Strength

Strength indicators are tested for compression in the company’s own laboratory, so there is no doubt about their quality. Concrete inspection is an important point for both construction companies and manufacturing companies. Laboratory testing of concrete is a priority, thoughtful and correct decision. Strength is indicated by a specific brand, which is prescribed in GOST 10180-78.

The strength of concrete depends entirely on its composition, as well as on the reliability of fastening materials. As a rule, the strength of aggregates is much higher than that of concrete itself, so it is not susceptible to environmental influences. The fillers are usually gravel, crushed stone, and sand.

From all of the above, we can conclude that the strength of concrete consists of hardened cement stone and aggregates.

The strength of cement stone consists of two characteristics. The first is the brand of cement. The second is the connection between cement and water. We can say about the brand of cement that it determines the reliability of the cement stone. This is explained by the fact that the hardening process of cement is chemically related to the percentage of water in the total mass of the mixture. In order for the mixture to be more mobile, it is necessary to take part of the water from the total mass of cement. It turns out that a much larger number of pores are formed in the cement stone, and this indicates its strength characteristics.

Concrete marking

Brand is a specific indicator that determines the components of the solution and its scope of application. Labeling occurs in laboratory conditions, after careful study of the component composition. A small cube made from a specific solution is subjected to mechanical stress. Next, a group of scientists observes the reaction and classifies the material according to appropriate criteria.

Basically, labeling allows the consumer to quickly determine for what purpose he needs the solution. We will consider the popular brands available on the construction market, as well as their scope of application. It is very important to focus your attention on these designations, because concrete for plastering cannot be used for installing curbstones.

M100

A solution marked M100 is a material with a low strength coefficient. The main specific application is plastering of premises, finishing and adjustment work. As a rule, for the construction of the foundation of a multi-story building or a complex structure, whose specific gravity exceeds the weight of concrete by 3 or 4 times, the M100 grade is not used.

In the rarest situations, M100 is used for pouring concrete footings - a flat area, for installing a reinforcement frame. In other cases, the mark is used to secure curb stones that are not subject to serious mechanical load.

From this series there is a mortar of the M150 brand, used for laying the foundation on private estates, because the strength of concrete is an order of magnitude higher than that of the M100 mixture, but this material is unsuitable for the construction of large-scale buildings.

M200

Brand M200 belongs to class B15. Used to make concrete floors or screeds. In addition, the strength of M200 allows you to fill stairs or paths with average traffic. If auxiliary additives are present, the brand can take part in pouring the foundation, but provided that the soil under the building is level, stable and not loose. Groundwater should flow at least 30–40 meters from ground level.

M300

The optimal solution when choosing a mixture for laying a foundation is to purchase a mortar of the M300 brand. The solution successfully combines incredible strength, density and resistance to significant mechanical loads. It belongs to the heavy type category, but is a rare representative of the middle class (the composition includes sand, but no crushed stone). M300 can be used to build a monolithic wall in an apartment building or warehouse.

M350

Brand M350 is a more durable material than M300. It is used for pouring the foundation of large objects or for the production of reinforced concrete panels. Any beam or tile structures will last a long time, because the M350 brand includes homogeneous structures that can withstand mechanical and physical stress, and are not subject to deformation in any weather conditions.

Pouring a floor, producing monoliths or laying a long route - the M350 brand is suitable in all situations. It should be clarified that maximum strength can only be achieved by thoroughly mixing the solution. Otherwise, all technical characteristics will decrease by 25-30%.

M400

Extremely durable and heavy material. Concrete grade M400 is a special solution used in the construction of bridges, hydroelectric dams or airfield strips. The specific gravity that this solution can withstand exceeds 2 thousand tons, which is an immediate advantage in the construction of large industrial facilities. Among the advantages is the ability to withstand any temperature, up to 1 thousand degrees, without deformation or the onset of a destructive process.

Having described all the advantages and disadvantages of each brand, I would like to focus on the specifics of such a building material as concrete. The mortar is used for long-lasting service, so if you intend to carry out frequent renovations or permanent home changes, it is recommended to use a medium-strength mortar. Otherwise, budget waste will no longer pay for itself.

Any industrial or general purpose building cannot stand for long without a decent foundation. When starting a large project, you should carefully familiarize yourself not only with the features and characteristics of the material, but also with its component composition. A solution that can withstand large loads, but begins to collapse at a certain temperature, is a losing option for large-scale production.

Porosity

For more convenient installation, the concrete mixture is obtained by introducing more water into its composition than for hardening cement. Excessive water content in the mixture indicates the formation of porosity. If you want to reduce the doughy content of concrete, then you need to reduce the porosity, i.e. reduce the water content in the mixture.

The porosity is usually six percent, and the concrete should not allow moisture to pass through. However, structures made of such concrete are easily exposed to petroleum products: kerosene, gasoline, gases.

Types and technology of manufacturing concrete compositions

To produce concrete, components are used in different proportions. Auxiliary components are often added to the mixture, affecting the performance characteristics of the material. Main types of concrete:

- cement concrete. This variety is most often found on construction sites. Made from cement, but more often Portland cement. Often the binding element is tensile and non-shrinking decorative cement;

- a special concrete mixture with a binder component at its base. Liquid glass is added to the mix, which makes the finished concrete chemically and fire resistant. Binders: additives in the form of slag, glass alkali or nepheline;

- silicate. This type is used less often than others in construction site conditions. Lime binder material is used for production. The manufacturing method is autoclave, which makes the composition hard and durable. The composition also includes quartz sand, and the technical parameters of the finished concrete depend on the degree of its grinding;

- slag-alkali. The main manufacturing component is crushed slag. In the construction industry, this variety has been used not so long ago;

- polymeric. Polymer concrete is made from a combination of resins, cement and latex;

- plaster. To bind the elements, gypsum is used. Due to the heat-insulating properties of the resulting composition, it is used for interior decoration. For example, using it, they erect interior partitions;

- cellular material. Refers to the “light” species. The basis is a mineral binder and silica additive. Using cellular concrete, the objects being built are insulated.

Each type finds one application or another at a construction site. Operational parameters vary depending on the proportions of the components, which is why the classification of concrete is so broad.

Fire resistance

This property shows the ability to withstand high temperatures, while concrete must maintain strength for a long time. When heated, all the water contained in concrete evaporates, including chemical water, thereby lowering the combustion temperature. However, structures should not be subjected to prolonged heating, because the material may lose strength.

There is special heat-resistant concrete for furnaces, industrial pipes, and furnaces. It consists of aluminous cement and fire-resistant fillers.

One more property needs to be mentioned - average density. This is the so-called ratio of the mass of the material to its total volume. The average density of concrete should be less than 100 percent.

Its strength characteristics depend on the average density of concrete, and this is a very important property for structures and structures.

Concrete M100 (B7.5)

The composition of concrete type M100 includes gravel or granite type crushed stone, sometimes limestone crushed stone.

Order M100 concrete with delivery from us by calling +7 (812) 703-90-66 or leave a request for a call back ↑ at the top of the page. We deliver concrete anywhere in St. Petersburg and the Leningrad region

Concrete M100 (B7.5): price list

The cost of concrete is indicated in rubles (RUB) per 1 cubic meter (RUB/m3) and does not include delivery costs

Price for concrete M100 (B7.5) from May 15, 2021:

*Price is valid for orders over 500 m3. For smaller volumes, check the cost with our managers.

Concrete M100: characteristics

- Corresponds to class B7.5

- Mobility: P1-5

- Frost resistance: F75

- Waterproof: W2

The characteristics of concrete depend on the composition and fillers.

Concrete of this brand reaches its strength indicators approximately 4 weeks after pouring. In this state, the strength of the material is estimated at approximately 100 kg/cm2.

The frost resistance of class B7.5 concrete is low and can withstand up to 50 freezing and thawing cycles. This makes it impossible to use the material for important external structures that are constantly exposed to temperature.

The water resistance of M100 concrete allows the material to withstand a minimum water pressure of 0.2 MPa. This is the lowest among concrete brands.

Concrete M100: application

Concrete M100 is used in the following areas:

Other brands (classes) produced by LenBeton factories:

М150 (В10) М200 (В15) М250 (В20) М300 (В22.5) М350 (В25) М400 (В30) М450 (В35) М500 (В40)

Kawabanga! Mosaic concrete floor

Water resistance

Water resistance is the resistance of concrete to moisture. To determine this parameter, two samples are used - dry and wet. The first and second samples are tested by applying pressure to the press. The strength coefficient of concrete saturation with moisture should be more than 0.8. Water resistance is also affected by hydrate formations with low solubility. Thanks to all this, concrete is considered one of the waterproof materials for structures. In other words, moisture resistance is especially important for buildings with the greatest risk of fire: platinum, piers, rumors.

Types of concrete

Concrete is one of the most common materials for construction and has a very rich history.

It has been used for the construction of buildings and other purposes for several centuries, and now technology has moved forward very much, so there are many varieties and brands that concrete plants put on the market. In this article, we will look at the features of these building mixtures and analyze where they are used, find out their parameters and differences.

What brands of concrete exist and where are they used?

They are classified according to parameters such as properties and type of filler, structure, hardening speed, purpose, etc. Adding various substances to the mixture allows you to change its characteristics depending on the purpose and purpose. It is easier to classify concrete by grade, which we will consider below.

Concrete M100-M1500. These are lightweight types of concrete that are used for purposes such as preliminary pouring of foundations, preparing a site for laying monolithic slabs, etc. Often such mixtures are used as the basis for laying borders. mm200-M250. Mixtures of this type have high compressive strength, so they have a fairly wide range of applications. It is used to make retaining walls, fill platforms, form paths, etc. In the road industry, this concrete is used to create a concrete curb cushion. Concrete M300-M350. The mixture of this brand has very high strength, so its scope of application is monolithic construction, pouring sites, etc. M350 is used to create pool bowls, produce load-bearing columns, and is certified for use in the construction of commercial and industrial facilities. M400-M450. This mixture is needed for the construction of hydraulic structures, water parks, bank vaults, and shopping and entertainment complexes. The price of M400 concrete is higher than previous brands, but its increased strength is indispensable in terms of the safety of most objects. The M450 grade is very durable and is used in the construction of dams and subways. It has a rapid degree of hardening, so work with it should be done by professionals.

When choosing a brand of mixtures for your business, you should be guided by the relevant regulations that apply to construction projects.

Classification of concrete solutions by grade

The brand is designated by the letter “M” followed by numbers. At the moment, the limits are as follows: M50 - 1000. The indicated value indicates how much cement is in one unit of volume of the mixture. By decoding this value, you can get the compressive strength, where the unit of measurement is kgf/cm2. A large number indicates the strength of concrete. Accordingly, it contains more cement, which increases its properties, and at the same time its cost.

High grade concrete is more difficult to work with because it sets faster. Therefore, when choosing the right material for work, a balance between price and quality characteristics is important. A specific brand is chosen based on the project. For example, you can pour a foundation or make a road surface cushion from M100 - 150. M200 is a variety more suitable for screeds, blind areas and paths. This is the most popular brand in individual construction that meets basic requirements.

Concrete classifications M250 and 300 are becoming less common, since they are an intermediate link between M200 and 350. Grade 350 is widely in demand for commercial construction. Using it, they create monolithic walls and foundations, beams, road surfaces that experience high loads, and so on.

Types of concrete M400 and 450 are relevant if hydraulic structures are being built that are subject to high loads. Subways, dams, dams and other special facilities are built using grades M500 and 550.

If desired, it is possible to determine the brand. For this purpose, a special press is used, located in a laboratory environment. There are other, less demanding methods: using a shock pulse or ultrasound.

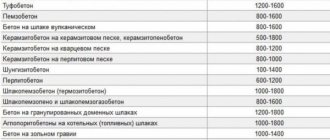

Figure 3. Characteristics of concrete