades in the form of a screw. Screwing a pipe into the ground is often done on your own, but as a rule, special equipment is used for this. The immersion of the barrel is accompanied by compaction of the side walls of the well. Next, the pipe cavity is filled with M300 concrete. One pile can withstand pressure up to 30 tons, depending on its diameter and blade area.

The undeniable advantage of this type of foundation is its low cost and ease of installation. The disadvantages include the susceptibility of metal piles to corrosion, which significantly reduces their service life. On average, the service life of metal piles is 40-60 years, which is quite sufficient for small country houses, but may not be sufficient for houses with permanent residence.

Types of pile foundations

Structurally, pile foundations are divided into two types: pile and pile-grillage. In the first case, each support stands separately and is not connected to the others in any way. Rows of piles can be combined into strips, often installed in several rows. If quicksand or unevenly saturated soil is detected in a certain drilling area, several more supports (pile bush) are immersed nearby. The minimum number of supports in a bush is three. The same method is used to strengthen large openings (garage doors, bay windows).

In a pile-grillage foundation, the supports are united by a frame made of reinforced concrete, steel channel, and timber. The grillage can be prefabricated, monolithic or combined. This design is the most stable and durable. This type of foundation is similar to a columnar foundation, in which the supporting reinforced concrete pillars are also connected by a monolithic strip.

To understand the costs of a monolithic grillage, you can use the online calculation of a strip foundation.