Purpose of heating concrete

The optimal parameters for gaining brand strength by concrete are temperature +15..+20°C, relative humidity – 95% or more. The period for gaining standard strength under such conditions is 28 days. With other characteristics of the ambient air, chemical processes in the mixture slow down, which leads to an increase in the setting and hardening period of concrete and a decrease in its strength.

During concreting at low temperatures, normal conditions for setting and hardening of the mixture can be created using special additives. Carrying out concrete work at temperatures below -5°C requires the use of other methods, and the best of them is heating the concrete mixture using a transformer.

Why is concrete heating needed?

During the cold season, when the ambient temperature drops below the freezing point of water, problems arise with the hydration of the concrete solution. Simply put, the mixture partially freezes rather than completely hardens. After the ambient temperature rises, the thawing process begins, the solidity of the mixture may be disrupted, which will negatively affect the solidity of the structure, its resistance to water penetration, which will lead to a decrease in durability.

Consequences of pouring mortar in the cold, in this case even the Aquabarrier waterstop or other waterproofing will not help

To avoid these consequences, it is imperative to electrically heat the concrete mixture in winter. In this isothermal process, there are no disturbances in its structure, which has a positive effect on the strength of the structure being built.

Installation of stations for heating concrete

The standard layout of this equipment includes:

- The active part is a steel magnetic circuit with two voltage windings, articulated with the housing. The magnetic core has high (input) and low (output) voltage windings.

- The housing is a steel cabinet with terminals for connecting a three-phase alternating current network with a voltage of 380 V and output terminals intended for connecting a heating cable, which receives a current with reduced voltage.

- Control Panel. Serves to regulate the thermal power of steel wires when ambient temperature conditions change.

- Cooling system - natural or forced. The forced cooling system is implemented using oil or a fan.

- Intermediate aluminum APV wire (route), required for connection to the main steel cable PNSV.

- “Cold ends” are insulated aluminum wires connecting the “route” to the PNSV wire. Their length does not exceed 1.5 m.

- A fuse installed in front of the high voltage coil reacts to the threat of short circuits and equipment overload.

- An ammeter on the low voltage side to monitor the output current.

Most models are equipped with an output power control device on the low voltage side. This provides an opportunity to save energy during warming. The greater the number of stages, the higher the functionality of the device and the efficiency of its operation. The transformers are powered from a three-phase network with a voltage of 380 V. Double-insulated copper conductors are used as the power cable.

Principle of operation

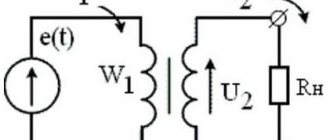

The electrical method of heating the concrete mixture using a transformer is simple to implement, but requires the participation of specialists in its preparation and implementation. The power engineer must draw up a diagram of the heating cable layout and calculate the required amount of materials. Careful round-the-clock monitoring is carried out even during warm-up, readings are recorded in a log.

Stages of pouring the mixture and heating the concrete using a transformer:

- Installation of formwork and installation of a reinforcing steel frame.

- Layout inside the formwork on the reinforcement frame of the PNSV steel wire. The most popular option is a wire with a cross section of 1.2 mm. The layout plan is drawn up in such a way that the entire reinforced concrete element is heated evenly.

- Pouring and vibrating the concrete mixture.

- Connecting the cable to the transformer.

- Warming up the mixture in accordance with the set temperature conditions.

The current value on the low voltage side usually does not exceed 14-16 A. One step-down transformer station, depending on the power, is capable of heating the volume of a concrete monolith from 10 to 100 m3.

Information about the contact heating method

Heating of the concrete mixture is carried out using conductive wires PNSV with a cross-section of 1.2 mm. They are attached to the reinforcing frame even before the process of filling the prepared space with concrete begins. The formwork filled with the mixture is covered with insulation and covered with a thick layer of sawdust. Next, the conductive cable is connected to the station (transformer) and the required time is set during which the liquid concrete will be heated to a temperature of 80 degrees.

The transformer is equipped with several voltage stages, which allows you to adjust the temperature of the solution to the ambient temperature. One transformer station is capable of heating 80 m 3 of concrete mixture.

Main elements of the station

The transformer station for heating concrete is a small installation equipped with an internal ventilation system, converters, temperature sensors and a timer, in a metal case. By converting electricity coming from the network, it transfers it to conductive cables, thereby promoting the spread of heat throughout the concrete mass.

Read also: Semi-professional guides for all types of drills

The active part of the installation is equipped with a core magnetic core having “LV” and “HV” windings, low voltage taps and yoke beams. The design of the station also includes automatic protection against overload and power surges, a dashboard with a control panel and light indicators for control circuits, and a casing with “LV” terminals.

Advantages of using concrete heating stations

The use of this equipment increases energy consumption during construction activities, but it pays off with a set of advantages, including:

- The ability to reduce construction time due to independence from weather conditions.

- Increasing the productivity of construction crews.

- Rational operation of construction equipment and transport. This is especially important if the equipment is rented.

- Ensuring quality indicators of concrete that fully comply with regulatory documentation.

- Savings due to the absence of expensive additives.

What parameters do you pay attention to when purchasing a transformer for heating concrete?

If there is a need to buy a station for heating concrete, it is recommended to pay attention to the range of control and protection devices. Modern models provide:

- automatic switch that turns off the transformer in the event of a short circuit, strong fluctuations or excessive input voltage and other emergency situations;

- control systems over all the main parameters, including the presence and characteristics of the power supply network, the properties of the output current on the low voltage side.

Prices for concrete heating stations depend on their characteristics, including:

- power;

- number of voltage stages;

- type of cooling;

- the metal from which the windings are made;

- degree of automation of transformer station control.

In dry-charged transformers, cooling is carried out naturally. Oil-filled transformer stations are cooled using mineral oil.

Review of common transformer models

The modern construction market is represented by a wide variety of models of transformer stations for heating foundations. But when performing these types of work, it is recommended to use devices that are most suitable according to the technical regulations.

The main criteria for choosing an installation:

- Internal equipment of the transformer;

- According to the power level of the unit and the presence of a different number of voltage levels;

- Type of cooling of current-carrying wires and transformer elements (models with natural (dry) cooling, oil and forced).

Below is a list of the most popular models of transformer stations that best meet the presented requirements.

KTPTO 80-86

The transformer installation has three operating phases, power is 80 kW and power supply is 380V. Scope of application: heating of foundations. An internal oil cooling system for conductive elements is installed. Fully automated workflow. Recommended operating temperature ranges from -40 to +10 degrees. The optimal work area is up to 40 m 3 .

The main advantages of the KTPTO 80-86 transformer:

- Simple design equipment of the installation;

- The presence of external terminals necessary for connecting other devices to the circuit.

The main disadvantages of the KTPTO 80-86 transformer:

- Large installation, causes some difficulties during transportation;

- The weight of the unit is quite large; movement is possible with the use of additional structural elements or third-party force;

- The unit requires frequent maintenance (every three months).

The transformer unit is manufactured in several different versions, some models have additional equipment. Modified stations have less weight and dimensions. Design features are distinguished by the presence of manual and automatic process control modes. The price range is 125,000 – 180,000 thousand rubles.

SPB-20

Three-phase transformer with a minimum set of functionality, with a power level of 20 kW. The scope of application is limited due to low power, suitable for minor construction work and the construction of small buildings. There is a natural (dry) cooling system. Recommended operating temperature ranges from -40 to +5 degrees. The optimal work area is up to 20 m 3 .

The main advantages of the SPB-20 transformer:

- Small dimensions and wheelbase for easy transportation;

- Characterized by increased reliability and protection from power surges.

The main disadvantages of the SPB-20 transformer:

- Fragile switching and adjustment components.

This model of transformer installation is presented in several versions. Modified stations have less or more power. The price range is 20,000 – 160,000 thousand rubles.

TSDZ-63/0.38

The transformer has three operating phases, with a power level of 63 kW. There is a forced cooling system. Recommended operating temperature ranges from -40 to +20 degrees. The installation operates uninterruptedly. Excellent for construction work on medium-sized buildings and structures.

The main advantages of the TSDZ-63/0.38 transformer:

- Small dimensions and weight;

- Equipped with an automatic switch.

The main disadvantages of the TSDZ-63/0.38 transformer:

- Frequent failure of the cooling system.

The price range is 61,000 – 79,000 thousand rubles.

TSDZ-80/0.38 UZ

This station is similar to the previous transformer installation. Except for some items. It is a modified analogue with expanded design equipment.

The main advantages of the transformer TSDZ-80/0.38 UZ:

- Small dimensions and weight;

- The operating mode is fully automated.

- Increased level of protection.

Read also: Is it possible to charge simple batteries?

The main disadvantages of the TSDZ-80/0.38 UZ transformer:

- If it breaks down, further restoration and repair is impossible.

The price range is 70,000 – 100,000 thousand rubles.

TSZP-80/0.38

This transformer is mobile. Has a natural (dry) cooling system. It is distinguished from other installations by the presence of 6 modes for controlling the process of heating the foundation base from 45V to 100V.

The main advantages of the TSZP-80/0.38 transformer:

- Mobility of the transformer installation;

- Small dimensions and weight.

- Easy operation and repair.

The main disadvantages of the TSZP-80/0.38 transformer:

- Automation is characterized by instability.

Price range from 58,000 thousand rubles.

Conclusion

Having at your disposal a transformer station for heating the foundations, carrying out construction work in the winter will not be a problem. Low temperatures will not be able to affect the water present in the concrete masses and thereby reduce the strength of the foundations. The main thing is to choose the right installation for the required amount of work.

Phone: (48142) 3-20-70

Address: Safonovo, st. Oktyabrskaya, 90

Popular types of concrete heating stations and their characteristics

ETA LLC produces stations with dry-type transformers, which have the abbreviation “SPB”. This equipment can be found at construction sites in most regions of the Russian Federation. Their popularity is ensured not only by the reasonable price of transformers for heating concrete, but also by other characteristics:

- Increased service life. Such stations are unpretentious to operating conditions and require low maintenance costs.

- Ability to withstand harsh operating conditions. Some models are designed to operate with overload up to 140%.

- The presence of phase ammeters that control the load value.

- Availability of protection devices based on magnetic starters that protect transformer equipment from overload.

- Convenient switching of operating modes using switches.

Models of SPB concrete heating stations:

- SPB-20. This model has the lowest power in this series - 20 kW. It is distinguished by its modest dimensions and mobility. Used in all types of construction of small buildings using monolithic technology. Available with aluminum windings.

- SPB-40, SPB-63, SPB-80. Medium power models. Provide heating of concrete at temperatures of +10…-40°C. In demand in mass construction.

- SPB-100. The most powerful equipment. Available with aluminum and copper windings.

Review of popular transformers

When choosing an electrical installation, you must take them into account:

- Design features.

- Power and number of voltage stages.

- How does the winding cool down? There are models with dry insulation, in which cooling occurs naturally (due to direct heat exchange with air), and there are also oil transformers that cool the winding using mineral oils. In addition, today there are units with a forced cooling system.

Let's consider a list of models that best meet these requirements.

But today more modern stations have appeared on sale, which are compact and lighter in weight. Moreover, in modified models you can adjust the temperature both manually and automatically.

The cost of the transformer ranges from 125,000 to 180,000 rubles.

SPB-20

This three-phase concrete heating station has a dry-type cooling system and a rated power of 20 kW. The temperature range at which the unit performs its functions is from -40 to +5 degrees.

Read also: Chainsaw chain lubrication device

The SPB-20 concrete heating station is more suitable for small construction projects with an area of up to 20 m3, so it is recommended to use it for self-construction of buildings.

The advantages of the equipment include the following:

- facilitated wheeled transportation;

- increased reliability and protection against power surges.

- During the adjustment process under network load, switches sometimes break down.

The cost of the station ranges from 49,000 to 61,000 rubles. You can also find a lower power model on sale - SPB-10, which will cost from 20,000 to 25,000 rubles. There are also more powerful units, for example, SPB-35 - SPB-100, but their use is rational only when we are talking about large areas. In addition, their cost will be from 60,000 to 160,000 rubles.

TSDZ-63/0.38

The next three-phase power unit, providing a power of 63 kW, is equipped with a forced ventilation system (built-in fan). The transformer is capable of operating in a wider temperature range from -45 to +20 degrees. In this case, the unit operates in uninterrupted mode.

- light weight, compact;

- equipped with an automatic switch.

Among the disadvantages, users highlight:

- Frequent breakdowns of the cooling system, due to which the entire installation ceases to function.

TSDZ-63/0.38 costs from 61,000 to 79,000 rubles.

TSDZ-80/0.38 UZ

This mobile station also heats concrete mortar and frozen soil. The unit also has a forced cooling system, which operates thanks to two fans installed on the rear of the unit.

- compactness;

- light weight;

- possibility of automated operation;

- high level of protection, due to which it is impossible to regulate the voltage during operation of the equipment.

However, this transformer has one significant drawback - if the station breaks down, it will be impossible to repair it.

The cost of a power transformer ranges from 70,000 to 100,000 rubles.

TSZP-80/0.38

This mobile unit is equipped with a natural cooling system. Its distinctive feature is that the concrete is heated by a transformer in 6 modes from 45 to 100 V.

The main advantages of the station:

- convenient transportation;

- compact size and light weight;

- possibility of self-repair.

There is only one drawback - the automation does not always work stably.

Such a power unit costs from 58,000 rubles.