General information

Properties

The formation of the operational characteristics of concrete structures begins with the preparation, laying and technologically correct hardening of the mixture.

These processes largely determine the future quality of reinforced concrete products.

- The consistency of the mixture depends on the composition of the components, and can vary from a rigid form to a liquid, easily movable form.

- Determination of the mobility of a concrete mixture is determined using special equipment (more on this below). The criterion for mobility (workability) is the slump of the concrete mixture cone, on the basis of which conclusions are drawn about the state of a particular solution.

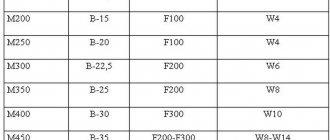

Workability according to GOST 7473-2010 is indicated by the letter “P” and has several meanings (table below).

The higher the grade, the more mobile the solutions. Grades P1-P3 are low-moving plastic compositions, and the mobility of concrete P4-P5 belongs to the category of very mobile mixtures.

Differences between concrete P4 and P3

If we consider the mobility of the concrete mixture, then it is worth saying that its levels differ not only in the pouring speed. Thus, concrete mixture P4 differs from P3 by a higher level of plasticity. P3 does not fill the space of reinforced structures due to insufficient ductility.

Another difference is that P4 concrete is used for pouring using a concrete pump. But the mobility of the P3 mixture is not enough for the use of special equipment.

Taking into account such differences, we can conclude that the advantage of the P4 brand relative to P3 is the simplification of work and acceleration of the construction process.

Factors affecting the mobility of solutions

The technological features of the concrete mixture determine its composition and the properties of the materials used.

The extent to which changes in the characteristics of solutions will occur, and with what results, depends on the following factors:

- Changing the amount of water is the main factor by which the consistency of the mixture is regulated. With an increase in the volume of water, with a constant amount of cement, the mobility of the solution increases, and the strength decreases.

- As the grain size of the aggregates increases, their impact on the cement stone decreases, and as a result, the mobility of concrete increases. Dust and clay components usually reduce workability.

- An important factor is the ratio of sand and crushed stone volumes. With an abnormal increase in these components relative to each other, the specific area of the aggregates increases and the mobility decreases.

Kawabanga! What is the difference between cement and concrete?

Mix consistency regulators

In order to regulate the properties of concrete and save cement, two types of chemical additives are used:

- Additives introduced into the mixture in small quantities (0.1–2% by weight of cement) and regulating their properties.

- Finely ground master alloys (5–20%) used to reduce cement consumption without changing the quality of the finished products.

The use of chemical additives is the most universal and accessible method of controlling concrete technology.

The most widely used additives in modern construction are complex additives—superplasticizers (SP).

These additives, unlike plasticizers, improve the properties of mixtures to a greater extent and more comprehensively:

- significantly increase the mobility of solutions;

- increase the construction and technological properties of concrete;

- reduce cement consumption.

By their structure, superplasticizers are synthetic polymer materials. Consumption is 0.1–1.2% of the total volume of cement. The effect of these plasticizers is limited to 2–3 hours, starting from the moment they are added to the concrete solution.

The use of SP is most effective in the production of precast reinforced concrete, where the setting speed of concrete is of significant importance.

The use of superplasticizers allows the use of low W/C concretes with the following advantages:

What type of concrete is needed for concrete pumps?

The peculiarity of transporting mortar is the need to take into account certain qualities of the composition. If the mixture is to be transported through a concrete pipeline, it must be homogeneous, pumpable and cohesive to avoid segregation. All ingredients used in the manufacture of the solution must comply with GOST standards.

Pouring concrete with a concrete pump will be effective and of high quality if the solution does not wash away the lubricating layer from the walls of the concrete pipeline, and workers organize the necessary pressure for movement. To do this, it is necessary to monitor the workability of the mixture and the ratio of small and large particles. If the solution has high voids, it will have difficulty moving through the pipes. The structure of the concrete mixture must correspond to indicators at which the solution under the influence of pressure will not be removed from the form of the aggregate.

When preparing a building composition for use, it is necessary to pay attention to the required mobility of the mixture, as well as the ratio of the components. Consider the required brand of concrete mix.

Cement and water can be added to the solution to stabilize the required state of the mass, and the optimal solution is the one that best meets the conditions necessary for comfortable pumping. If necessary, the concrete mixture can be supplemented with plasticizing additives, which seriously affect the quality of the solution and its physical characteristics. The latter directly affect the possibility of transporting the composition using specialized equipment.

Determination methods

Determination of the mobility of a concrete mixture can be carried out both directly on site and in laboratory conditions.

Determination of elasticity by cone

The simplest and most commonly used measurement method is to check the slump of a concrete cone.

The check is performed in the following sequence:

Under the influence of its own weight, the material settles until a balance is reached between the forces of adhesion and spreading.

Using crosshairs, the difference between the heights of the two cones is measured, which determines the mobility.

If there is insufficient fluidity, the concrete worker can resort to the method of diluting the solution. Deviation from water content standards (0.4-0.5 by weight of cement) is fraught with a decrease in the strength of the material.

Determination of elasticity by monolith analysis

The check is performed as follows:

Using a laboratory vibrating table

During the construction of critical structures, laboratory measurements of the fluidity of the mixture can be carried out. For this purpose, vibrating tables are used to compact fresh concrete.

The mobility of a material can be assessed by two methods:

What is the mobility of a concrete mixture?

The degree of mobility of a concrete mixture is characterized by its ability to fill formwork and building forms. This property depends on the components used in the concrete, namely:

- Fraction size of crushed stone and sand;

- Brand and quality of cement;

- Availability of additives;

- The ratio of water, cement and fillers;

- Weather and environmental conditions under which the pouring was carried out.

In general, the mobility of concrete, also known as cone shrinkage, is the ability of the mixture to spread over the formwork or other structure being poured due to the material’s own weight.

The mobility of concrete (cone slump) is the ability of the mixture to spread only due to the weight of the material. This property of concrete is very important, along with its strength and other performance characteristics.

Determining the mobility of the concrete mixture will help you choose the right pouring method and calculate the associated resources.

If, during pouring, all the characteristics of the concrete mixture are correctly taken into account, then you can get a strong, reliable and long-lasting structure.

How is it determined?

There are several proven methods used to carry out measurements. For more detailed information, please refer to GOST 10181-2014. We will focus on the simplest and most universal method, which is suitable for both private construction and for pouring large monolithic structures.

In order to set the parameter level for a concrete mixture, a special cone is used to determine the mobility of the concrete mixture. The size of the unit is determined by the dimensions of the crushed stone fraction.

The process of determining the mobility of a concrete mixture using a sediment cone is as follows:

- A metal cone of suitable size is selected;

- It is placed on a flat surface, close to the concrete mixture;

- It is filled with three layers of the test substance;

- Each layer is compacted with a smooth reinforcement bar (5-9 times for each layer);

- The cone is then removed, releasing the solution;

- After a while, experts measure the change in height relative to the top cut of the form;

- The experiment is repeated several times to obtain a more accurate result.

Based on the result obtained, it is possible to establish the mobility grade of the concrete mixture. A strong decrease in the height of the cone characterizes the mixture as mobile, and if the difference in the height of the cones does not exceed 150 mm, the mixture belongs to the group of inactive ones.

There are more accurate methods that require more time. These include measurement with a viscometer and testing in molds.

Designations of concrete mixtures

The mobility characteristic is designated by the letter “P” with a digital extension indicating its degree. A higher grade means better fluidity of the mixture. For example, low-flow concrete p3 or p4 have higher fluidity.

Kawabanga! Mosaic concrete floor

Determination of mobility

If there is no difference between the results, this means that the mixture has the maximum possible hardness. If the difference is ≤ 150 mm, then the mixture is considered slow-moving. If the difference in the height of the cones is ≥ 150 mm, the solution is defined as maximally mobile.

Composition and mobility of the solution

The water-cement ratio is considered the main characteristic in determining the fluidity of concrete, and its violation in one direction or another can reduce the strength of the structure several times. According to GOST, the optimal ratio of water to cement is 0.4.

Mobility - what is it?

The main technological parameter of a fresh concrete mixture is workability - the ability of the solution to fill the formwork and take its shape without losing homogeneity and solidity.

Formability affects not only the speed of working with the material on a construction site, but also its structural characteristics. With high viscosity, voids and pores will form in the concrete, and with strong fluidity, the strength of the structure will be reduced.

A large amount of filler will make the solution unyielding, inactive and hard. The rigidity of concrete is determined not only by the content of filler particles (sand, gravel, etc.), but also by their dispersion.

Pouring conditions

The plasticity index of concrete is also determined by the pouring conditions. We are talking about the frequency of the reinforcing frame and the shape of the future structure.

If the frequency of placement of reinforcement is high, then the solution must have increased fluidity. The fact is that it will be problematic to work with a composition that is too thick. Also, when using rigid concrete, there is a possibility of a decrease in marking strength upon completion of the pouring job. The risk of formation of cavities and pores, which will negatively affect the final quality, cannot yet be ruled out.

The size of the structure being poured also influences the determination of the plasticity of a building material. The larger the dimensions of the structure and the more complex its shape, the more flexible the concrete composition should be.

Concrete is one of the most popular building materials sold on the market. But in order for the solution to cope well with its tasks, and for the design to be reliable, resistant to any impact and durable, it is important to choose the right type of mixture, taking into account a number of basic characteristics. We are talking about workability, cone settlement and mass mobility.

The last parameter is considered the most important, since it directly affects the ease of working with the material and the performance characteristics of the building. To avoid troubles at different stages of construction, it is important to carry out an accurate calculation in advance and select the optimal ductility ratio. In this case, the problem will be solved in the best possible way.

Classification and how it is designated

The mobility of concrete is indicated by the letter “P”. According to this criterion, concrete solutions are classified into 5 groups from P-1 to P-5. The higher the fluidity of the material, the higher the number indicated in the fluidity mark.

Concrete mixture mobility table

| Type of mixture | Test cone draft, cm | Where is it poured? | Peculiarities |

| P-1 | 1-5 | Monoliths with minimal configuration complexity | Must be compacted by vibration |

Rigid and super-rigid mixtures that have zero cone slump are designated Zh and SZh (for example, SZh-2). Due to the technological difficulties of laying them in formwork, they are used in a limited range of work.

Mix consistency regulators

Mixture consistency regulators can liquefy concrete. Depending on the characteristics of the regulator, which is otherwise called a plasticizer, the cone settlement characteristics can vary from 2 to 6 cm with a loss of strength of no more than 5 percent.

There are two main types of plasticizer:

- Dry additives occupying from 5 to 20% of the total volume of the mixture.

- Liquid superplasticizers, which are required from 0.1 to 1.5% of the total volume of the mixture.

The first option is much cheaper. In this case, the following are used as a plasticizer:

Additives to concrete for mix mobility - which ones can be used?

Depending on what parameter you need to use, the temperature of the working environment and the composition of the concrete mixture, you can select suitable additives that will improve the quality of concrete.

invites you to familiarize yourself with our product range. Low prices, high quality and guaranteed effect of Polytem ® concrete additives.

To increase mobility, additives with a plasticizing effect are suitable:

- Polytem Force®

- Polytem Extra time®

- Polytem NoFrost®

Each of the additives is produced according to a unique formula, which has a positive effect on the overall performance characteristics of concrete mixtures, increases the mobility of the mixture, thereby increasing the strength of structures

Determination method

Just as the specific gravity of concrete differs from the volumetric one, the workability of concrete indicated by the manufacturer may also differ from the actual one. To determine it, you can use laboratory tests or a special cone.

Cone tests are used to quickly obtain results, but more detailed information can be obtained in a laboratory setting.

Mobility of concrete. What is the fluidity of concrete

What is the fluidity of concrete

The following parameters influence the fluidity of concrete:

- brand of cement;

- proportions of cement and water;

- density of concrete dough;

- size and shape of filler fractions;

- quantity and quality of components and additives.

Diluting the concrete mixture with water to increase mobility

The use of grade P2 or P3 often slows down the construction process. In this case, builders often resort to diluting the concrete with water. In this way, P4 or even P5 indicators are achieved. But this method has a disadvantage due to construction standards.

The fact is that the key parameter affecting the reliability of a concrete structure is the ratio of cement and water. If this ratio is violated in favor of increasing the volume of water, there is a high probability that the structure will lose its strength qualities. This can lead to the formation of cracks and subsequent destruction of the house. Therefore, experienced builders do not dilute the concrete and use during the work the brand of concrete mixture whose parameters correspond to the characteristics of the building being constructed.