X

To accurately calculate the concrete mixture required for construction, a concrete calculator is used. This will allow you to determine the required volume of ingredients based on the final composition of heavy concrete. The calculation takes into account all types of large and small aggregates, indicators of density and mobility of cement, as well as the presence of plasticizers.

The calculator allows you to calculate the volume of a concrete mixture for free (online), taking into account the parameters and current cost of mixing components.

Detailed explanations of how to calculate cubic capacity are given below as accurately as possible.

Helpful information:

- Grinding concrete with a grinder

- Penetrating waterproofing for concrete

- Laminate - calculation of the number of boards

- Energy consumption of heated floors: online calculator...

- Brand of concrete for the foundation

- How to choose impregnation for concrete

Calculation of the mass of materials may differ from the actual ones, since the ingredients used have different properties (humidity, temperature, density, etc.). Also, errors may occur due to the amount of water actually added, which cannot be very accurately controlled on the scale of a large construction project. In this case, it is worth doing a test mixing of concrete and testing for strength in order to know how much sand, crushed stone and cement is needed.

For high-quality mixing of building materials, it is important to remember that the maximum load of the concrete mixer should be no more than 70% of the total volume.

Characteristics of concrete

The type and quantity of components mixed to create heavy concrete directly depends on the properties that need to be obtained in the end:

- Strength is the most important characteristic, reflecting the ability to prevent destruction as a result of exposure to external factors. The class of concrete according to this indicator ranges from B3.5 to B60, which makes it indispensable in the construction industry. The strength grade of the building composition ranges from M50 to M1000 (from 5 to 100 MPa).

- Temperature resistance, fire resistance is a property of concrete that allows products not to change as a result of exposure to high temperatures. The maximum permissible temperature for concrete, above which the material will be subject to destruction, is 500 degrees, but its strength disappears already at 200 degrees. For a floor area of 1 m, filled with heavy concrete, there is up to 0.5 mm of expansion.

- Water resistance and frost resistance are indicators that together affect the reliability and duration of operation of reinforced concrete products. The first indicator indicates the material’s ability to resist water pressing on the surface. This important property allows the use of heavy concrete in the construction of bridges and canals. Resistance to low temperatures is determined by the number of freezes, after which the strength remains unchanged.

Laminate - calculation of the number of boards

Footing for strip foundation

Concrete preparation for the foundation is mandatory in cases where the building planned for construction will be located in the following conditions:

- climatic zone with seasonal changes in soil volume and density;

- the type of terrain of the site is closer to hilly or slope;

- unstable soil type.

Kawabanga! Weight of expanded clay concrete block 400x200x200 - table

If you plan to do the work yourself, adhere to the following technology:

- The area of the footing is marked, taking into account allowances of 10 cm on each side.

- According to the markings, trenches are dug along the perimeter of the building and under the load-bearing walls.

- The bottom of the trench is covered with a layer of crushed stone 10 cm thick. The crushed stone is compacted and covered with bitumen mastic.

- Formwork panels are installed. Horizontal reinforcement is laid inside the formwork and vertical rods are inserted to connect the footing with the foundation.

- The concrete base solution is poured and compacted.

- After a week, the formwork panels can be removed. The concrete base is left until it sets completely. After completion of the work, the upper plane of the concrete base and the side parts are treated with bitumen mastic or the selected primer for waterproofing.

Calculated values

Starting the calculation on the calculator: the amount of concrete that needs to be obtained for construction work is indicated. Its weight is calculated in cubic meters. You can calculate heavy concrete in various volumes - from industrial to small, by first converting the number of liters into a cubic meter (for example, 40 l = 0.04 m3).

Concrete strength grades in calculation

The most important conditions for obtaining the required grade of cement mortar are the correct choice and accuracy of calculation of the components. The quality and purpose of concrete depends on the proportions calculated:

- Brand M500 serves as the best basis for the construction of foundations for industrial facilities, special buildings, structures and hydraulic structures.

- M250 - M350 - used for strip foundations in private construction, walls in apartment buildings, as well as slab foundations.

- M150 – M200 – suitable for the construction of light structures in individual construction.

- M50 - M150 - used in finishing works, when arranging areas (landscape design).

The calculation formula for preparing the concrete composition is recommended by the methodology prescribed in GOST 27006 - 86 (1989) “Concrete. Rules for the selection of compositions" and GOST 7473 - 94 "Concrete mixtures. Technical conditions".

Composition and proportions of aggregates

The characteristics of the concrete mixture depend on the accuracy of the calculations of cement, gravel, and water, so the online calculator will become a convenient tool for calculating the proportions in cubes.

When using a solution, it is important to consider the size of the fractions, the ratio of sand, crushed stone or gravel. The properties of heavy concrete will depend on the following types of aggregates used simultaneously:

- large - these include crushed stone (granite, limestone, slag) or gravel. They are responsible for stability and also give less shrinkage after concrete is cast.

- fine sand is quarry, river or expanded clay types. Its presence in the mixture removes porosity and increases the density of concrete. The size of the grains of sand affects the water resistance and density of concrete: the smaller, the better and stronger.

How to make concrete flowerpots that the whole family will love

When creating a concrete mixture, it is important to adhere to exact proportions. They determine the durability of the work performed and act as a guarantee of quality.

Cement brand

Cement is the material that binds all components together. The choice of brand depends on the concreting technology, type of concrete and solution consumption in m3. In case of violation of the proportion, the cement affects the short-term operation, which entails repeated work.

In Portland cement (for example PC 500), the amount of various impurities is kept to a minimum, so additional ingredients will only improve the quality of the concrete mixture. It is convenient and easy to prepare such cement; it is very affordable. The grade of cement indicates the maximum compressive strength in kg per square meter.

Mobility of concrete mixture

Mobility is the ability of the solution to effectively fill the formwork. It indicates the ease of working with the mixture and the quality of compaction. Filling the mold for pouring the site is done using compaction, vibration, or simply under its own weight. There are the following categories of concrete mobility:

- Zh1 and Zh2 are rigid mixtures of concrete used in the construction of civil and industrial facilities, reinforced concrete structures, as well as support platforms. The use of vibration devices for shrinkage is mandatory.

- P1 - used in the construction of thin walls, supports, slabs with reinforcement of no more than 1%. Casting is accompanied by a manual or mechanical seal.

- P2 - used for products with reinforcement of more than 1% - beams, bridge parts or in private construction - for the manufacture of garage floors, giving them special strength. Compaction is done manually or technically.

- P3 - such a solution fills space well, but is not yet flexible enough to fill complex shapes without using vibration technology. Suitable for individual and commercial construction.

- P4 – concrete easily fills cavities on its own, without additional shrinkage equipment. You can use a concrete pump. This solution saves time on filling the site and simplifies it.

When using less flexible grades of concrete, you should not increase the amount of water, deviating from the recommended proportions. This will increase the elasticity of the mixture and the rate of shrinkage, but construction standards will be violated, which will lead to a decrease in strength, the appearance of cracks and even destruction. It is worth using concrete mixtures with characteristics corresponding to the type of structures being built.

The presence of plasticizers, in addition to the main purpose of increasing the plasticity of the solution, contributes to the effective movement of sand-gravel mixtures and various fillers, which ensures high-quality casting. This has a positive effect on the structure of concrete, removing excess air from the composition. Plasticizers are an essential ingredient in high-end construction projects.

Pipe length calculator for corrugated gates

Algorithm for calculating the proportions of concrete components

To calculate the components for the production of heavy concrete, the book by V.P. was taken as a basis. Sizova: Guidelines for the selection of heavy concrete compositions.

1. We calculate the W/C (water-cement ratio) using the formulas:

2. Determine the water consumption for crushed stone (gravel) of different fractions:

The water requirement of sand is not taken into account in the calculator and is taken by default at 7% (medium-sized sand).

3. Determine cement consumption:

When using superplasticizer S-3 or an analogue (Dofen, SP-1, SP-3), the consumption of cement and water to obtain the specified mobility (hardness) of the concrete mixture is reduced.

4. Determine the particle separation coefficient. The sliding data was taken from Appendix No. 4 of M. Feiner’s book “New Patterns in Concrete Science and Their Practical Application.”

Kawabanga! The procedure for selecting and agreeing on recipes for asphalt concrete mixtures STP 15-01

For mixtures with hardness Zh3-Zh4, the average value of the grain expansion coefficient was taken equal to 1.1.

5. Determine the crushed stone consumption:

6. Determine sand consumption:

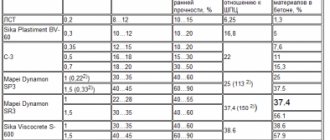

The following data was used for the calculation:

The use of superplasticizer S-3 in the selection of concrete composition

The purpose of the superplasticizer in this calculator is to obtain the specified mobility (stiffness) of the concrete mixture without reducing the strength of the concrete.

For the calculation, we used “Table 1. Change in the mobility of the concrete mixture” from the book by Yu.P. Chernysheva: “Plastic concrete.”

Useful information on the use of superplasticizer S-3 (Dofen):

Brand of concrete for the foundation

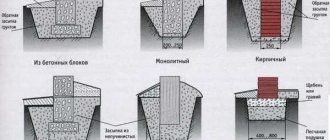

And yet, the choice of concrete grade for the foundation depends on several initial data:

- type of foundation

- groundwater level

- aggressiveness of groundwater

- soil bearing capacity

It’s better to play it safe and order a higher grade than to regret later and have to deal with strengthening a torn foundation.

The foundation is the most important structure for any structure and the entire future existence and safe operation of the building depends on its quality: strength and load-bearing capacity.

The bearing capacity of the future foundation depends on three indicators:

- spatial geometry

- reinforcement

- concrete grade

Accordingly, all these indicators must be involved in calculating the bearing capacity of the foundation.

But, if you are making a foundation without calculation, for example, for a small bathhouse, then based on the fact that a strip foundation and a brand of concrete that can be purchased and that our industry can offer, M200, are usually chosen for the bathhouse, then the only thing left to strengthen the foundation is reinforcement.

But, nevertheless, let's consider various options:

- for strip foundations with groundwater levels below the freezing depth of the soil, M200 concrete is used

- if you order ready-mixed concrete with delivery for also a strip foundation, take M300, because for private clients manufacturers often inflate the grade

- if for the same strip foundation you mix concrete yourself and cement for concrete in bags from an unknown manufacturer, then also add 20-30% more of it

- for strip foundations lying below the groundwater level - concrete grade M350

- for a pile foundation or floating slab - concrete grade M350 with granite aggregate.