Progress does not stand still. Previously, changing a toilet on your own was equated to a feat - excavating in the bathroom, restoring screeds and tiles, removing a toilet that exactly matches the cast-iron sewer outlet. Otherwise - replacement of cast iron pipes, which is quite consistent with a fire. Today, thanks to the availability of plastic fittings and pipes, do-it-yourself plumbing repairs have become quite accessible to the home craftsman.

Toilet corrugation, or flexible vent pipe, is the topic of this article. In it we will talk about the installation. In it we will talk about installing corrugation, its varieties and other useful little things. We hope that the article will be useful to you, our reader, when choosing materials and connecting the toilet with your own hands.

Advantages and disadvantages

Corrugation (cuff) is a transitional element of the plumbing system, designed to connect the toilet to the sewer system. It is a fairly wide pipe with corrugated walls, made of modern thermoplastic.

The corrugated toilet connector allows you to connect plumbing to the sewer quickly and efficiently. The duration of its operation depends on proper installation

The edge is decorated with a cuff, which facilitates the process of connecting to the pipes and the toilet outlet. The design of the walls, which gave the name to this product, allows you to increase the size of the adapter to certain limits. Typically the sleeve length varies between 23-50 cm.

The diameter of the cuff that is attached to the toilet is 13.4 cm on the outside and 7.5 cm on the inside. The end that is installed on the sewer pipe usually has a hole with a diameter of 11 cm.

The main advantages of corrugation designed for toilets are low price and easy installation. This element is often used in cases where the diameter of the toilet outlet and the sewer pipe do not match. The corrugation is very convenient if the position of the toilet needs to be changed, moving it relative to the entrance to the sewer.

It is also often used as a temporary element, when during repairs the toilet is not yet fixed, but it needs to be used. However, corrugation cannot be called an ideal choice; it is not the most durable element. For example, if a piece of ceramic tile or a sharp piece of glass accidentally falls into the toilet, the corrugated joint can easily be damaged.

If the corrugation is located at too large an angle or incorrectly curved, blockages often occur in it, and an element that is too long sometimes sags under the influence of its contents. Corrugation should never be placed inside a wall; it is only suitable for open installation.

pros

The use of corrugation for a toilet bowl has both advantages and disadvantages. Let's look at both sides of this phenomenon.

So, the advantages of using corrugated pipes:

- Installing corrugation will not be difficult even for those who are just starting to take their first steps in the field of plumbing work.

- In difficult connection cases, you cannot do without corrugation, as it is the most flexible of all the options offered.

- Corrugation can be considered as a temporary connection option that can be quickly dismantled.

- If the type of toilet outlet does not match the sewer pipe, then a corrugated pipe easily solves this problem.

When should you install a corrugated connector?

A corrugation or cuff for a toilet bowl is not always used when connecting to a sewer system. A plastic pipe is more reliable and will last much longer. But sometimes you can’t do without a corrugated connector.

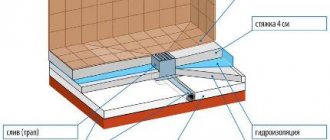

For example, if it is impossible to install the toilet directly opposite the sewer outlet, or when the floor level has become higher after renovation.

The toilet corrugation can be stretched quite strongly, but it should be remembered that excessive tension reduces the strength of this element

This happens if new floor tiles are laid without dismantling the old covering. Sometimes the position of the toilet has to be changed due to rearrangement, for example, if additional elements appear in the bathroom: a washing machine, a shower stall, etc.

The corrugation is useful if the type of outlet of the new toilet does not match the existing sewer system. This problem is faced by owners of new plumbing fixtures who live in Soviet-built apartments.

The old sewer system is designed to be connected to a toilet with an oblique outlet, but in modern imported plumbing fixtures the outlet is usually made straight.

Kinds

Reinforced and unreinforced

Corrugations are available in two types - reinforced and non-reinforced.

The first option is made of rubber or plastic. Has greater strength, wear resistance and rigidity. Used for hidden installation or when there is a significant load on plumbing fixtures. To create a rigid frame, stainless steel wire is used, which is installed during the process of pouring the product.

The service life of reinforced corrugations is significantly higher than that of non-reinforced products. That's why their cost is higher.

Non-reinforced products are rarely used, mainly for temporary installation of a “pot”. With constant use, the service life is short.

Rigid and non-rigid

The strength of rigid corrugations is higher than that of non-rigid ones. Due to the thickness of the walls, they have increased wear resistance. Installation of rigid corrugation is allowed if there is a slight deviation in level between the pipe and the toilet.

The advantages of rigid bends are durability and strength. But due to their low mobility, their scope is limited.

If it is necessary to create a more flexible connection, non-rigid pipes are used. The products take any shape and can be installed in the most difficult places with sharp bends, including for toilets with straight and oblique outlet systems.

The walls of “soft” corrugated bends are thin and, accordingly, their wear resistance is low. Such corrugation can be easily damaged - careless impact with a sharp object is enough. Installation of flexible hoses is recommended in cases where it is not possible to use rigid corrugation or smooth-walled pipes. The tightness of the connection with the outlet of the sewer riser is ensured by a rubber coupling.

How to solve the problem of choice

Before purchasing a corrugated connector, you should check the dimensions of the holes with which it will be connected. The likelihood of errors will be less if you buy the corrugation at the same time as the toilet. The second important indicator is the length of the pipe. There are models of different types and purposes.

For example, for a small combined bathroom, a corrugated outlet with an outlet can be a very convenient option, allowing you to connect two objects to one sewer outlet at once. Sometimes it is more convenient to use a special rubber cuff for the toilet.

To connect the toilet to the sewer system, you can use not only the corrugation (2), but also a special rubber cuff (1) and a plastic outlet (3)

It makes no sense to purchase cheaper corrugation, since the cost of even the most expensive option is low. The connector may be a little more expensive, but it meets the expected level of quality. Imported products have good strength and durability characteristics.

Western manufacturers additionally strengthen their products with reinforcing metal wire. Such models are more rigid, they sag less and resist mechanical stress better.

To install the corrugation, you may also need the following elements:

- coupling, straight or eccentric, for connecting to the sewer pipe of the toilet, which is located right next to it;

- a pipe with a cuff or a plastic outlet intended for installing a toilet bowl, the position of which is shifted relative to the entrance to the sewer system;

- the corrugation is hard or soft, allowing you to bypass small obstacles that prevent the direct connection of the toilet to the sewer.

When choosing a suitable corrugation for a toilet, you should remember that problems can arise not only when using an element that is stretched too much. It is also not recommended to use an excessively short pipe.

Strong compression or sharp bending will soon lead to breakage.

With such a bend in the corrugation installed on the toilet, liquid will most likely accumulate at the bottom. It is necessary to change the position of the toilet or choose a different connection method

Recommendations

To ensure that the corrugation does not require replacement or re-installation, it is necessary to take into account some features of using this accessory:

- Do not stretch the corrugated toilet flush before it is installed. Stretching must be done only before installation work takes place. A corrugation that is too stretched cannot be quickly returned to its normal position.

- After installation and in the future, the sewer connection cannot be used using corrugation as a shelf for various household items. It might just burst under the weight.

- When purchasing a corrugated attribute, you must pay attention to the thickness of the walls. The more, the better, which means it will last longer. Such models are more expensive, but after installation you won’t have to think about replacing them, since they will work for a short period of time.

- If a sewer connection needs to be installed in a house, then you should think several times and decide whether it is advisable to use a plastic product. This material is an excellent product for rats, mice and other rodents to eat. Therefore, it is better to pay attention to metal pipes.

Removing the old connector

If the toilet is already installed, then before installing a new corrugation, you must remove the old one. In this case, it is necessary to take into account a number of important points. Of course, before starting dismantling, it is worth draining the water from the tank and shutting off the water supply to the system.

First of all, it should be remembered that the corrugated connector is not characterized by increased rigidity. Some of the liquid remains inside.

First, the part that is attached to the toilet is usually disconnected. Then the liquid remaining inside the corrugation can be drained into the sewer. Following this sequence is especially important if the old connector is very stretched or the toilet is installed at an angle to the sewer pipe.

If, on the contrary, the corrugation is in a compressed position, to remove it it may be necessary to first dismantle the toilet, i.e. remove it from its mountings. These points must also be taken into account when connecting the toilet to the sewer using corrugation, since over time it will still have to be replaced.

Minuses

Like everything rational and artificial, there are also production disadvantages that arise due to the improvement of the system:

- A regular soft cuff is not very durable and is easily susceptible to external damage. All this creates additional difficulties during installation and greater attention to maintaining the fastener.

- The corrugation for the toilet bowl can be mounted and operated only in an open space, without installation into a wall, as is used with other installation options.

- With a large angle of rotation and sagging of the material, it is prone to frequent blockages and damage.

- Due to the high demand for goods, there are a large number of fakes and replicas that are sold by entrepreneurs under the guise of original goods.

How to install corrugation

After the old connecting element is removed, you should carefully inspect the corrugation. You need to make sure that no cracks or other damage appears on the pipe walls during transportation and storage. You should also check that the length of the connector matches the distance between the toilet and the sewer pipe.

But if the corrugation and the new toilet are installed at the same time, it makes sense to first connect the pipe to the toilet outlet, then install the toilet, and then connect this entire structure to the sewer system.

This procedure may turn out to be less complex and time-consuming than the procedure in which the toilet is first installed and then the corrugated connector is attached to it.

If the toilet has not yet been installed, it may be worthwhile to first attach a corrugation to it, and then install the product and connect it to the sewer system

The preparatory stage also includes cleaning the toilet outlet from contaminants after dismantling the old corrugation or pipe. These can be either particles of previous communications or remnants of cement or sealing composition.

The cleaned surface can even be degreased if this is in accordance with the instructions for use of the new sealant. Before installing the corrugation, a fan pipe should be placed on the outlet of the new toilet.

After this, you can begin to actually install the corrugation. First, the required amount of sealant is applied to the edge of the toilet outlet. To work with plumbing, it is recommended to use a special sanitary sealant based on acrylic or silicone.

Such compositions expand well and provide high tightness of the connection; they are specially designed for conditions of high humidity and prevent the penetration of fungus and mold on treated surfaces.

Before starting to work with sealant, you should carefully study the manufacturer's instructions and strictly follow them.

The corrugation is attached to the toilet hole quite reliably, but the use of sanitary sealant will reduce the likelihood of leaks at the joints to a minimum

A corrugated pipe is placed on the edge of the outlet, treated with a sealing compound. It should be turned towards the toilet with the side on which the inner membrane is located. The corrugation should block the exit from the toilet by about five to six centimeters; these dimensions are considered optimal.

It is very important that the corrugation is put on very evenly, this will ensure maximum reliability of the connection. To ensure a reliable fit of the corrugation at the connection point, it is necessary to carefully press the pipe section to the toilet outlet surface.

After this, you should wait until the sealant is completely dry, the timing is indicated in the instructions. During this period, you should not displace the corrugated connector; it is best to leave the structure alone to prevent possible leaks.

After this, the new toilet can be installed in its intended place. The procedure for connecting the corrugation to the entrance to the sewer is approximately the same. Part of the pipe must be treated with sealant and connected in the right place. It should be noted that the installation of a corrugated connector can be performed without the use of sealant.

There are special internal membranes along the edges of the pipe that allow you to fix its position. But in practice, the lack of a sealing compound often leads to leaks and displacement of the corrugation.

This is an example of the correct installation of a toilet corrugation: it is not too stretched, does not sag or bend, i.e. there are no obstacles to the free removal of waste

The main work of installing the corrugation at this stage can be considered completed, however, the reliability of the connection should be checked to prevent possible leaks. First, of course, you should wait for the sealant that was applied to the part of the pipe connected to the sewer to dry.

After this, water is supplied to the system to fill the tank, and the flush is performed. If for some reason you cannot connect the water, just pour a few liters of water into the toilet.

Now you need to observe the joints. If water seeps or leaks through them, it means that the seal is broken and the defects need to be eliminated. To do this, you do not need to redo all the work; it is enough to apply one or two layers of sealant to problem areas.

If there are no leaks, it is not necessary to reseal the connections from the outside. After repairing leaks, you need to wait for the composition to dry and check the connections again for leaks.

An important nuance when installing a cuff designed for a toilet is the degree of its stretch along the length. If the distance from the toilet to the sewer system is too large, over time the corrugation will begin to noticeably sag under the influence of the contents.

The smaller this distance and the sagging of the corrugation, the longer the connecting element will last. When under tension, the corrugation can easily break, so any additional stress on the connector should be avoided.

Detailed recommendations for installing a corrugated pipe on a toilet are presented in the following video:

Dimensions

Corrugations have two main characteristics: diameter and width. Their sizes are standardized:

- Diameter. At the junction with the toilet, the diameter of the liner is 130 mm. The diameter of the end intended for connection to the riser outlet is 110 mm, the sealing socket is 75 mm.

- The length of the corrugation is available in two versions - long and short. In the first case, the length of the product in the compressed state is 280 mm, in the stretched state - 550 mm. The lengths of the short corrugated eyeliners are 210 and 320 mm, respectively.

Sealing the outlet

After installing the corrugation, carefully check how tightly and securely it is mounted, simply drain the water into the toilet.

The installed outlet should cover the edge of the protrusion by approximately five centimeters. Check for distortions, they are unacceptable. The corrugation should be installed as evenly as possible. In order for the drainage structure to be strong and never leak, it must be treated with a cement solution or a special sealing agent.

If you are replacing an old toilet outlet, clean the outlet of the old cement mortar. Do not skip this stage; layers of old mortar, even the slightest, will negatively affect the tightness of the structure’s connection. If you are installing new plumbing, there is no need to prepare it for this stage.

Treat the corrugation and drain hole with sealant, leave for a while, and let dry. As you can see, installing the corrugation is not difficult. After the solution has dried, you can use the sewer.